Patents

Literature

34results about How to "Reduce road construction costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sludge curing agent and application thereof

ActiveCN101081718AGood boardIncreased durabilitySludge treatment by de-watering/drying/thickeningSolid waste managementSludgeSlag

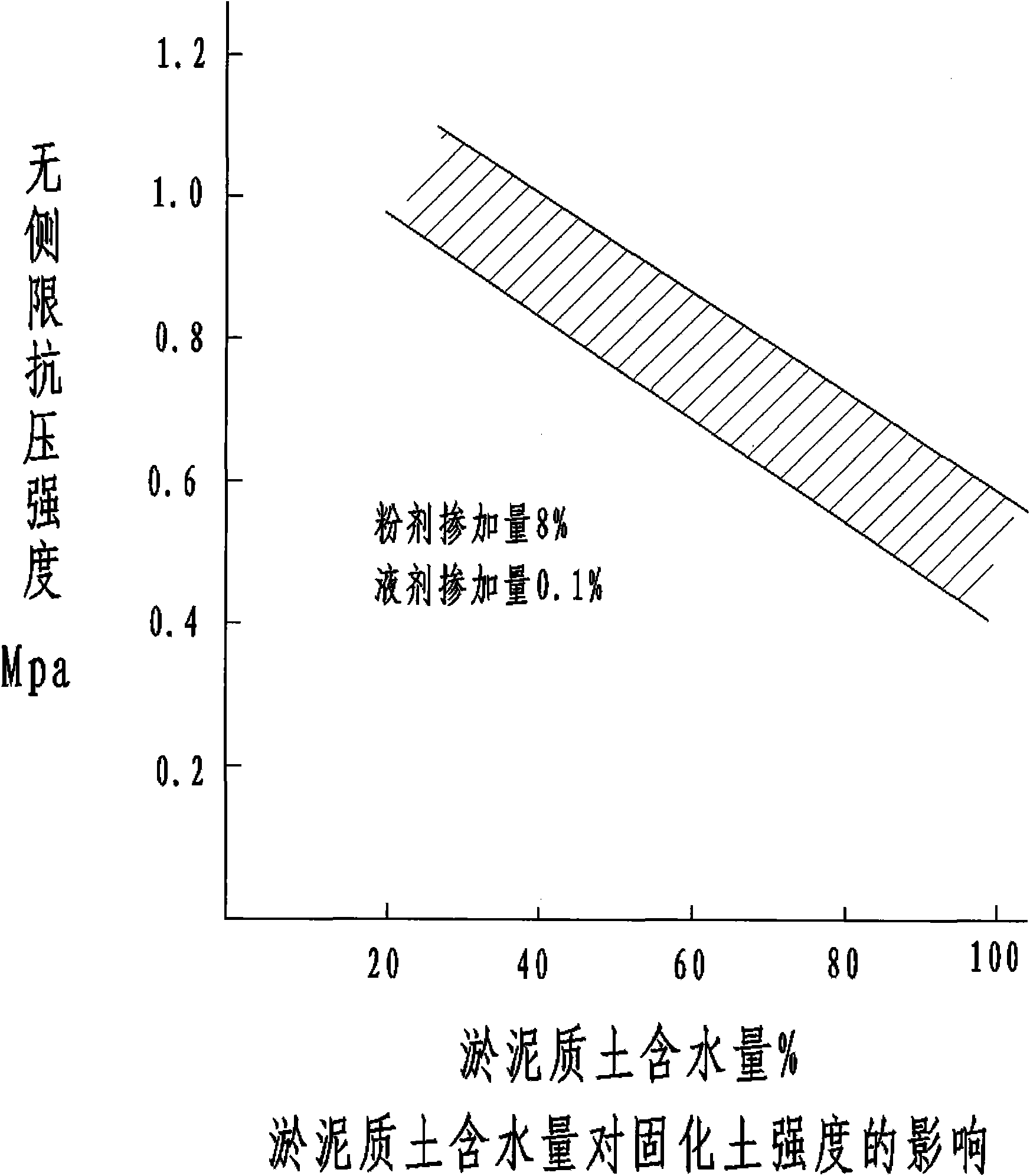

The present invention is sludge curing agent and its application, and belongs to the field of soil treating chemicals technology. The sludge curing agent includes powdered components and liquid components, the powdered components include cement clinker 30-60 weight portions, slag 30-60 weight portions, lime 3-8 weight portions, gypsum 1-7 weight portions and other sulfates 1-7 weight portions; and the liquid components include polyacrylamide 5-30 weight portions, polyaluminum chloride 0-20 weight portions, mannitol 0-30 weight portions, lignosulfonate 20-80 weight portions, lignosulfonate-iron or chromium ion complex 0-30 weight portions, alkylphenol ethoxylate 0.2-2 weight portions, tannin 0-10 weight portions, humate 0-10 weight portions, and alpa-olefin sulfonate 0.2-2.5 weight portions. The sludge curing agent has low cost, small consumption, high cumulate strength and high cumulate water tolerance, and may be applied widely.

Owner:BEIJING ZHONGYONGJI FIRMING AGENT TECH DEV

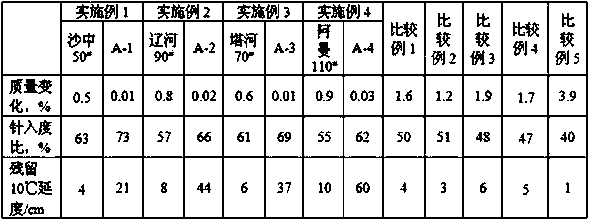

Hot in-plant reclaimed asphalt mixture

ActiveCN101654347AIncrease dosageImprove high temperature performanceSolid waste managementEconomic benefitsRoad surface

The invention relates to a hot in-plant reclaimed asphalt mixture. The mixture includes the following components by mass percent: 30 to 50 percent of milling materials, 44 to 67 percent of newly collected materials, 1.5 to 4 percent of mineral powder, 1.5 to 4 percent of new asphalt, and ARA regenerant which is 0 to 10 percent of the mass of the recycled asphalt contained in the milling materials.The processing method includes the following steps: (1) extraction and analysis of the milling materials; (2) asphalt performance test; (3) regenerant addition; (4) formation of mixture of the recycled asphalt; (5) Marshall test or rotary compacting test; and (6) mixture performance test. The proportion of milling material RAP reaches as high as 50 percent in the engineering application of the hot recycled asphalt mixture, the milling material RAP can be applied to a middle layer, and the proportion is higher than the proportions of other hot recycled mixtures by more than 20 percent. The mixture can be applied to various grades, such as the AC type, SUPERPAVE, and the like, and the RAP proportion can respectively reach 30 percent or even more than 50 percent. When the mixture is used forpaving a road surface, the road performance can respectively meet the requirements on performance of a newly proportioned asphalt mixture, and the high temperature performance is even superior to thenewly proportioned asphalt mixture. Therefore, the invention has obvious economic benefit.

Owner:JIANGSU HUAIAN TRAFFIC SURVEY & DESIGN INST

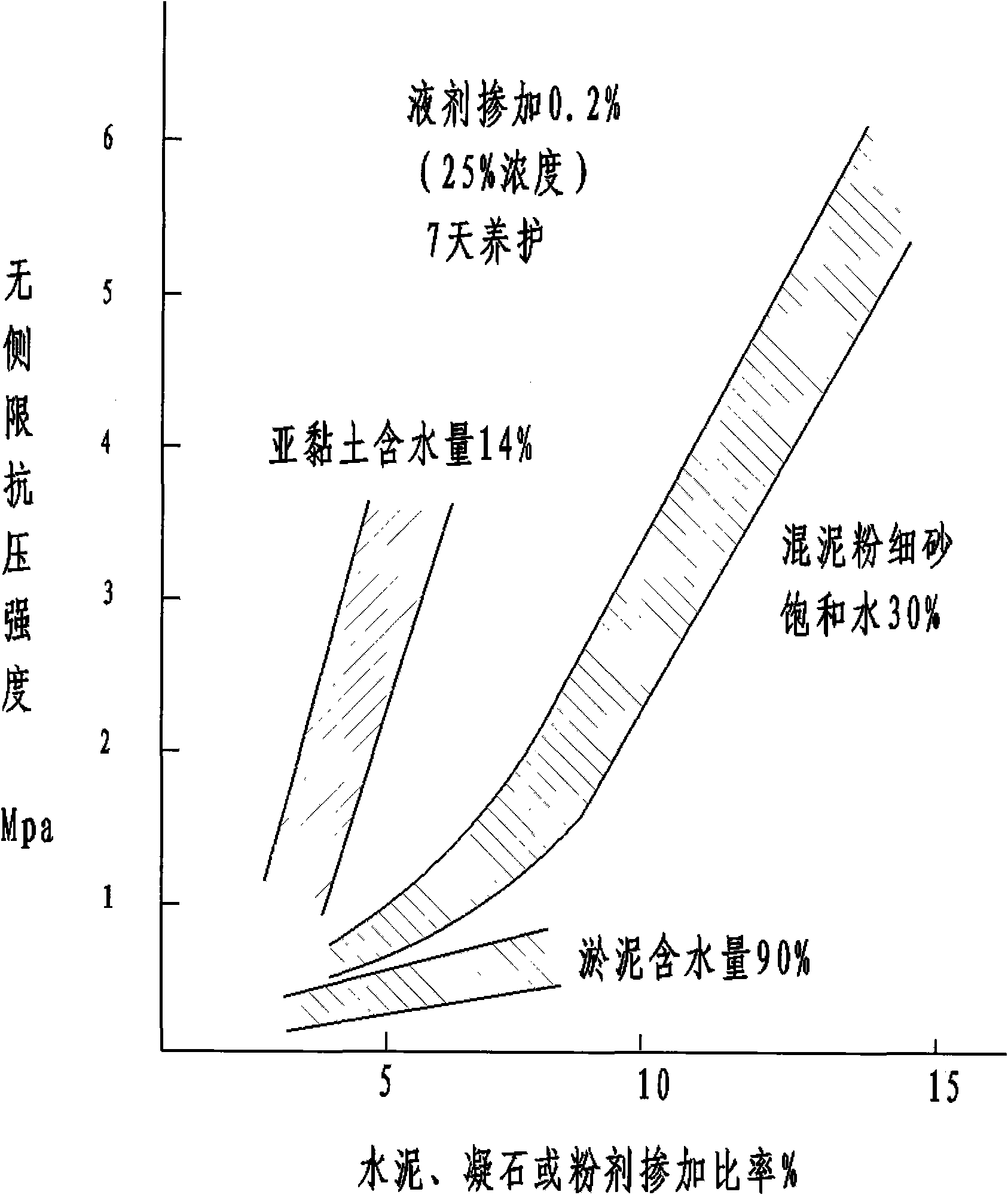

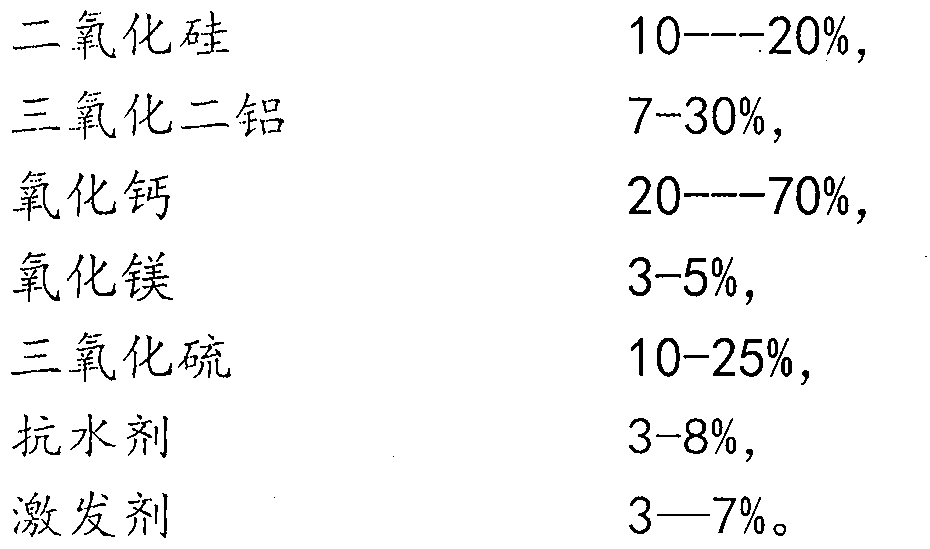

Curing agent and construction method of weak soil

InactiveCN101684038AReduce adverse effectsReduce manufacturing costSolid waste managementSlagCarrageenan

The invention relates to a curing agent and a construction method of weak soil. The curing agent of the weak soil is characterized by comprising powder and liquid, wherein the powder comprises cementand congealing stones or the following materials in parts by weight: 0-20 parts of cement clinker, 60-95 parts of grain slag or slag, 1-5 parts of lime, 1-5 parts of plaster, 1-5 parts of anhydrous sodium sulphate, 0-10 parts of caustic soda, 0-10 parts of water glass and 0.1-3 parts of sodium fluosilicate; the liquid comprises the following components in parts by weight: 1-15 parts of polyacrylamide, 20-60 parts of pulp waste liquid, 10-40 parts of cement retarder, 0.5-1.5 parts of OP emulsifier, 0.3-1.0 part of carrageenan, 0.3-1.0 part of xanthan gum and 0.5-1.5 parts of alpha-olefin sulfonate. The curing agent is previously prepared into seriflux before being used, and the weak soil and the curing agent seriflux are uniformly stirred by mechanical stirring equipment and then are spreador compacted. The addition quantity of the powder is greatly reduced because a small quantity of the liquid is added; in addition, materials can be easily obtained, and the performance of consolidated soil is superior, thus the curing agent of the weak soil, i.e. sludge and the like, has high efficiency and environmental protection.

Owner:要明伦

Beach sludge composite curing agent as well as preparation method, use method and application thereof

InactiveCN105924109AEnvironmental protection is goodObvious superioritySludge treatment by de-watering/drying/thickeningPortland cementSludge

The invention discloses a beach sludge composite curing agent as well as a preparation method, a use method and an application thereof. The beach sludge composite curing agent is obtained by mixing and grinding of an ordinary Portland cement clinker, a sulphoaluminate cement clinker, phosphogypsum, desulfurization gypsum, mineral waste residues, a naphthalene-based additive and sulfates, wherein the weight percentages of the raw materials are as follows: 40-60% of the ordinary Portland cement clinker, 5-10% of the sulphoaluminate cement clinker, 2-4% of the phosphogypsum, 3-6% of the desulfurization gypsum, 30-50% of the mineral waste residues, 1-3% of the naphthalene-based additive and 3-5% of the sulfates. The beach sludge composite curing agent disclosed by the invention can greatly shorten the curing time of sludge, and is small in doping amount, high in concretion strength, low in construction cost, and good in curing stability.

Owner:天津市三川恒泰科技有限公司

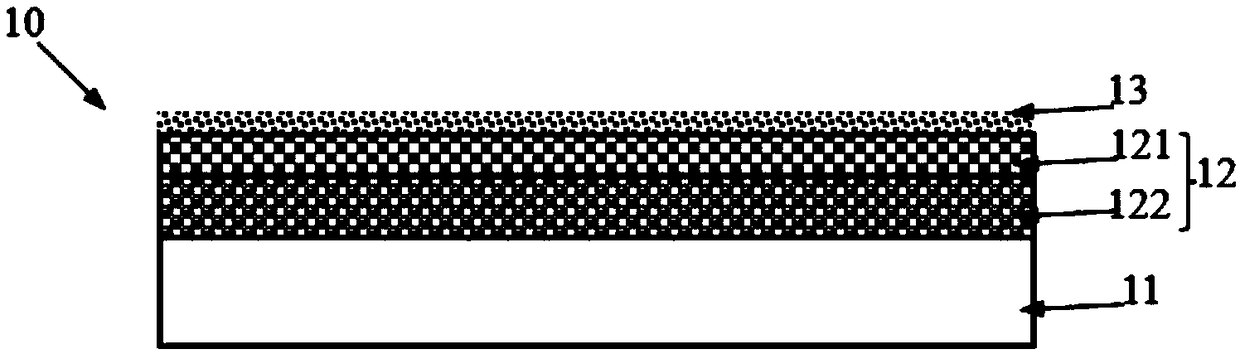

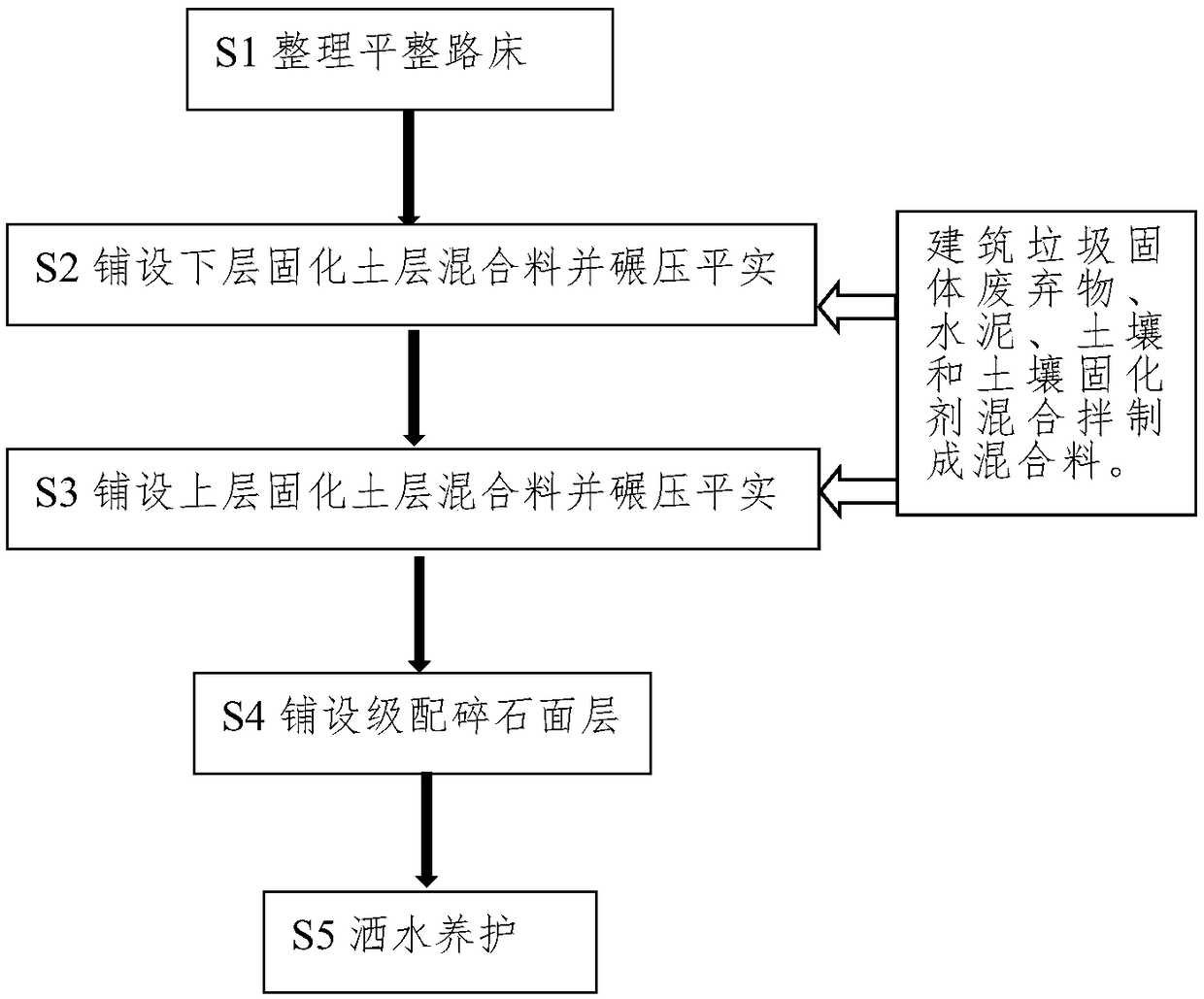

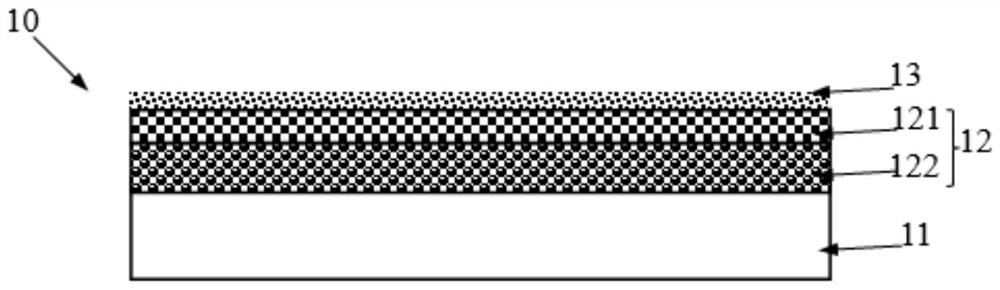

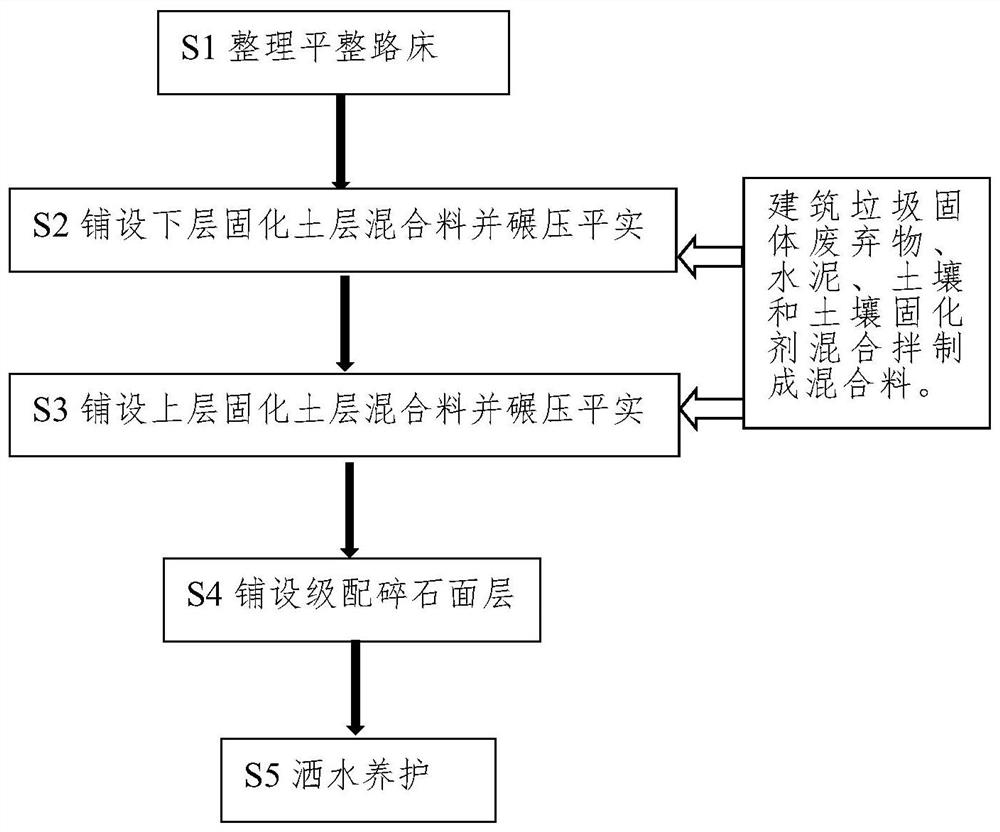

Temporary road pavement structure and road construction method

ActiveCN108842557AIncreased durabilityWide adaptabilityTemporary pavingsChemical reactionSurface layer

The invention discloses a temporary road pavement structure which comprises a roadbed, a base layer and a surface layer from bottom to top in sequence, wherein the base layer is a cured soil layer with cement and a soil curing agent; the surface layer is a macadam floor consisting of graded broken stone. By virtue of properties of the soil curing agent, the soil curing agent is mixed with mixing materials, through a series of physical and chemical reactions, the compactness of a soil body is increased, the soil body is a dense stable soil layer, and thus the bearing capability of the roadbed can be greatly improved. The soil curing agent is wide in adaptability, is capable of effectively curing soil, mud, various solid building wastes and the like, and is applicable to large-scale recycledand reused building wastes. The cured soil layer made of the soil curing agent is used as the road base layer, so that compared with a conventional temporary road, the temperature road made with theroad base layer is high in strength and good in water stability and dry shrinkage resistance, the amounts of conventional road construction materials such as lime, cement, coal ash and macadam can bereduced, and the road construction cost can be effectively reduced.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

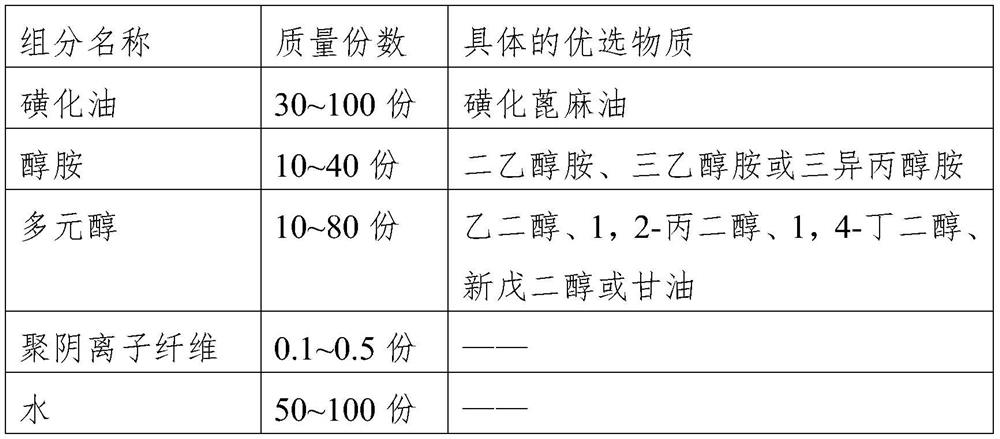

Curing agent for stabilizing soil

InactiveCN102086399AEnvironmental protection is goodGood value for moneySolid waste managementBuilding constructionsCelluloseBrick

The invention relates to an environment-friendly curing agent for stabilizing soil, which can improve the bearing capacity of a subgrade. The curing agent for stabilizing the soil is characterized by comprising the following components in parts by weight: 2-18 parts of polyanionic cellulose, 2-6 parts of sodium sulfate or calcium sulphate, 12-50 parts of sulfonic acid, 2-53 parts of granulated blast furnace slag, 1-5 parts of neutral water glass and 38-150 parts of water. The curing agent for stabilizing the soil can remarkably improve the bearing capability of the cured soil and has good antiseepage effect and durability, and the situation of argillization can be reduced after the curing agent is soaked in the water; therefore, the environment-friendly curing agent is suitable for various construction pavements, in particular rural roads developed for travel and agriculture with the requirements of low cost, short construction period and fast effect. The environment-friendly curing agent not only improves the road construction quality, but also makes the material application and the construction process more environment-friendly, can be further applied to the base course and surface course of road and construction engineering and the fields of wind prevention and sand consolidation, canal seepage control, burning-free low-carbon environment-friendly bricks and the like, and is suitable for the semimechanical operation and the large-scale mechanical construction operation in country.

Owner:RUIFUXIANG PHARMA GUANGXI

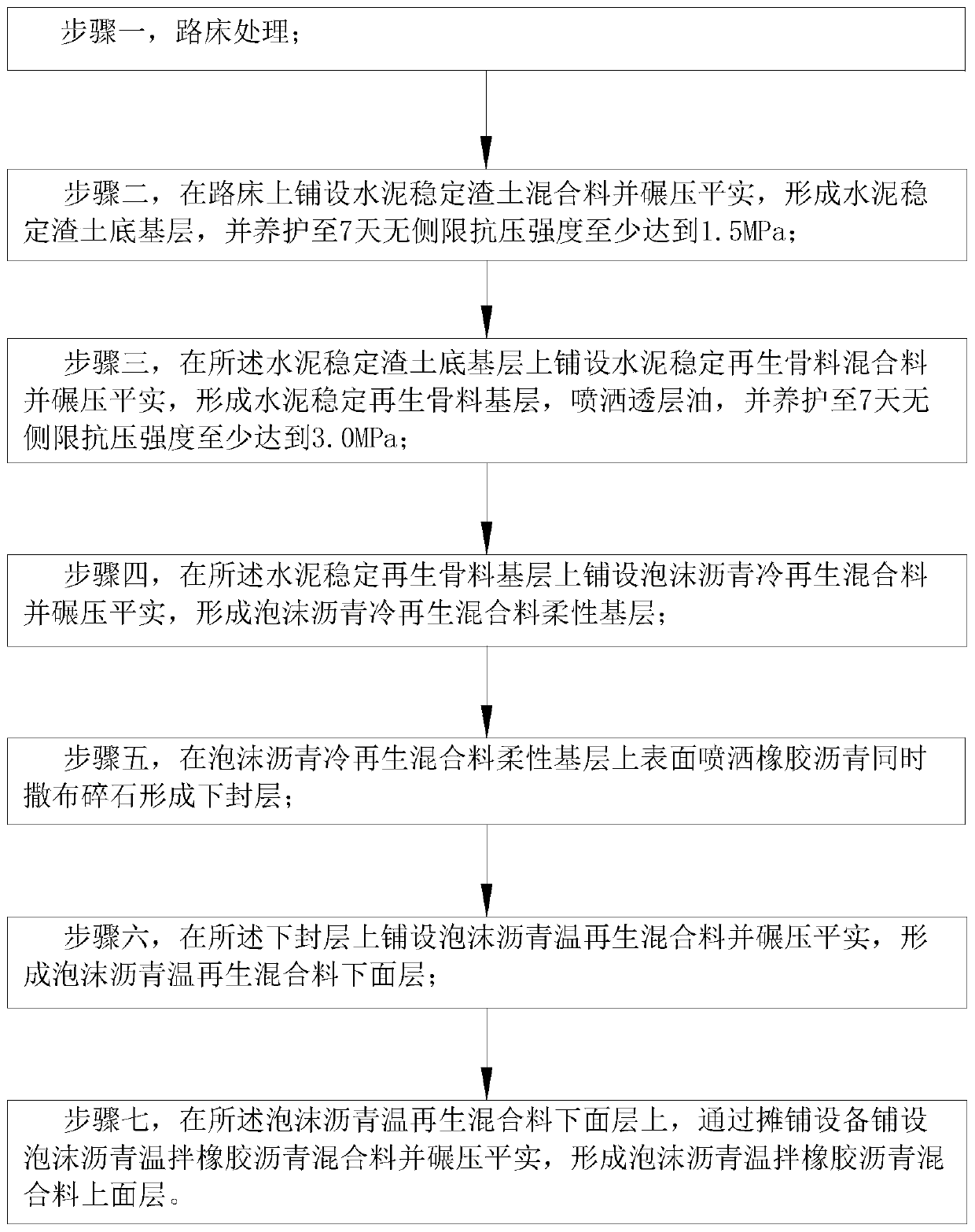

Recycled pavement structure and road construction process thereof

ActiveCN110607726AImprove durabilityReduce road construction costsIn situ pavingsClimate change adaptationRubberized asphaltPitch blende

The invention belongs to the technical field of road engineering and specifically relates to a recycled pavement structure and a road construction process thereof. The recycled pavement structure comprises base courses and surface courses. The base courses include the cement stabilized muck subbase course, the cement stabilized recycled aggregate base course and the foamed asphalt cold-recycled mixture flexible base course which are arranged from bottom to top. The surface courses include the warm-mixed recycled asphalt mixture lower surface course and the warm-mixed rubber asphalt mixture upper surface course. Through the recycled pavement structure, large-scale and high-value utilization of construction waste recycled materials can be realized, the recycling rate of construction waste reaches up to 95% or more, the utilization ratio of recycled aggregate can reach up to 100%, and the ratio of the recycled materials in an overall pavement structure can reach up to 80%-90%. Comprehensive recycling on solid waste such as construction waste is realized, and the requirements of relevant specifications are met. There is no need to conduct degrading utilization on the recycled aggregate. The effects of energy conservation and emission reduction are achieved. The environment is protected. Exploitation and consumption of new aggregated rocks can be reduced. The construction funds canbe saved.

Owner:沧州市市政工程股份有限公司

Rock-soil solidifying agent as well as preparation method and application of rock-soil solidifying agent

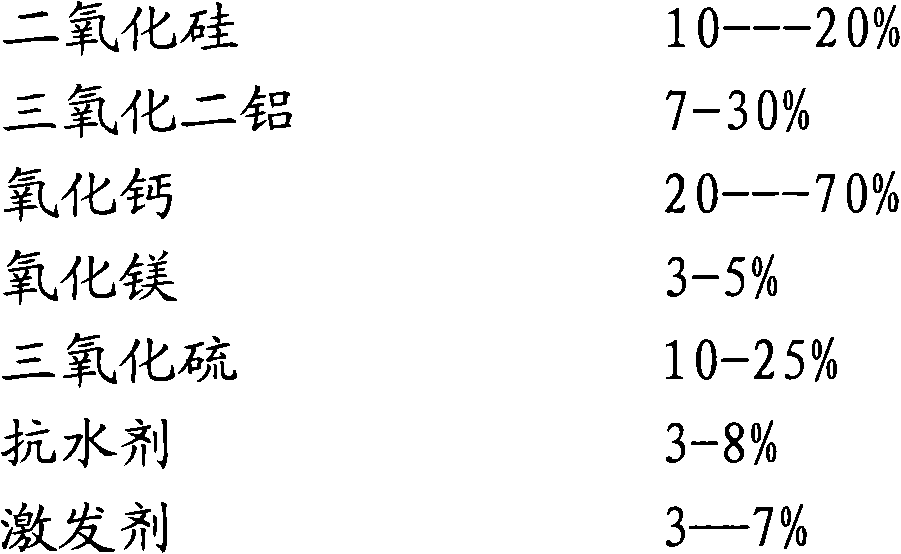

InactiveCN104817297ATargeted optimizationImprove compatibilitySolid waste managementRoad surfaceSilicon dioxide

The invention provides a rock-soil solidifying agent. Based on the total mass of the rock-soil solidifying agent, the rock-soil solidifying agent is prepared from such raw materials in parts by weight as fluorgypsum powder, zinc sulfate, polyester resin powder, acid, methylbenzene, early strength agent, sodium dodecyl sulfate and lignosulfonate. The rock-soil solidifying agent has excellent pertinence and compatibility to the waste materials of urban architecture excavation; after the rock-soil solidifying agent is applied to road construction, the rock-soil solidifying agent is capable of functioning in enhancing together with urban architecture excavation, silicon dioxide and cement; the rock-soil solidifying agent is capable of penetrating to form a pavement high in strength and durability; as a result, the waste resources are effectively utilized and the road building cost is effectively reduced.

Owner:上海三凯工程咨询有限公司

New method for old road reconstruction by recycling waste materials

InactiveCN103161119AImprove bearing capacityImprove toughnessBuilding constructionsRoads maintainenceEnvironmental engineeringRoad surface

The invention relates to a new method for old road reconstruction by recycling waste materials. The method comprises the processes of: first, treating an old road surface, and in the event of a cement road surface, using equipment to dig out a concrete base layer and breaking it for stand-by use, conducting an indoor test to obtain an optimal mix proportion, according to designed strength, compactness, the optimal mix proportion of test and an optimal moisture content, subjecting LF-S1 and LF-S2 soil solidifying agents, cement and water to smashing stirring till the compactness by recycling equipment, before the last three times of rolling compaction, laying two centimeters of gravel, then performing rolling compaction for three times or paving an asphalt wearing layer, using water to dilute a soil solidification solution in a ratio of 1:200 and carrying out maintenance with the obtained solution, and then paving a colored asphalt surface layer or colored gravel, with old road bed soil, the cement, the liquid soil solidifying agent (L1f-S2) and the powder soil solidifying agent (LF-S3) being in a proportion of, for per cube of compaction: 90-93%:5-8%:0.7kg:5-7%kg. Old road reconstruction by the method provided in the invention can have greatly reduced cost and reduced waste, thus the method is environment-friendly.

Owner:LUOYANG LUSHIFENG SOIL SOLIDIFICATION SCI & TECH

Recycling pavement structure and pavement building technology thereof

InactiveCN106758654AIncreased durabilityPromote and improve resource utilization levelIn situ pavingsClimate change adaptationSurface layerRoad engineering

The invention discloses a recycling pavement structure and a pavement building technology thereof and relates to the technical field of road engineering. The recycling pavement structure comprises a roadbed, a base layer and a surface layer. The base layer comprises a cement stabilization muck subbase, a cement stabilization recycled aggregate base layer and a foamed asphalt cold-recycling mixture flexible base layer, all of which are arranged from bottom to top. The surface layer comprises a lower warm mixing recycling asphalt mixture surface layer and an upper warm mixing rubber asphalt mixture surface layer. By the adoption of the recycling pavement structure, a large-scale and high-valued trend can be achieved, the recycling rate of construction waste can reach over 95%, the use rate of recycled aggregate can reach 100%, recycled materials account for 70% to 80% of the whole pavement structure, solid waste such as the construction waste is comprehensively recycled, meanwhile the requirements of related standards are met, energy is saved, emission is reduced, the environment is protected, exploitation and consumption of new building stones can be reduced as well, the construction capital is saved, meanwhile, the recycled aggregate does not need to be degraded for use, the structure is suitable for rainy season construction, and the construction period can be shortened.

Owner:沧州市市政工程股份有限公司

Soil stabilizer

InactiveCN102807869AAvoid pollutionSolve the shortage of resourcesBuilding constructionsOrganic fertilisersMass ratioRoad engineering

The invention discloses soil stabilizer, which consists of industrial waste and chemical reagent, wherein the industrial waste consists of ground steel slag, coal gangue powder after being spontaneously-combusted, grain slag or furnace slag, the chemical reagent consists of calcium oxide, powder grinding aid and sodium sulfate, wherein the mass ratio of the industrial waste and the chemical reagent is 7: 3, and the fineness of the stabilizer powder is brinell specific surface area 500 to 900 m<2> / kg. The soil stabilizer has beneficial effects that mixture of the industrial waste is adopted as raw materials, so that the environmental pollution caused by the industrial waste can be solved; the original chemical activity of the mixture is used for rapidly condensing and solidifying the soil and sand, and no other surface active agent and alkaline excitant is needed, so that the cost is remarkably reduced, simultaneously the construction speed is fast, and the delivery period can be shortened; and the soil stabilizer is widely applied to the dam crest solidification and slope protection of foundation layers of road engineering and hydraulic engineering and is free from being restricted by any environment.

Owner:YANAN HUIHAI BUILDING ENG

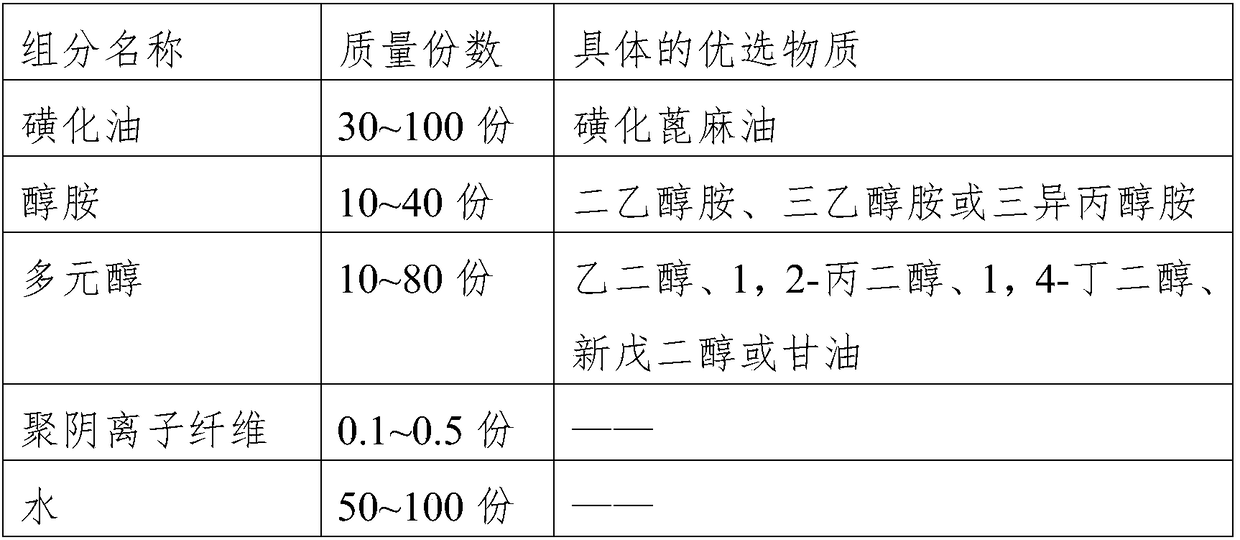

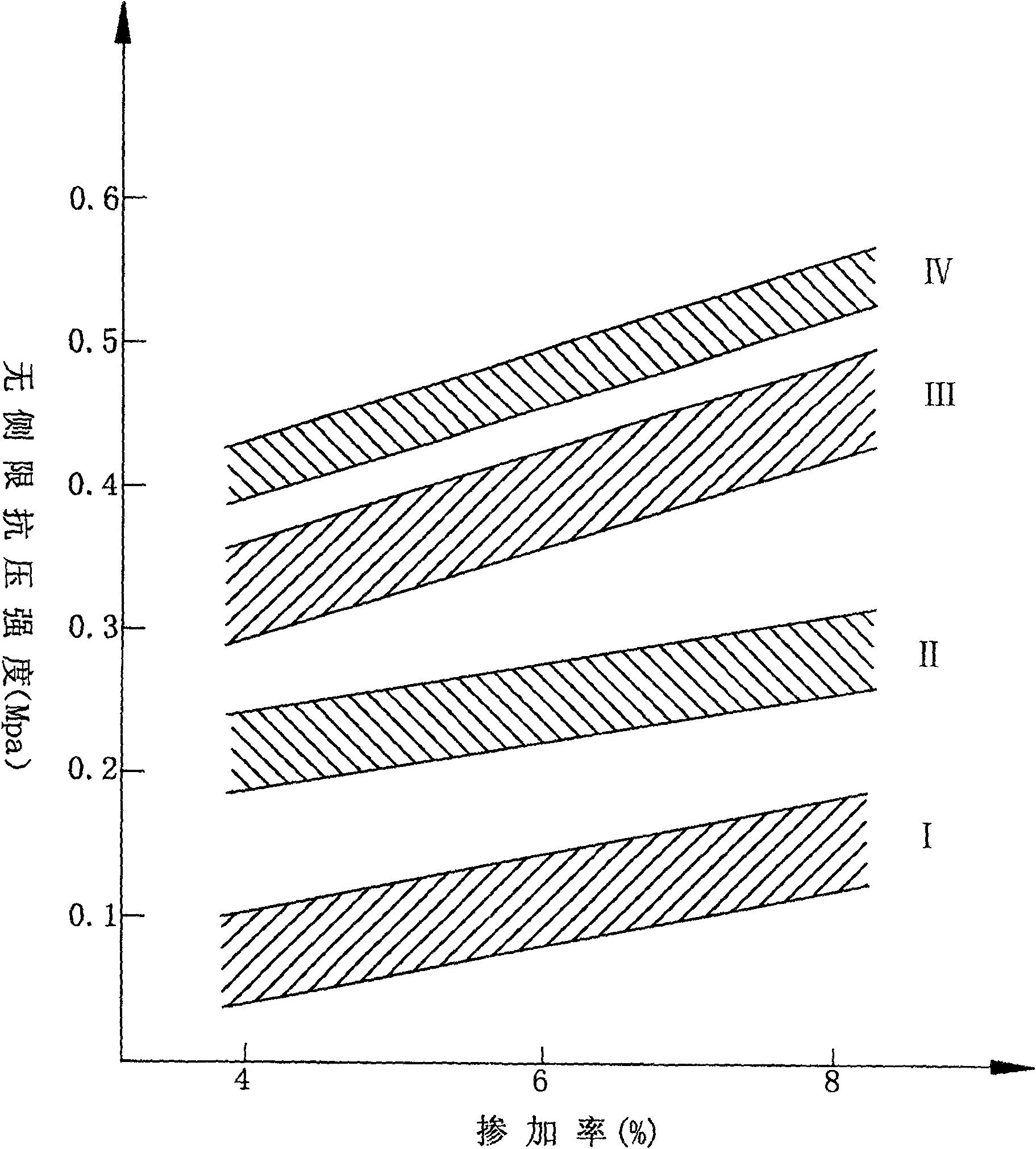

Silt compounded curing agent

InactiveCN106365539AAdjust delay timeAct as surface activeSoil preservationDynamic compactionAdhesive

The invention relates to a curing agent, in particular to a silt compounded curing agent which is prepared from the following components in parts by mass: 20-50 parts of an inorganic material adhesive, 2-5 parts of an activator and 2-10 parts of an organic matter surfactant. The silt compounded curing agent is mainly acted on silt, can replace the traditional construction process of vacuum preloading, rockery skin changing and filling and dynamic compaction and can be used for foundation treatment of expressways, municipal roads, storage yards and various building places.

Owner:天津恒吉生科技有限公司

Sludge curing agent and application thereof

ActiveCN100562501CImprove performanceGood boardSludge treatment by de-watering/drying/thickeningSolid waste managementSludgeSlag

The present invention is sludge curing agent and its application, and belongs to the field of soil treating chemicals technology. The sludge curing agent includes powdered components and liquid components, the powdered components include cement clinker 30-60 weight portions, slag 30-60 weight portions, lime 3-8 weight portions, gypsum 1-7 weight portions and other sulfates 1-7 weight portions; and the liquid components include polyacrylamide 5-30 weight portions, polyaluminum chloride 0-20 weight portions, mannitol 0-30 weight portions, lignosulfonate 20-80 weight portions, lignosulfonate-iron or chromium ion complex 0-30 weight portions, alkylphenol ethoxylate 0.2-2 weight portions, tannin 0-10 weight portions, humate 0-10 weight portions, and alpa-olefin sulfonate 0.2-2.5 weight portions. The sludge curing agent has low cost, small consumption, high cumulate strength and high cumulate water tolerance, and may be applied widely.

Owner:BEIJING ZHONGYONGJI FIRMING AGENT TECH DEV

Road surface based material by sintering red mud and construction method thereof

ActiveCN100339332CHigh strengthImprove frost resistanceRoadwaysSolid waste managementRed mudMining engineering

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Hot in-plant reclaimed asphalt mixture

ActiveCN101654347BIncrease dosageImprove high temperature performanceSolid waste managementEconomic benefitsRoad surface

The invention relates to a hot in-plant reclaimed asphalt mixture. The mixture includes the following components by mass percent: 30 to 50 percent of milling materials, 44 to 67 percent of newly collected materials, 1.5 to 4 percent of mineral powder, 1.5 to 4 percent of new asphalt, and ARA regenerant which is 0 to 10 percent of the mass of the recycled asphalt contained in the milling materials. The processing method includes the following steps: (1) extraction and analysis of the milling materials; (2) asphalt performance test; (3) regenerant addition; (4) formation of mixture of the recycled asphalt; (5) Marshall test or rotary compacting test; and (6) mixture performance test. The proportion of milling material RAP reaches as high as 50 percent in the engineering application of the hot recycled asphalt mixture, the milling material RAP can be applied to a middle layer, and the proportion is higher than the proportions of other hot recycled mixtures by more than 20 percent. The mixture can be applied to various grades, such as the AC type, SUPERPAVE, and the like, and the RAP proportion can respectively reach 30 percent or even more than 50 percent. When the mixture is used for paving a road surface, the road performance can respectively meet the requirements on performance of a newly proportioned asphalt mixture, and the high temperature performance is even superior to the newly proportioned asphalt mixture. Therefore, the invention has obvious economic benefit.

Owner:JIANGSU HUAIAN TRAFFIC SURVEY & DESIGN INST

Soil stabilizing and curing agent

InactiveCN101525541BReduce maintenance costsImprove the quality of road constructionOrganic fertilisersSoil preservationPolyvinyl alcoholPolyethylene glycol

The invention relates to a soil stabilizing and curing agent for paving road beds and coating road surfaces by using soil adjusting materials. The soil stabilizing and curing agent adopts a technical proposal that two compositions of a soil stabilizing agent and a soil curing agent which are matched are developed, wherein the composition of the soil stabilizing agent comprises the following components in percentage by weight: 32 to 42 percent of dodecylbenzene sulfonic acid, 6 to 12 percent of dodecyl polyoxyethylene ether sodium sulfate; 0.5 to 3 percent of dilute sulphuric acid, 2 to 4 percent of disodium sulfosuccinate monoester, 1 to 3 percent of neutral water glass (modulus is between 3.1 and 3.4) and 38.5 to 54 percent of water; and the composition of the soil curing agent comprisesthe following components in percentage by weight: 17 to 25 percent of polyvinyl alcohol, 4 to 8 percent of polyvinyl-pyrrolidone, 3 to 6 percent of droxyethylcellulose, 5 to 10 percent of polyethylene glycol, 2 to 4 percent of hydroxypropyl methylcellulose and 47 to 69 percent of water. The use of the soil stabilizing and curing agent for processing the road beds in the road laying engineering changes the conventional road laying method, and not only improves the road laying quality, but also greatly improves the environmental protection condition in the process of construction. At the same time, the road laying cost and the maintenance and servicing expense of the roads are also reduced.

Owner:钟维安

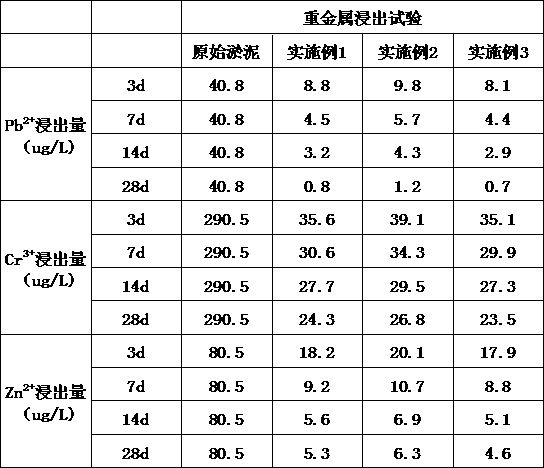

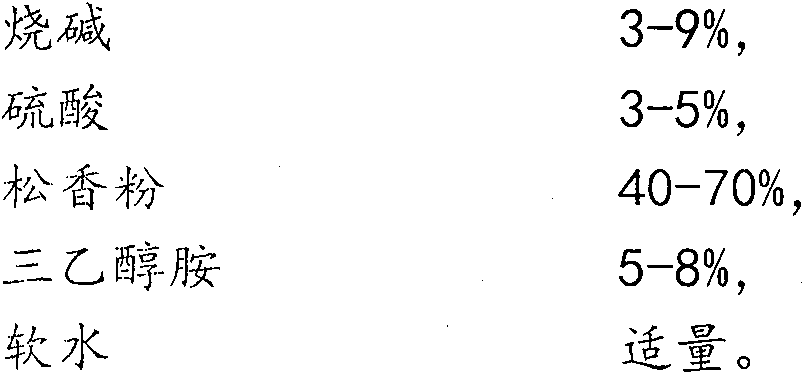

Composite sludge curing agent

InactiveCN112794591AAvoid secondary pollutionEffective absorptionFixation/solidifcation sludge treatmentHeavy metal chelationSludge

The invention relates to the field of sludge treatment, in particular to a composite sludge curing agent. The composite sludge curing agent is prepared from the following raw materials in parts by weight: 30-40 parts of fly ash, 15-20 parts of citric acid residue, 11-13 parts of calcium bentonite, 58 parts of cement, 0.5-0.8 part of carbide slag, 0.3-0.5 part of a polycarboxylate superplasticizer and 0.12-0.15 part of a heavy metal chelating agent. The composite sludge curing agent provided by the invention not only can improve the strength of sludge, but also can effectively absorb water in the sludge in a short time, and has a better heavy metal adsorption effect, the sludge treated by the composite sludge curing agent can be used on a road bed, the road building cost is reduced, meanwhile, the composite sludge curing agent is relatively environment-friendly, and secondary pollution of the sludge is effectively prevented; the fly ash, the citric acid residues and other wastes are used as main raw materials, the doping amount is small during sludge consolidation treatment, the cost is low, and large-scale popularization is facilitated.

Owner:深圳瑞新达生态科技有限公司

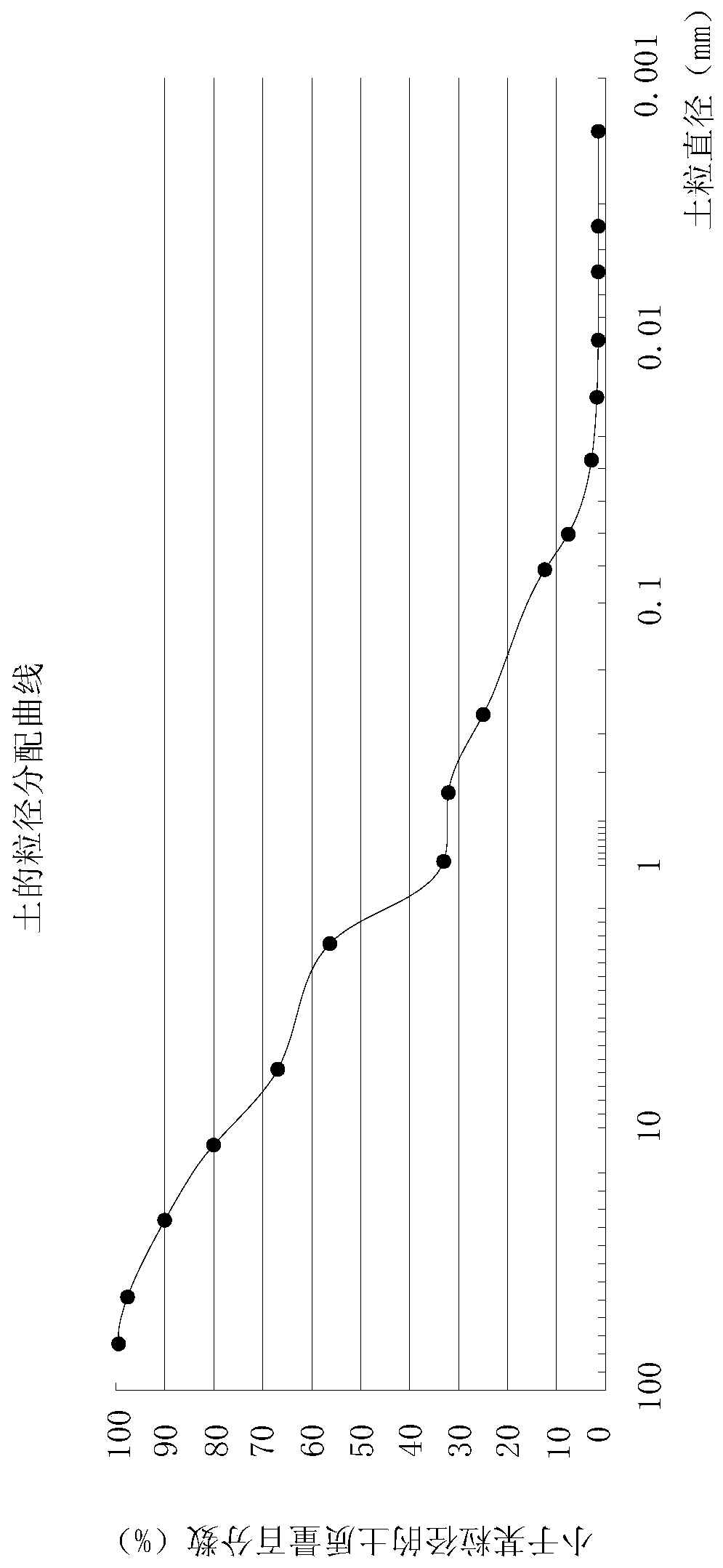

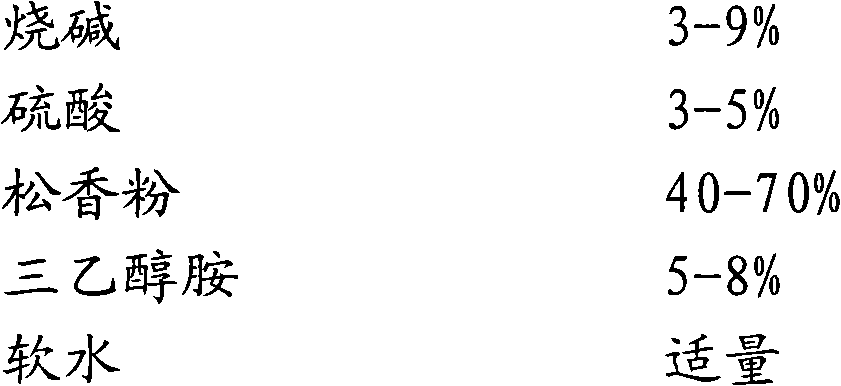

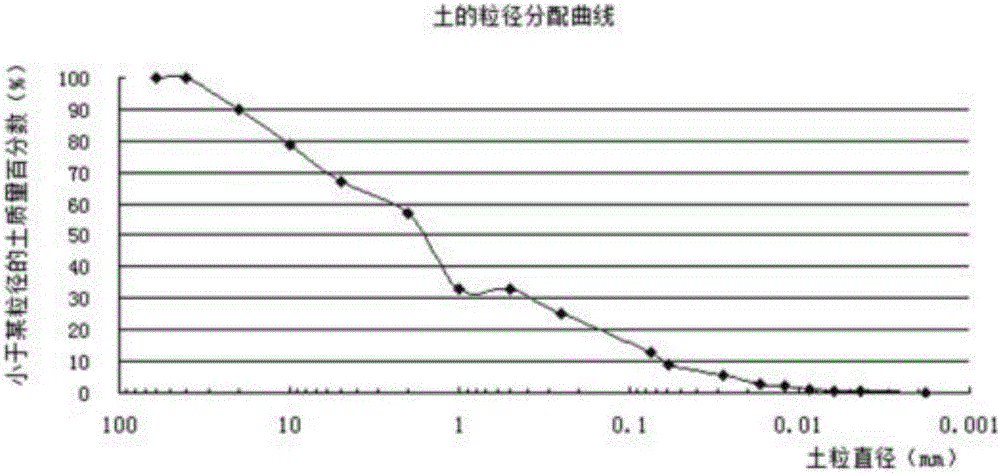

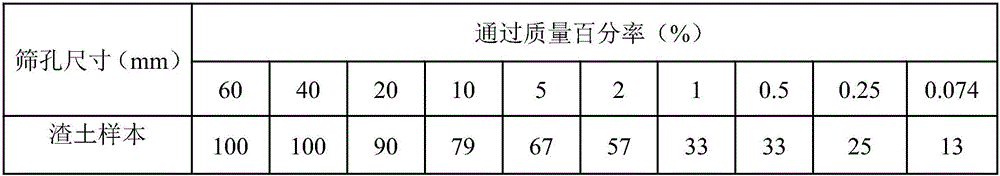

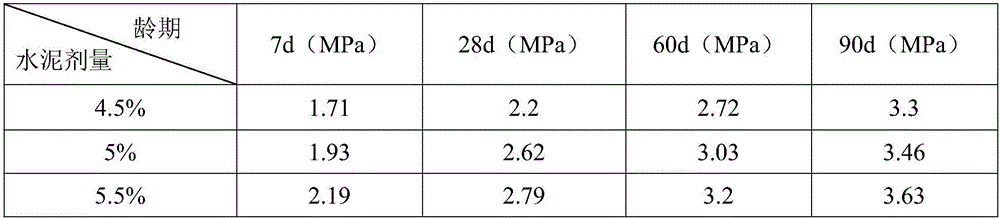

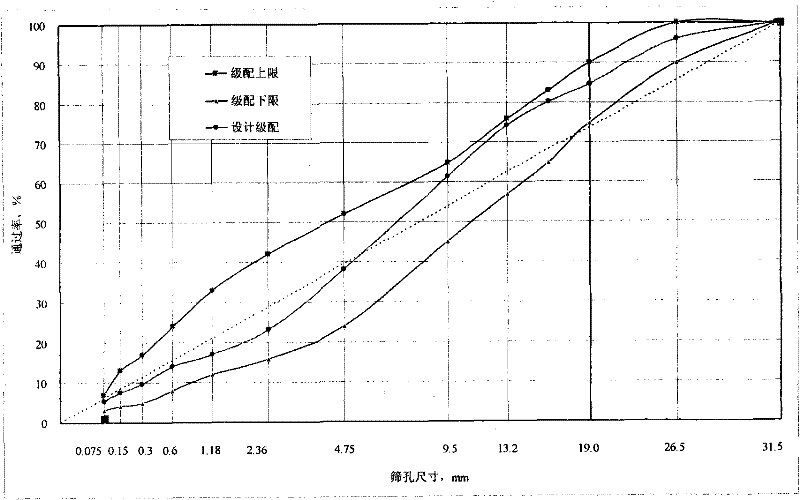

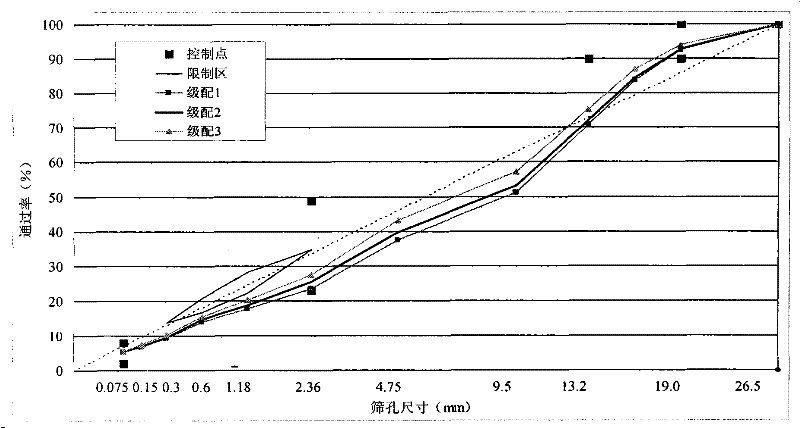

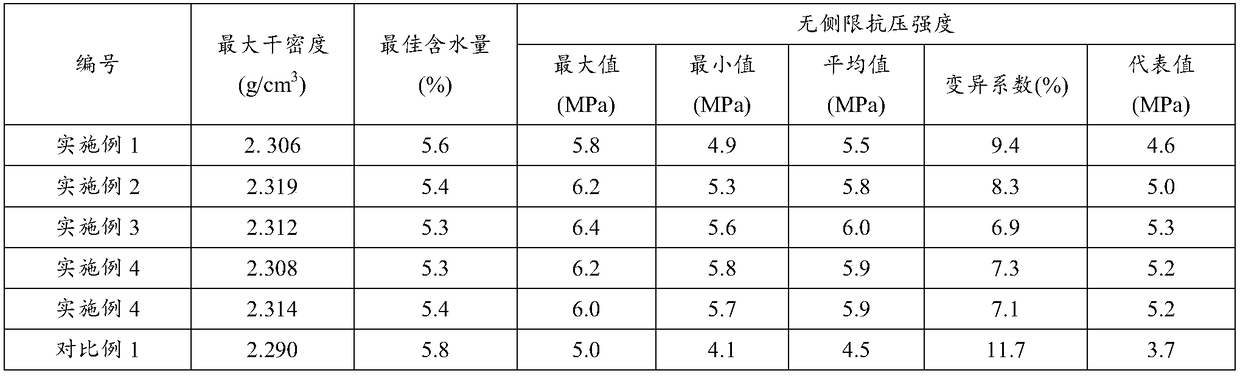

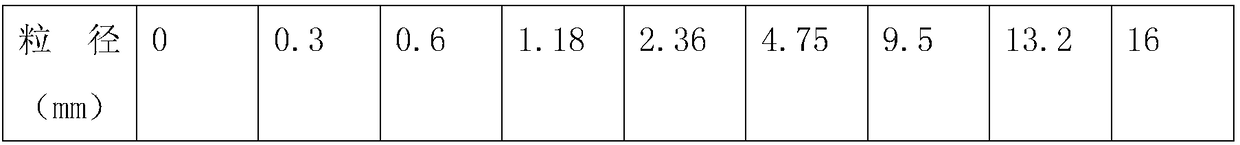

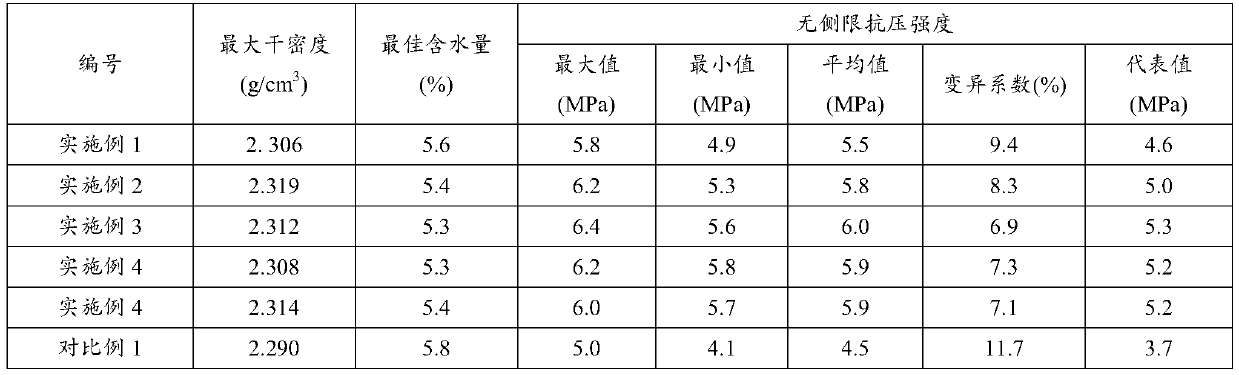

Aeolian sand cement stabilized graded broken stone

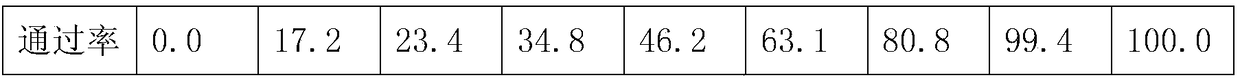

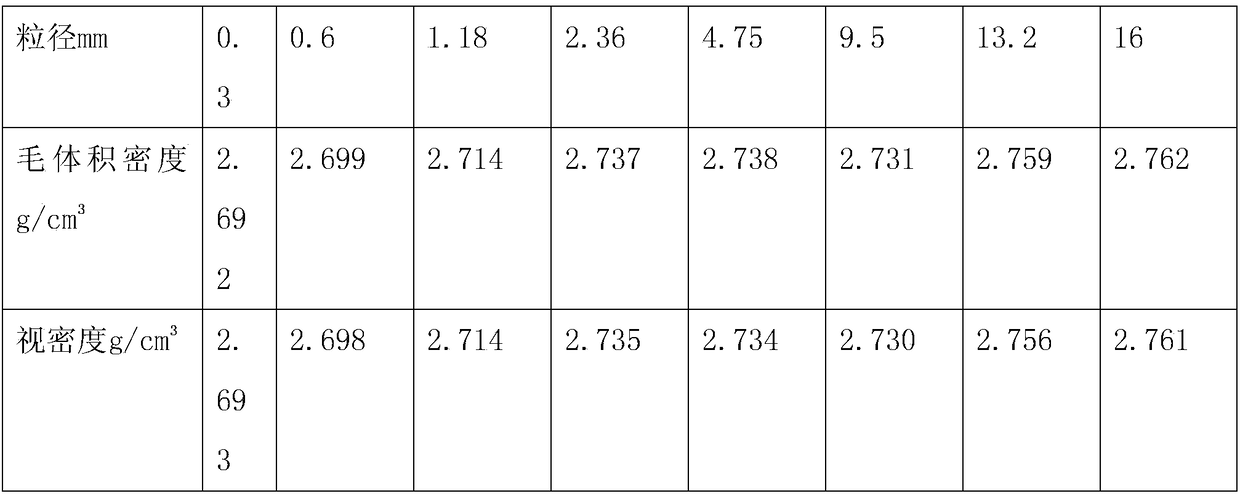

The invention discloses aeolian sand cement stabilized graded broken stone. The aeolian sand cement stabilized graded broken stone comprises the following raw materials by mass percent: 4.2-5.2% of cement, 4.6-6.6% of water, and the balance of aeolian sand graded broken stone; the aeolian sand graded broken stone comprises the following raw materials by mass ratio, and the ratio of the aeolian sand to the stone chips to the broken stone is equal to (8-13):(17-26):(66-70). According to the aeolian sand cement stabilized graded broken stone, the capital input of the highway projects is relatively low, the cost of the raw materials for building the road is low, and the flexural-tensile strength and the crack resistant property of the cement stabilized graded broken stone are improved.

Owner:CCCC SECOND HARBOR ENG +1

A temporary road pavement structure and road construction method

The invention discloses a temporary road pavement structure which comprises a roadbed, a base layer and a surface layer from bottom to top in sequence, wherein the base layer is a cured soil layer with cement and a soil curing agent; the surface layer is a macadam floor consisting of graded broken stone. By virtue of properties of the soil curing agent, the soil curing agent is mixed with mixing materials, through a series of physical and chemical reactions, the compactness of a soil body is increased, the soil body is a dense stable soil layer, and thus the bearing capability of the roadbed can be greatly improved. The soil curing agent is wide in adaptability, is capable of effectively curing soil, mud, various solid building wastes and the like, and is applicable to large-scale recycledand reused building wastes. The cured soil layer made of the soil curing agent is used as the road base layer, so that compared with a conventional temporary road, the temperature road made with theroad base layer is high in strength and good in water stability and dry shrinkage resistance, the amounts of conventional road construction materials such as lime, cement, coal ash and macadam can bereduced, and the road construction cost can be effectively reduced.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

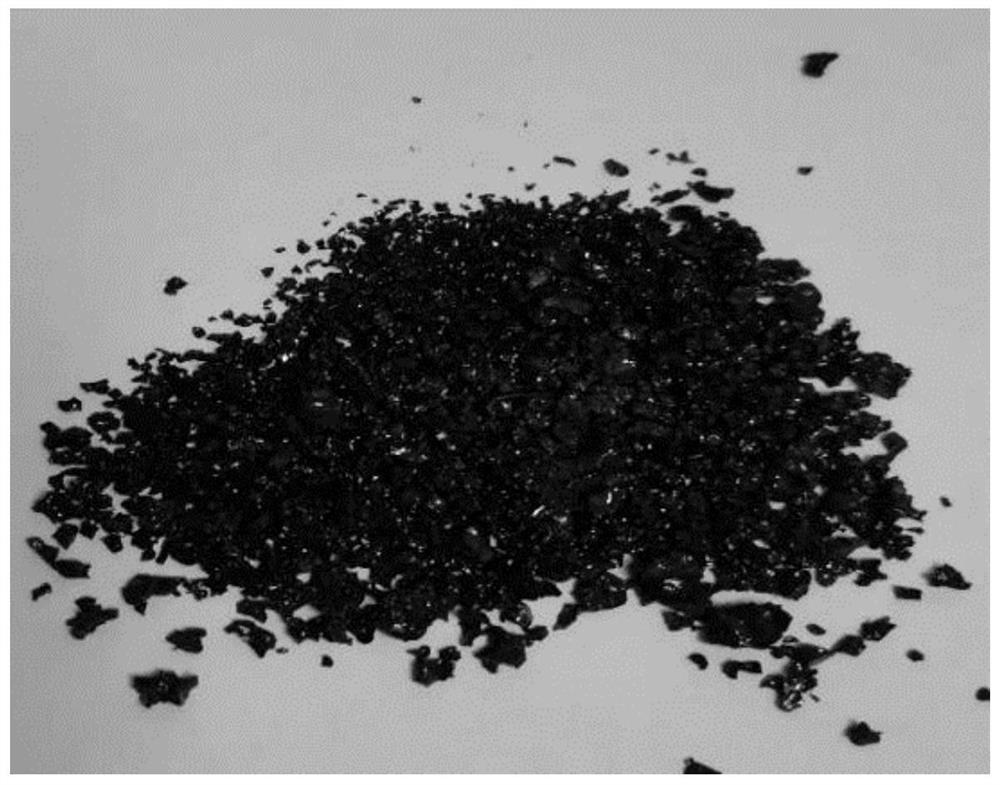

Road building slag taking municipal sludge as raw material, preparation method and application thereof

InactiveCN113354222AMild biological responseOperational securitySludge treatment by de-watering/drying/thickeningIn situ pavingsMicroorganismSludge

The invention belongs to the technical field of municipal sludge treatment, and particularly discloses road building slag taking municipal sludge as a raw material, a preparation method and application thereof. According to the invention, microorganisms subjected to enrichment culture are added into municipal sludge, and active thalli in the sludge are completely replaced by the microorganisms through a biological extraction reaction; the extraction microorganisms are mainly autotrophic bacteria, the sludge is mainly heterotrophic bacteria, the oxidation and acidification effects of the flora are utilized to condition the sludge, and the water content is reduced to the sludge treatment requirement after mechanical dehydration; and the slag is prepared by means of drying, calcining and the like and is used as a road building material, so that an efficient and economic new way is opened up for reduction, harmlessness and resourceful treatment of the municipal sludge and development of cheap road building materials.

Owner:GUANGZHOU UNIVERSITY

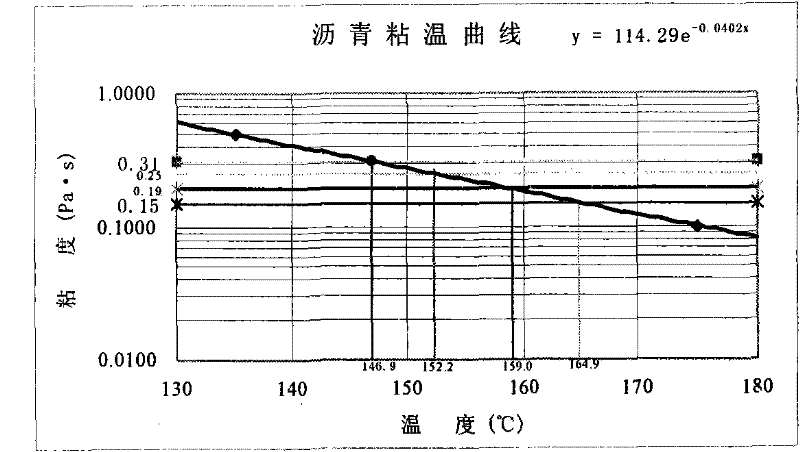

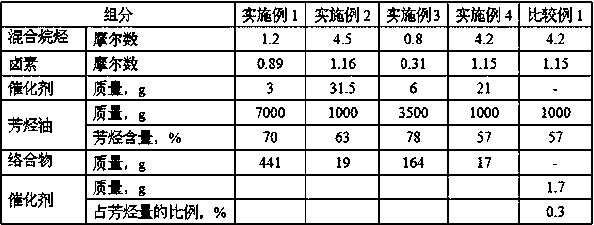

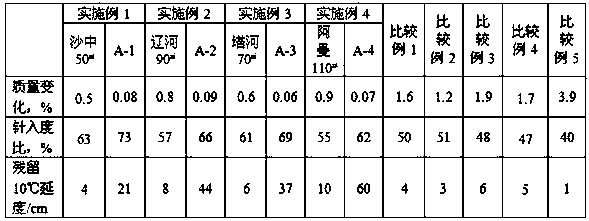

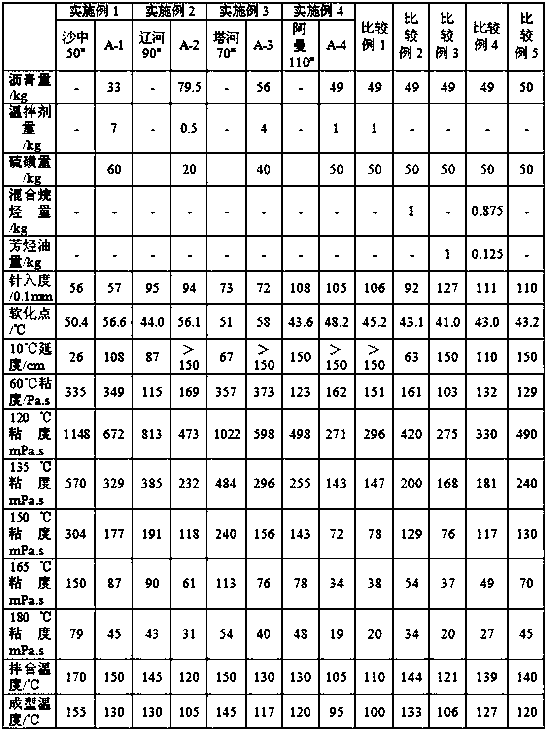

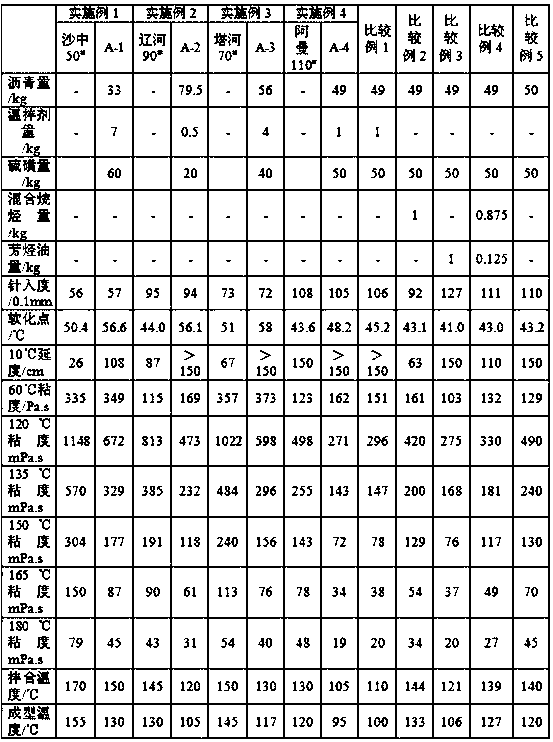

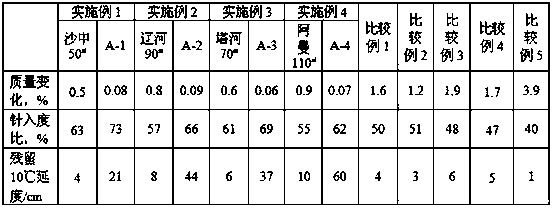

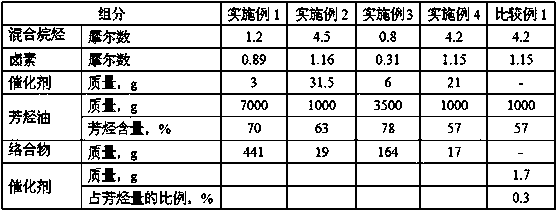

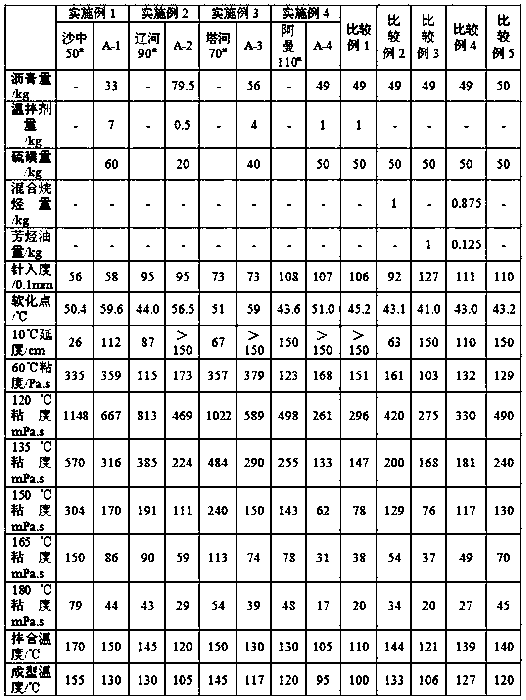

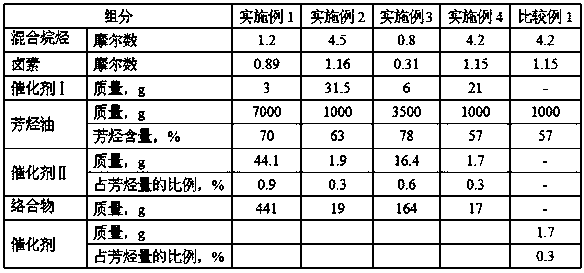

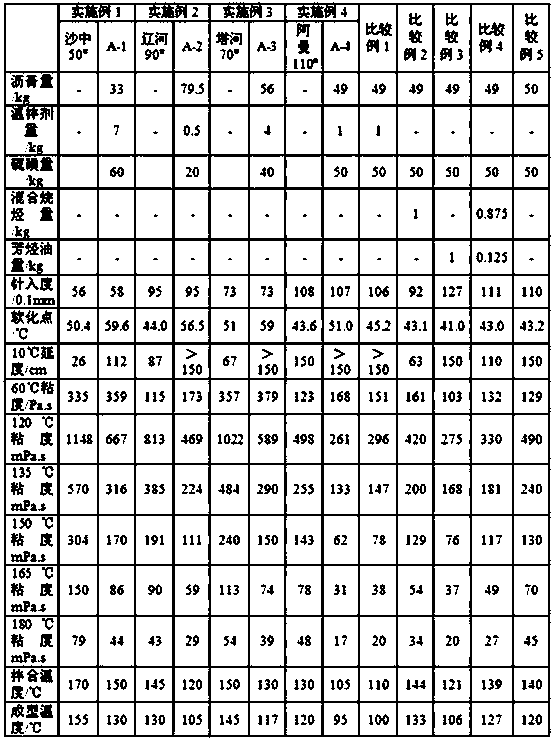

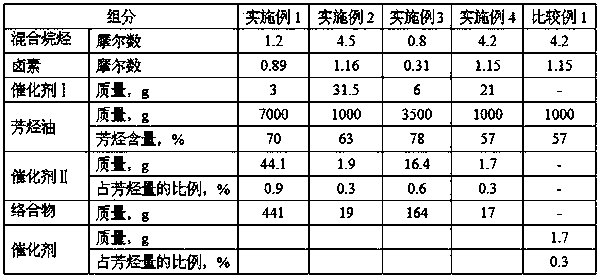

A kind of warm sulfur asphalt mixture and preparation method thereof

The invention discloses a warm-mixing sulfur asphalt mixture and a preparation method thereof. The warm-mixing sulfur asphalt mixture is prepared from 4.0 to 6.0 parts of warm-mixing sulfur asphalt, 1.0 to 3.0 parts of mineral powder and 91.0 to 95.0 parts of aggregate, wherein the warm-mixing sulfur asphalt is prepared from 0.5 to 7 parts of warm-mixing agent, 33 to 79.5 parts of matrix asphalt and 20 to 60 parts of sulfur; the warm-mixing agent is prepared by adopting the following method: firstly, reacting polymer paraffin with a halide element at a certain temperature and a pressure under the action of a catalyst to obtain an intermediate; uniformly mixing aromatic hydrocarbon oil with a complex to obtain an aromatic hydrocarbon complexing component; secondly, reacting the aromatic hydrocarbon complexing component with the intermediate at a certain temperature to obtain the warm-mixing agent for the warm-mixing sulfur asphalt mixture disclosed by the invention. The mixture disclosed by the invention uses sulfur asphalt containing the warm-mixing agent; by use of the warm-mixing agent, thermal stability of the asphalt is improved, the aging resistant property is improved, the use temperature of the mixture is reduced, and the pollution of the mixture to air due to release of harmful gases in a use process is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of warm mixed sulfur asphalt and preparation method thereof

ActiveCN106633941BEasy to grasp performanceImprove performanceClimate change adaptationBuilding insulationsPtru catalystAromatic hydrocarbon

The invention provides warm-mixing sulfur asphalt. The warm-mixing sulfur asphalt is prepared from the following components in parts by mass: 0.5 to 7 parts of warm-mixing agent, 33 to 79.5 parts of matrix asphalt and 20 to 60 parts of sulfur. The warm-mixing agent is prepared by adopting the following method: firstly, reacting polymer paraffin with a halide element at a certain temperature and pressure under the action of a catalyst to obtain an intermediate; uniformly mixing aromatic hydrocarbon oil with a complex to obtain an aromatic hydrocarbon complexing component; secondly, reacting the aromatic hydrocarbon complexing component with the intermediate at a certain temperature to obtain the warm-mixing agent for the warm-mixing sulfur asphalt provided by the invention. According to the warm-mixing agent used by the warm-mixing sulfur asphalt provided by the invention, a warm-mixing effect on asphalt can be realized, the high-and-low temperature performance of the asphalt is considered, the thermal stability of the asphalt can be improved, and the aging resistant property is improved; the warm-mixing asphalt is prepared from the warm-mixing agent and the asphalt, so that the melting temperature of the asphalt and the viscosity of the asphalt at the temperature are reduced; particularly when the sulfur asphalt is prepared, the preparation temperature of the sulfur asphalt can be reduced, and the occurrence quantity of the harmful gases is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Plant-mixed hot recycled asphalt mixture and its preparation method

The invention belongs to the technical field of road engineering, and concretely relates to a plant hot-mix recycled asphalt mixture and a preparation method thereof. The plant hot-mix recycled asphalt mixture and the preparation method thereof are provided against the problem of difficult improvement of the admixture of wastes in the plant hot-mix recycled asphalt mixture on the basis of meeting the performances of the asphalt mixture. The recycled mixture comprises, by weight, 70-90 parts of milling wastes, 10-15 parts of heavy aromatic hydrocarbons, 10-15 parts of acrylamide, 15-30 parts of new aggregates, 3-6 parts of mineral powder, 3-6 parts of new asphalt and 2-5 parts of a regenerant. The recycled asphalt mixture has the advantages of high admixture and high recycling efficiency; and a new mixture has uniform texture and stable performances, and meets performance requirements of the hot-mix asphalt mixture.

Owner:HEILONGJIANG ZHONGXIN ROAD & BRIDGE MATERIAL CO LTD

Warm-mix sulfur asphalt mixture and preparation method thereof

The invention discloses a warm-mix sulfur asphalt mixture and a preparation method thereof. The warm-mix sulfur asphalt mixture comprises 4.0 to 6.0 parts of warm-mix sulfur asphalt, 1.0 to 3.0 parts of mineral powder and 91.0 to 95.0 parts of an aggregate, wherein the warm-mix sulfur asphalt comprises 0.5 to 7 parts of a warm-mix agent, 33 to 79.5 parts of matrix asphalt and 20 to 60 parts of sulfur. The warm-mix agent is prepared by the following method: reacting macromolecular alkane with elementary halogen in the presence of a catalyst to obtain an intermediate; reacting aromatic hydrocarbon oil with a complex in the presence of the catalyst to obtain an arene complex component; introducing the arene complex component into the intermediate, and performing reaction and curing at certain temperature to obtain the warm-mix agent. According to the mixture, the sulfur asphalt containing the warm-mix agent is used, and by the warm-mix agent, the heat stability of the asphalt is improved, the ageing resistance is improved, the usage temperature of the mixture is reduced, and air pollution caused by releasing of harmful gas in the mixture during use is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of aeolian sand cement stabilized graded crushed stone

The invention discloses aeolian sand cement stabilized graded broken stone. The aeolian sand cement stabilized graded broken stone comprises the following raw materials by mass percent: 4.2-5.2% of cement, 4.6-6.6% of water, and the balance of aeolian sand graded broken stone; the aeolian sand graded broken stone comprises the following raw materials by mass ratio, and the ratio of the aeolian sand to the stone chips to the broken stone is equal to (8-13):(17-26):(66-70). According to the aeolian sand cement stabilized graded broken stone, the capital input of the highway projects is relatively low, the cost of the raw materials for building the road is low, and the flexural-tensile strength and the crack resistant property of the cement stabilized graded broken stone are improved.

Owner:CCCC SECOND HARBOR ENG +1

Warm-mix sulfur pitch and its preparation method

ActiveCN106633945BEasy to grasp performanceImprove performanceClimate change adaptationBuilding insulationsAlkaneHalogen

The present invention provides a warm mix sulfur asphalt, which comprises, by mass, 0.5-7 parts of a warm mix agent, 33-79.5 parts of a matrix asphalt, and 20-60 parts of sulfur. The warm mix agent preparation method comprises: under the effect of a catalyst, carrying out a reaction on a macromolecule alkane and an elemental halogen at a certain temperature under a certain pressure to obtain an intermediate; carrying out a reaction on an aromatic hydrocarbon oil and a complexing compound under the effect of a catalyst to obtain an aromatic hydrocarbon complexing component; and carrying out a reaction on the aromatic hydrocarbon complexing component and the intermediate at a certain temperature, and aging to obtain the warm mix agent. According to the present invention, with the warm mix agent, the warm mix effect is provided for the asphalt, the high temperature performance and the low temperature performance of the asphalt are considered, the thermal stability of the asphalt is improved, and the aging resistance is improved; and with the application of the warm mix agent and the asphalt to prepare the warm mix asphalt, the melting temperature of the asphalt and the viscosity of the asphalt at the melting temperature are reduced, and especially during the preparation of sulfur asphalt, the preparation temperature of the sulfur asphalt can be reduced, and the harmful gas generation can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

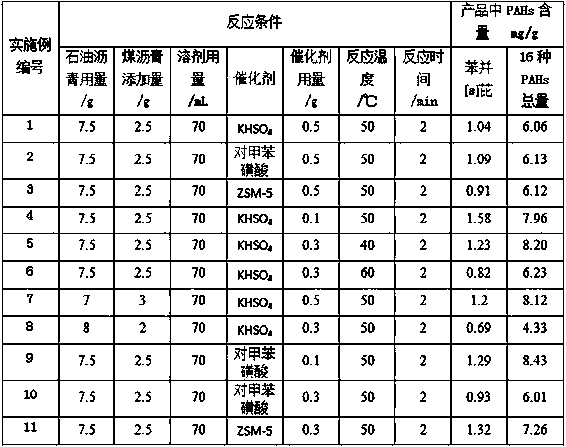

Preparation method for modified blended asphalt for road construction

ActiveCN108976833ALow toxicity solutionReduce road construction costsBuilding insulationsTar working-up by solvent extractionWater bathsDistillation

The invention discloses a preparation method for a cost-efficient and environment-friendly modified blended asphalt for road construction. According to the method, petroleum asphalt is completely dissolved into toluene solvent by ultrasonic oscillation under normal temperature, coal pitch and acidic catalyst are then added together, the mixture is put into a thermostat water bath to react at constant rotational speed, a reduced pressure distillation means is adopted to recover the toluene solvent for recycling after the reaction is complete, residue is then dried under vacuum for 12 hours, andthereby the modified blended asphalt for road construction is obtained. According to the invention, the process is simple, the preparation period is short, needed energy consumption is low, the pavement performance of the obtained modified blended asphalt product is obviously improved, moreover, the content of polycyclic aromatic hydrocarbon is low, the low toxicity of coal asphalt as an added component for road construction is basically realized, and thereby the cost of road asphalt is greatly reduced; and furthermore, the petroleum asphalt has better compatibility than other polymer or compound modifiers, solving the phenomenon of segregation which can easily take place after modified asphalt is stored for a long term.

Owner:TAIYUAN UNIV OF TECH

A New Method of Transforming Old Roads from Waste into Treasure

InactiveCN103161119BImprove bearing capacityImprove toughnessBuilding constructionsRoads maintainenceSurface layerBalance of nature

The invention relates to a new method for old road reconstruction by recycling waste materials. The method comprises the processes of: first, treating an old road surface, and in the event of a cement road surface, using equipment to dig out a concrete base layer and breaking it for stand-by use, conducting an indoor test to obtain an optimal mix proportion, according to designed strength, compactness, the optimal mix proportion of test and an optimal moisture content, subjecting LF-S1 and LF-S2 soil solidifying agents, cement and water to smashing stirring till the compactness by recycling equipment, before the last three times of rolling compaction, laying two centimeters of gravel, then performing rolling compaction for three times or paving an asphalt wearing layer, using water to dilute a soil solidification solution in a ratio of 1:200 and carrying out maintenance with the obtained solution, and then paving a colored asphalt surface layer or colored gravel, with old road bed soil, the cement, the liquid soil solidifying agent (L1f-S2) and the powder soil solidifying agent (LF-S3) being in a proportion of, for per cube of compaction: 90-93%:5-8%:0.7kg:5-7%kg. Old road reconstruction by the method provided in the invention can have greatly reduced cost and reduced waste, thus the method is environment-friendly.

Owner:LUOYANG LUSHIFENG SOIL SOLIDIFICATION SCI & TECH

Soil stabilizer

InactiveCN102807869BAvoid pollutionSolve the shortage of resourcesBuilding constructionsOrganic fertilisersMass ratioRoad engineering

The invention discloses soil stabilizer, which consists of industrial waste and chemical reagent, wherein the industrial waste consists of ground steel slag, coal gangue powder after being spontaneously-combusted, grain slag or furnace slag, the chemical reagent consists of calcium oxide, powder grinding aid and sodium sulfate, wherein the mass ratio of the industrial waste and the chemical reagent is 7: 3, and the fineness of the stabilizer powder is brinell specific surface area 500 to 900 m<2> / kg. The soil stabilizer has beneficial effects that mixture of the industrial waste is adopted as raw materials, so that the environmental pollution caused by the industrial waste can be solved; the original chemical activity of the mixture is used for rapidly condensing and solidifying the soil and sand, and no other surface active agent and alkaline excitant is needed, so that the cost is remarkably reduced, simultaneously the construction speed is fast, and the delivery period can be shortened; and the soil stabilizer is widely applied to the dam crest solidification and slope protection of foundation layers of road engineering and hydraulic engineering and is free from being restricted by any environment.

Owner:YANAN HUIHAI BUILDING ENG

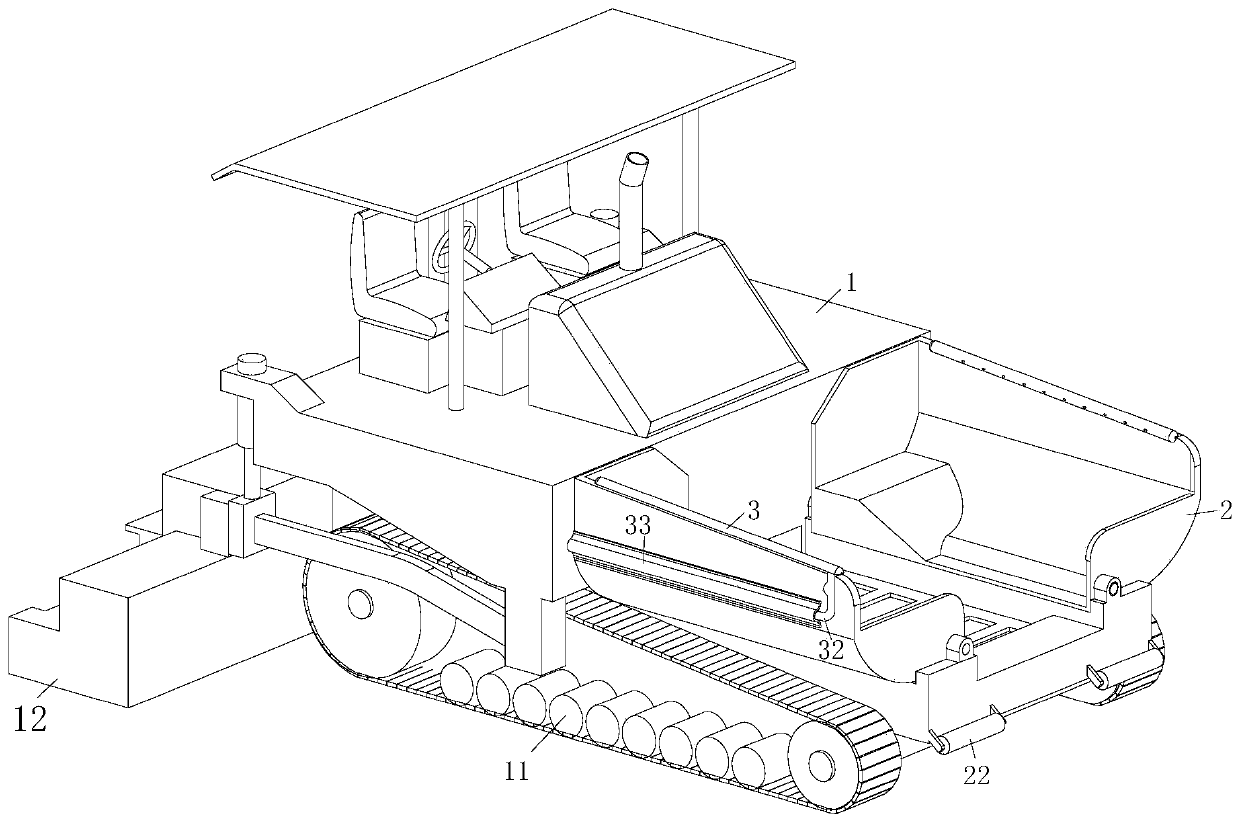

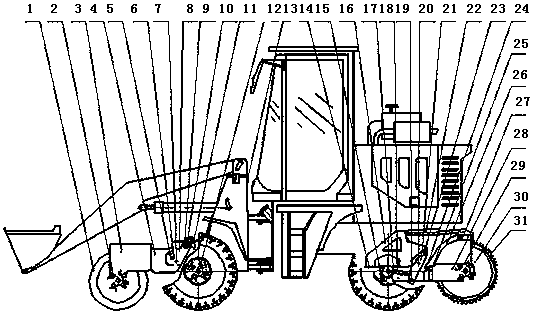

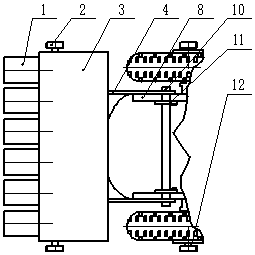

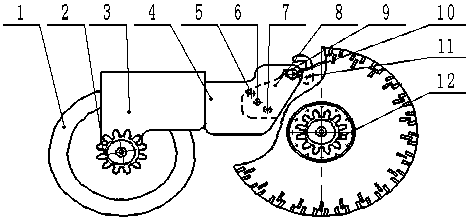

Loader for road construction or road construction maintenance

PendingCN109750695AQuick disassemblyAchieve rollingMechanical machines/dredgersRoads maintainenceHydraulic cylinderFixed frame

The invention discloses a loader for road construction or road construction maintenance. One ends of fixing plates are welded on the left and right sides of a front wheel frame of the loader, the other ends of the fixing plates are processed with positioning holes and are connected with rotating arms of rubber wheel fixing frames through pin shafts; rubber wheel sprockets are symmetrically arranged on the left and right sides below the rubber wheel fixing frame and are connected with a central sprocket of the front wheel of the loader through a chain; the fixing plates welded on the left and right sides of the loader are provided with rotating grooves for placing rubber wheels or rotating shafts for lifting steel wheels and are fixed by locking hooks; saddle fixing plates are welded on theleft and right sides of the swing support plate of the rear wheel of the loader; the tail ends of lifting hydraulic cylinders are fixed on the saddle fixing plates; positioning cylinders are arrangedbehind the positioning plates; steel wheel sprockets are arranged on the left and right under the steel wheel fixing frame and are connected with the rear wheel of the loader through chains; and icebreakers are fastened on the wheel surfaces of the steel wheels through screws. The existing loader can be used for rolling rubber wheels and steel wheels on the road surface, so the loader has multiple functions and reduces the road construction cost.

Owner:新乡市路康机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com