Open lower temperature waste heat utilization system of ultra-clean emission coal-fired unit

A coal-fired unit, low and low temperature technology, applied in the direction of preheating, feed water heater, greenhouse gas reduction, etc., can solve the problem of unit low heating adjustment and control difficulties, large disturbance, insufficient heat transfer effect of plate heat exchanger, and smoke temperature at the chimney inlet Difficult regulation and other problems, to achieve the effect of avoiding condensation of flue gas, simple and convenient control method, and preventing low-temperature corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following non-limiting examples illustrate the invention.

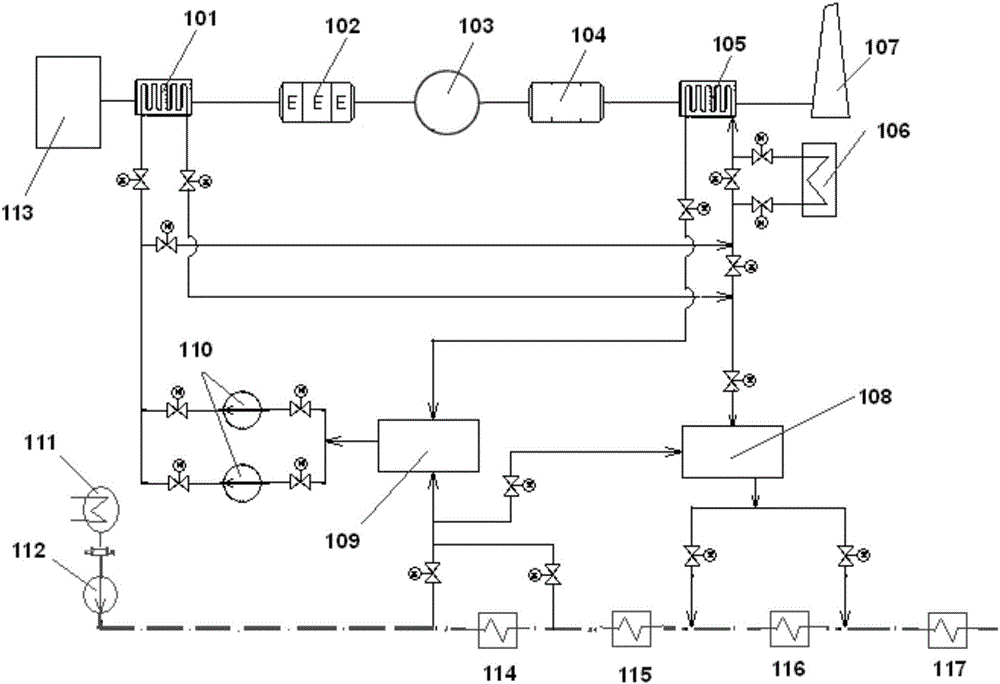

[0031]refer to figure 1 As shown, the open-type low-temperature waste heat utilization system of the ultra-clean emission coal-fired unit includes a flue gas cooler 101, a flue gas reheater 105, an auxiliary steam heater 106, a waste heat recovery hot water mixer 108, circulating water and replenishing water Mixer 109, variable frequency booster pump 110, and piping systems, valves and control systems connected to the system, as well as the electrostatic precipitator 102, desulfurization system 103, wet electrostatic precipitator 104, condenser 111, condensate pump 112, The first level of low addition 114, the second level of low addition 115, the third level of low addition 116, boiler air preheater 113, chimney 107, etc.

[0032] The flue gas cooler 101 is arranged in the flue between the outlet of the air preheater 113 at the boiler tail and the inlet of the electrostatic precipitator 102, the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com