Road building slag taking municipal sludge as raw material, preparation method and application thereof

A technology for municipal sludge and slag, applied in sludge treatment, combustion methods, biological sludge treatment, etc., can solve the problem of increasing the proportion of inorganic matter in sludge filter cakes, affecting the utilization of sludge resources, reducing organic matter and heat Value and other issues, to achieve the effect of reducing road construction costs, avoiding operational risks, and mild biological reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

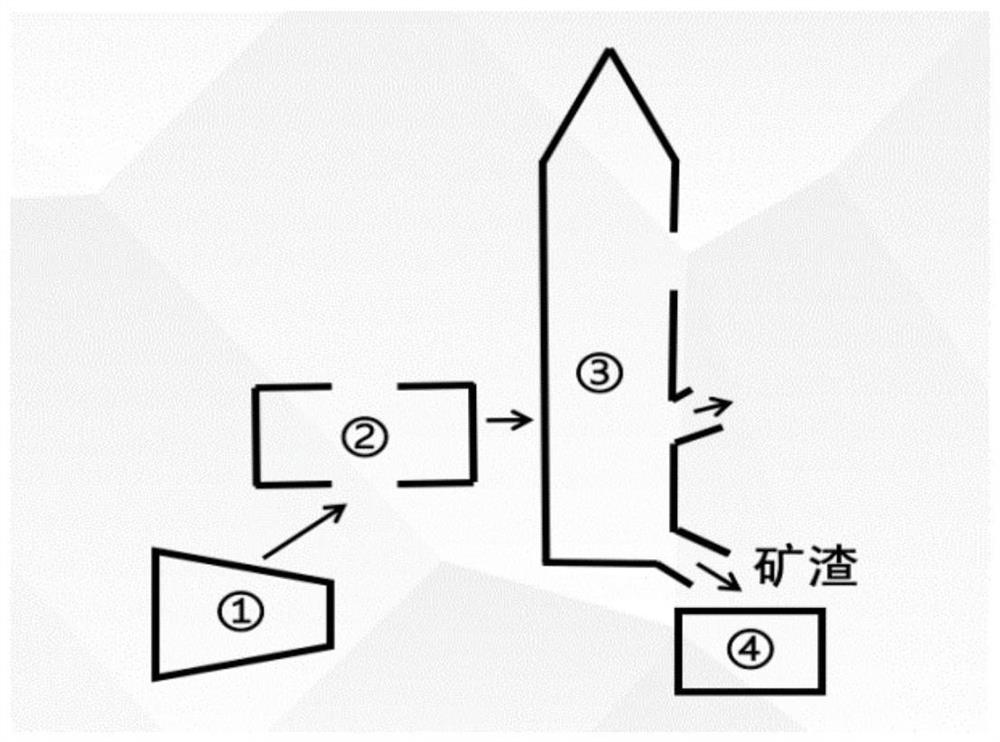

Method used

Image

Examples

Embodiment 1

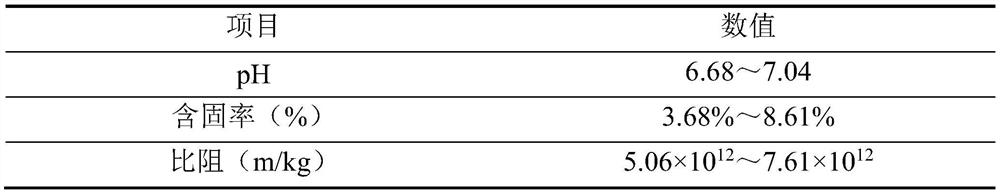

[0046] 1. The sludge to be tested is taken from the residual sludge in the secondary settling tank of a sewage plant, and its basic properties are shown in Table 1.

[0047] Table 1 Basic properties of the tested sludge

[0048]

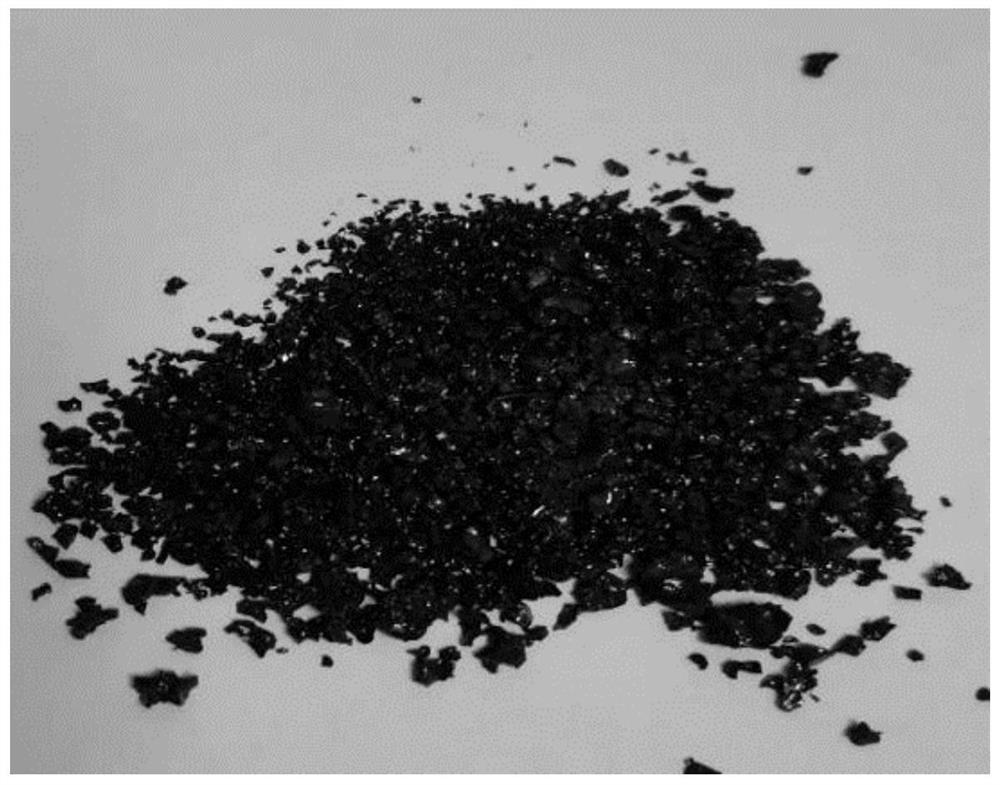

[0049] 2. Production of slag

[0050] (1) Inoculum enrichment culture

[0051] Take 150mL of the test sludge with the properties shown in Table 1 and put it into a 250mL Erlenmeyer flask, and add 6g / L sulfur powder and 2g / L pyrite powder as microbial energy materials. Place the Erlenmeyer flask in a 180r / min, 28°C constant temperature water bath shaker for shaking culture. When the pH value of the sludge system dropped to 2.8 or below, 20 mL of acidified sludge was added to 130 mL of the test sludge, and 2 g / L of reducing sulfur and ferrous sources were added at the same time, and the above operation was repeated twice. The acidified sludge after 3 enrichment cultures can meet the requirement of inoculum.

[0052] (2) Bioleaching test

[0053...

Embodiment 2

[0059] 1. The sludge to be tested was taken from the residual sludge in the secondary sedimentation tank of a sewage plant, and its basic properties are shown in Table 3.

[0060] Table 3 Basic properties of the tested sludge

[0061]

[0062]2. Production of slag

[0063] (1) Inoculum enrichment culture

[0064] Take 150mL of test sludge with the properties shown in Table 3 and put it into a 250mL Erlenmeyer flask, and add 6g / LNaS at the same time 2 o 3 and 2g / LFeSO 4 as microbial energy sources. Place the Erlenmeyer flask in a 180r / min, 28°C constant temperature water bath shaker for shaking culture. When the pH value of the sludge system dropped to 2.8 or below, 20 mL of acidified sludge was added to 130 mL of the test sludge, and 2 g / L of reducing sulfur and ferrous sources were added at the same time, and the above operation was repeated twice. The acidified sludge after 3 enrichment cultures can meet the requirement of inoculum.

[0065] (2) Bioleaching test

...

Embodiment 3

[0073] 1. The sludge to be tested is taken from the residual sludge in the secondary sedimentation tank of a sewage plant, and its basic properties are shown in Table 5.

[0074] Table 5 Basic properties of the tested sludge

[0075]

[0076] 2. Sludge solid content adjustment

[0077] (1) Inoculum enrichment culture

[0078] Take 150mL of test sludge with the properties shown in Table 5 and put it into a 250mL Erlenmeyer flask, and add 6g / LNaS at the same time 2 o 3 And 2g / L pyrite powder as microbial energy material. Place the Erlenmeyer flask in a 180r / min, 28°C constant temperature water bath shaker for shaking culture. When the pH value of the sludge system drops to 2.8 or below, take 20mL of acidified sludge and add it to 130mL of the test sludge, and add 2g / L NaS 2 o 3 And pyrite powder, repeat the above operation 2 times. The acidified sludge after 3 enrichment cultures can meet the requirement of inoculum.

[0079] (2) Bioleaching test

[0080] Put the tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com