Industrial solid waste degradation device for geopolymer-based foam light soil production

A technology of foam light soil and solid waste, applied in the direction of solid waste removal, etc., can solve the problems of long time, insufficient contact of degradation liquid, and large amount of one-time output, so as to accelerate the degradation speed and reduce the degradation time. , the effect of accelerating the rate of waste degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

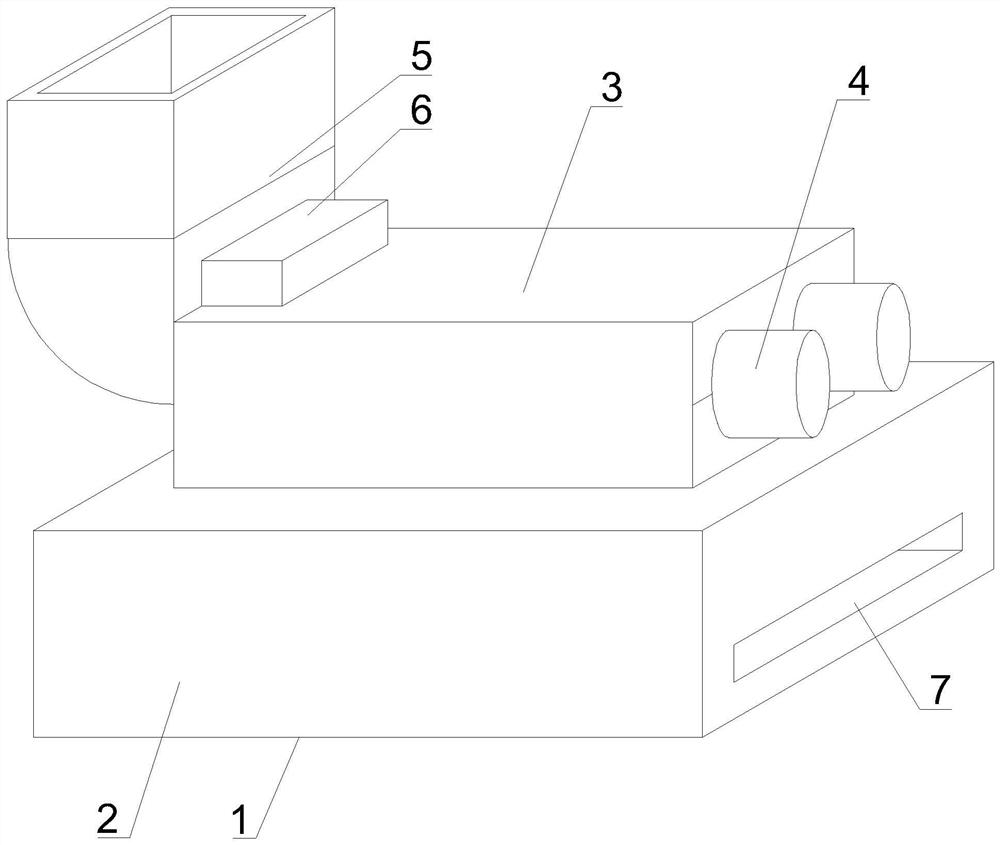

[0039] like Figure 1-10 , The present invention provides a lightweight foam-based geopolymer Soil degradation of industrial solid waste production means, including industrial waste degradation apparatus 1, the housing 2 degradation riving humidifier 3, the pressurizer 4, a funnel grinder 5, 6 and the vacuum cleaner discharge opening 7, industrial waste degradation degradation apparatus 1 comprises a housing 2, the housing 2 on the top surface degradation of the material is fixedly connected watched humidifier 3, the right side of the humidifier 3 riving the outer surface of the pressurizer 4 is connected is fixed, the left outer surface of the pressurizer 4 is fixedly connected with a pressurizing tube, on the outer surface of the left side of the riving humidifier 3 is fixedly connected with a funnel grinder 5 riving 3 top of the left edge position of the humidifier 6 is fixedly connected, vacuum cleaner output terminal 6 extend to the inner surface of the funnel grinder 5 on the...

Embodiment 2

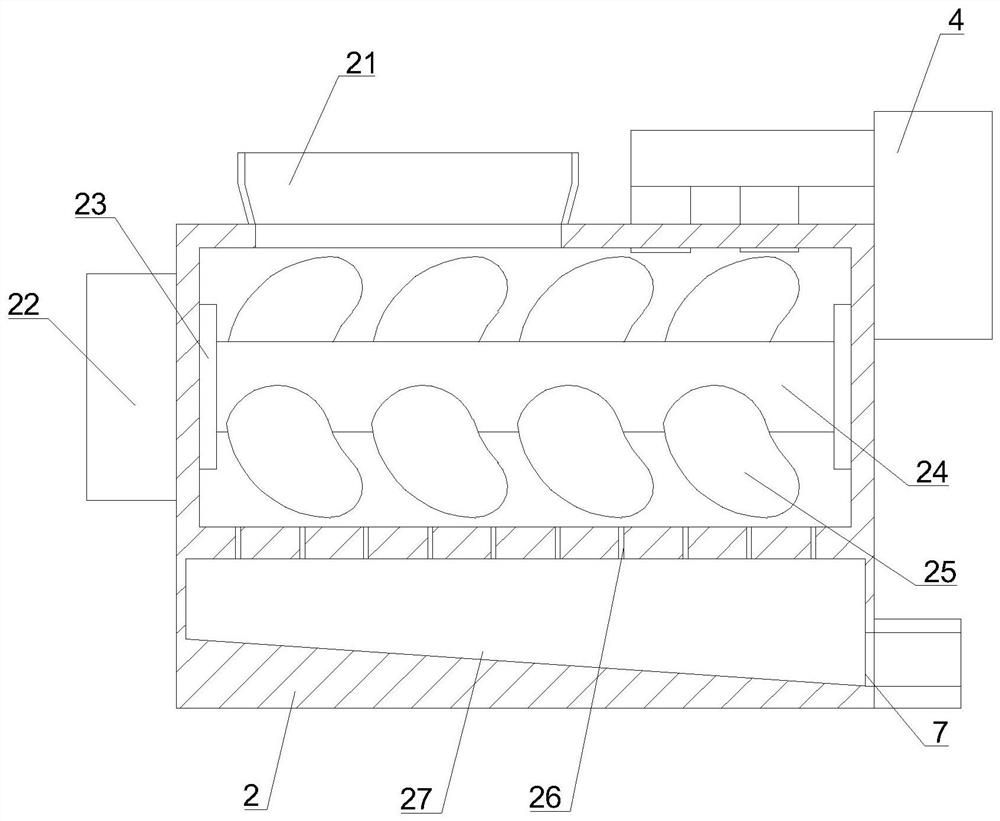

[0044] like Figure 1-10 , In the embodiment 1 on the basis of embodiments, the present invention provides a technical solution: Preferably, the degradation is fixedly connected to the top left position of the left edge of the casing 2 on a one-way inlet horn 21, the casing 2 of the degradation side of the bottom surface of the fixed outer rotating machine 22 is connected to the output terminal 22 extends to a rotating machine degradation on the inner surface of the left side of the housing 2, rotation of the output end of the rotating machine 22 is fixedly connected with a rotation of the roller 24, the degradation of the casing 2 left inner upper surface of the sealing ring 23 is fixedly connected, rotation of the outer surface of the roller 24 is rotated in a lap seal 23 on the inner surface of the collar up and down the outer surface of the rotating roller 24 is fixedly connected with the sheet 25 is heated with stirring, degradation intermediate housing compartment 2 is fixedl...

Embodiment 3

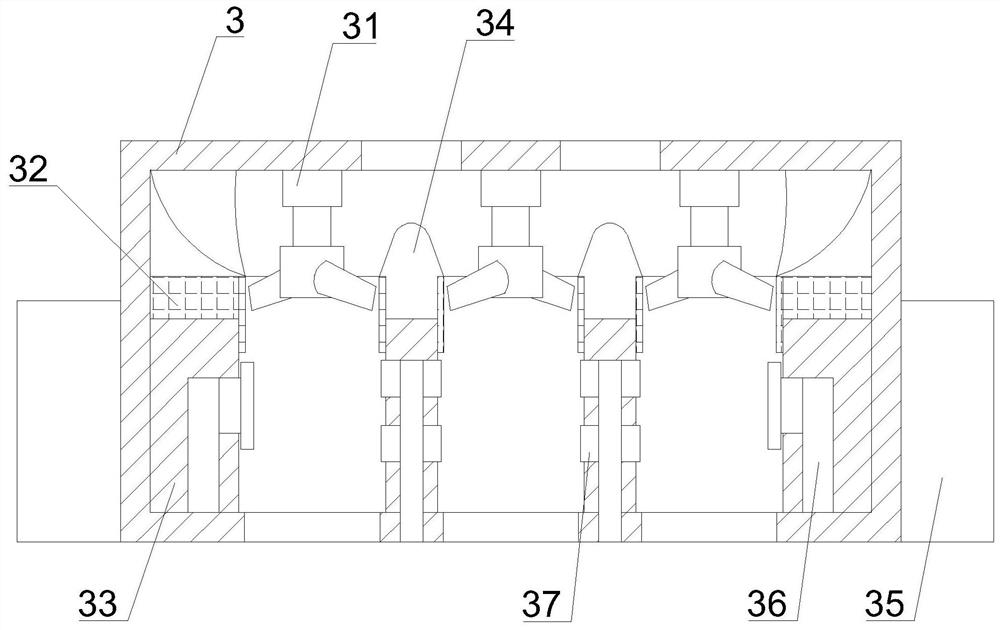

[0047] like Figure 1-10 , In the embodiment 1 on the basis of embodiments, the present invention provides a technical solution: Preferably, the humidifier Dose 3 provided on the top surface of the feed inlet, Dose fixedly connected on the inner surface of the top of the humidifier has 3 rotator 31, rotatably connected to the output of the rotation of the diffuser vanes 31, the spacer 32 is fixedly connected on the inner surface of the left and right feed humidifier 3, fixedly connected to the supporting post 33 on the lower surface of the separator 32, the support posts One end 33 is fixedly connected to the inner bottom surface of the riving humidifier 3, the output of the rotator 31 extends to the lower surface of the spacer 32, the spacer is fixedly connected to the top surface 32 of head 34 material watched riving inner surfaces of left and right outer sides of the feed opening located in the bottom of the central axis of the head 34, the humidifier 3 riving biodegradation is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com