A temporary road pavement structure and road construction method

A pavement structure and temporary road technology, applied in roads, roads, buildings, etc., can solve the problems of poor uniformity of powder soil curing agent, unfavorable restoration of planting soil, and low early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

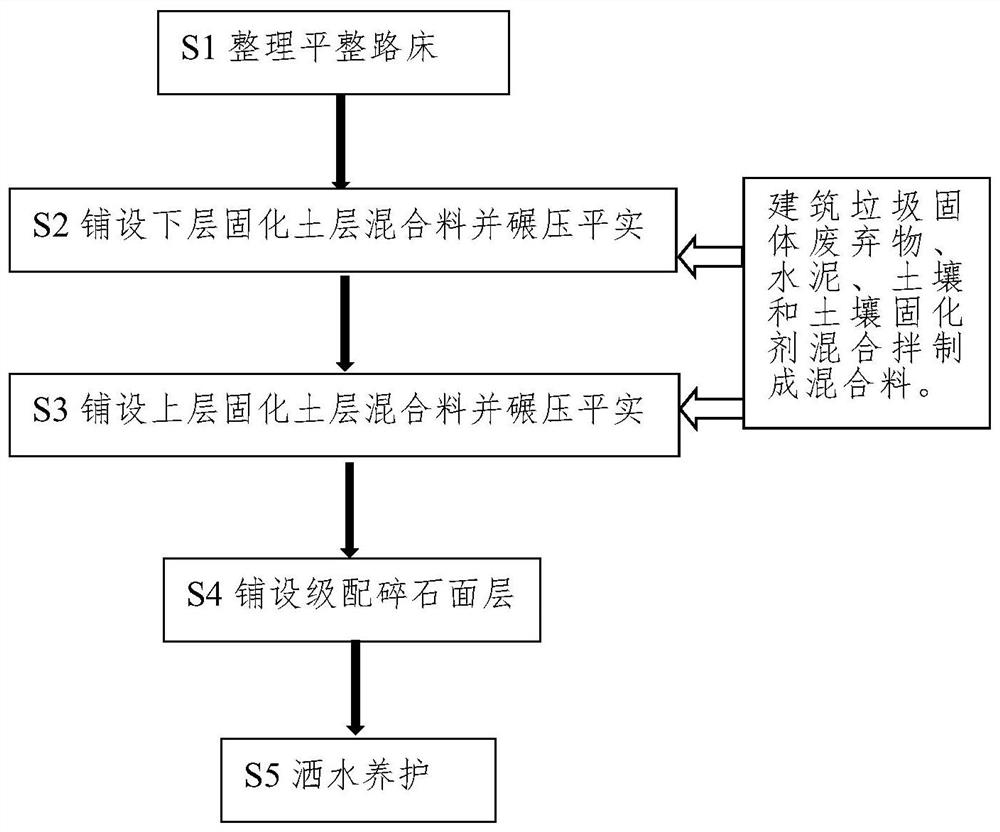

[0052] S1: Road bed preparation: including weed removal, large rocks, pit filling, etc. to level the road bed in preparation for laying the road bed.

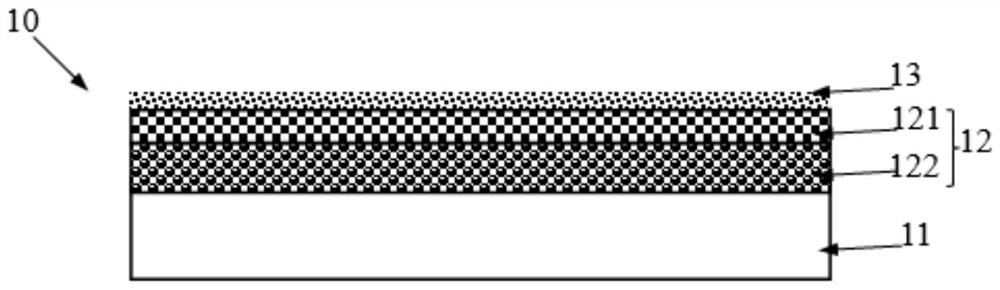

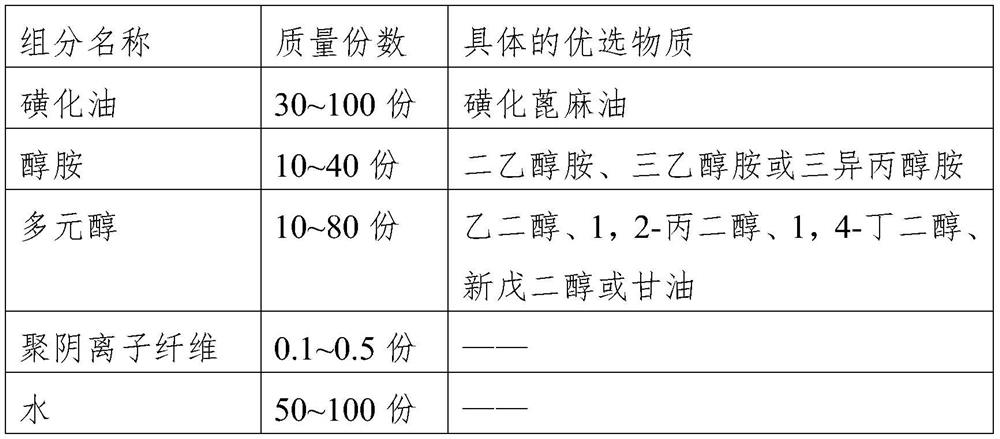

[0053] S2: Mix 4700 parts by mass of construction waste solid waste, 5000 parts by mass of soil, 298 parts by mass of cement, and 2 parts by mass of Outset soil curing agent, and mix them in a factory mixing method to form a lower layer of solidified soil mixture. Lay the mixed material on the roadbed 11 and roll it flat, the rolling density is 91%, forming the lower solidified soil layer 122 .

[0054] S3: Mix 5000 parts by mass of construction waste solid waste, 4500 parts by mass of soil, 497 parts by mass of cement, and 3 parts by mass of Outset soil curing agent, and mix them in the factory mixing method to form the upper layer of solidified soil mixture. Lay the upper solidified soil mixture on the lower solidified soil layer 122 with a compactness of 96% to form the upper solidified soil layer 121 .

[0055] S4: Lay con...

Embodiment 2

[0058] S1: Road bed preparation: including weed removal, large rocks, pit filling, etc. to level the road bed in preparation for laying the road bed.

[0059] S2: Mix 4800 parts by mass of construction waste solid waste, 5000 parts by mass of soil, 199 parts by mass of cement, and 1 part by mass of a new type of soil curing agent, and mix them into the lower layer of solidified soil mixture by factory mixing method. Lay the mixed material on the road bed 11 and roll it flat, the rolling density is 92%, to form the lower solidified soil layer 122 .

[0060]S3: Mix 5100 parts by mass of construction waste solid waste, 4300 parts by mass of soil, 400 parts by mass of cement, and 2 parts by mass of a new type of soil curing agent, and mix in the factory mixing method to form the upper layer of solidified soil mixture. Lay the upper solidified soil mixture on the lower solidified soil layer 122 with a compactness of 96% to form the upper solidified soil layer 121 .

[0061] S4: La...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com