Assembling type sectional precast concrete hollow plate girder structure and manufacturing method thereof

A technology of prefabricated concrete and hollow slab girders, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., which can solve the problems of inconvenient transportation, poor integrity, and difficult erection, and achieve improved utilization efficiency, shortened prefabricated construction period, and easy shedding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

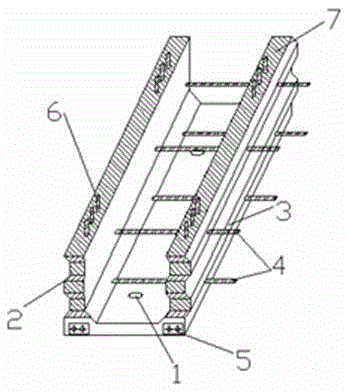

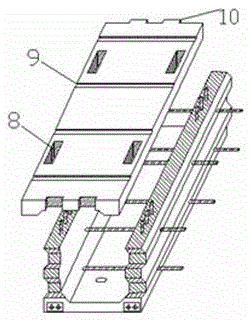

[0042] An assembled segmental prefabricated concrete hollow slab girder structure, including a roof and U beams surrounding the slab girder structure. The roof and U beams are all made of concrete pouring. It is required to reduce the weight of the concrete hollow slab beam, the roof and the U beam are spliced by several sections in the longitudinal direction, and at the same time, the roof of the beam body is separated from the U beam.

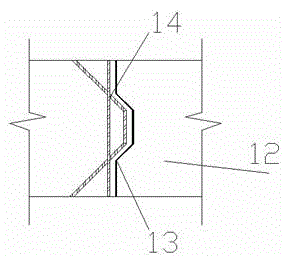

[0043] The outer surface and longitudinal section of the U-beam web and the longitudinal section of the roof are all arranged with shear keys through matching prefabrication; the plate beam structure is provided with longitudinal prestressed tendons and transverse prestressed tendons, and epoxy resin is applied to the interface of each splicing joint . The U-shaped beams divided into several sections are connected longitudinally by longitudinal prestressed tendons.

[0044] The roof is also divided into several sections in the longitudinal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com