Sound-absorption and noise-reduction material and preparation method thereof

A noise reduction and sound absorption technology, applied in the field of building noise reduction, can solve the problems of low hardness, weak tensile strength, and inconvenient construction of sound absorption and noise reduction materials, and achieve the effects of improving tensile strength, low cost, and easy construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

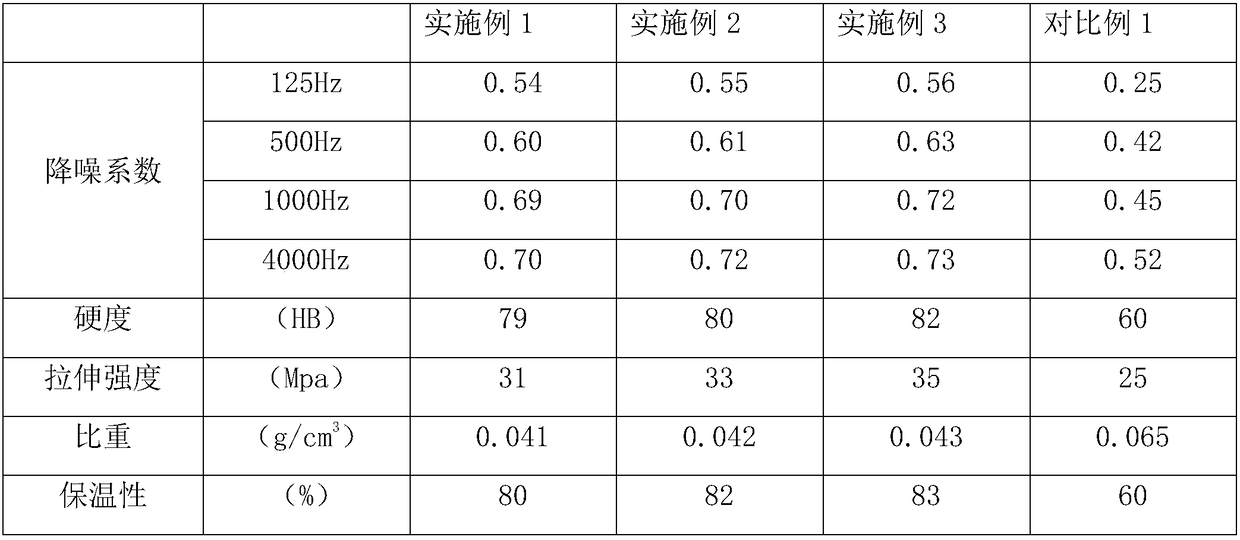

Examples

Embodiment 1

[0024] A sound-absorbing and noise-reducing material is composed of the following raw materials in parts by weight: 50 parts of PE resin, 6 parts of graphene, 12 parts of polypropylene fiber, 1 part of stabilizer, and 5 parts of foaming agent.

[0025] The foaming agent is a mixture of sodium lauryl sulfate and sodium ethoxylated alkyl sulfate at a mass ratio of 1:1. The stabilizer is silicone oil.

[0026] A method for preparing the above-mentioned sound-absorbing and noise-reducing material, comprising the following production steps: (1) Adding the raw material PE resin, graphene, polypropylene fiber, and stabilizer in the above-mentioned parts by weight to a ball mill in sequence for 30 minutes to prepare mortar A (2) put mortar A into a mixer, then add the above-mentioned raw material foaming agent in parts by weight to the mixer, and then stir evenly to obtain mortar B; (3) send mortar B into an extruder for extruding and granulation to obtain the sound-absorbing and noi...

Embodiment 2

[0029] A sound-absorbing and noise-reducing material is composed of the following raw materials in parts by weight: 60 parts of PE resin, 10 parts of graphene, 16 parts of polypropylene fiber, 3 parts of stabilizer, and 9 parts of foaming agent. The foaming agent is a mixture of sodium lauryl sulfate and sodium ethoxylated alkyl sulfate at a mass ratio of 1:1. The stabilizer is silicone oil.

[0030] A method for preparing the above-mentioned sound-absorbing and noise-reducing material, comprising the following production steps: (1) adding the raw material PE resin, graphene, polypropylene fiber, and stabilizer in the above-mentioned parts by weight into a ball mill in sequence for 50 minutes of ball milling to obtain mortar A (2) put mortar A into a mixer, then add the above-mentioned raw material foaming agent in parts by weight to the mixer, and then stir evenly to obtain mortar B; (3) send mortar B into an extruder for extruding and granulation to obtain the sound-absorbi...

Embodiment 3

[0033] A sound-absorbing and noise-reducing material is composed of the following raw materials in parts by weight: 55 parts of PE resin, 8 parts of graphene, 14 parts of polypropylene fiber, 2 parts of stabilizer, and 7 parts of foaming agent. The foaming agent is a mixture of sodium lauryl sulfate and sodium ethoxylated alkyl sulfate at a mass ratio of 1:1. The stabilizer is silicone oil.

[0034] A method for preparing the above-mentioned sound-absorbing and noise-reducing material, comprising the following production steps: (1) Adding the raw material PE resin, graphene, polypropylene fiber, and stabilizer in the above-mentioned parts by weight into a ball mill in sequence for 40 minutes of ball milling to obtain mortar A (2) put mortar A into a mixer, then add the above-mentioned raw material foaming agent in parts by weight to the mixer, and then stir evenly to obtain mortar B; (3) send mortar B into an extruder for extruding and granulation to obtain the sound-absorbin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com