Preparation method for modified blended asphalt for road construction

An asphalt and blending technology, applied in construction, building components, building construction, etc., can solve the problems of high polycyclic aromatic hydrocarbon content, shortage of petroleum asphalt, rising prices, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

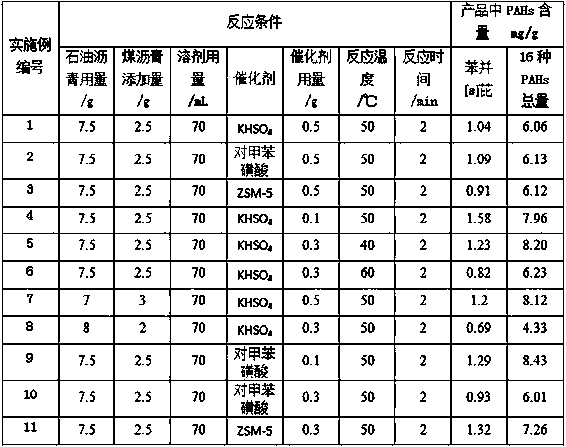

Embodiment 1

[0020] Firstly, the sample is pretreated, specifically, the coal tar pitch is crushed to be below 100 mesh, and the petroleum pitch is made into 4-6 g small pitch blocks. Then, put 7.5g of petroleum pitch and a sufficient amount of toluene solvent in the reactor, and ultrasonically vibrate for 20-30 minutes to completely dissolve the petroleum pitch in the toluene solvent, then add 2.5g of coal tar pitch and 0.5g of KHSO 4 After the catalyst is completely dissolved, it is placed in a constant temperature water bath at 50°C, continuously stirred at a speed of 600r / min, and reacted for 2 hours. The permanent blended asphalt product 1 was used after vacuum drying at 70°C for 12 hours. The solvent toluene is recovered or used in the blending modification reaction process of petroleum pitch and coal pitch.

Embodiment 2

[0022] First, the sample is pretreated, and the specific steps are the same as in Example 1. Then, put 7.5g of petroleum pitch and a sufficient amount of toluene solvent in the reactor, and ultrasonically vibrate for 20-30 minutes to completely dissolve the petroleum pitch in the toluene solvent, then add 2.5g of coal tar pitch and 0.5g of molecular sieve ZSM-5 catalyst, After being completely dissolved, put it in a constant temperature water bath at 50°C, continuously stir at a speed of 600r / min, react for 2 hours, and then go through solvent recovery and product aging steps to obtain modified blended asphalt product 2 and solvent toluene. Solvent recovery and product aging steps are the same as in Example 1.

Embodiment 3

[0024] First, the sample is pretreated, and the specific steps are the same as in Example 1. Then, put 7.5g of petroleum pitch and a sufficient amount of toluene solvent in the reactor, ultrasonically vibrate for 20-30 minutes to completely dissolve the petroleum pitch in the toluene solvent, then add 2.5g of coal tar pitch and 0.5g of p-toluenesulfonic acid catalyst, After being completely dissolved, place it in a constant temperature water bath at 50°C, continuously stir at a speed of 600r / min, react for 2 hours, and then go through solvent recovery and product aging steps to obtain modified blended asphalt product 3 and solvent toluene. Solvent recovery and product aging steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com