Device and method for processing waste gas from molybdenum disulfide production

An exhaust gas treatment device and molybdenum disulfide technology are applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., which can solve the problems of failing to meet the requirements of exhaust gas treatment and the decline in exhaust gas absorption efficiency, so as to prevent the treatment from failing to meet standards, Effect of improving utilization rate and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

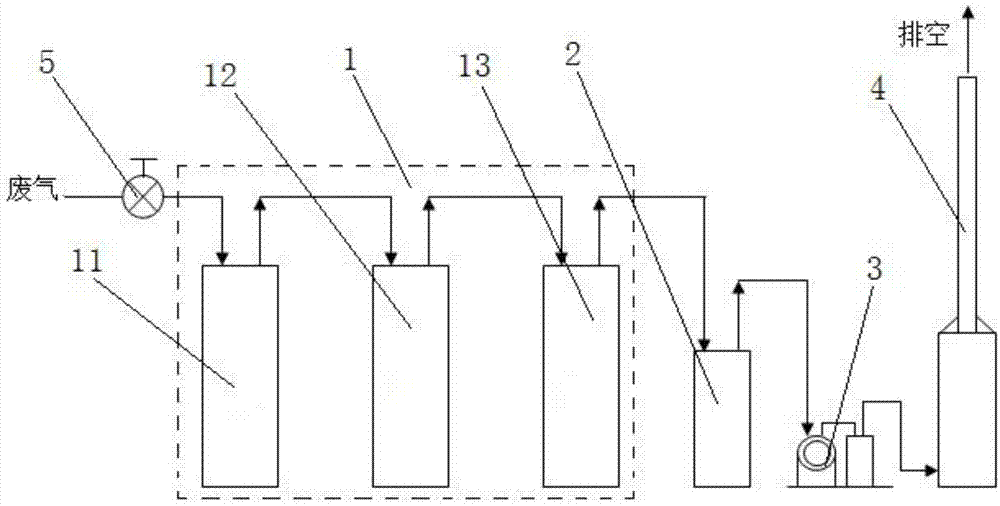

[0027] The treatment device of molybdenum disulfide production waste gas of the present invention, as figure 1 As shown, including alkali tank 1, buffer tank 2, vacuum pump 3 and emptying tower 4, alkali tank 1, buffer tank 2, vacuum pump 3 and emptying tower 4 are connected through pipelines successively, and alkali tank 1 includes 1 connected through pipelines successively #Alkali tank 11, 2# alkali tank 12 and 3# alkali tank 13; 1# alkali tank 11, 2# alkali tank 12, 3# alkali tank 13 and buffer tank 2 are glued with anti-corrosion rubber sheets on the inner wall.

[0028] The molybdenum disulfide production waste gas treatment device of the present invention adopts the alkali tank 1 to directly absorb and treat the waste gas, uses the vacuum pump 3 to provide power, and uses the buffer tank 2 to supplement and absorb the tail gas. Long-ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com