Heavy oil viscosity reducer and preparation method thereof

The technology of viscosity reducer and catalyst for heavy oil is applied in chemical instruments and methods, drilling compositions and other directions, which can solve the problems of complex production process, high viscosity of heavy oil and high production cost, and achieve simple production process, High degree of mechanization and obvious effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

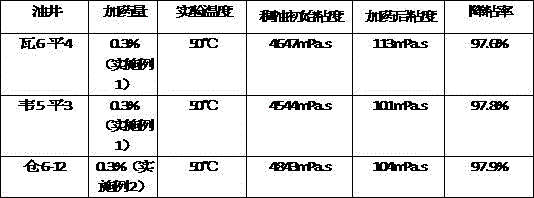

Examples

Embodiment 1

[0015] Put 160g of fatty acid methyl ester into a 2L reaction kettle equipped with a stirrer, condensing reflux, thermometer and heating mantle, heat up to 50°C, seal the reaction kettle, and after the vacuum pump vacuumizes, feed N 2 After purging for 20 minutes, stir and raise the temperature to 135°C. Under the pressure of 0.2mpa, add 20g of sodium hydroxide, dropwise add 400g of ethylene oxide, then dropwise add 100g of propylene oxide, react for 8 hours, cool to 50°C, and add 300g Lauryl dimethyl betaine, 300g of methanol, and 600g of water are mixed evenly to obtain the finished viscosity reducer.

Embodiment 2

[0017] Put 150Kg of fatty acid methyl ester into a 2m tank equipped with stirrer, condensing reflux, thermometer and heating mantle 3 In a stainless steel reaction kettle, heat up to 50°C, seal the reaction kettle, vacuumize it with a vacuum pump, and feed N 2 After purging for 20 minutes, stir and raise the temperature to 135°C. Under the pressure of 0.3mpa, add 20Kg of potassium hydroxide, dropwise add 500Kg of ethylene oxide, then dropwise add 120Kg of propylene oxide, react for 7 hours, cool to 60°C, and add 400kg Lauryl dimethyl betaine, 220Kg methanol, and 500Kg water are mixed evenly to obtain the finished viscosity reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com