Spraying method for infrared anti-counterfeit label

An anti-counterfeit label and infrared technology, applied in the printing field, can solve the problem of high production cost and achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

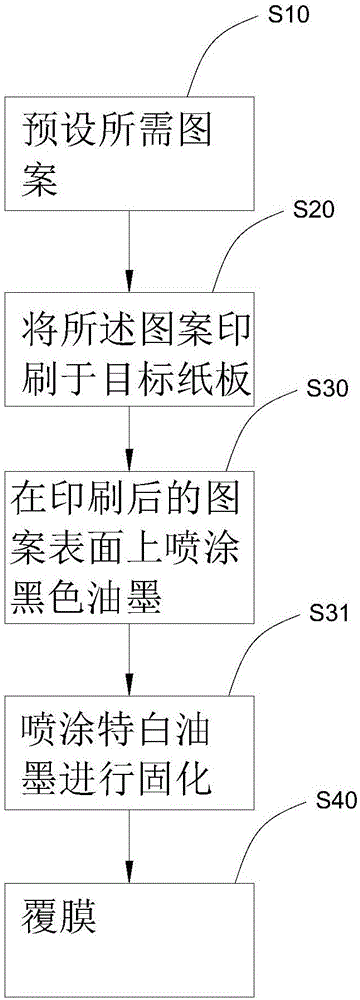

[0020] see figure 1 Embodiment 1 of infrared anti-counterfeiting label spraying method of the present invention shown, comprises:

[0021] S10 preset the pattern to be printed;

[0022] S20 printing the pattern on the target cardboard;

[0023] S30 sprays black ink on the surface of the printed pattern, and the concentration of black ink is 75%;

[0024] S31 sprays special white ink to cure after spraying black ink;

[0025] S40 lamination.

[0026] Wherein, in step S30, the setting of the pattern is generally performed by a computer, preferably using a barcode or a two-dimensional code for anti-counterfeiting representation, and may also use a color pattern printing method.

[0027] In step S40, the coating is to cover the surface of the pattern completed in step S31 with a polymer plastic layer to protect the pattern.

[0028] Through the above scheme, by spraying black ink on the printed anti-counterfeiting pattern, the light absorption effect of the black ink is used ...

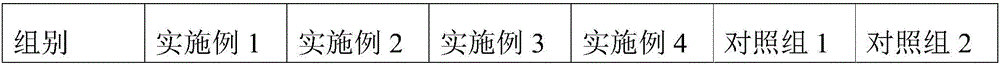

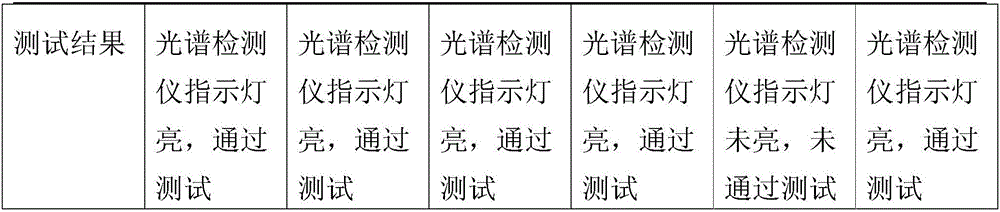

Embodiment 2

[0030] In this embodiment, the difference from Embodiment 1 is that the black ink concentration is 80%. Other steps of this embodiment are the same as in Embodiment 1.

Embodiment 3

[0032] In this embodiment, the difference from Embodiment 1 is that the black ink concentration is 70%, and the curing step of S31 is omitted. Other steps of this embodiment are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com