Butyl pressure-sensitive adhesive as well as preparation method and application thereof

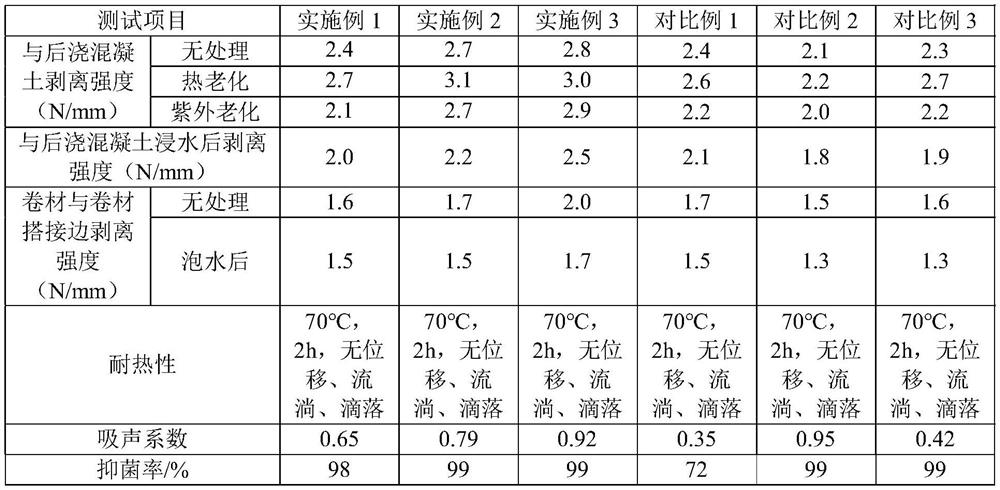

A pressure-sensitive adhesive, butyl technology, applied in the field of butyl pressure-sensitive adhesive and its preparation, can solve the problems of mildew resistance and poor noise reduction performance, and achieve good adhesion performance and cohesive strength, high mildew resistance and Antibacterial and antibacterial ability, the effect of raw material cost without pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0045] According to a particularly preferred embodiment, the method also includes preparing the silica airgel-silver-zinc composite by steps comprising the following operations:

[0046] (a) ball milling the silica airgel for 2-3 hours at a rotational speed of 100-150 rpm to obtain a powder;

[0047] (b) Put the powder and the mixed solution containing silver nitrate, zinc sulfate, glucose and ammonia water in a light-proof reactor, heat up to 60-80°C, and stir at a speed of 150-200rpm (for example, For mechanical stirring) 3-4h, obtain reaction product;

[0048] In the mixed solution, the concentration of silver nitrate is 0.1-0.2mol / L, the concentration of zinc sulfate is 0.2-0.4mol / L, the concentration of glucose is 0.5-1mol / L, and the concentration of ammonia water is 0.2-0.4mol / L L, the dosage ratio of the powder and the mixed solution is 1g: 100-150mL;

[0049] (c) filter the reaction product to obtain a filter cake, dry the filter cake for 24-28 hours, and then grind it...

preparation example 1

[0127] Silica Airgel-Silver Zinc Composite AA-1:

[0128] (a) 1 g of silica airgel was ball milled for 2 hours at a rotational speed of 150 rpm to obtain a powder;

[0129] (b) Put the powder and a mixed solution containing silver nitrate, zinc sulfate, glucose and ammonia water in a light-proof reaction kettle, heat up to 60° C., and mechanically stir for 3 hours at a rotation speed of 200 rpm to obtain a reaction product;

[0130] In the mixed solution, the concentration of silver nitrate is 0.1mol / L, the concentration of zinc sulfate is 0.2mol / L, the concentration of glucose is 1mol / L, and the concentration of ammonia water is 0.2mol / L. The powder and the The dosage ratio of the mixed solution is 1g: 150mL;

[0131] (c) Filter the reaction product to obtain a filter cake, freeze-dry the filter cake for 28 hours, and grind for 1 hour at a rotation speed of 100 rpm to obtain the silica airgel-silver-zinc composite AA-1.

Embodiment 1

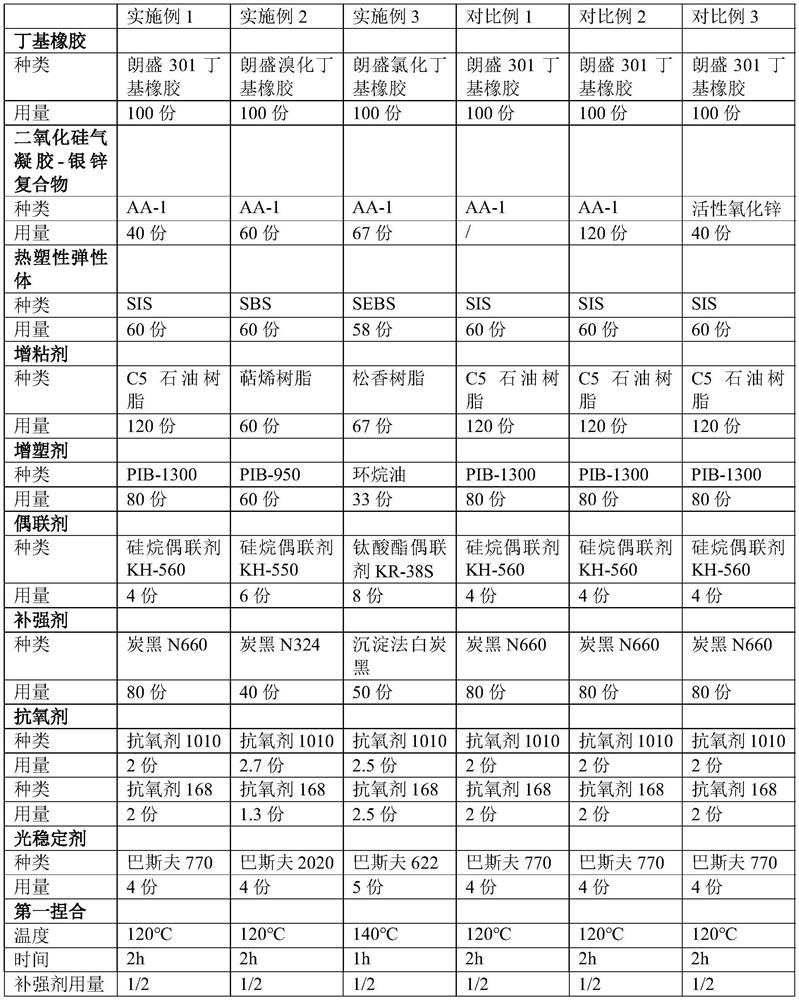

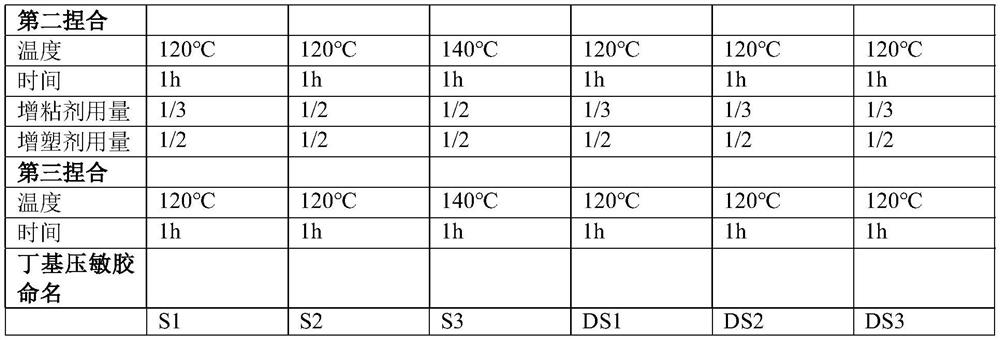

[0133] This example is used to illustrate the method for preparing butyl pressure-sensitive adhesive according to the present invention. Specifically, according to the formula and process parameters in Table 1, butyl pressure-sensitive adhesive was prepared according to the following method.

[0134] The method for preparing butyl pressure-sensitive adhesive comprises the following steps:

[0135] (1) butyl rubber, silica airgel-silver-zinc composite, thermoplastic elastomer, antioxidant, light stabilizer and reinforcing agent accounting for 1 / 2 weight of the total amount are added in the vacuum kneader, Kneading for 2 hours at 120°C and vacuum <-0.096Mpa;

[0136] (2) sequentially add tackifier accounting for 1 / 3 weight of the total amount, plasticizer accounting for 1 / 2 weight of the total amount and remaining reinforcing agent, and knead for 1 hour at 120°C and vacuum <-0.096Mpa;

[0137] (3) Add the remaining tackifier, the remaining plasticizer and all the coupling agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com