Low-temperature early-strength salt-resistant well cement slurry system

A technology for cementing cement slurry, early strength and salt resistance, applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems of high on-site construction risk, casing corrosion, high difficulty coefficient, etc., and achieve on-site construction conditions. It is not harsh, has good low temperature resistance, and ensures the effect of construction safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

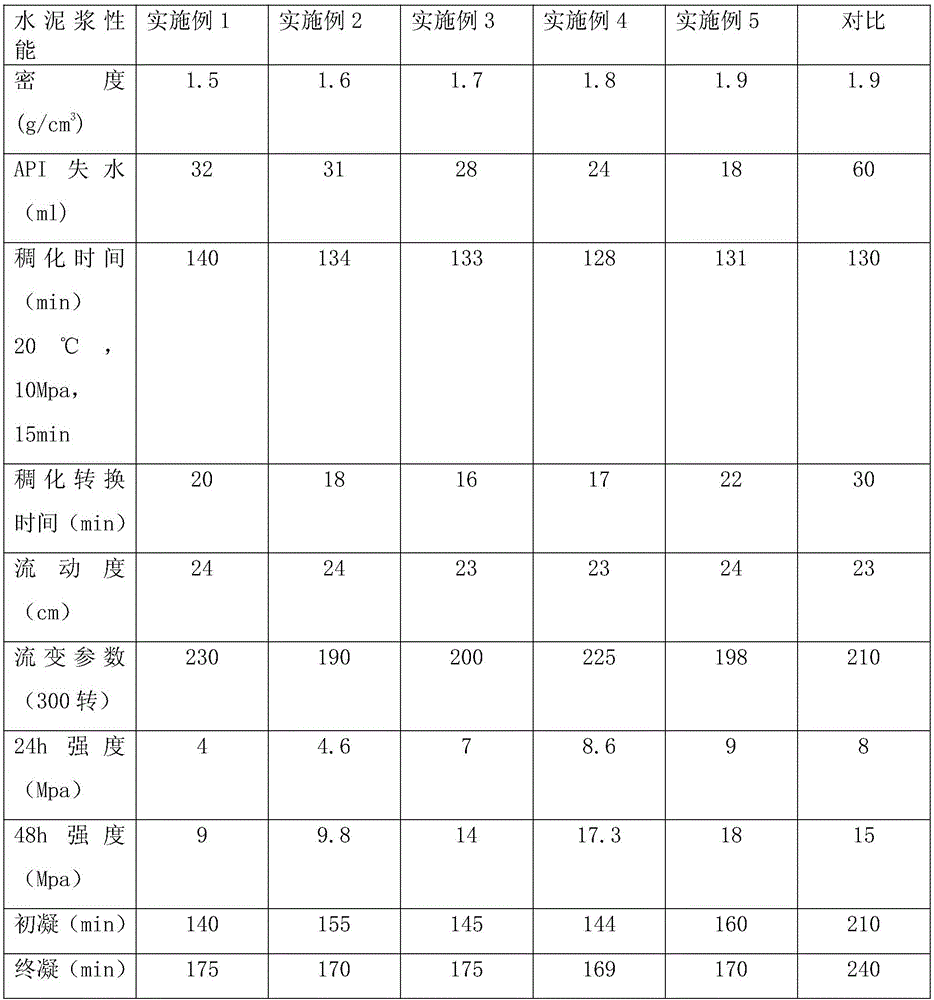

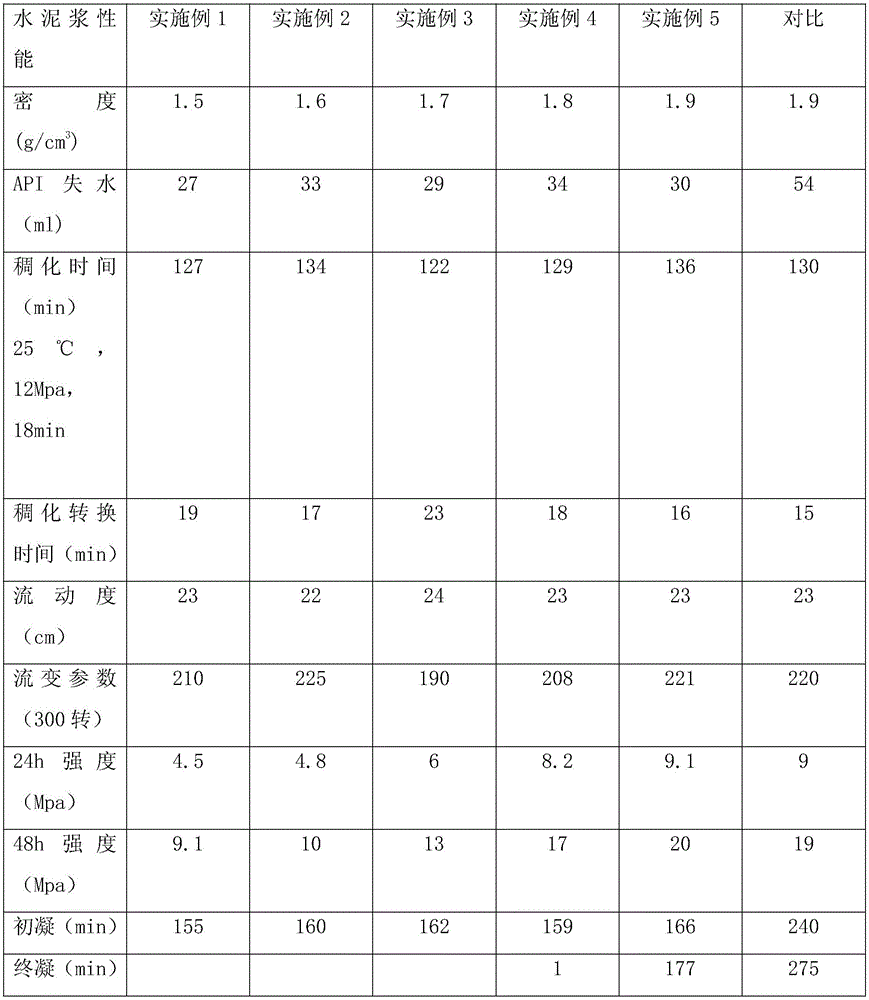

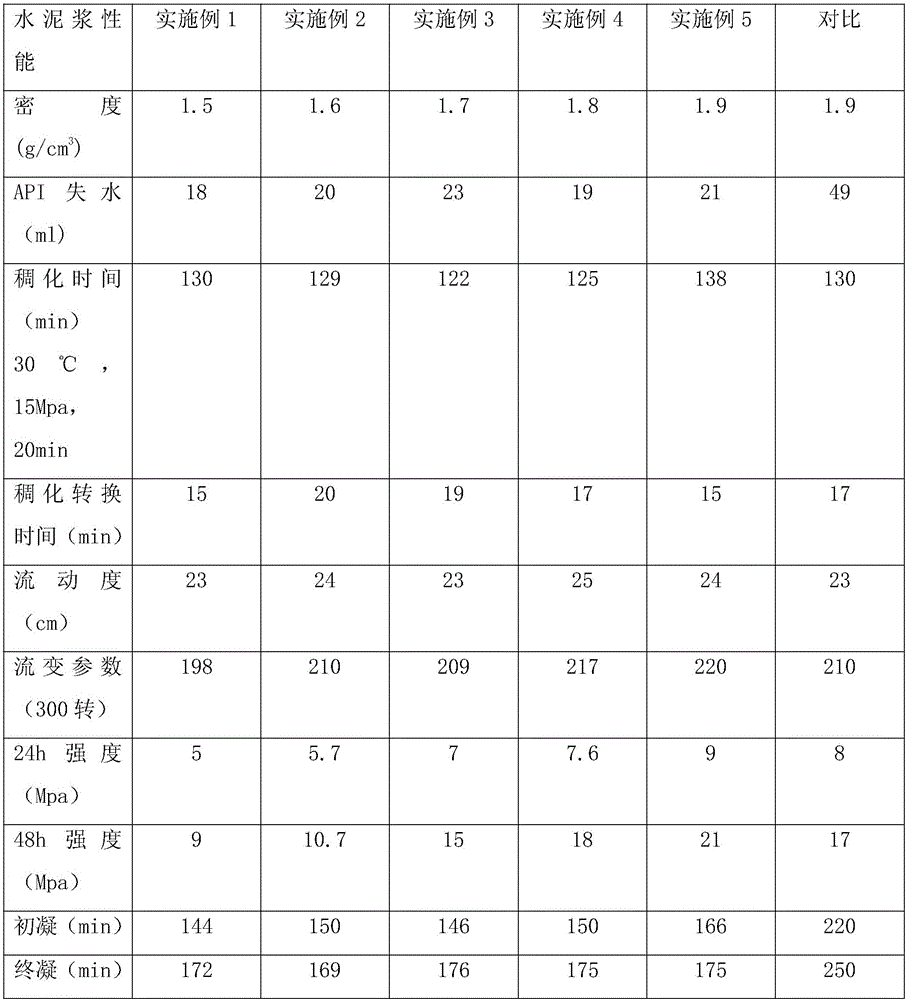

Embodiment 1

[0076] Example 1: 100 parts of G-grade oil well cement, 1 part of low-temperature anti-salt fluid loss reducing agent, 3 parts of composite early strength agent, 13.5 parts of hollow glass microspheres, 0.2 parts of dispersant, 4 parts of micro silicon, and 81 parts of brine.

Embodiment 2

[0077] Example 2: 100 parts of G-grade oil well cement, 0.95 parts of low-temperature salt-resistant fluid loss reducing agent, 2.8 parts of composite early strength agent, 6 parts of hollow glass microspheres, 0.3 parts of dispersant, 3.8 parts of micro-silicon, and 67 parts of brine.

Embodiment 3

[0078] Example 3: 100 parts of G-grade oil well cement, 0.9 parts of low-temperature anti-salt fluid loss reducing agent, 2.5 parts of composite early strength agent, 3 parts of hollow glass microspheres, 0.4 parts of dispersant, 3.6 parts of micro-silicon, and 58 parts of brine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com