Composite sludge curing agent

A curing agent and sludge technology, applied in the field of composite sludge curing agent, can solve the problems of poor adsorption of heavy metals, high moisture content of sludge, poor water absorption effect, etc., to prevent secondary pollution, improve sludge strength, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

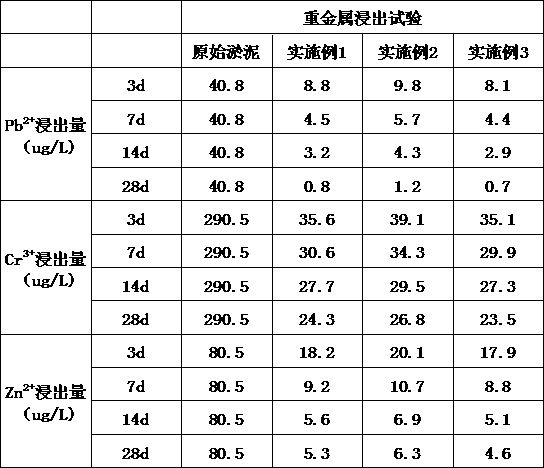

Examples

Embodiment 1

[0018] The composite sludge curing agent, calculated in parts by weight, its raw materials include: 30 parts of fly ash, 15 parts of citric acid slag, 11 parts of calcium-based bentonite, 5 parts of cement, 0.5 part of carbide slag, polycarboxylate water reducer 0.3 parts, 0.12 parts of ethylene glycol diethyl ether diamine tetraacetic acid.

Embodiment 2

[0020] The composite sludge curing agent, calculated in parts by weight, its raw materials include: 40 parts of fly ash, 20 parts of citric acid slag, 13 parts of calcium-based bentonite, 8 parts of cement, 0.8 part of calcium carbide slag, polycarboxylate superplasticizer 0.5 parts, 0.15 parts of ethylene glycol diethyl ether diamine tetraacetic acid.

Embodiment 3

[0022] The composite sludge curing agent, calculated in parts by weight, its raw materials include: 33 parts of fly ash, 17 parts of citric acid slag, 11.5 parts of calcium-based bentonite, 5.3 parts of cement, 0.72 parts of calcium carbide slag, polycarboxylate superplasticizer 0.33 parts, 0.01 parts of ethylenediamine disuccinic acid, 0.02 parts of nitrilotriacetic acid, 0.1 parts of ethylene glycol diethyl ether diamine tetraacetic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com