Patents

Literature

77results about How to "Avoid operational risk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

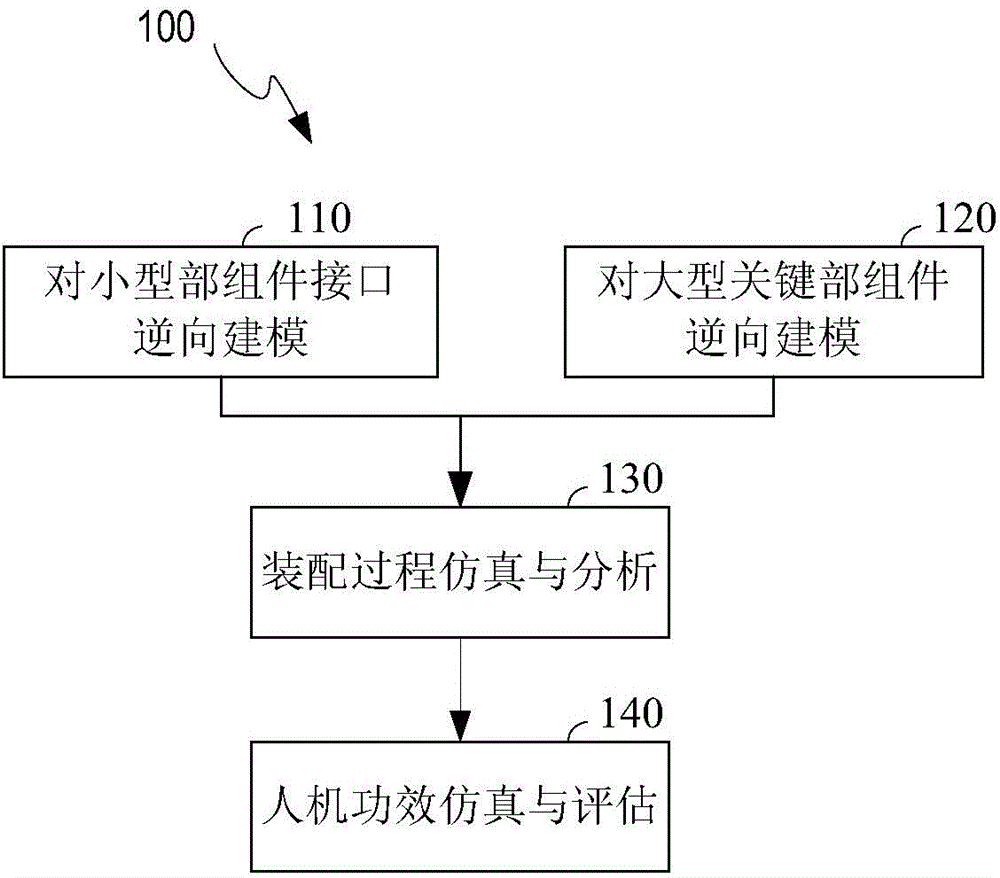

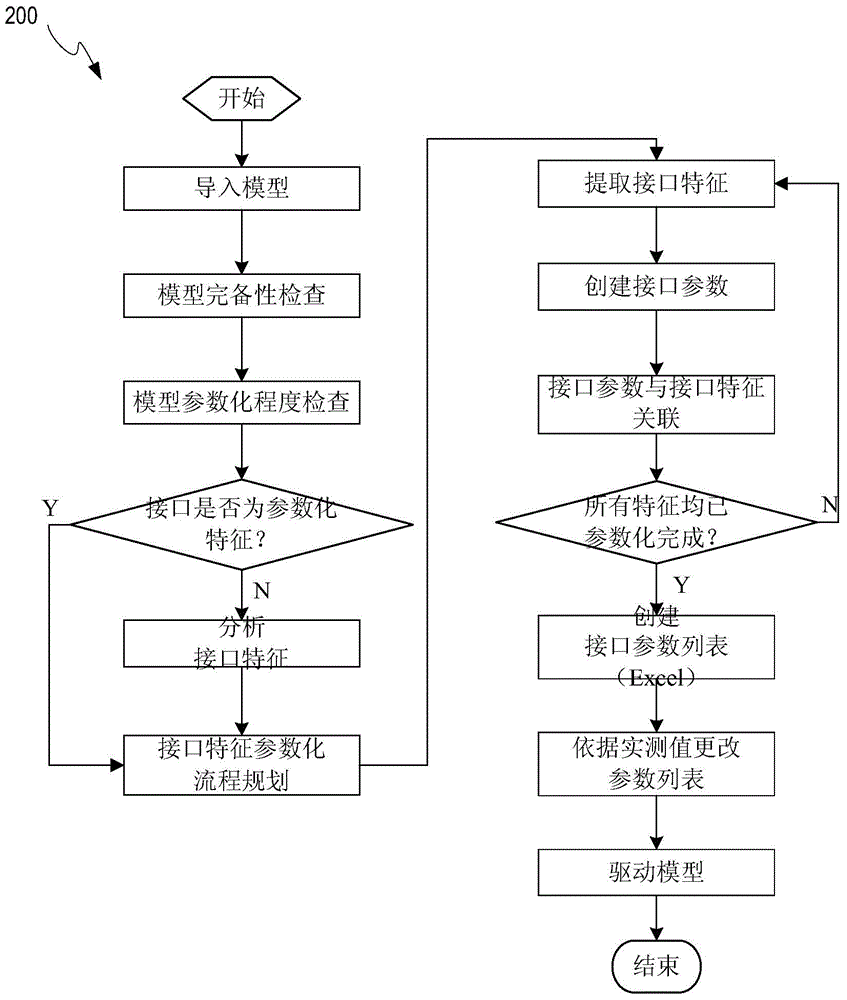

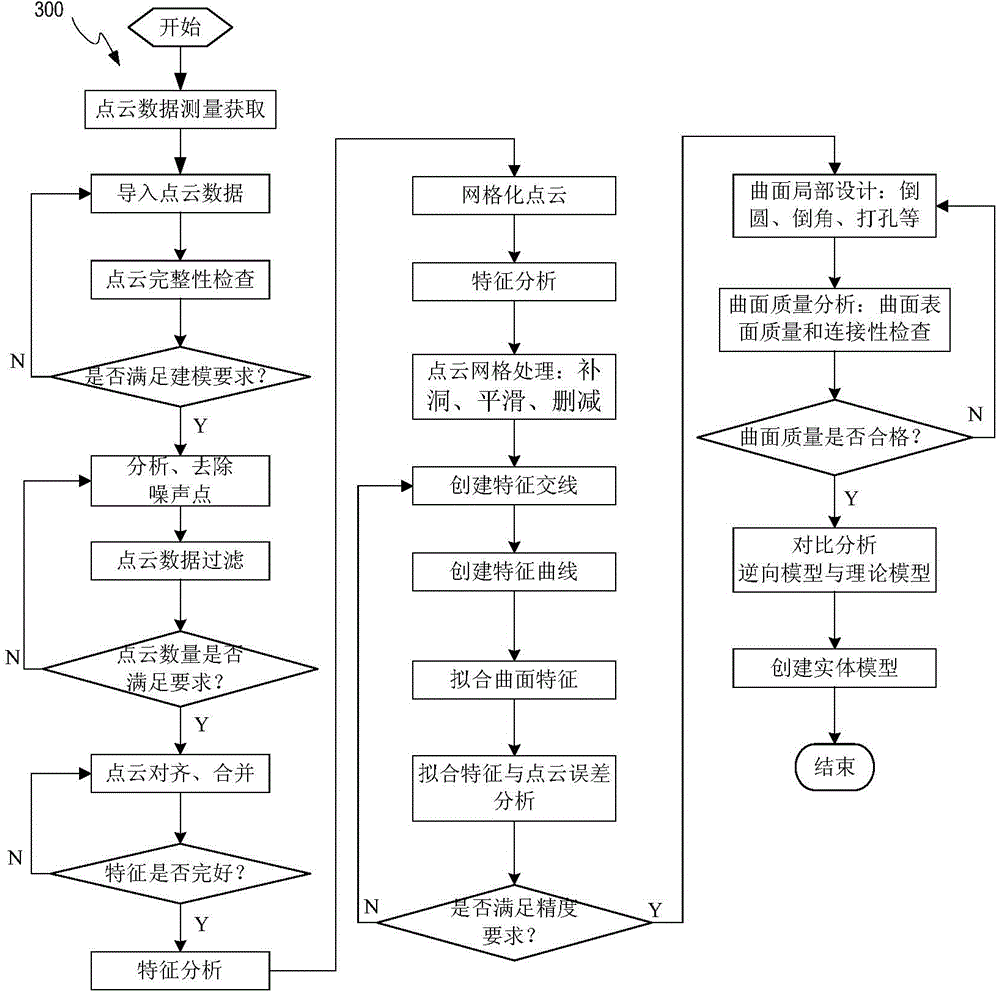

Actually measured data-based spacecraft component assembly simulation method

ActiveCN104598675AImprove reliabilityImprove efficiencySpecial data processing applicationsSimulationThree dimensionality

The invention discloses an actually measured data-based spacecraft component assembly simulation method. The assembly simulation method includes the following steps that a parametrized three-dimensional rapid modeling method is utilized to generate actually measured dimension-based three-dimensional small component models after final assembly inspection personnel actually measure and input the dimensions of key small component interfaces into a corresponding parametrized three-dimensional modeling system; a reverse point cloud curved surface fitting method is utilized to convert the surface shapes of real objects of large key components into discrete geometric coordinate points, and on the basis, the modeling of complex curved surfaces is carried out, so that reverse three-dimensional digitalized models of the large key components are formed; the assembly process is simulated and analyzed; ergonomics is simulated and evaluated. By combining a virtual reality scene with reverse real object modeling, the actually measured data-based spacecraft component assembly simulation method disclosed by the invention detects interference points and risk sources in advance to find out assembly incoordination and other problems, thus increasing the reliability of the final spacecraft assembly process and the efficiency of final assembly.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

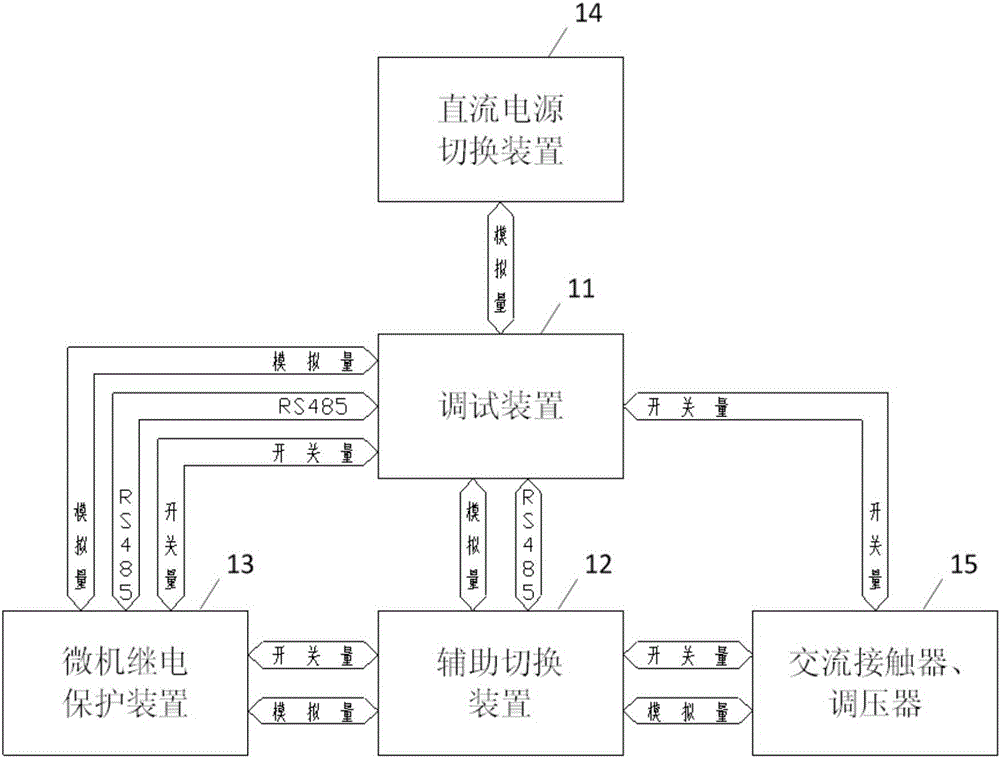

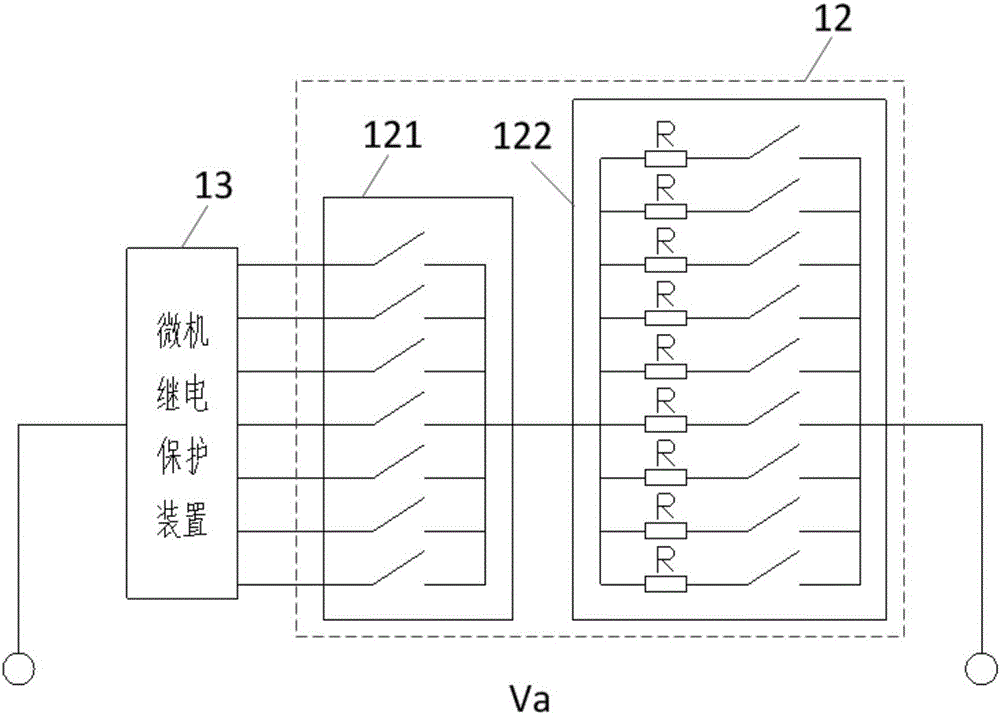

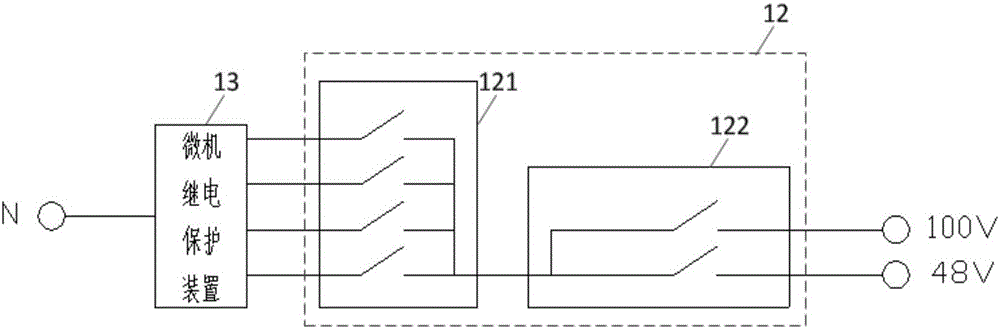

Full-automatic debugging method of microcomputer relay protection device and full-automatic debugging system thereof

The invention discloses a full-automatic debugging method of a microcomputer relay protection device and a full-automatic debugging system thereof. A test scheme matched with the tested microcomputer relay protection device is selected through identification code matching, and read-write testing, analog quantity testing, switching quantity testing and protection motion testing are performed according to the test scheme so that full-automatic relay protection test verification is realized. With application of the method that automatic quantity adding replaces manual operation of tester quantity adding, labor cost and time cost consumed by manual wiring can be reduced, the risk of error caused by repeated manual operation can be avoided, the accuracy of test data can be guaranteed, real-time fault analysis can be performed according to the test data and the test result can be timely fed back so that test result generation efficiency and reliability can be enhanced.

Owner:ZHUHAI KEZHONG TECH

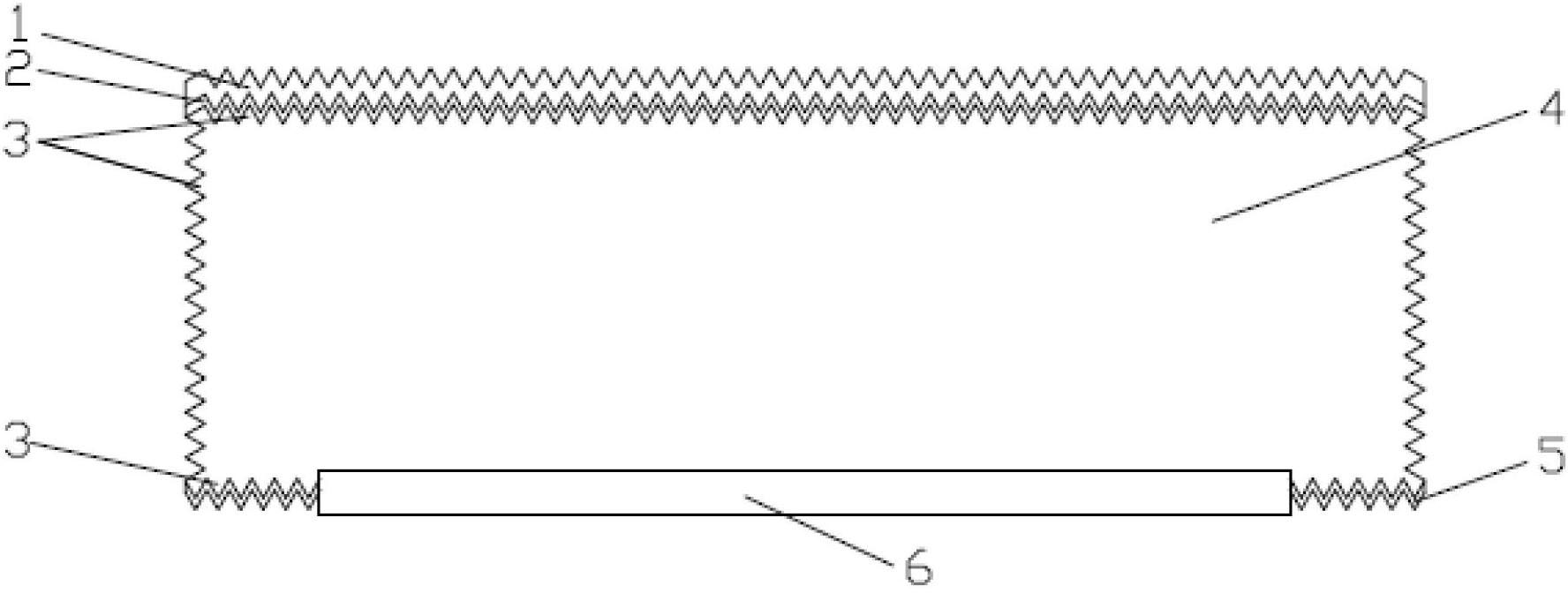

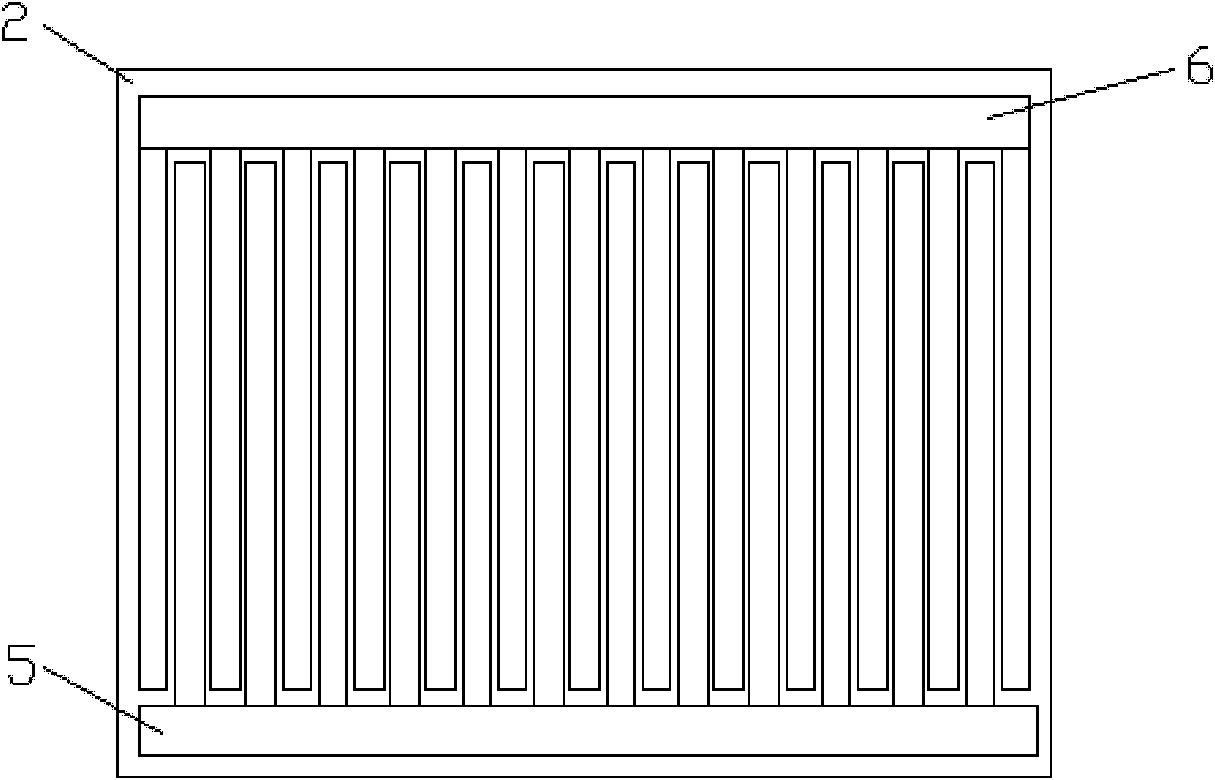

Production process of crystalline silicon double-sided solar battery

InactiveCN102664217AEliminates thermal diffusion stepLeave out the edgeFinal product manufactureSemiconductor devicesTrappingOptoelectronics

The invention relates to a production process of a crystalline silicon double-sided solar battery, comprising the following steps of: etching to enable a silicon substrate to have an etched face; manufacturing a window which accords with an electrode pattern on a backlight face of the silicon substrate; carrying out heat treatment on the silicon substrate to form a PN junction in the window; washing the silicon substrate; plating at least two layers of antireflection films on a light reflective face of the silicon substrate; plating the antireflection film on a backlight face of the silicon substrate; printing electrode slurry on a silk screen; and sintering to obtain a metal electrode so as to finish the manufacturing of a battery cell. The production process disclosed by the invention is ingenious in concept, is compatible with a conventional industrial battery production line and is easy for industrial manufacture; compared with the conventional solar battery, an electrode grid line is not arranged on the light reflective face of the double-sided solar battery so as to prevent the electrode grid line of the light reflective face from shielding sunlight; the backlight face is provided with a light trapping structure and an antireflection film layer so that the backlight face of the battery also can absorb and utilize the sunlight; and the antireflection films of the light reflective face and the backlight face can passivate the solar battery, so as to be good for improving the efficiency of the battery.

Owner:杨正刚

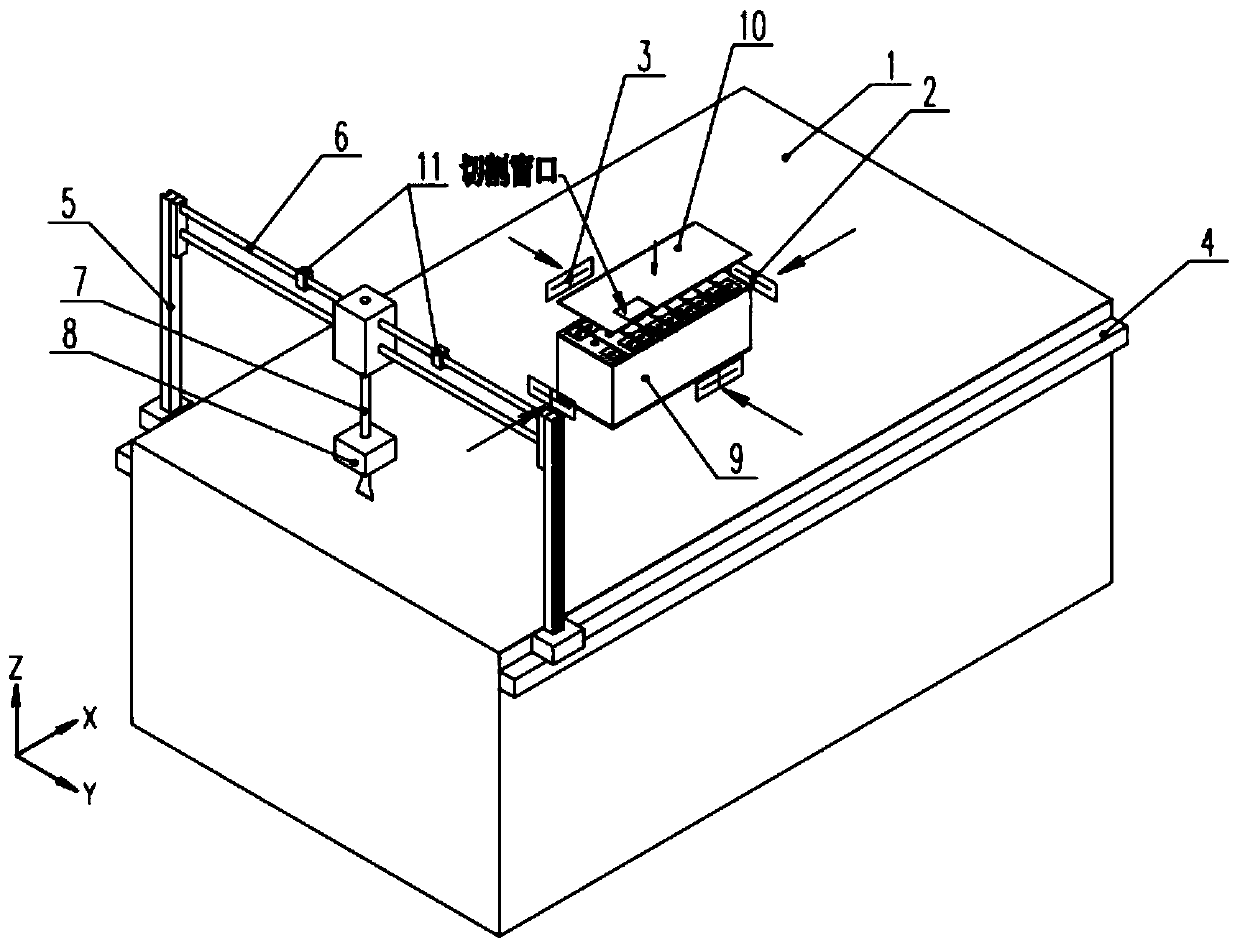

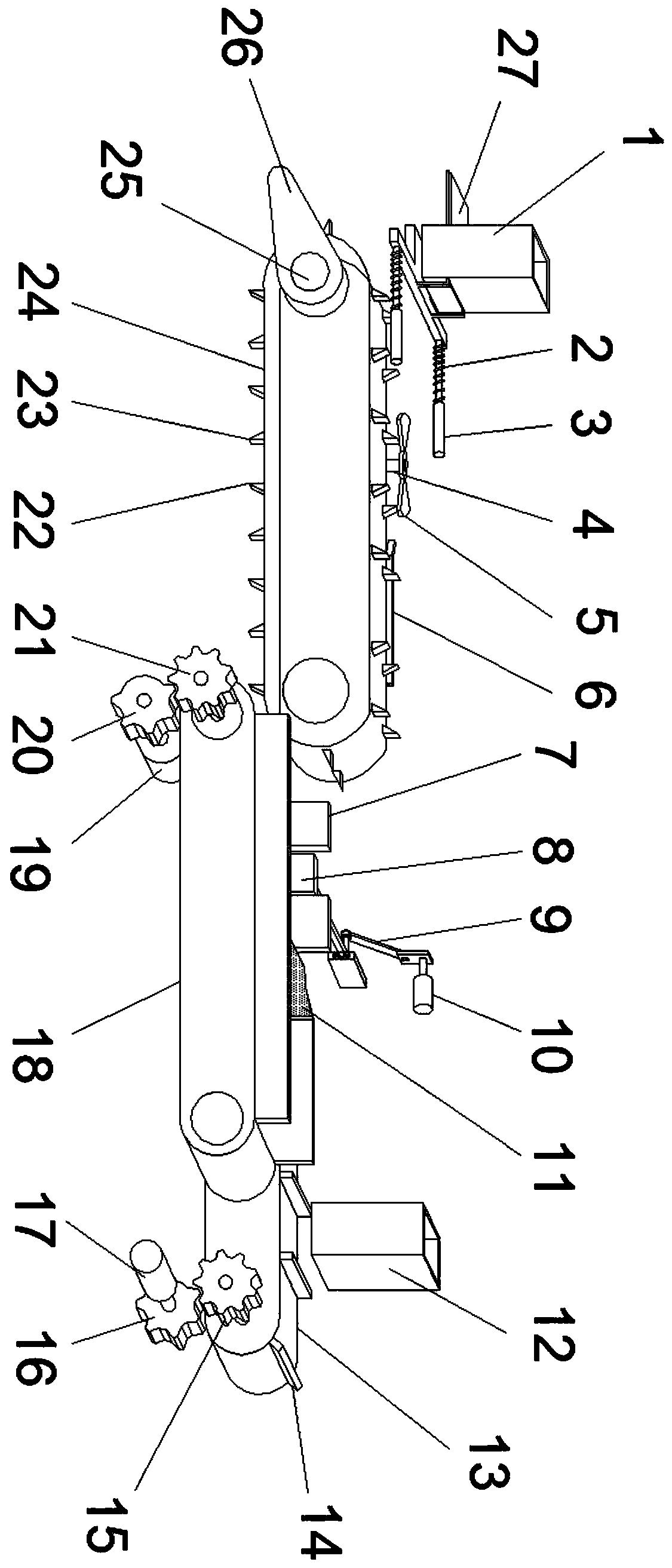

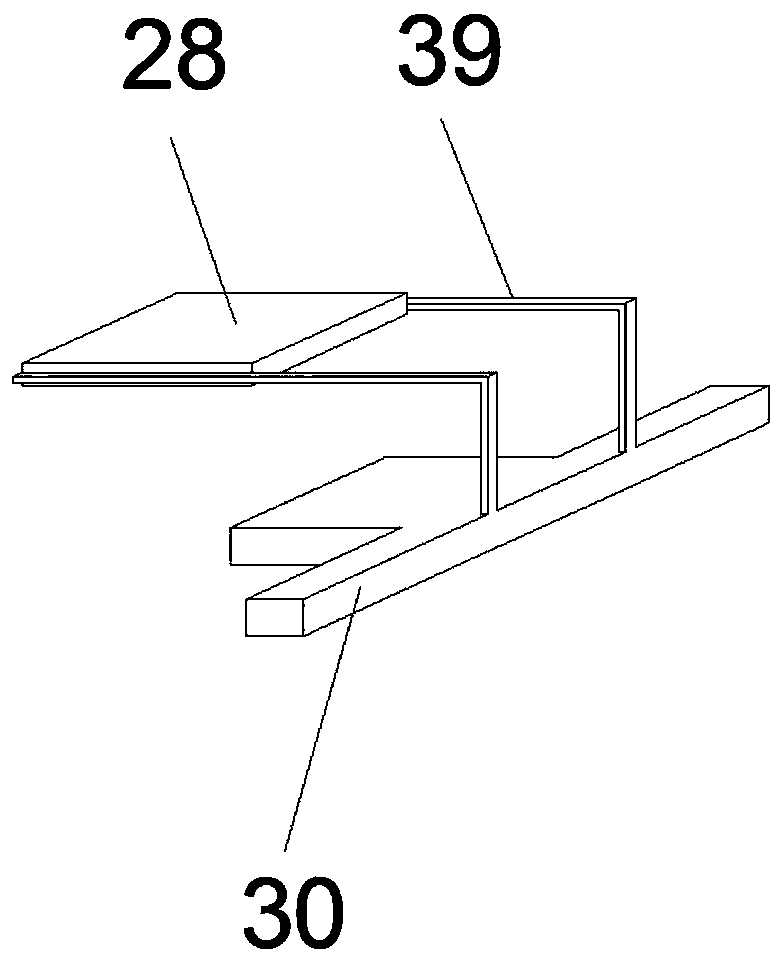

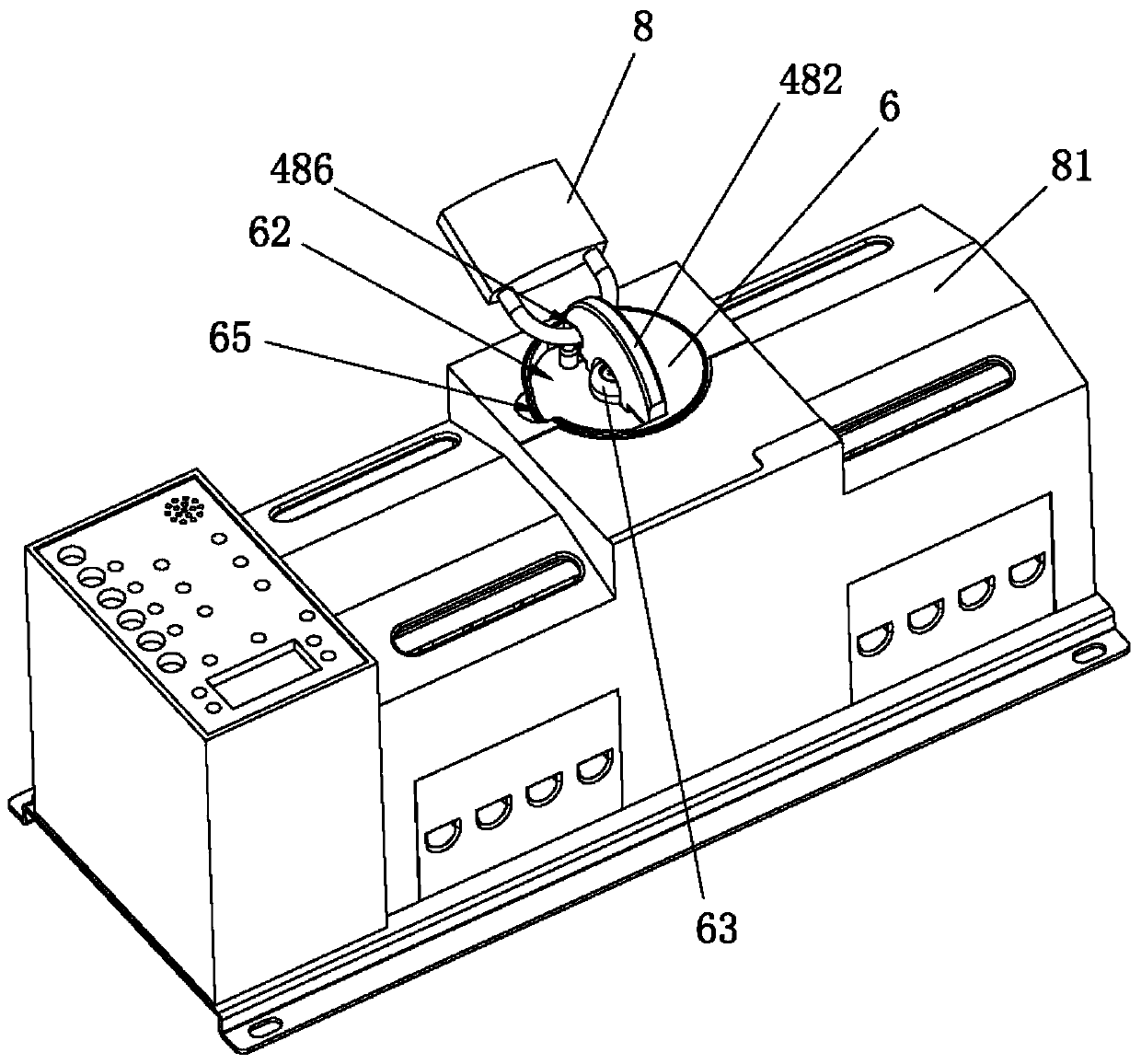

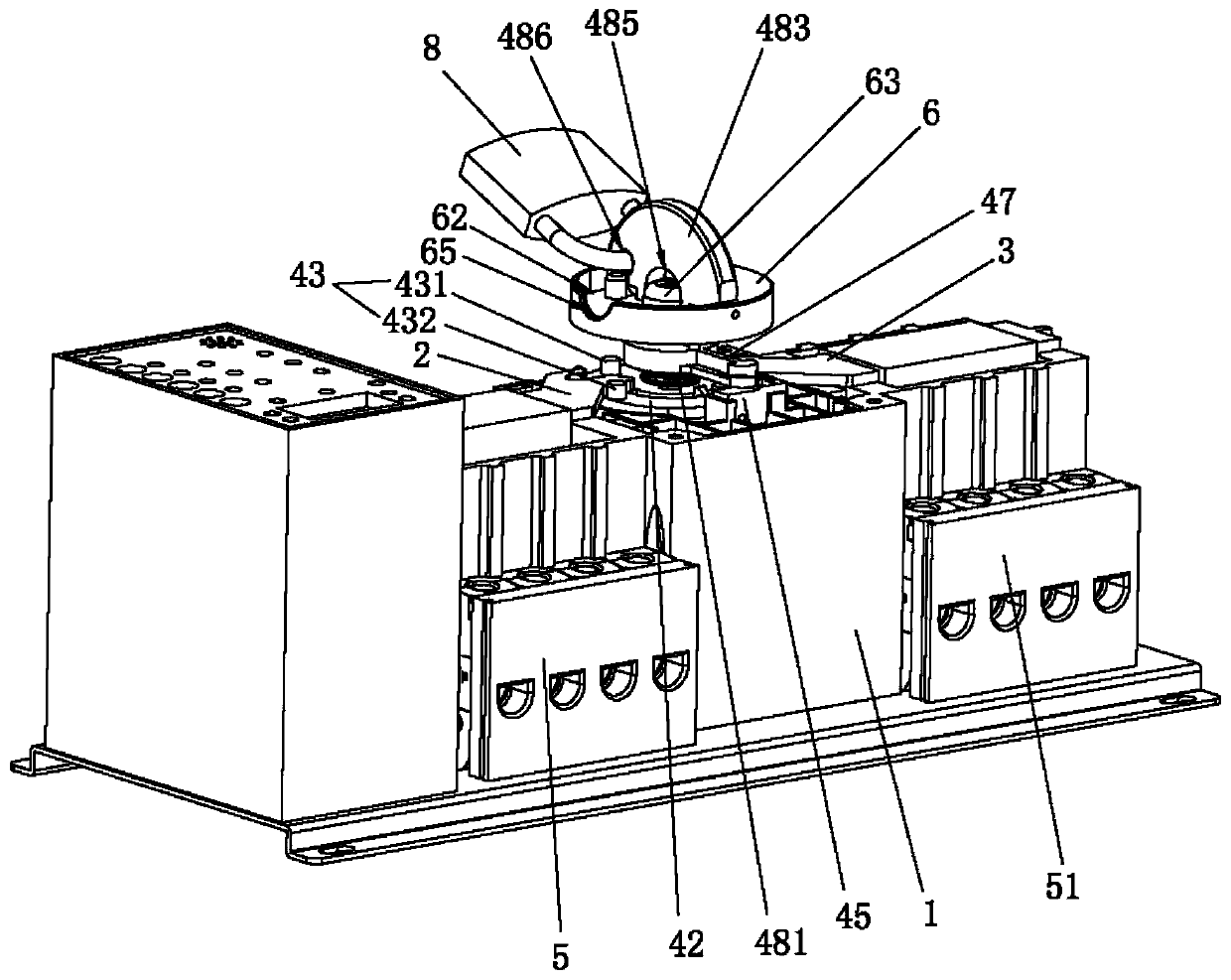

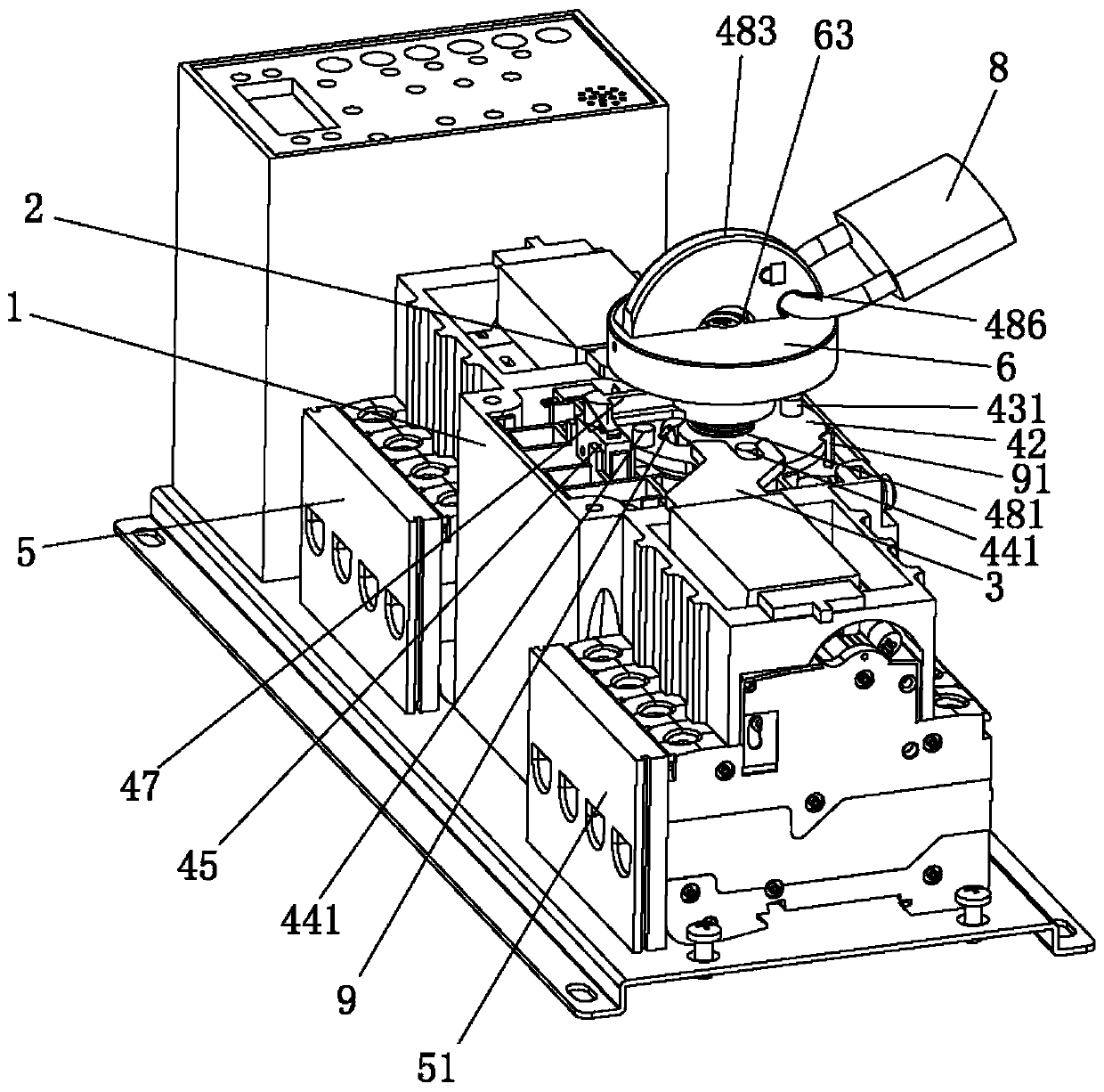

Disassembling device and method for decommissioned power batteries

PendingCN110860740AAvoid operational riskLow costWaste accumulators reclaimingLarge fixed membersPower batteryElectrical battery

The invention discloses a disassembling device and method for decommissioned power batteries. The device comprises a workbench, wherein two movable workpiece positioning sliding blocks are arranged ateach of the X-axis direction and the Y-axis direction of the workbench, and the workpiece positioning sliding blocks are used for locking and fixing battery packs or battery modules; a portal frame capable of sliding in the X-axis direction is arranged on the workbench and is used for adjusting a cutting module in the X-axis direction; a first sliding rail is fixed to the portal frame in the Z-axis direction, a second sliding rail and a third sliding rail are fixed in the Y-axis direction, two limiting sliding blocks are arranged on the second sliding rail, and the cutting module fixed on thesecond sliding rail and the third sliding rail is arranged between the two limiting sliding blocks. According to the disassembling device and method for the decommissioned power batteries, reciprocating vibration type cutting is adopted to replace mechanical rotary type cutting for disassembling the decommissioned power batteries, and the technical problem that in the prior art, due to the fact that a mechanical rotary type tool has large rotating inertia, and is not easy to control, a grinding wheel sheet or a steel saw blade is damaged and flown off very easily when operation is slightly careless, and certain potential safety hazards exist is solved.

Owner:珠海瓦特电力设备有限公司 +1

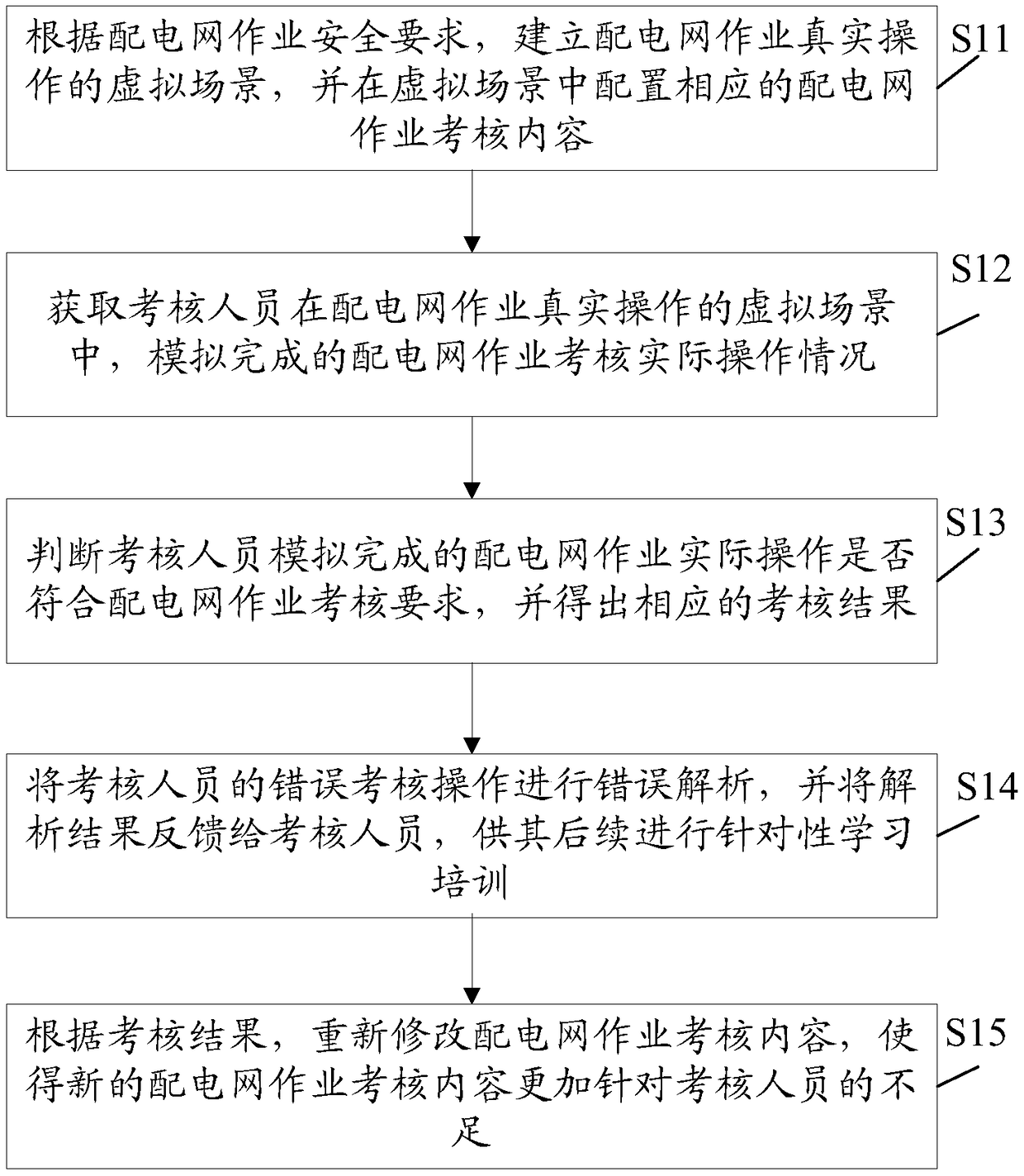

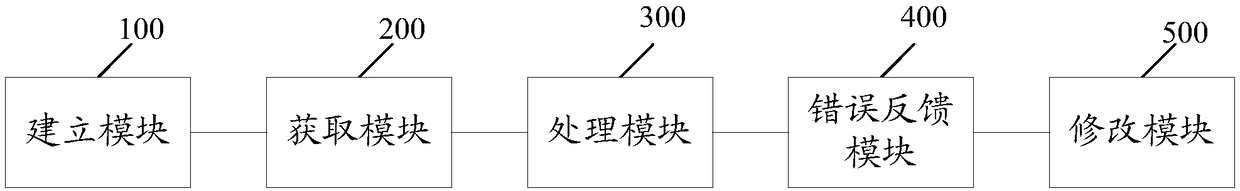

Distribution network operation simulation examination method and system based on VR technology

InactiveCN109272801AAvoid the problem of only understanding theory but not practical operationAvoid operational riskCosmonautic condition simulationsSimulatorsSimulationExamination method

The invention discloses a distribution network operation simulation examination method and system based on VR technology. The method comprises: according to the safety requirements of distribution network operation, the virtual scene of the real operation of distribution network is established, and configuring corresponding assessment contents of distribution network operation in the virtual scene, In the virtual scene of the real operation of the distribution network operation, the actual operation of the distribution network operation completed by the appraisers is simulated, whether the actual operation of the distribution network operation completed by the appraisers meets the requirements of the distribution network operation appraisal is judged, and the corresponding appraisal results are obtained. The invention provides a simulation examination method, not only to avoid examiners only knowing theory, In order to avoid the problem of actual operation, the real distribution network operation site is restored by 1: 1, so that the appraisers can carry out the distribution network operation personally in the virtual scene, but can effectively avoid the operational risks brought by the actual distribution network operation, and the appraisal form is more safe and reliable, without worrying about safety problems.

Owner:SHENZHEN POWER SUPPLY BUREAU +1

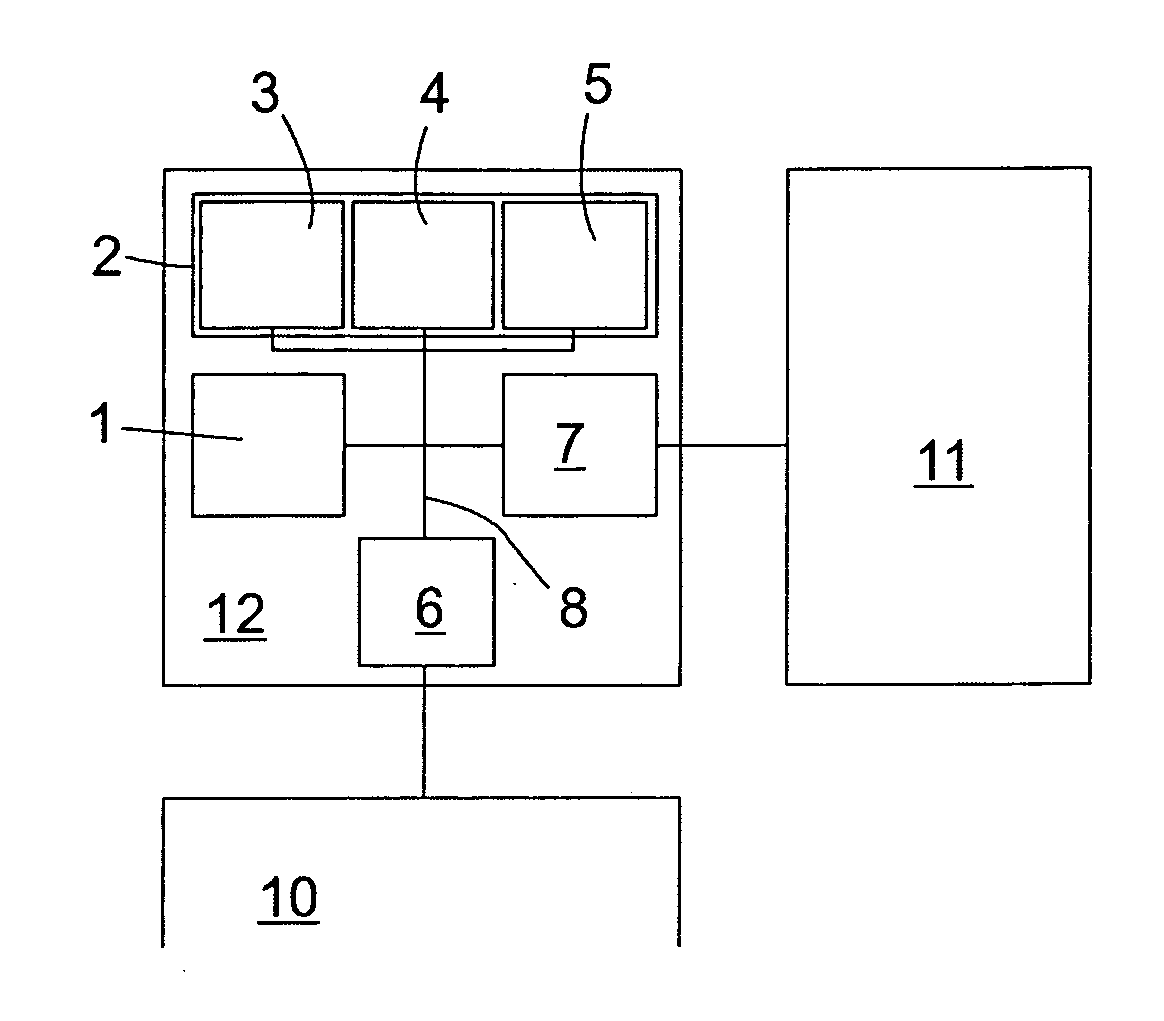

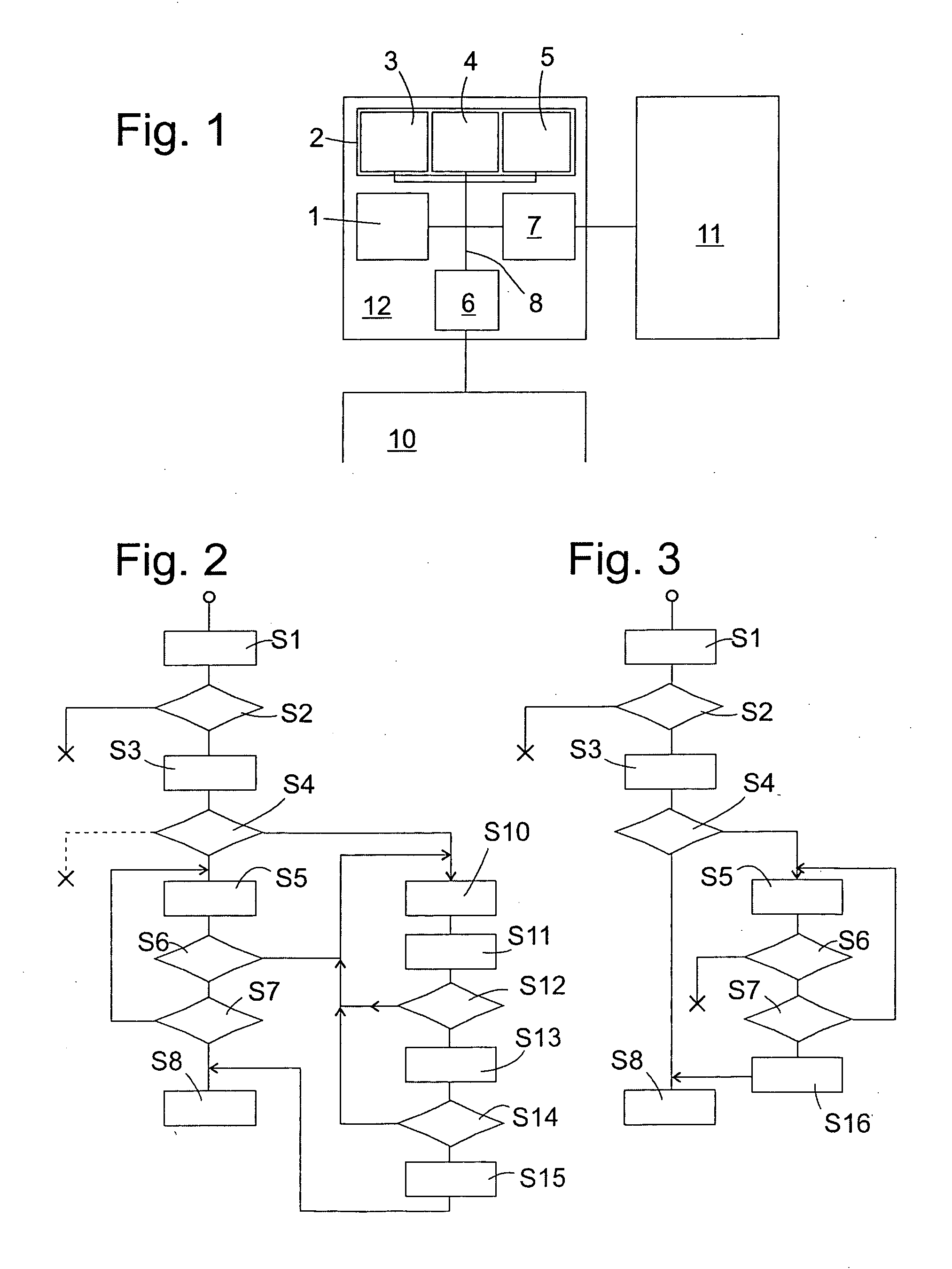

Control unit for a machine

InactiveUS20070226694A1Avoid operational riskAvoid performanceProgramme controlElectrical controlProgram instructionControl unit

A control unit for a machine includes a processor and a memory for program instructions and parameter values. A first portion of the program instructions defines a first process which accesses the parameter values in order to ascertain control information and to transmit same to the machine, and a second portion defines a second process which evaluates the quality of the application data, and either permits or prevents the execution of the first process based on the evaluation results. The second process checks whether the value of at least one first physical parameter specified by the application data is valid and does not permit execution of the first process using these application data unless the value of the parameter has been determined to be valid.

Owner:ROBERT BOSCH GMBH

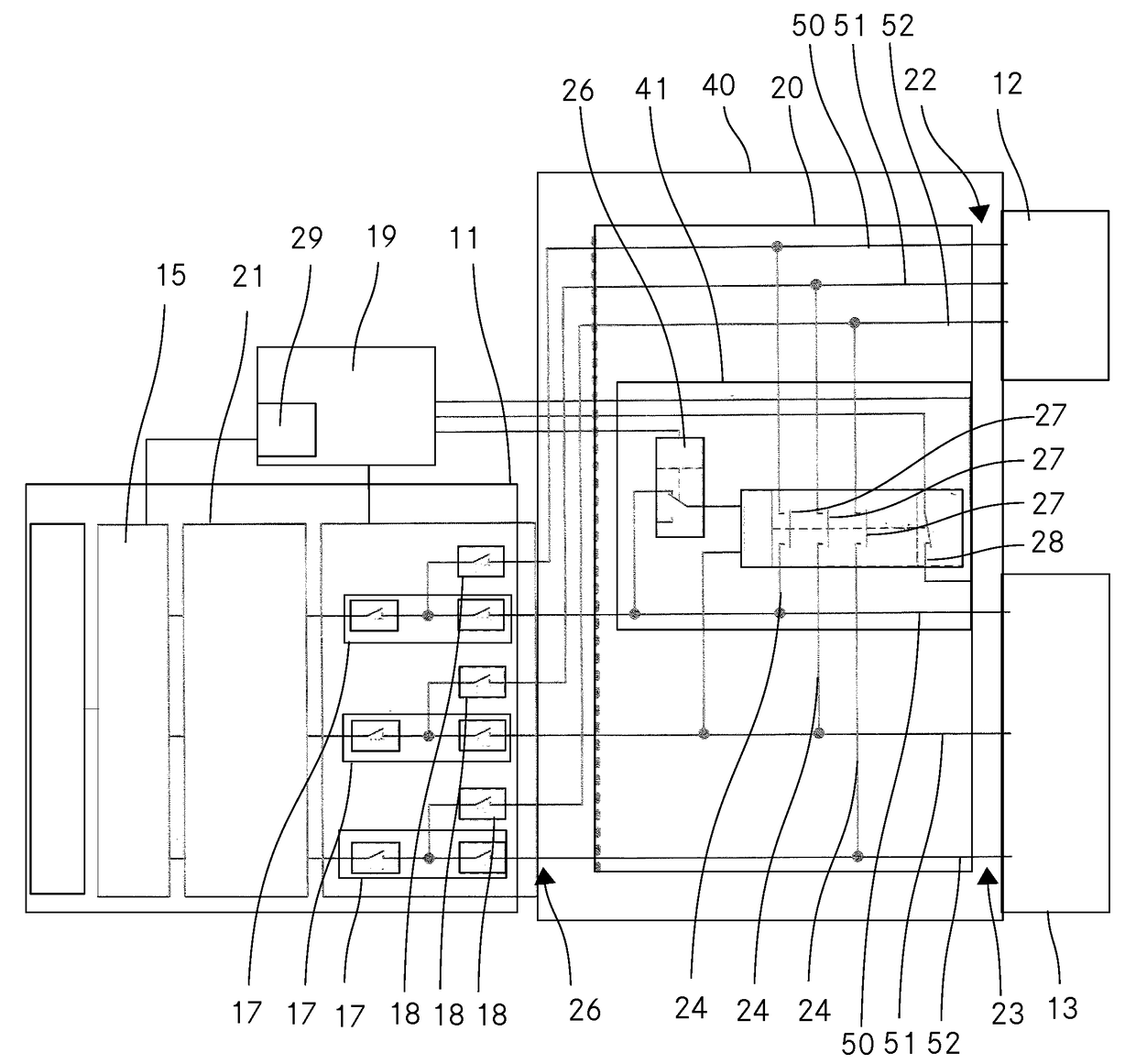

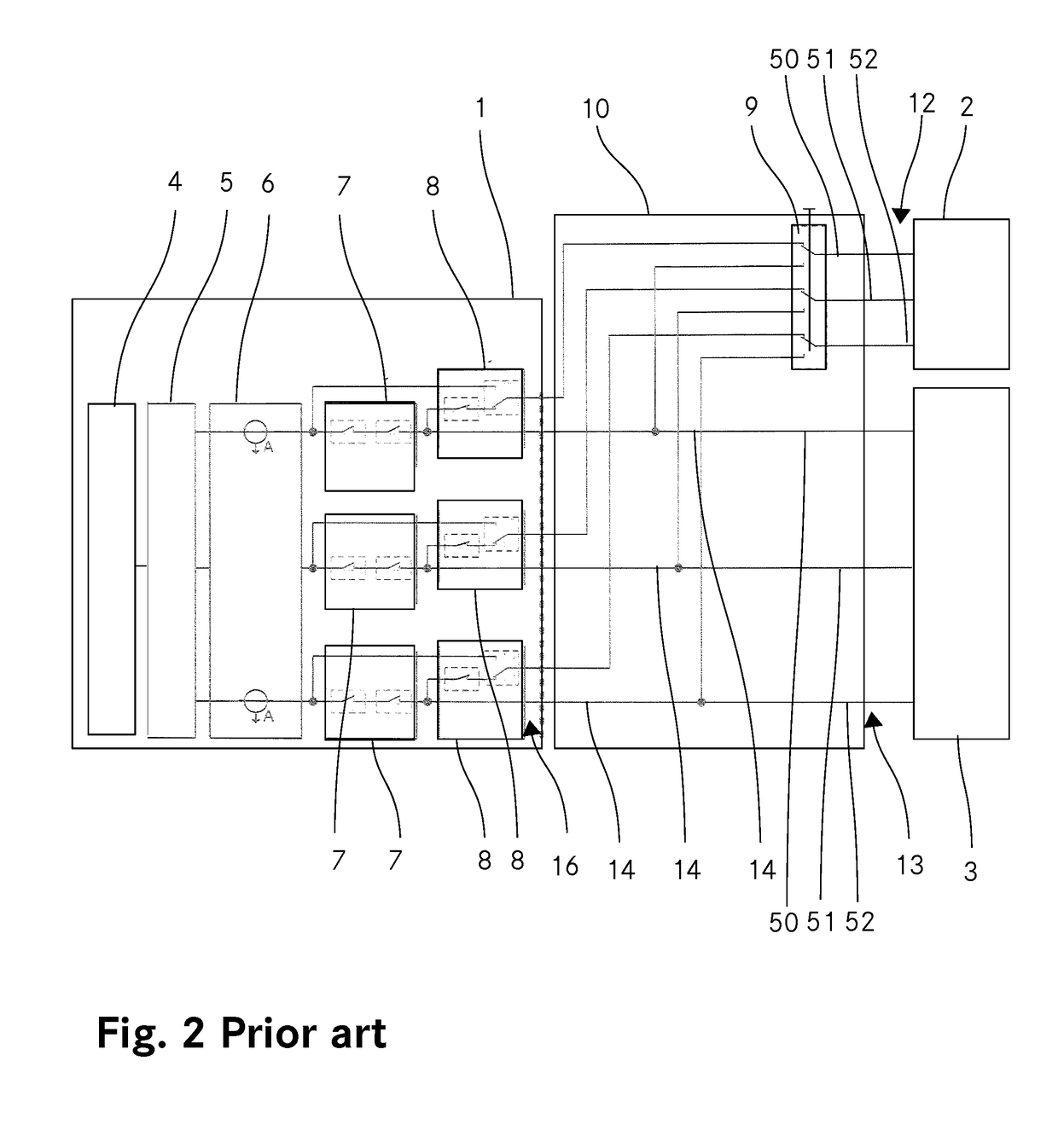

Power supply arrangement

ActiveUS20170302081A1Improve securityConvenient ArrangementSingle network parallel feeding arrangementsWind energy generationPower gridGrid interface

The present application relates to a power supply arrangement comprising a power source and a switching arrangement. The switching arrangement includes a switching block, wherein the switching block includes a source interface for connecting the power source, a load interface for connecting a load and a grid interface for connecting a power grid. The switching arrangement includes further a controller for controlling the switching block in dependency of the condition of the power source. The switching arrangement is implemented as a unit separate from the power source. The power supply arrangement comprises further a monitoring device for monitoring the condition of the power source.

Owner:DELTA ELECTRONICS (THAILAND) PUBLIC CO LTD

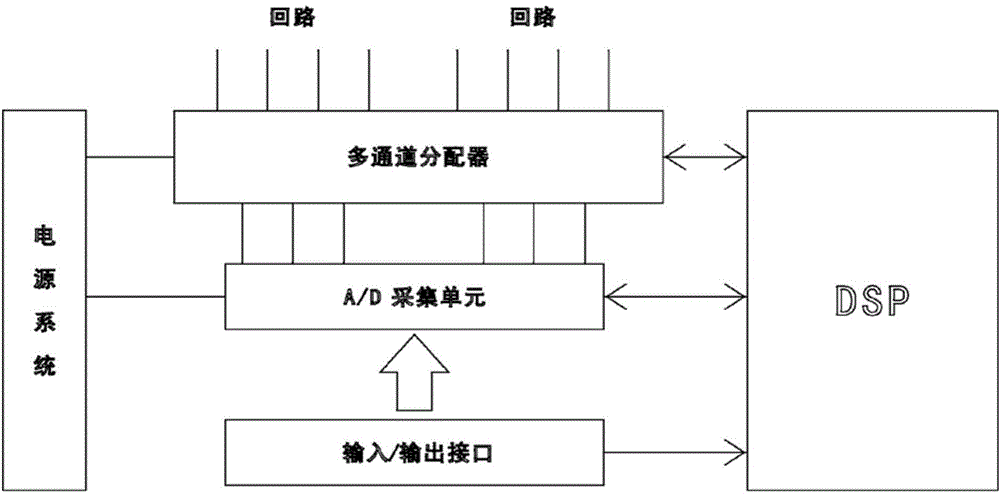

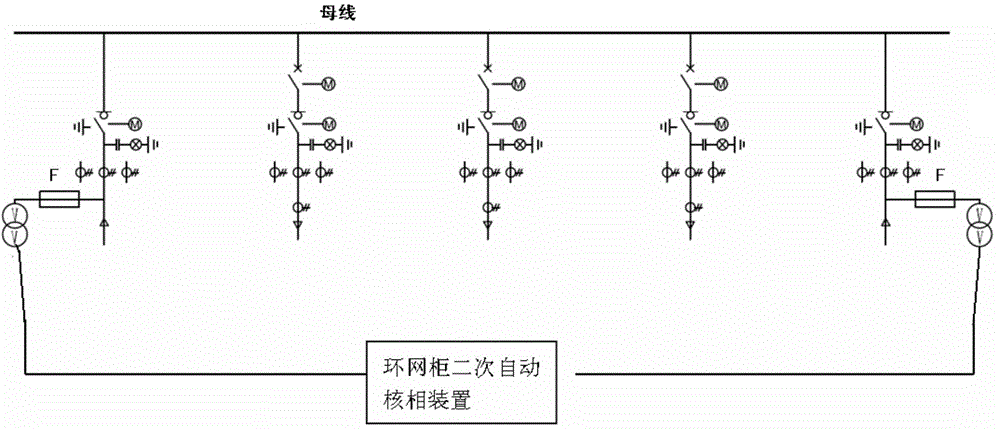

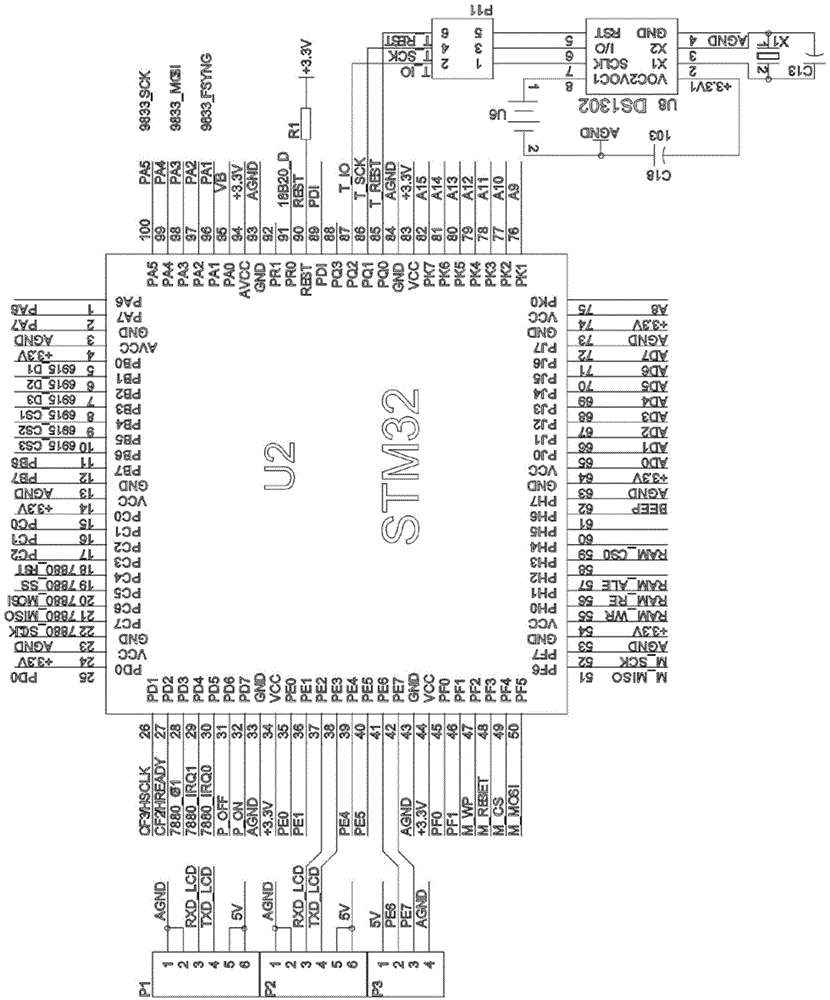

Secondary automatic nuclear phase device of ring main unit

ActiveCN104360174AHigh speedImprove the quality of power supplyVoltage-current phase anglePhase sequence/synchronism indicationTransformerBusbar

The invention discloses a secondary automatic nuclear phase device of a ring main unit. The secondary automatic nuclear phase device comprises a multi-channel distributor, an AD collecting unit, a processing operation unit, an input / output interface circuit and a power supply system, wherein the multi-channel distributor, the AD collecting unit and the input / output interface circuit are all connected with the processing operation unit; the power supply system is connected with the multi-channel distributor and the AD collecting unit; the input / output interface circuit is connected with the AD collecting unit; the multi-channel distributor is connected with a voltage transformer loop on an inlet wire busbar of a tested ring main unit; the multi-channel distributor and the inlet wire busbar of the tested ring main unit are connected with a fuse F and a voltmeter V in series; one end of the voltmeter V is connected with the fuse F, and the other end of the voltmeter V is connected with the multi-channel distributor. The secondary automatic nuclear phase device of the ring main unit has the advantages of being capable of achieving the automatic nuclear phase operation of the double-power-supply inlet wire busbar, improving the efficiency, accuracy and reliability of nuclear phase operation, shortening the power failure time, improving the power supply quality and the like.

Owner:STATE GRID CORP OF CHINA +1

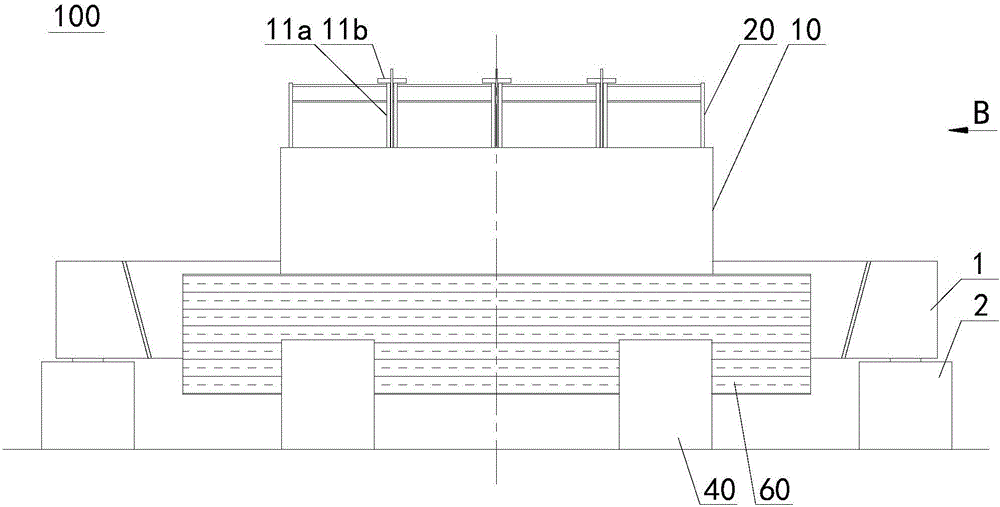

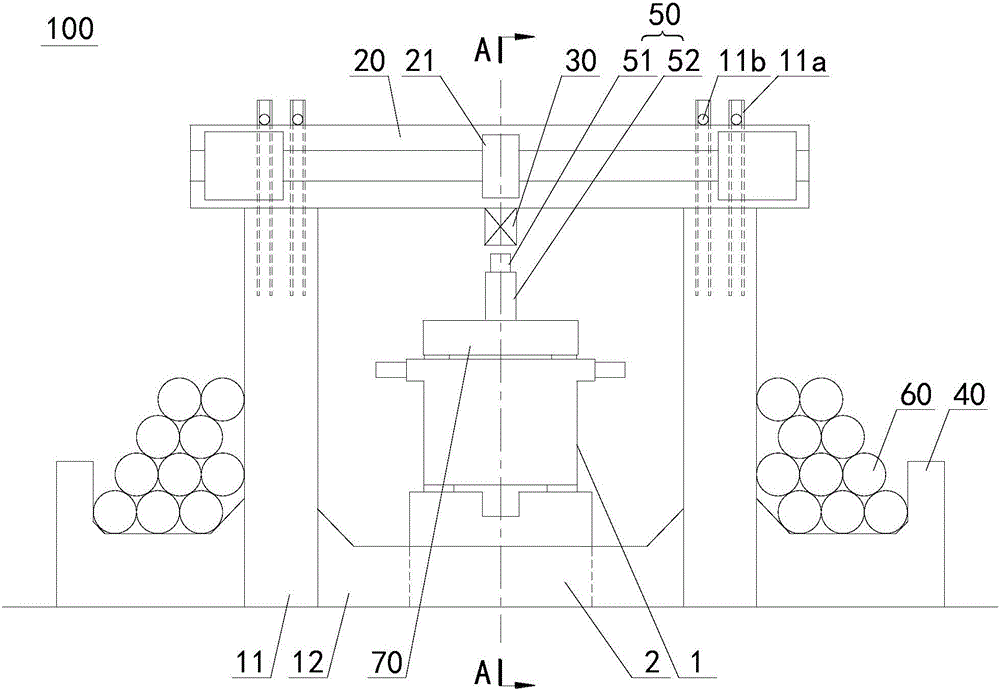

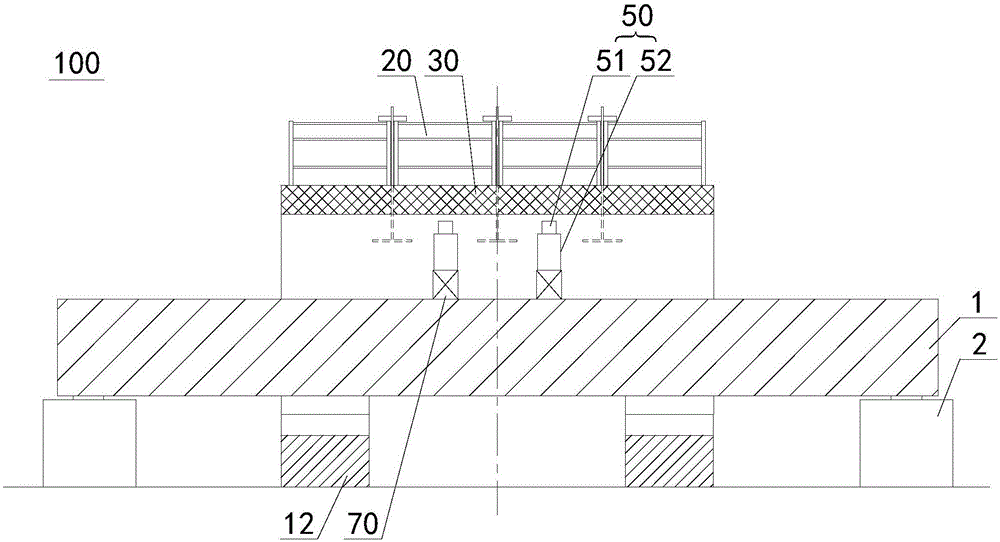

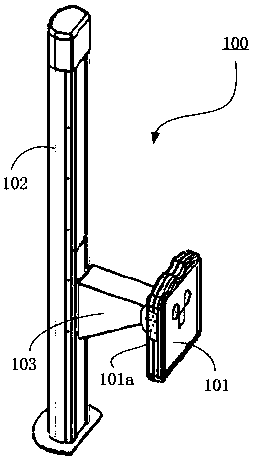

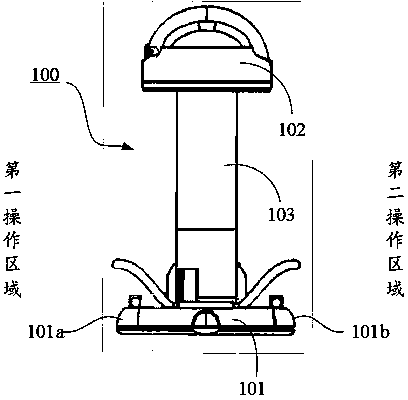

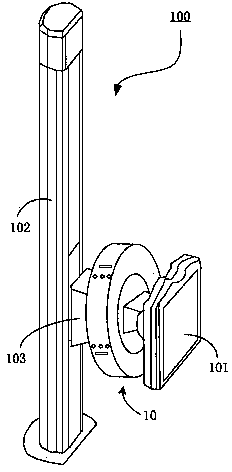

Balance weight loading device and loading method thereof

PendingCN106153443AHeavy loadFlexible choiceMaterial strength using tensile/compressive forcesButtressReinforced concrete

The invention relates to a balance weight loading device and a loading method thereof, relating to the technical field of test detection of prefabricated parts. The invention aims at solving the problems that the working efficiency is reduced, and the experimental cost is increased because an existing loading test method has a limited application range and depends on a fixed test site. The balance weight loading device comprises a reinforced concrete weight counter-force frame, wherein the reinforced concrete weight counter-force frame comprises a pair of pillar bodies, a plurality of tie beams, a yard beam, an auxiliary beam and a plurality of brackets, the pillar bodies are vertically and oppositely arranged, the pillar bodies are connected to the bottom ends of the pillar bodies, the yard beam transversely stretches across and fixedly connected to the top ends of the pillar bodies, and the auxiliary beam is fixedly connected to the bottom of the yard beam and is parallel with the pillar bodies; and the brackets are fixedly connected to the outer sides of the pillar bodies. The loading method comprises the following steps: bridging a test beam on buttresses and between two pillar bodies of the reinforced concrete weight counter-force frame; putting a reverse-jacking device between the test beam and the auxiliary beam, and pre-forming a gap between the reverse-jacking device and the auxiliary beam; and applying load to the test beam through the reverse-jacking device, applying the maximum load to balance weight objects at the bracket on two sides of the pillar bodies, and observing and recording data tested by the reverse-jacking device.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

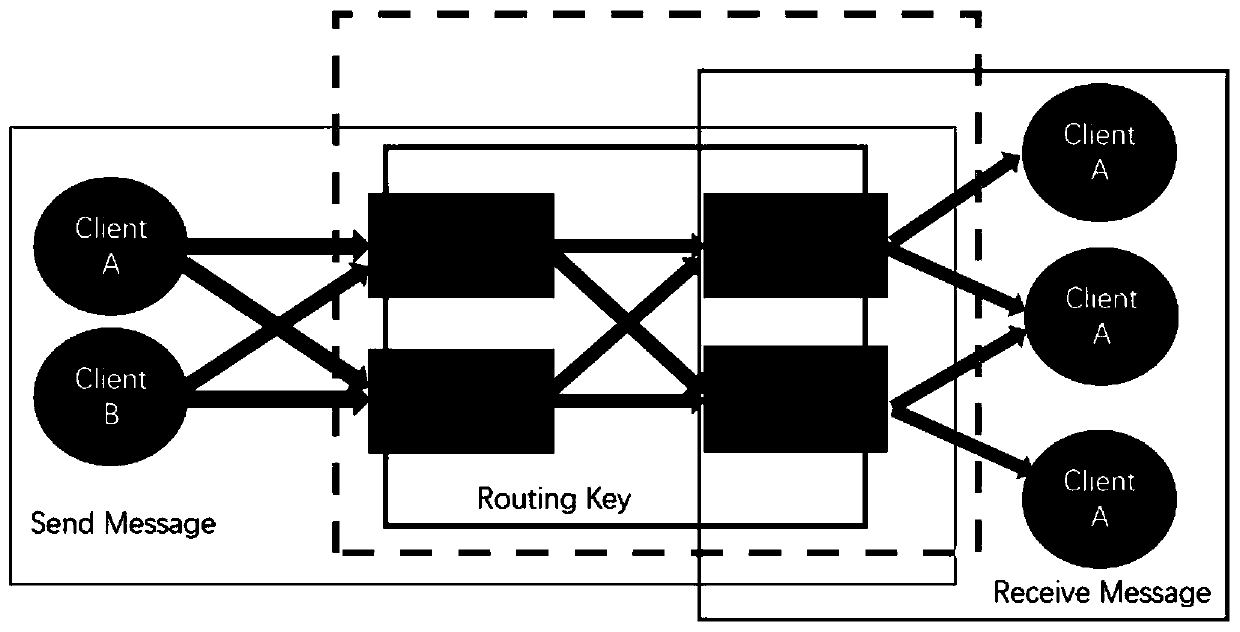

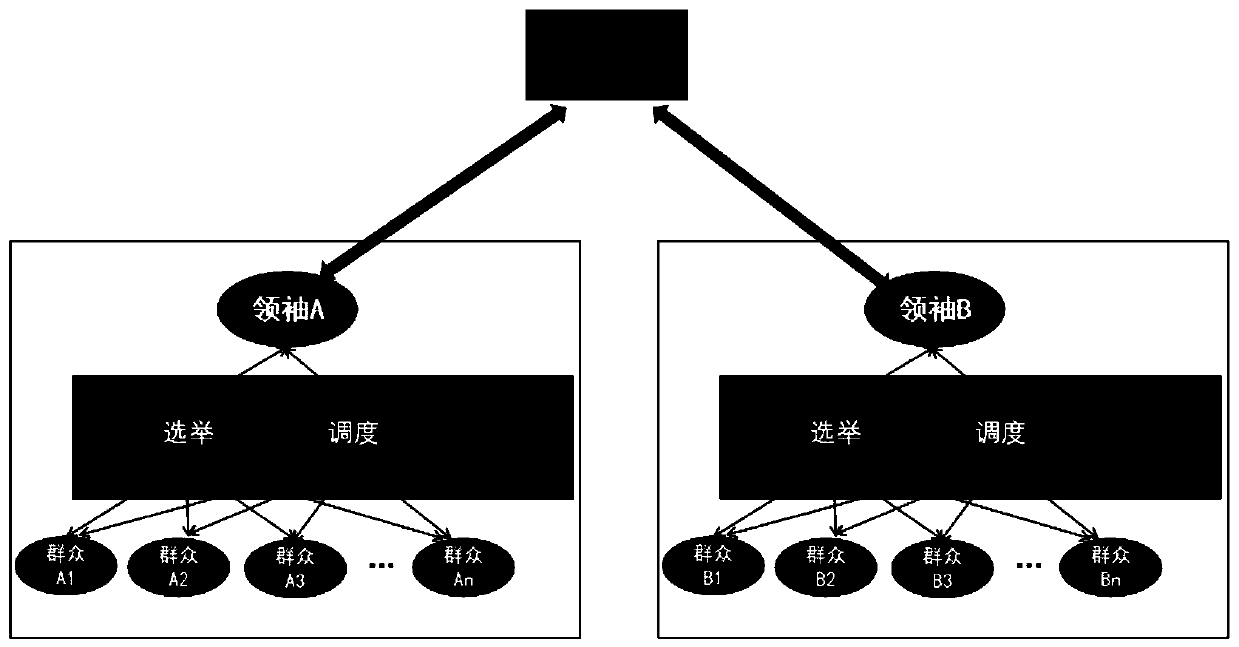

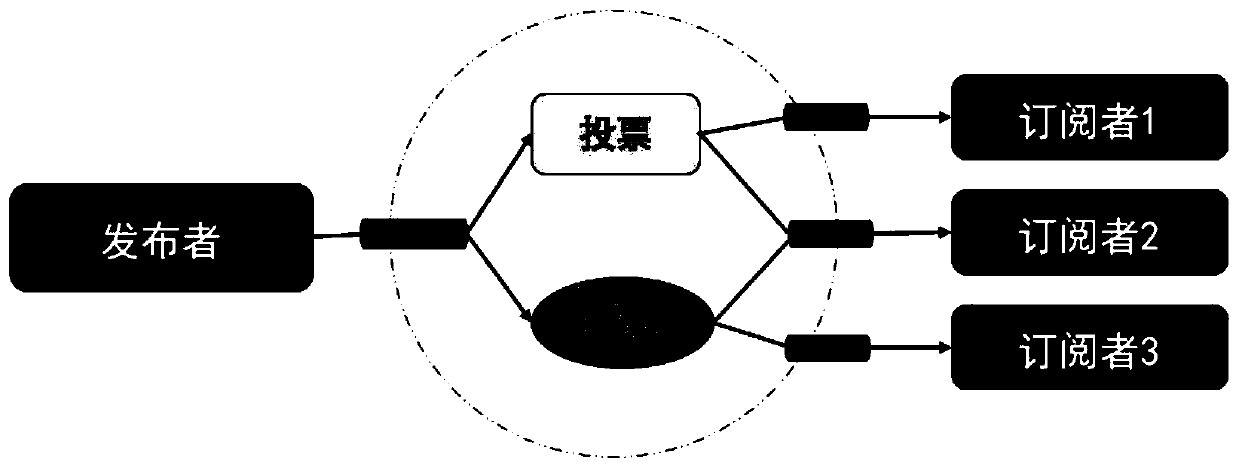

Cloud platform communication system, election method and resource scheduling management method

InactiveCN111064672AImprove real-time scheduling management capabilitiesEnsure consistencyData switching networksCommunications systemWorkload

The invention provides a cloud platform communication system. A bidirectional publishing / subscribing mode and a cluster consistency management method are provided to ensure real-time message communication between leaders of the cloud platform software robots and people. and consistency of intra-cluster messages. According to the cloud platform resource scheduling actual situation of a data center,an election method is provided so that cloud platform resource scheduling management intelligence is improved. A resource scheduling management method is provided, the automatic operation and maintenance capacity of the system is improved by achieving a cloud platform resource scheduling system of the robot technology, and the workload of maintenance personnel is reduced.

Owner:国网甘肃省电力公司信息通信公司 +2

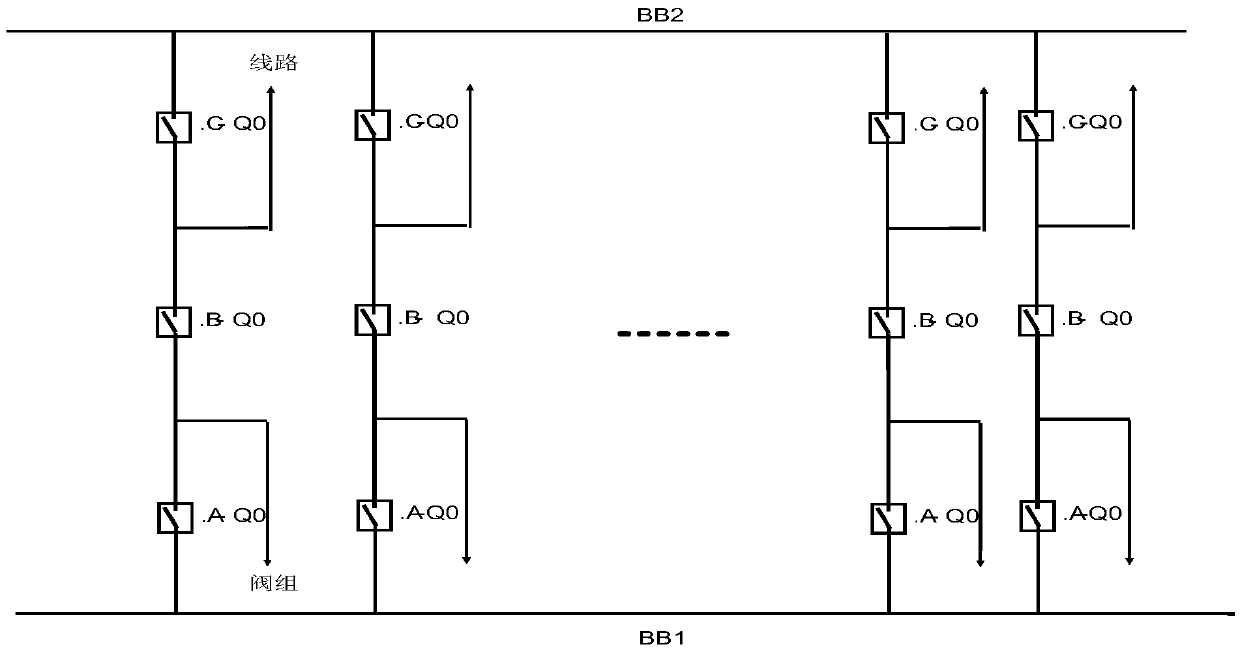

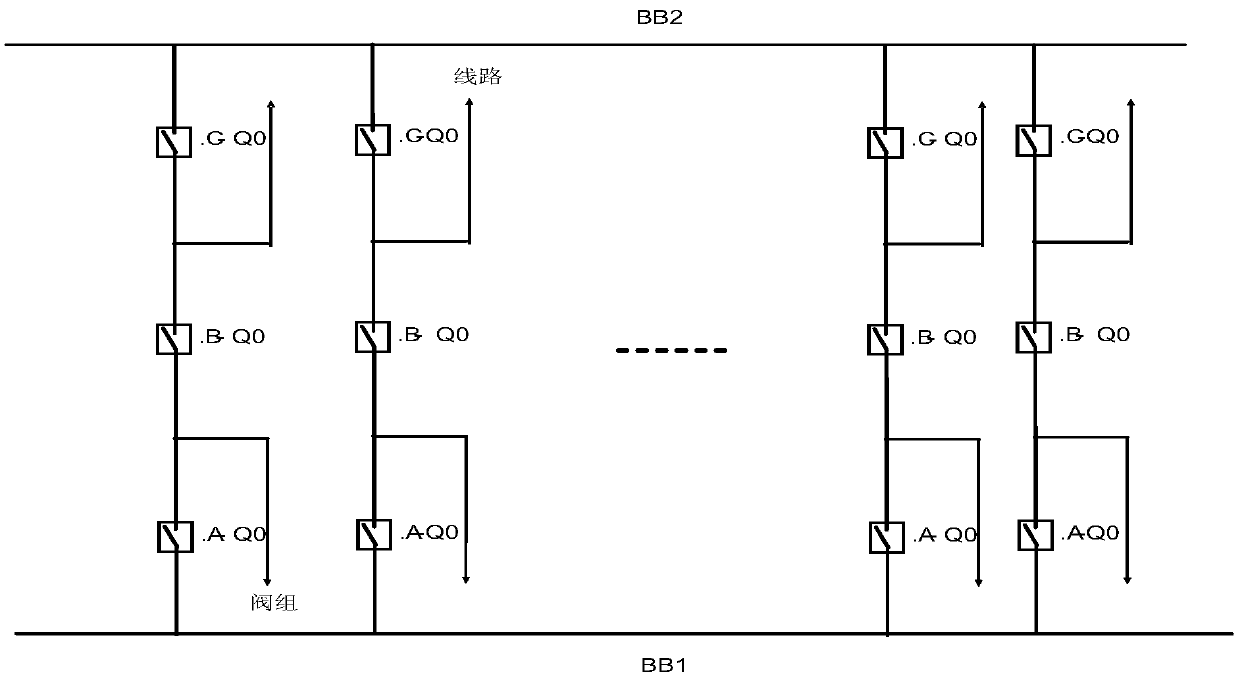

Adaptive discrimination method and apparatus for valve block last breaker of extra-high-voltage converter station

ActiveCN105514940ASave human effortSave moneyEmergency protective circuit arrangementsHigh-voltage direct currentEngineering

The invention relates to an adaptive discrimination method and apparatus for a valve block last breaker of an extra-high-voltage converter station. The method comprises: if a first kind of path and a second kind of path can be connected, no last breaker exists in a valve group; if any of the first kind of path and the second kind of path can not be connected, paths between the line and the valve group are traversed; if any of the first kind of path and the second kind of path can be connected, count values are increased for all breakers of the path; and the breaker with the largest count value is determined to be the last breaker. The adaptive discrimination function of the valve block last breaker in the extra-high-voltage direct-current power transmission project is realized; and a phenomenon that the logic of the valve block last breaker is not correct when the alternating-current intervals are connected step by step, alternating-current strings are connected step by step, or, alternating-current incoming wires are connected step by step at the alternating-current field can be avoided effectively.

Owner:XJ ELECTRIC +2

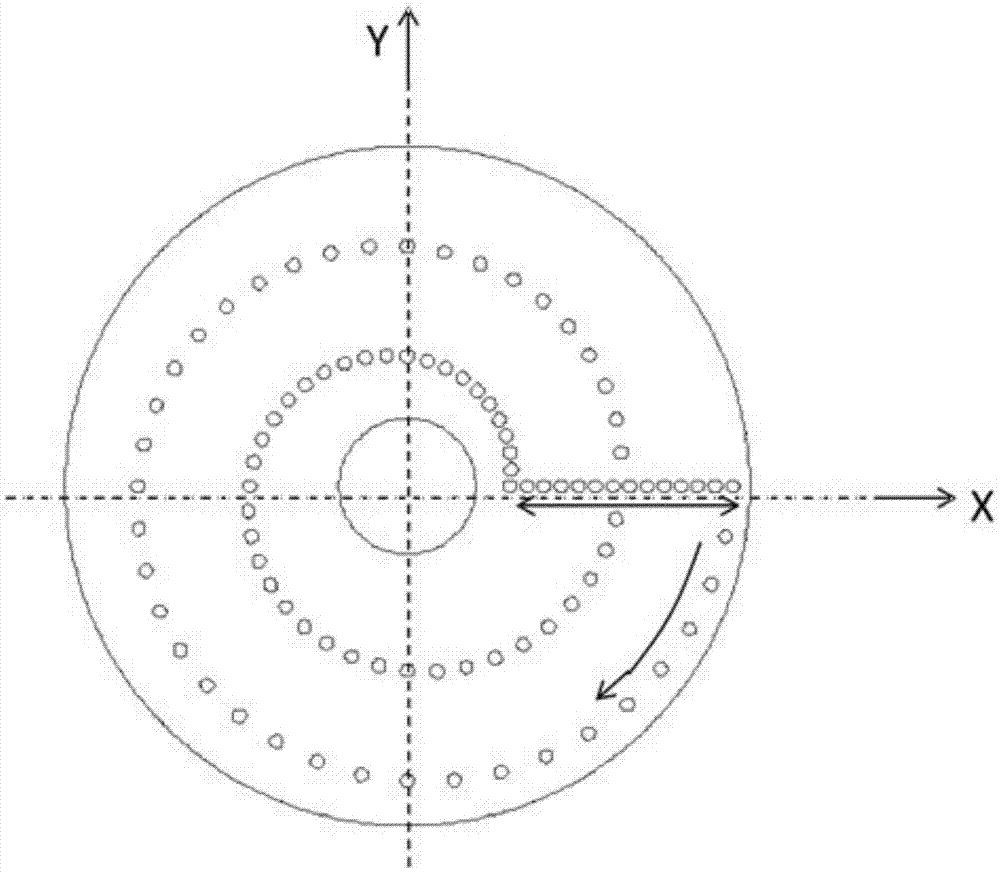

Extreme ultraviolet recessed surface reflector coated film uniformity assessing method

ActiveCN105444714AReduce processing costsImprove reliabilityMeasurement devicesAlcoholModel parameters

The invention discloses an extreme ultraviolet recessed surface reflector coated film uniformity assessing method belonging to the extreme ultraviolet optical technology application field. The method is characterized in that a film coating die, the shape of which is the same as the shape of the recessed surface reflector, can be processed, and by taking one point of the outer edge of the film coating die as the starting point, the points can be selected and the holes can be punched in the film coating die sequentially according to the helix shape, and the last intersection point between the helix and the radius of the starting point can be used as the terminal point, and then the points can be numbered according to the coordinate positions; the points can be selected and the holes can be punched in the radial straight line between the starting point and the terminal point, and then the points can be numbered according to the coordinate positions; quartz glass testing sample wafers are selected, and the ultrasonic cleaning, the slow-pulling and the dehydrating, and the alcohol drying of the testing sample wafers can be carried out, and then the testing sample wafers can be divided into two groups and are numbered respectively according to the helix sequence and the radial straight line sequence, and then can be attached to the hole positions; the extreme ultraviolet single-layer film can be disposed on the testing sample wafer; the XRD test of the testing sample wafers can be carried out sequentially according to the above mentioned sequences, and then the thickness of the extreme ultraviolet single-layer film can be analyzed under the same model parameter.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

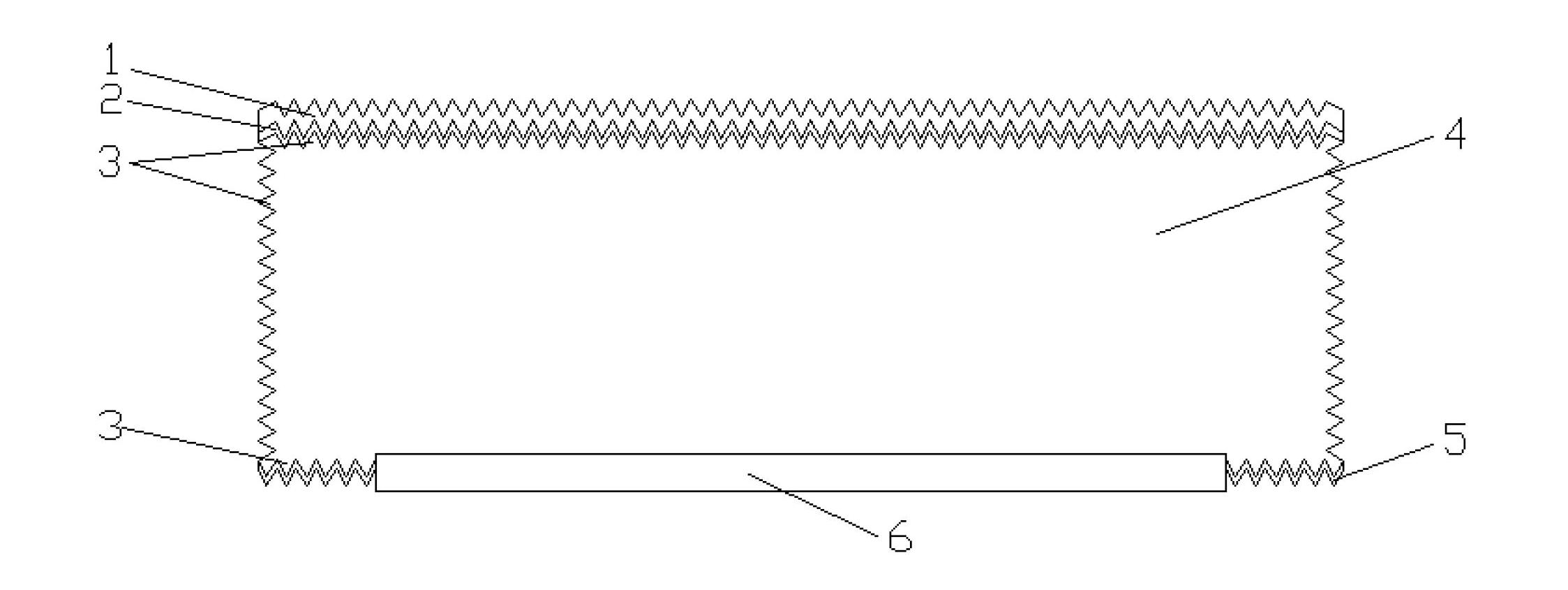

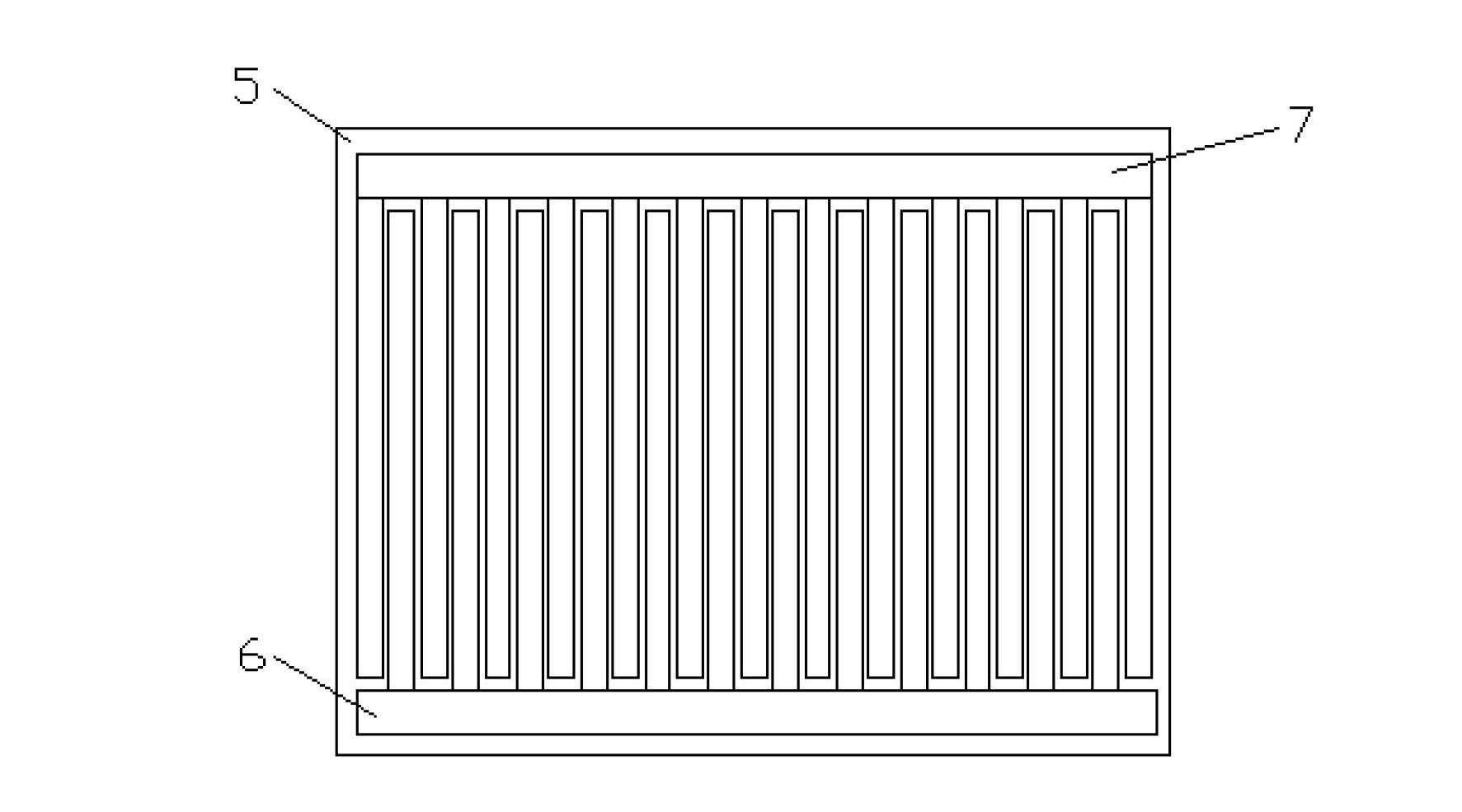

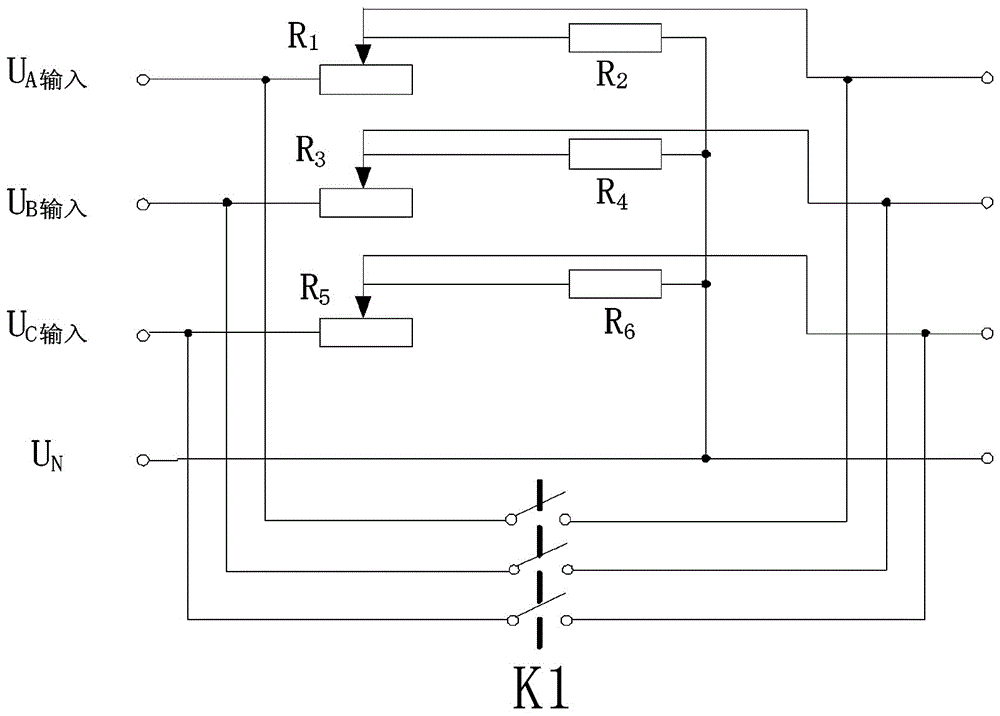

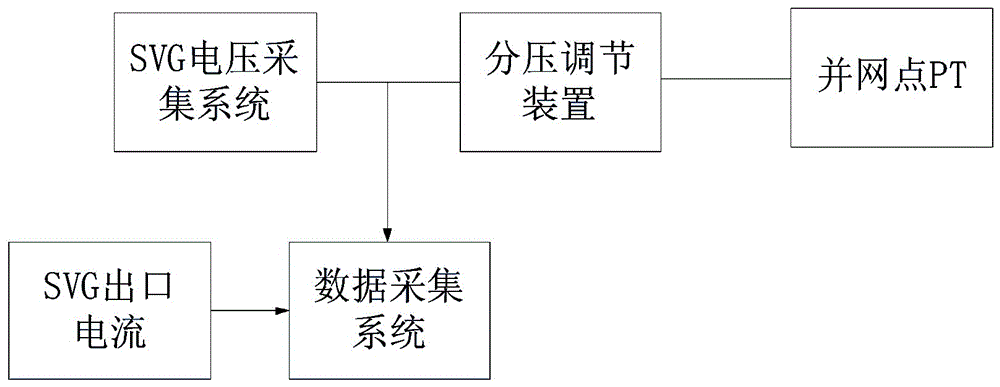

Wind power plant static var generator (SVG) response time test system of with voltage dividing regulating device

ActiveCN105759159AAvoid damageAvoid operational riskElectrical testingElectric power systemData acquisition

The invention relates to the technical field of power systems, in particular to a wind power plant static var generator (SVG) response time test system with a voltage dividing regulating device.The system can test time of reactive response which is sent by a wind power plant SVG due to the fact that a grid connection point which the wind power plant SVG tracks and compensates for is reactive or is subject to voltage changes.The wind power plant SVG response time test system comprises the voltage dividing regulating device and a data collection system.The voltage dividing regulating device is in series connection between the grid connection point and a SVG voltage collecting system.The data collection system collects an output voltage of the voltage dividing regulating device and a SVG outlet current.According to the wind power plant SVG response time test system with the voltage dividing regulating device, a method does not need to generate artificial disturbance in a wind power plant primary system, corresponding operating risks are avoided, a band carrier running line does not need to be removed, and the damage to a running wind turbine generator caused by voltage loss shutdown is avoided.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +1

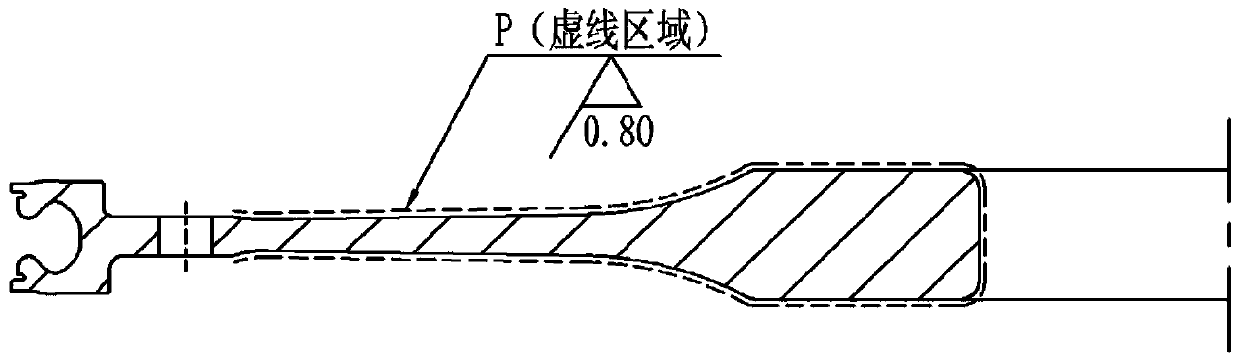

Vibrational finishing machining method for high-temperature alloy disc parts

ActiveCN110860953AUniform surface textureReduce surface roughness valueEdge grinding machinesPolishing machinesElectric machinerySurface roughness

The invention relates to the technical field of aero-engine manufacture, in particular to a vibrational finishing machining method for high-temperature alloy disc parts. Vibrational finishing is a free abrasive tumbling and finishing machining technology, and a shock excitation source produced by an imbalance motor drives an abrasive material to perform micro-impact, scratching and grinding on thepart surfaces, so that purposes of improving surface stress states of workpieces, reducing surface roughness values of the parts and improving surface quality of the parts are achieved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

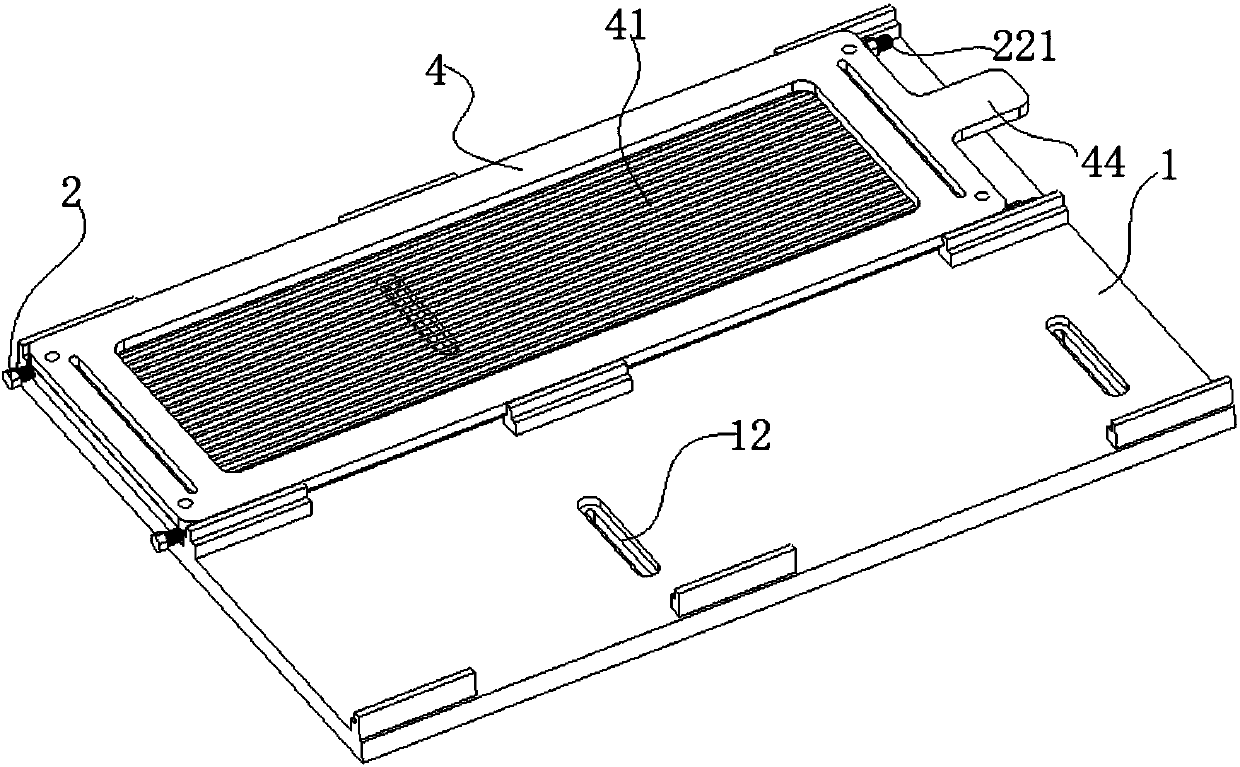

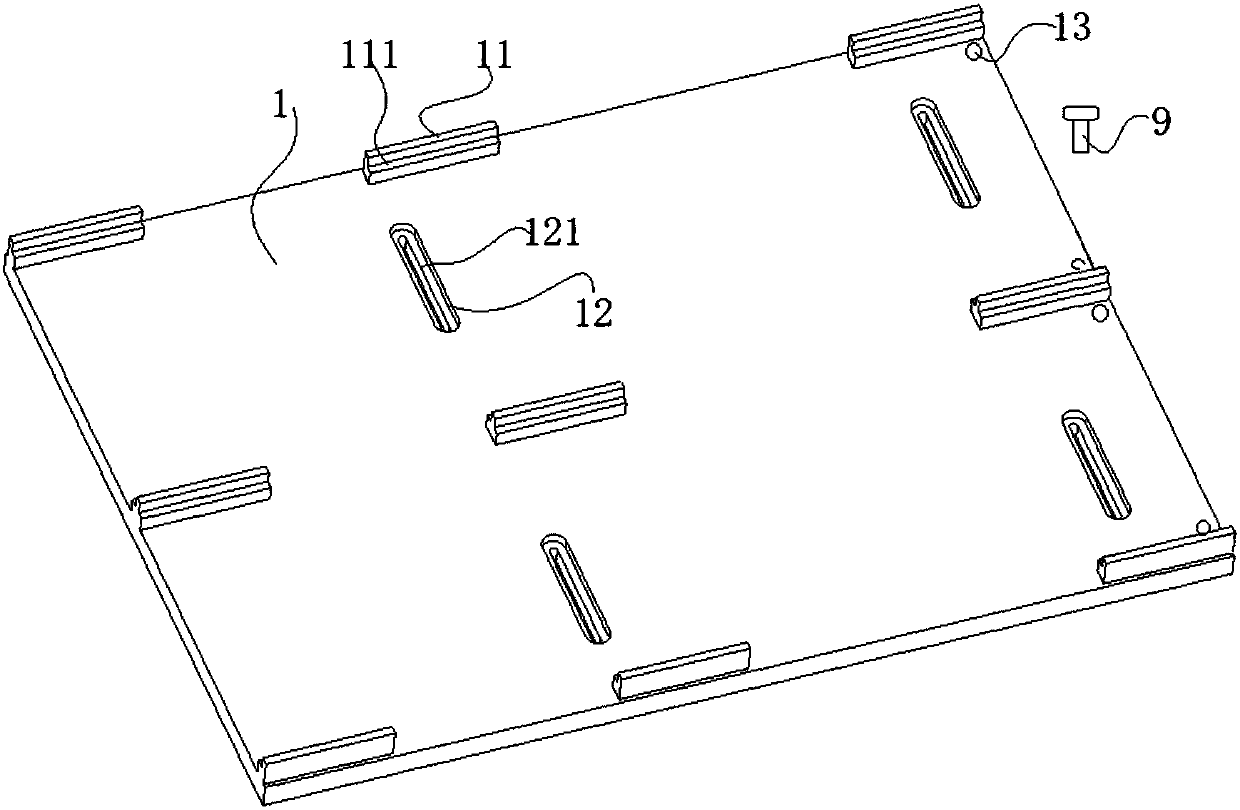

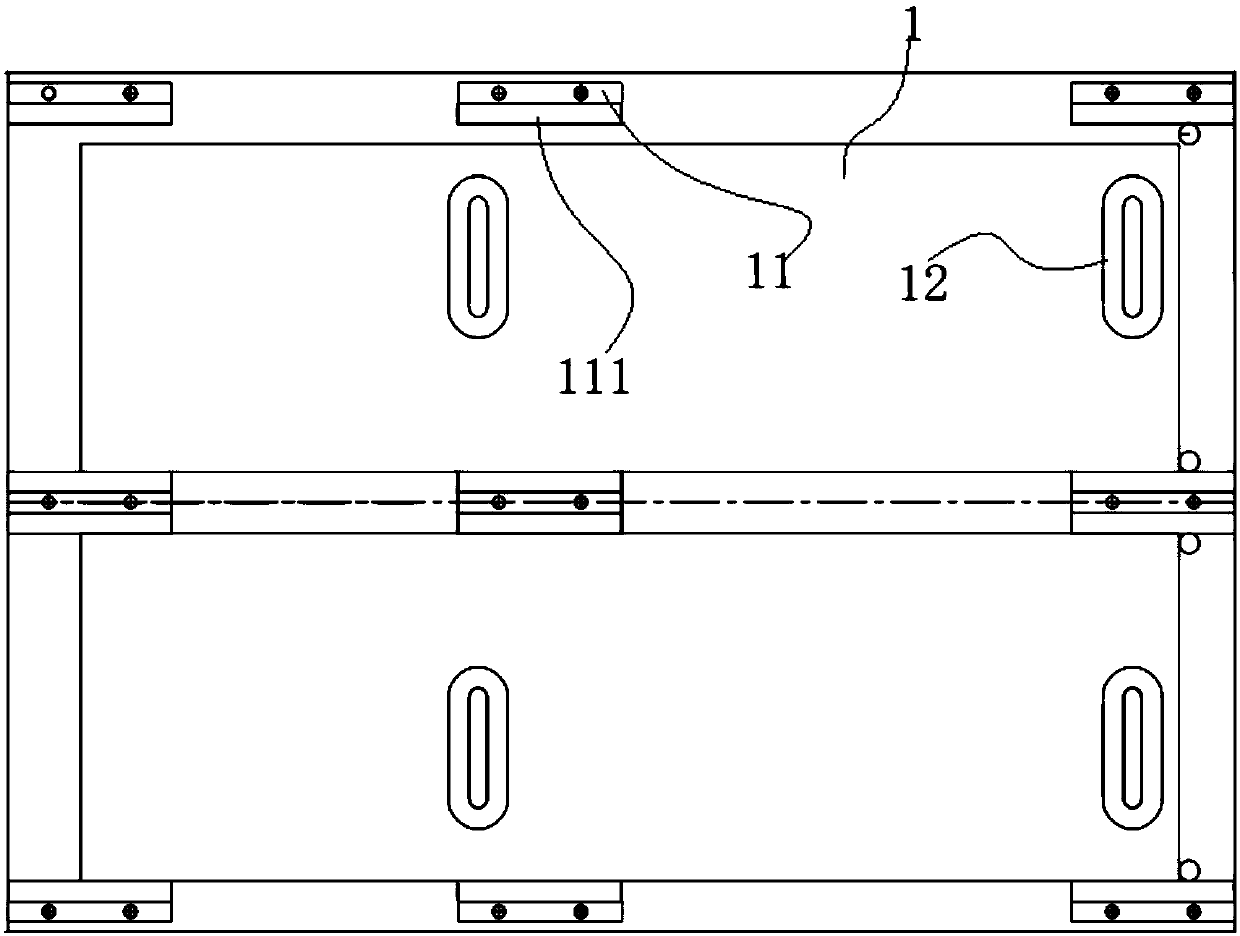

LED flexible light bar glue dispensing tool and assembly method and application thereof

InactiveCN107790335AImprove stabilityAvoid spillage of glueLiquid surface applicatorsCoatingsEngineeringLight fixture

The invention discloses a glue dispensing tool for an LED flexible light strip, an assembly method and an application thereof, and belongs to the technical field of LED lighting devices. The LED flexible light strip dispensing tooling of the present invention includes a square flat bottom plate, a bracket and a pressure plate covering the bracket, wherein: the two ends of the bottom plate are protruded with symmetrically distributed limiting platforms; Square adjustment blocks arranged in parallel, both sides of the adjustment block are fixedly connected by connecting rods; the upper surface of the adjustment block is evenly protruded with a fixed column; both ends of the LED flexible light strip are fixedly connected with the fixed piece; the fixed piece is evenly pierced with a Bracket fixing holes; the hollow part in the middle of the pressure plate is a square glue dispensing area, the area is equal to the LED flexible light strip row in the bracket. Stable and uniform dispensing is achieved through the cooperation of the adjustment block, the connecting rod, the fixed piece and the limit step in the open bracket, and the hollow part of the pressure plate is set as a square dispensing area to control the dispensing material. non-spill purpose.

Owner:MAANSHAN DAYI ELECTRONICS LIGHTING TECH

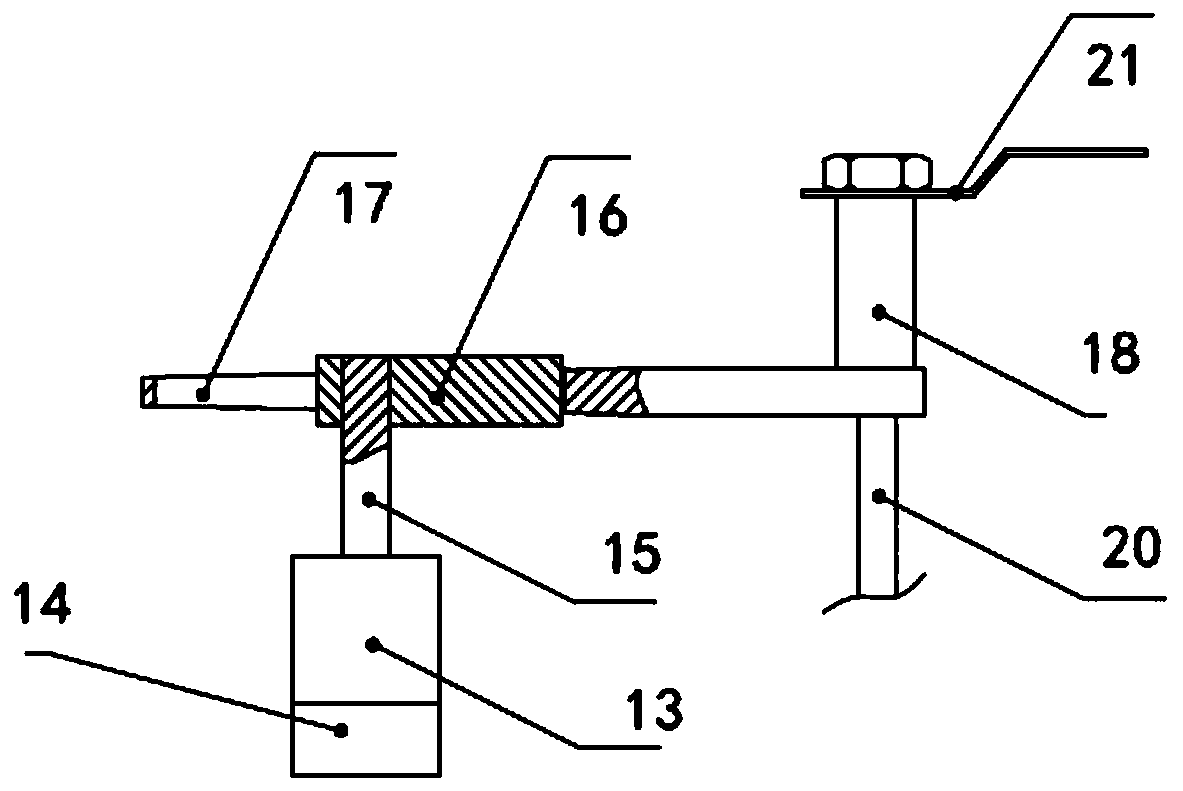

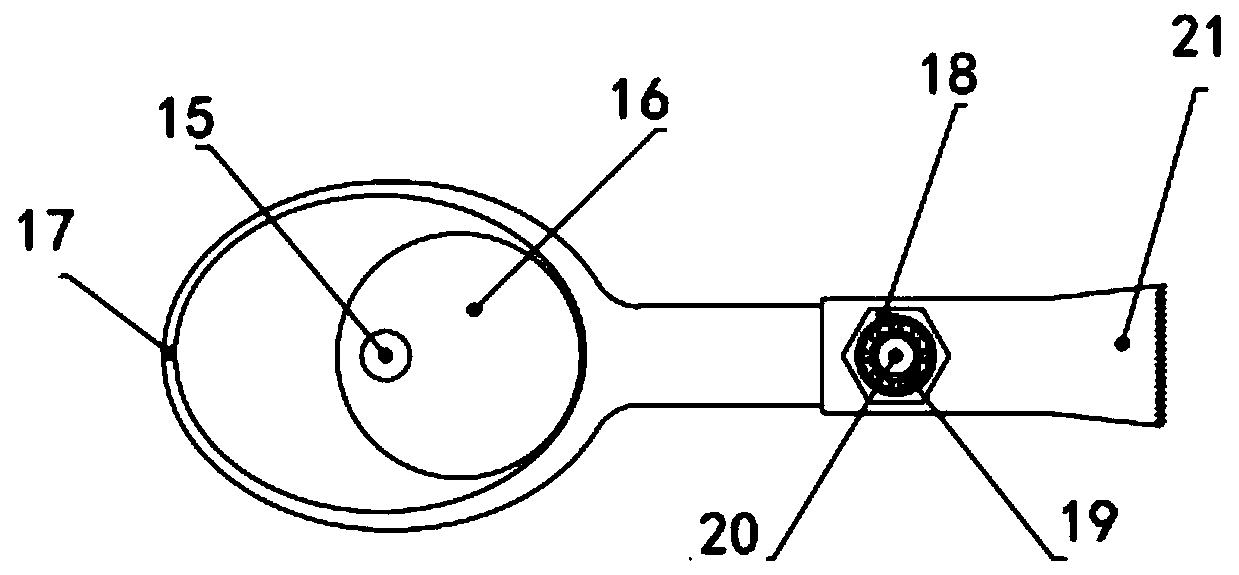

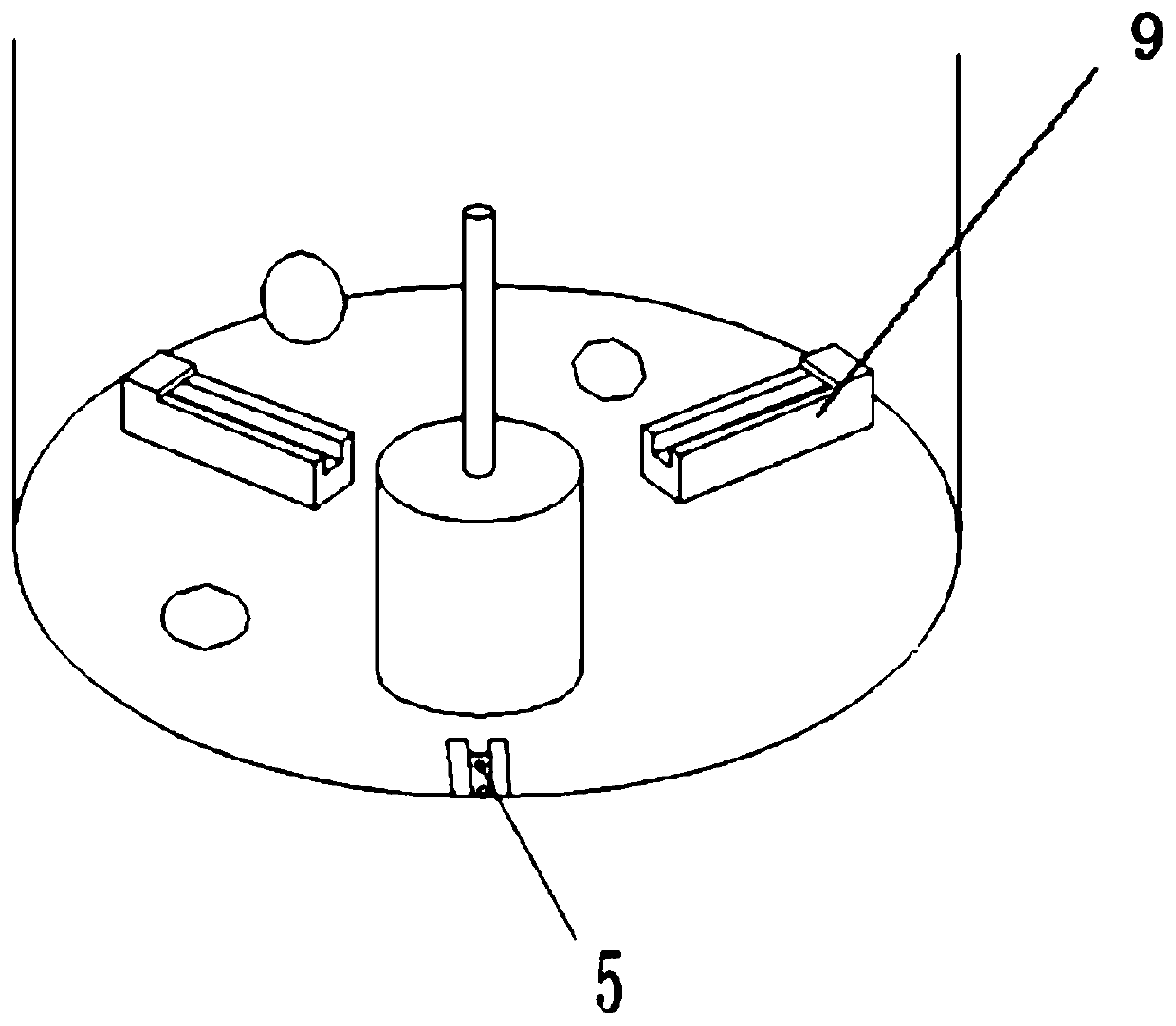

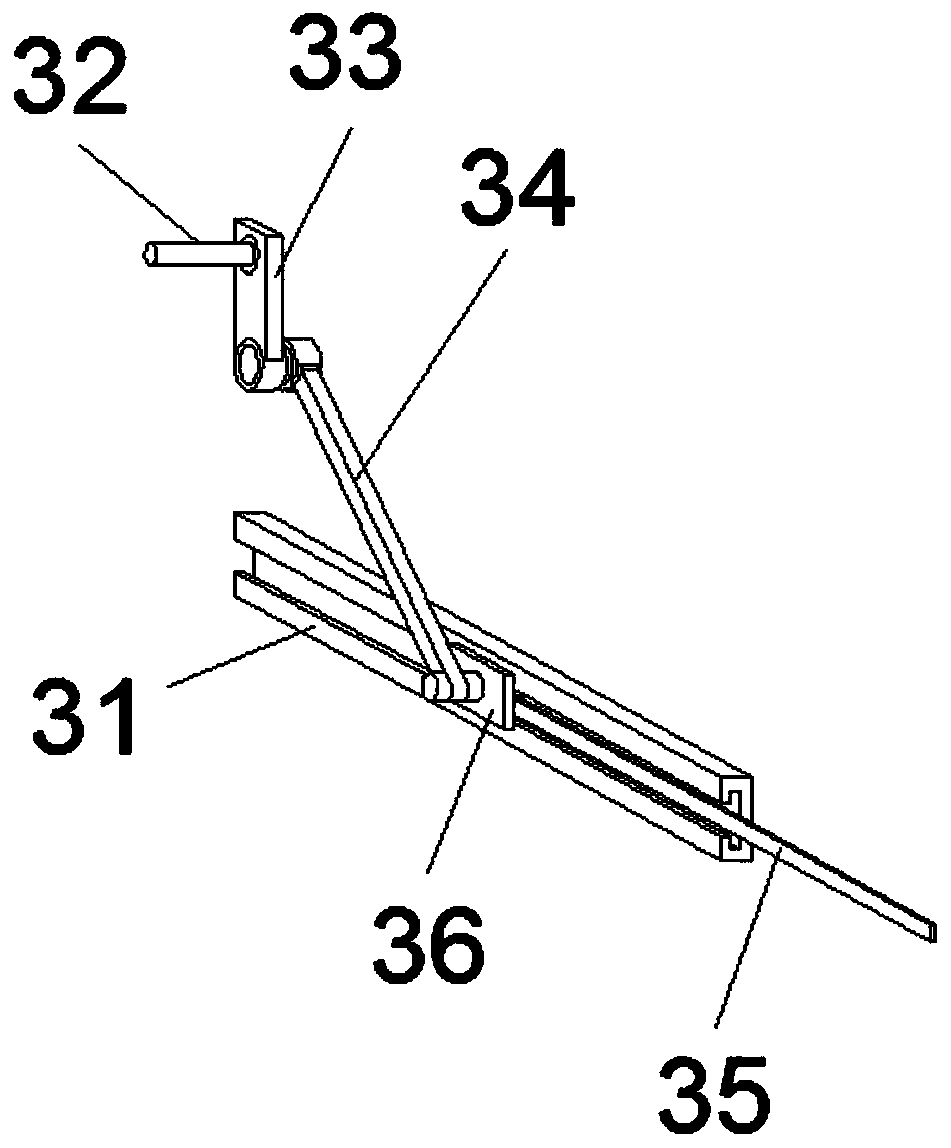

Remote device for leakage detection of ultrahigh-pressure helium

ActiveCN105043676AAvoid operational riskAutomatically findDetection of fluid at leakage pointLinear motionUltra high pressure

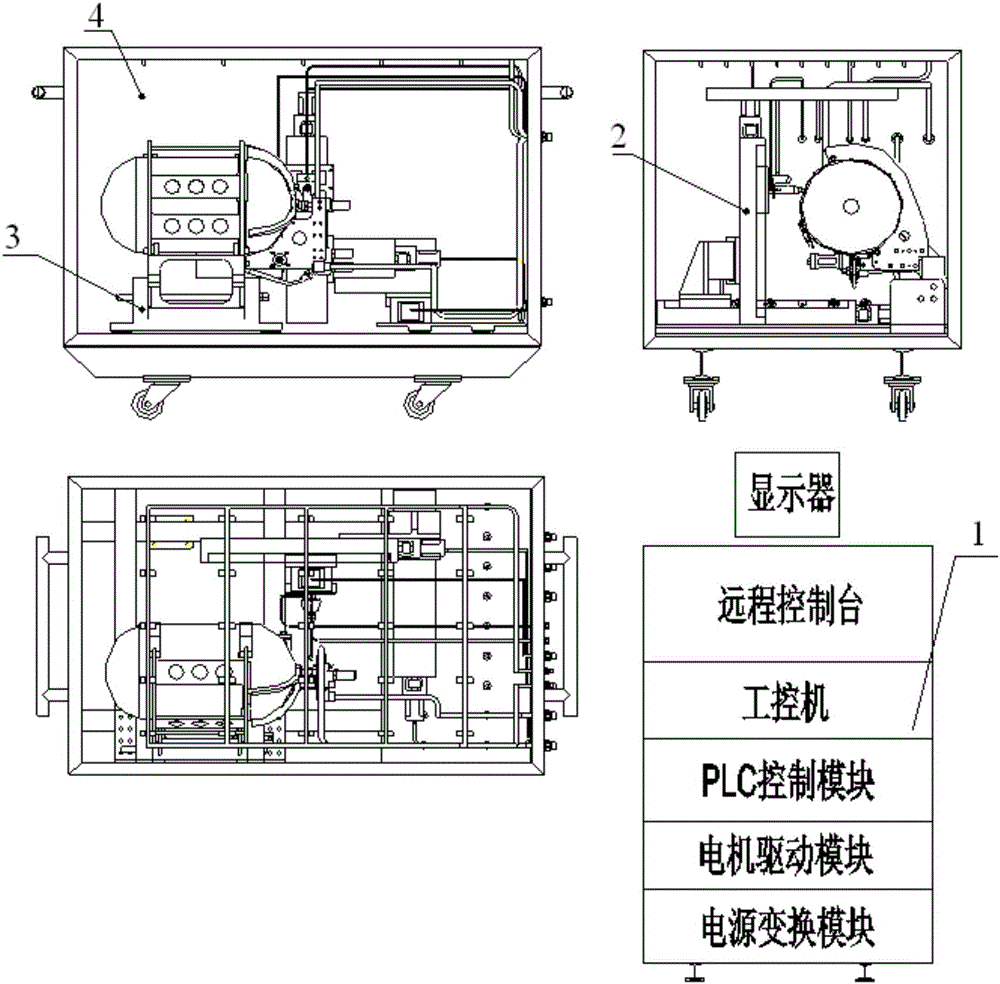

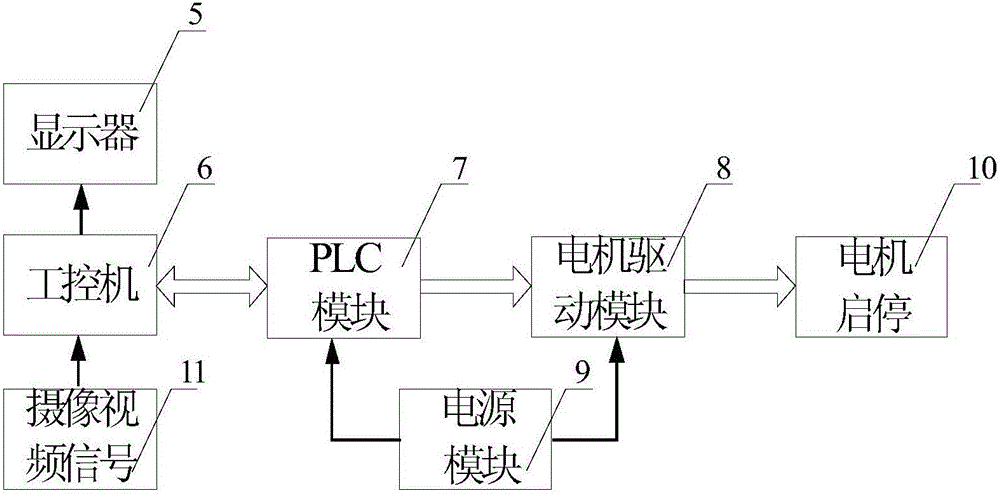

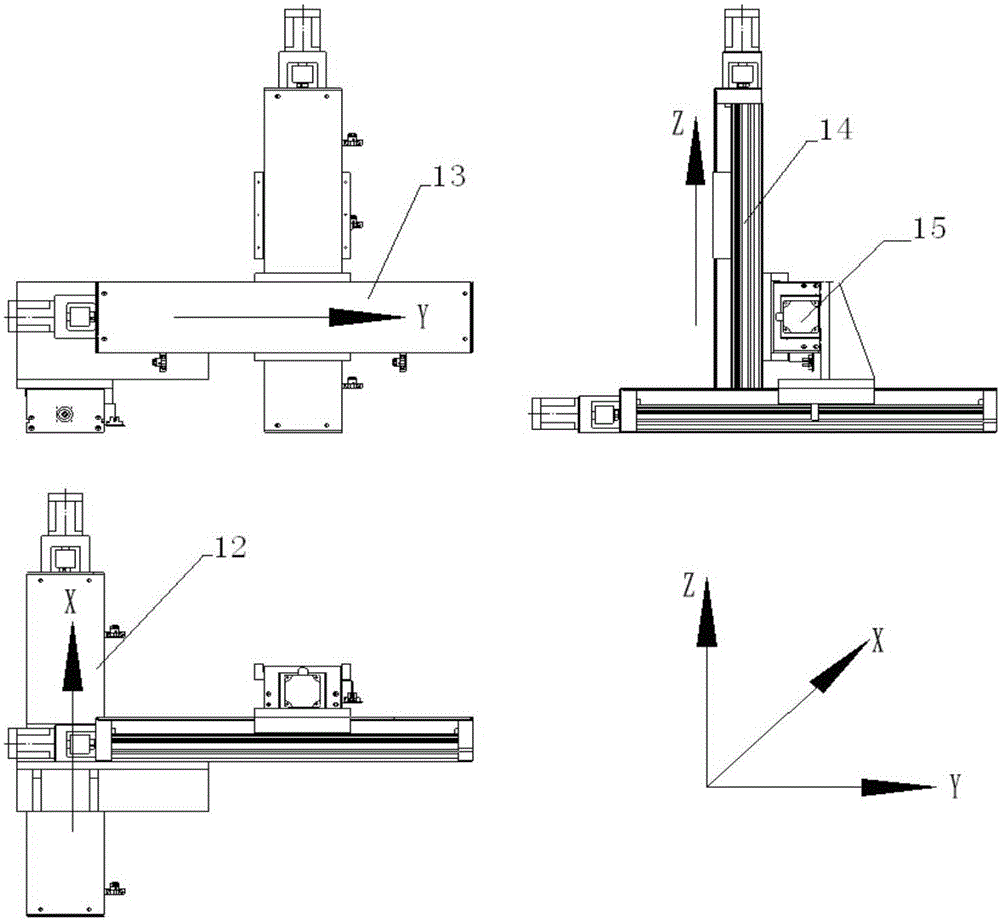

The invention provides a remote device for the leakage detection of ultrahigh-pressure helium. The remote device comprises a helium source installation mechanism, a three-axis linear motion platform, a remote console, and a special test environment box body, a helium source is arranged in the helium source installation mechanism, a detection suction gun is arranged on the three-axis linear motion platform and can be driven to perform three-axis movement by the three-axis linear motion platform, programming is performed to control the three-axis linear motion platform to drive the detection suction gun to move in a remote manner and perform leakage point detection of the helium source, and the ultrahigh-pressure helium source installation mechanism and the three-axis linear motion platform are arranged in the special test environment box body. According to the remote device, remote control is employed, personnel can perform air-tightness detection of the ultrahigh-pressure helium source in a remote manner and do not need to be close to the ultrahigh-pressure helium source, and operation risks are avoided.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

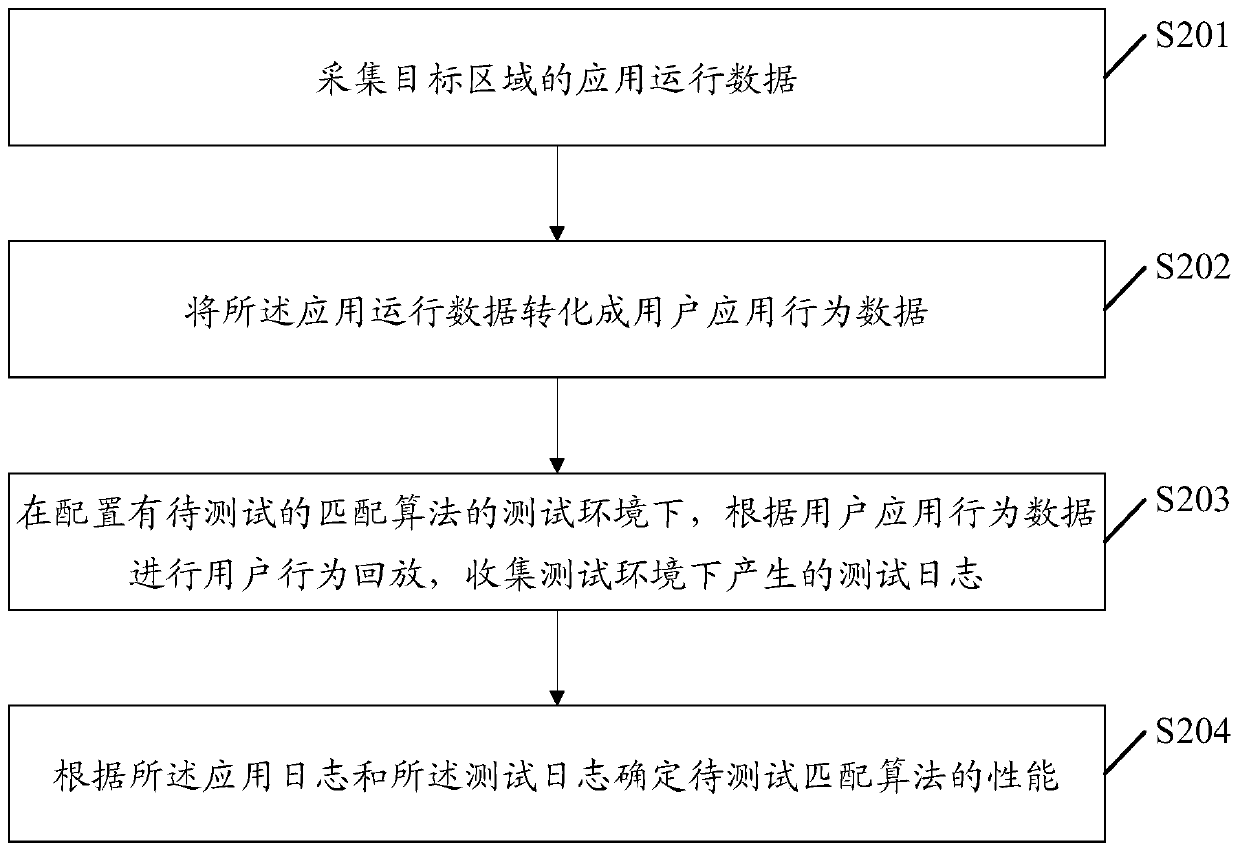

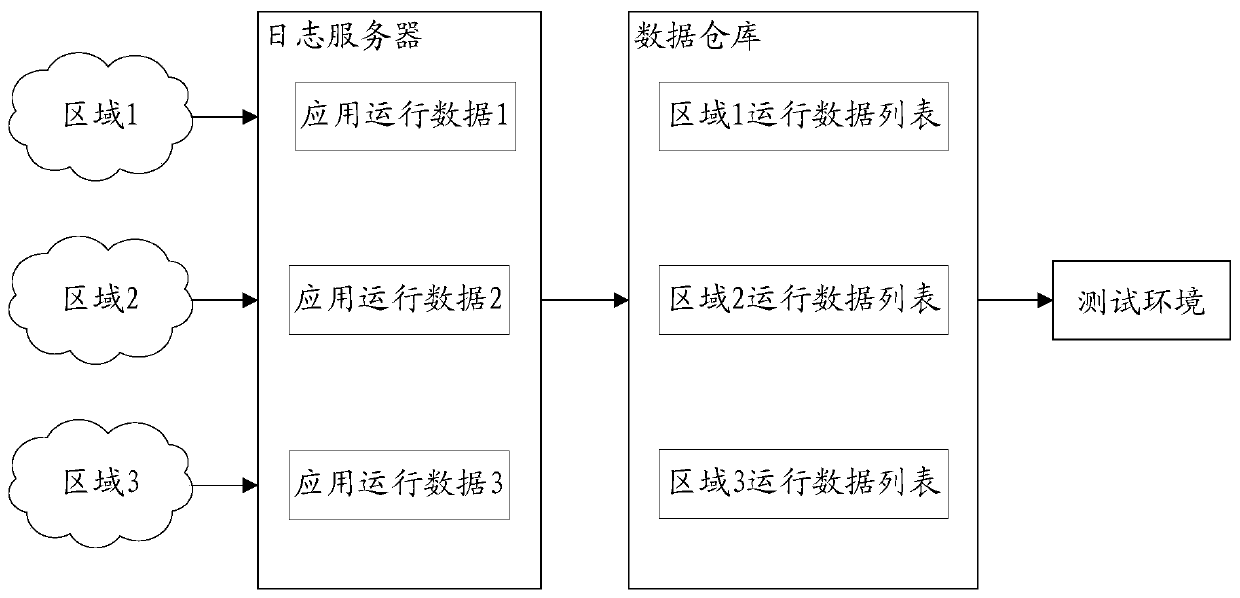

Matching algorithm performance test method, device, equipment, system and medium

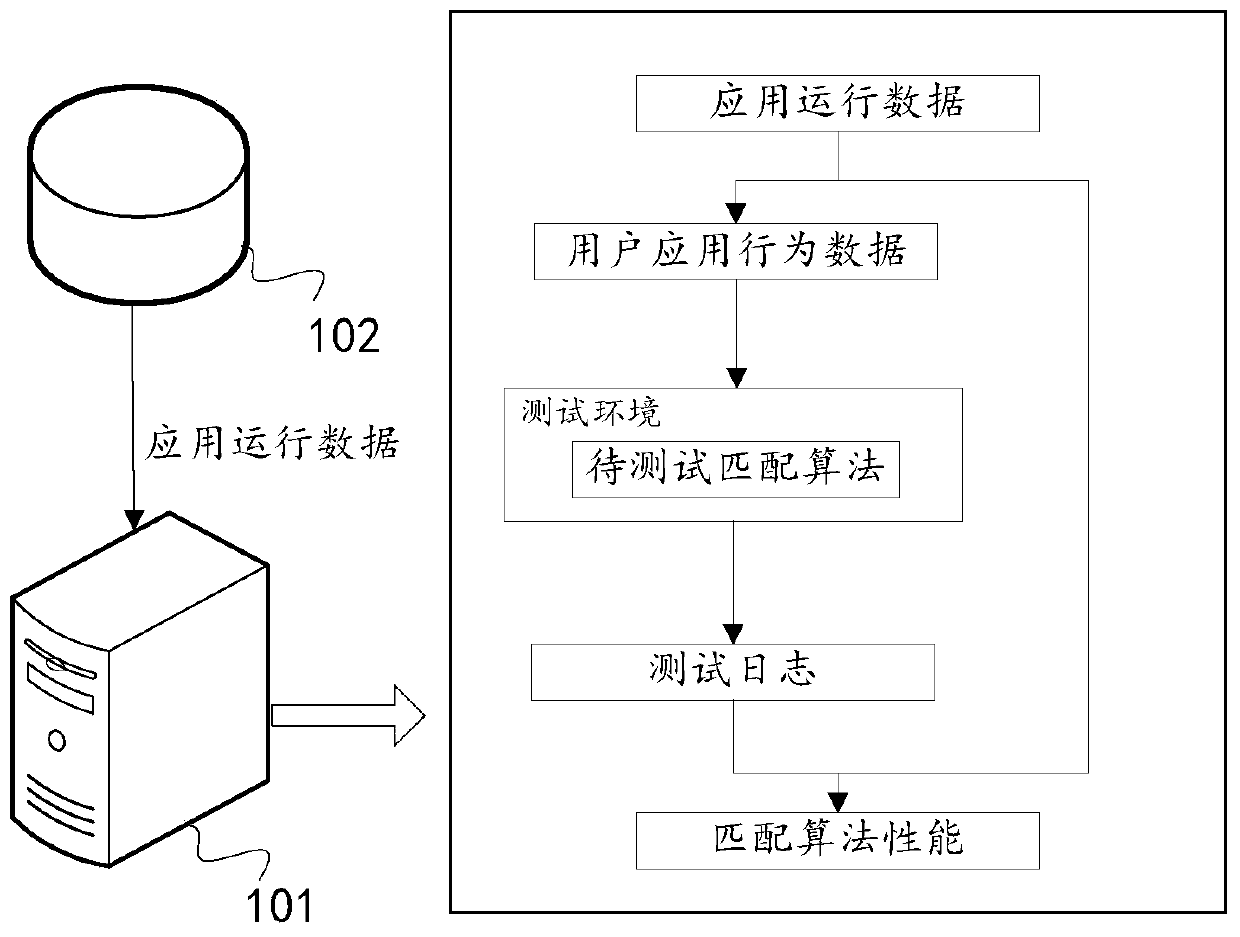

ActiveCN110825636AEasy to operateImprove reliabilitySoftware testing/debuggingVideo gamesEvaluation resultMatch algorithms

The invention discloses a matching algorithm performance test method. The method comprises the steps of collecting application operation data of a target area; converting the operation data into userapplication behavior data; in a test environment configured with a to-be-tested matching algorithm, performing user behavior playback according to the user application behavior data, and collecting test logs generated in the test environment; and determining the performance of the to-be-tested matching algorithm according to the application log and the test log. Thus, the matching algorithm is tested by simulating the matching request of the real target user, the predicted matching algorithm performance can fit the target user, the evaluation result is accurate, and the method can be used forfurther optimization or configuration of the subsequent matching algorithm. The invention further discloses a corresponding device, equipment and a storage medium.

Owner:TENCENT TECH (SHENZHEN) CO LTD

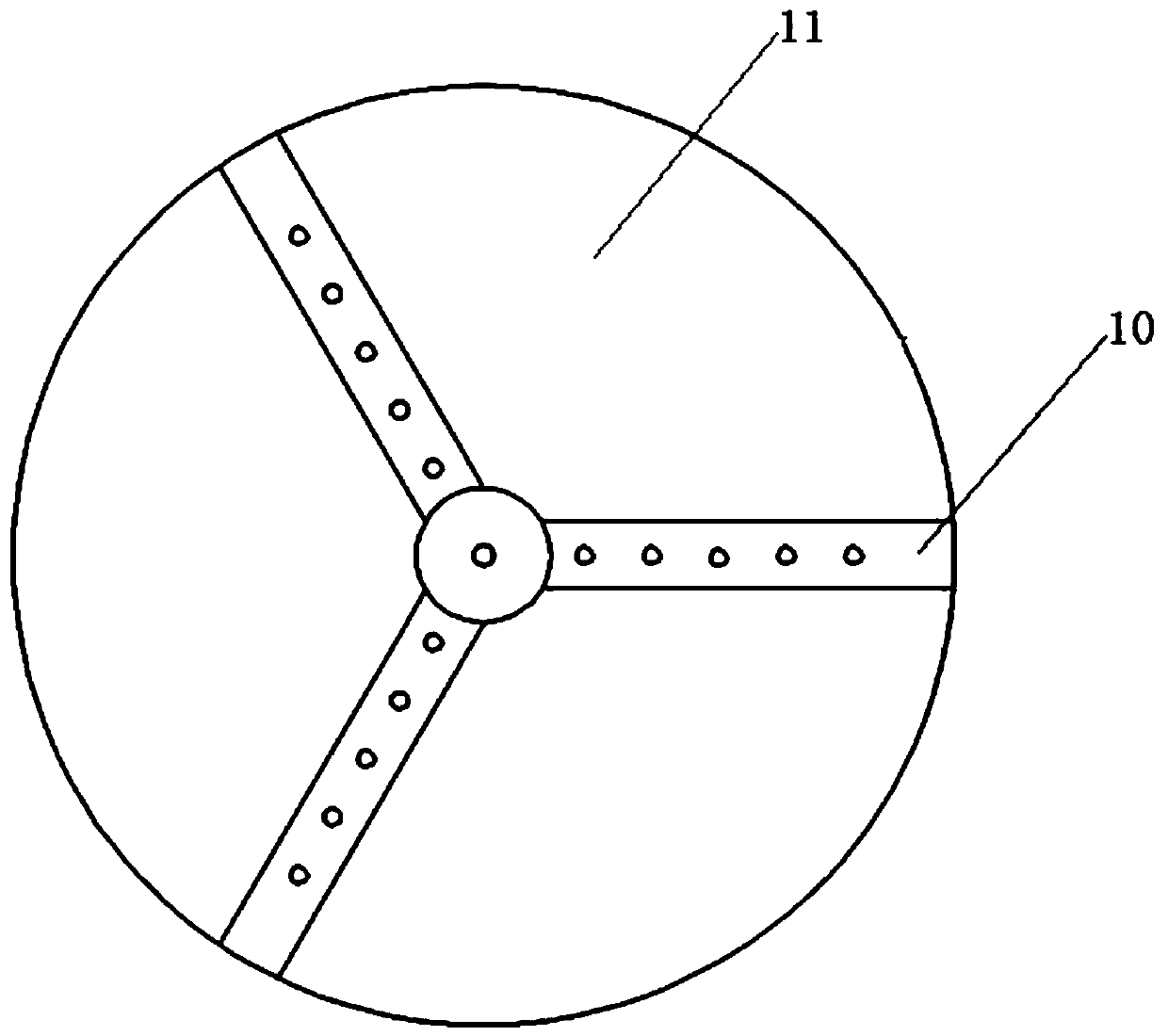

Device with rotary control panel

ActiveCN103876758AReduce wiring difficultyShorten the timeRadiation diagnosticsKey pressingEngineering

Disclosed is a device with a rotary control panel. The device comprises a rack and a control assembly, the control assembly comprises a first body, a second body, indicating buttons, an angular displacement acquisition device and at least one built-in switch, the first body is fixedly connected with the rack, the second body rotatably sleeves the first body, and the second body is provided with more than one gear; the indicating buttons are arranged on the second body; the angular displacement acquisition device is connected with the first body and the second body, the angular displacement acquisition device is used for outputting a first signal which is related to angular displacement according to open gears of the second body which rotates relative to the first body, and the angular displacement includes rotating direction and rotating angle of the second body relative to the first body; the built-in switch is used for giving an enabling signal according to the operation of exerting pressure on the indicating buttons which the open gears correspond to. According to the device with the rotary control panel, the function which can be only achieved by multiple sets of control panels can be achieved by one wiring mode, wiring difficulty is reduced, and the working efficiency of configuring device parameters and the like is increased.

Owner:联影(常州)医疗科技有限公司

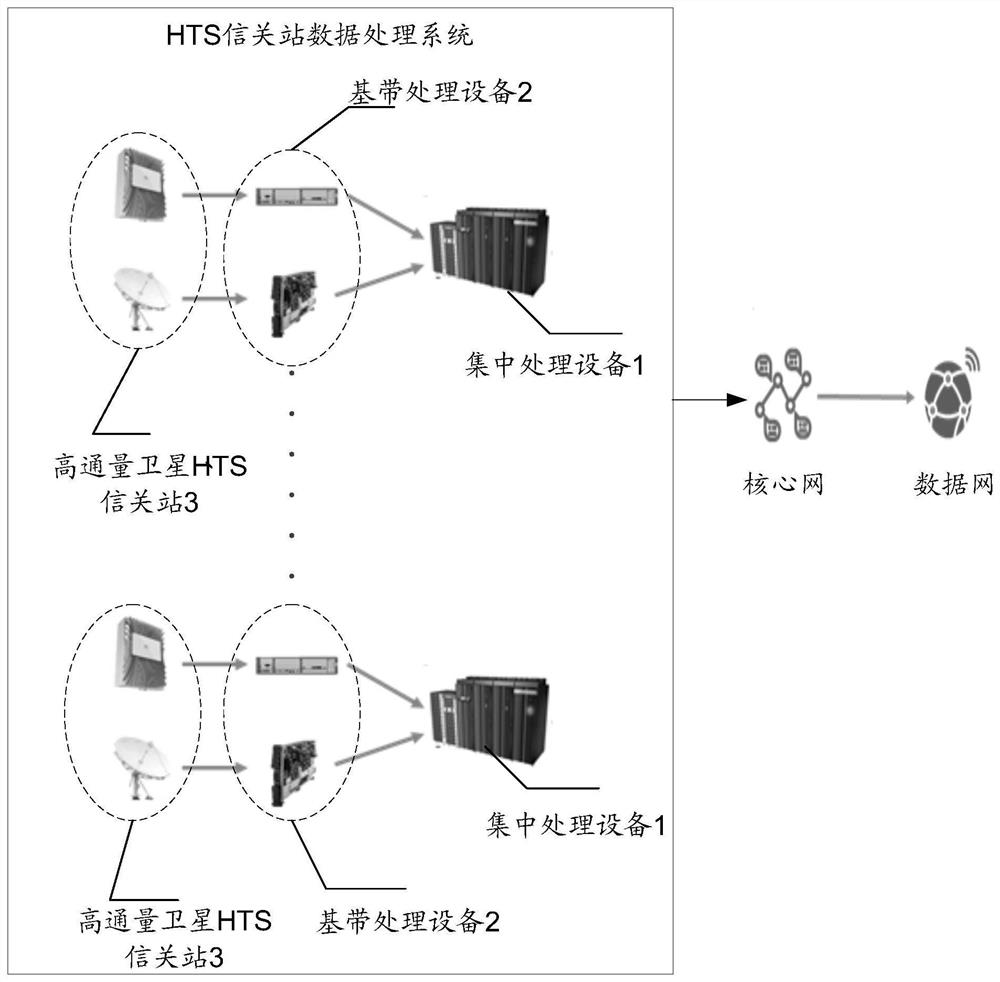

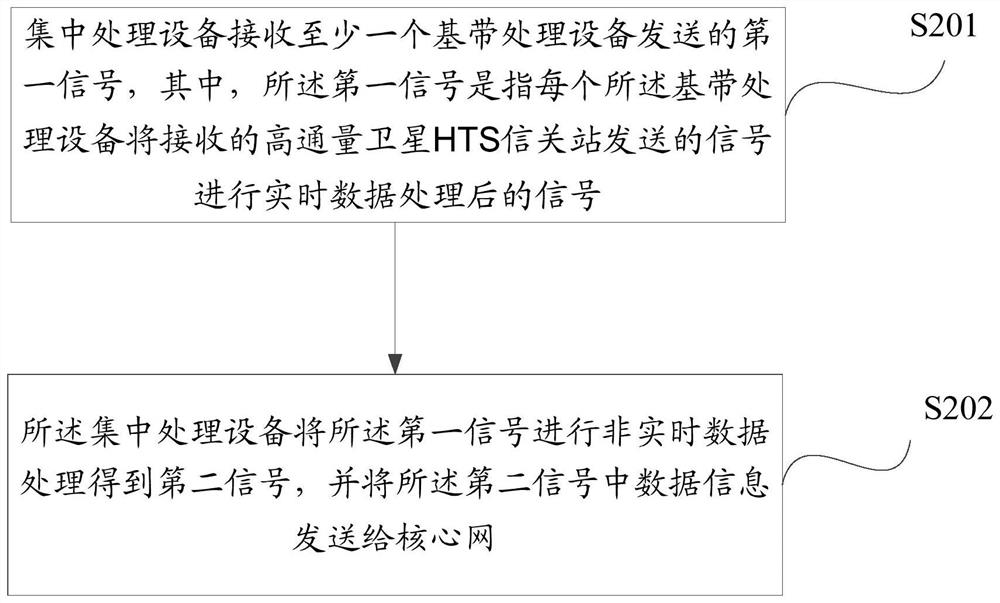

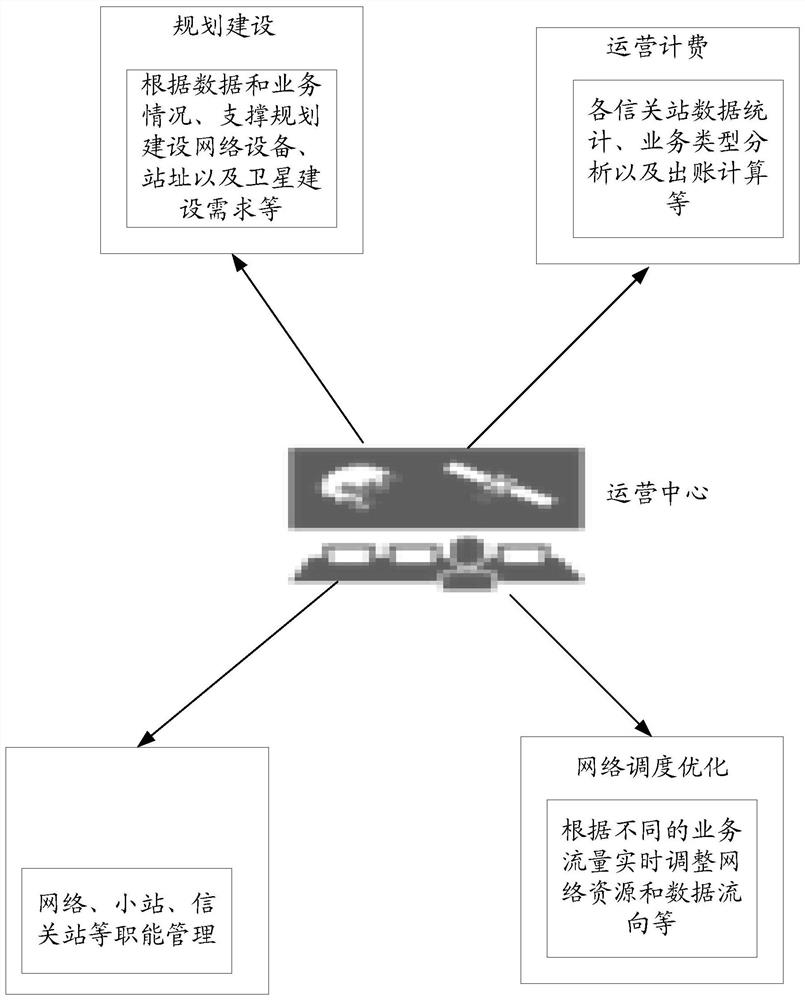

HTS gateway station data processing method and system based on 5G heterogeneous access architecture

ActiveCN112165351AInfluence network constructionImprove network performanceNetwork traffic/resource managementRadio transmissionEngineeringTime data

The invention discloses an HTS gateway station data processing method and system based on a 5G heterogeneous access architecture, and the method comprises the steps that centralized processing equipment receives a first signal transmitted by at least one piece of baseband processing equipment, wherein the first signal is a signal obtained after each piece of baseband processing equipment performsreal-time processing on a received signal in real time sent by a high-throughput satellite HTS gateway station; and the centralized processing equipment performs non-real-time data processing on the first signal to obtain a second signal, and sends data information in the second signal to a core network. According to the method, the technical problem of poor space-ground integrated network performance in the prior art is solved.

Owner:中国卫通集团股份有限公司

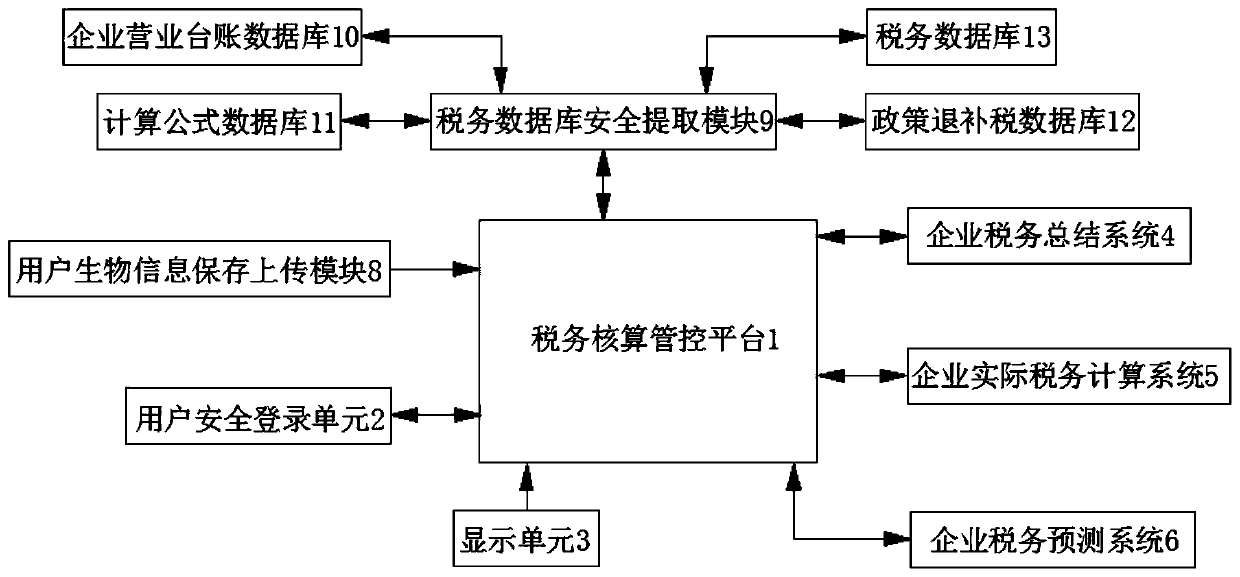

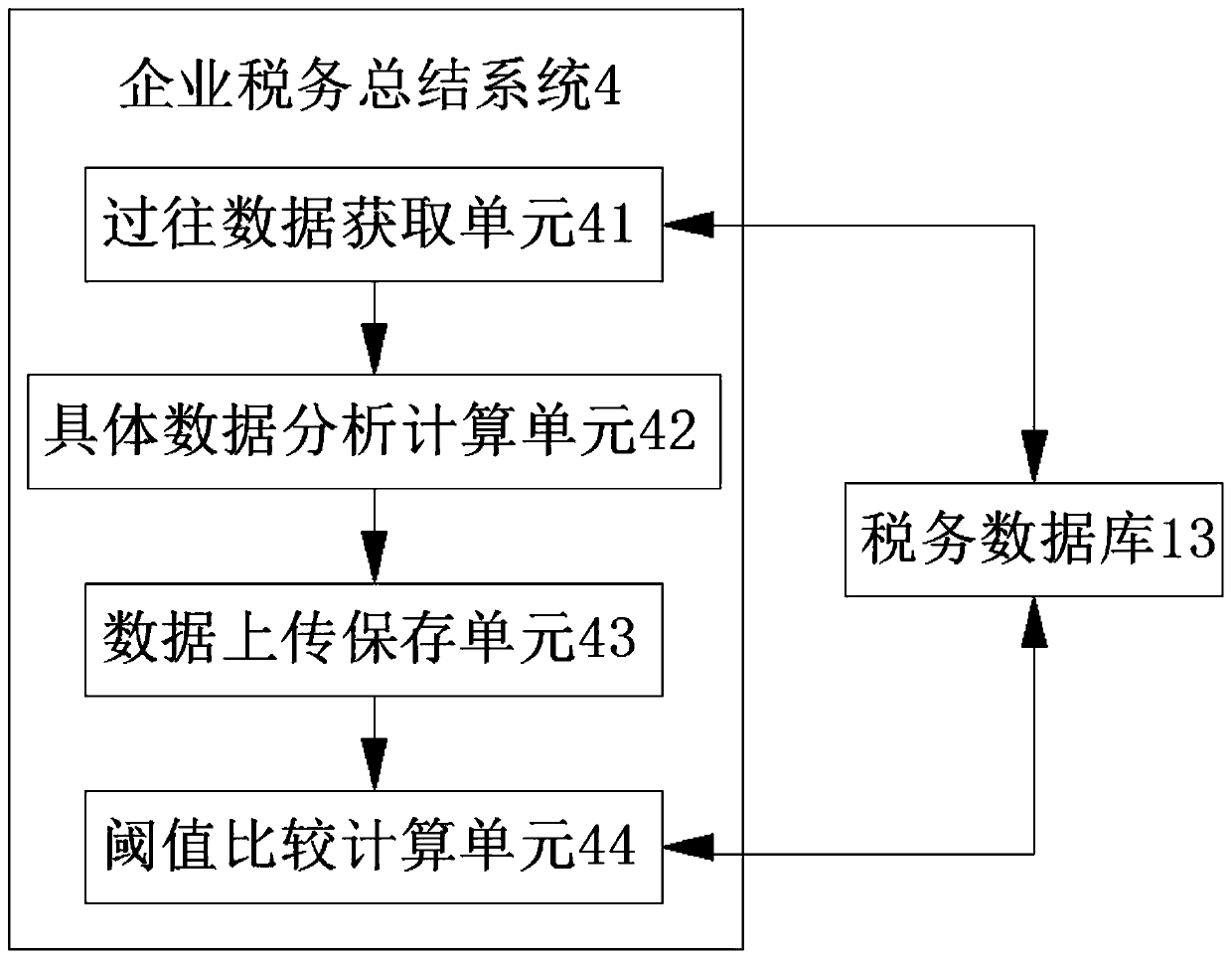

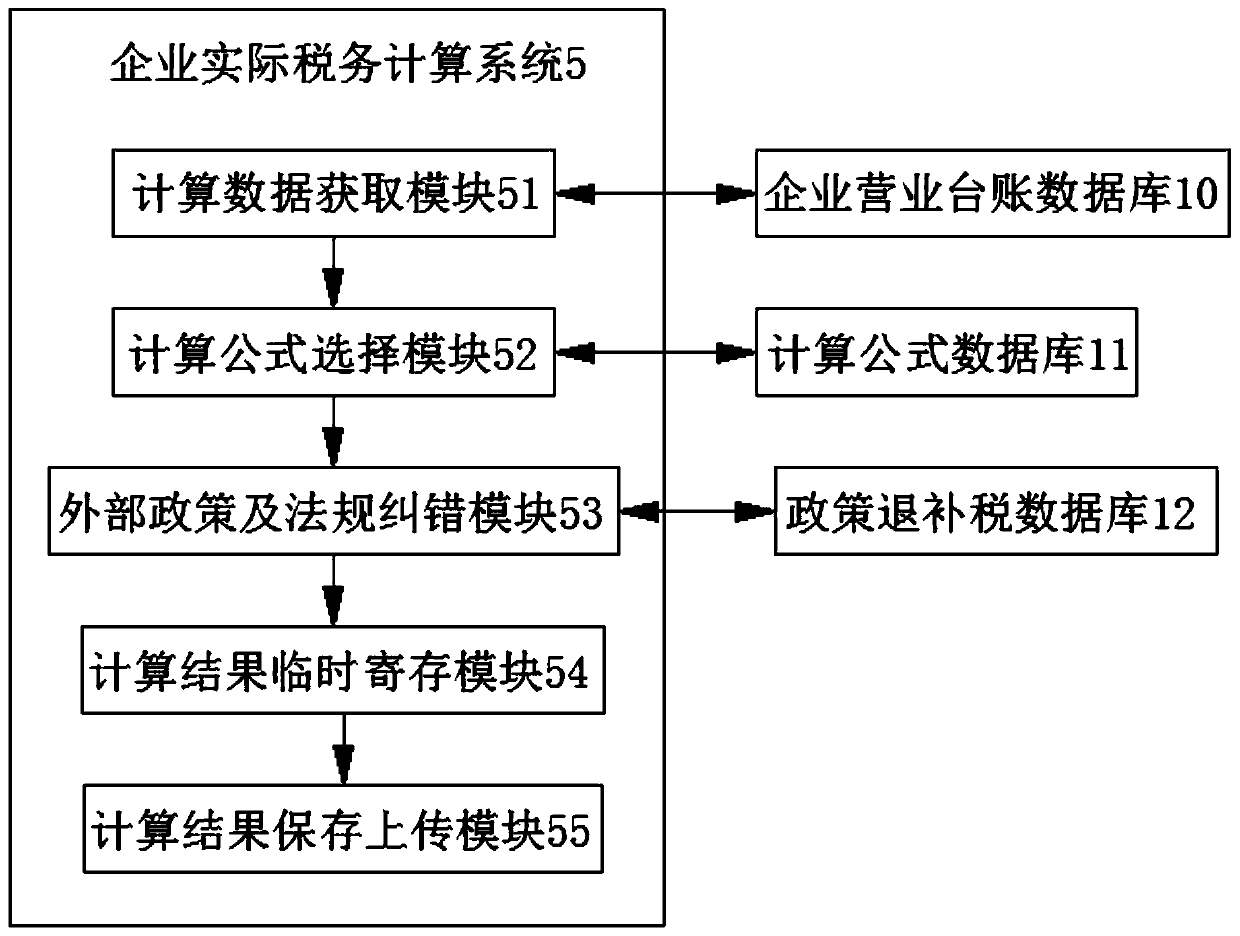

Tax accounting management and control platform

PendingCN110097439AImprove operational safetyAccurate understanding of tax burdenFinancePrediction systemComputing systems

The invention discloses a tax accounting management and control platform. The tax accounting management and control platform comprises a tax accounting management and control platform and a user security login unit, the tax accounting management and control platform is in bidirectional connection with the user security login unit; the output end of the tax accounting management and control platform is connected with the input end of the display unit, and the tax accounting management and control platform is respectively in bidirectional connection with the enterprise tax summary system, the enterprise actual tax calculation system and the enterprise tax prediction system. The invention relates to the field of tax accounting technology. According to the tax accounting management and controlplatform, the calculation formula selection module is combined with the policy refund tax supplement database and the calculation formula selection module, so that the actual tax system of the enterprise can accurately calculate the amount of tax paid under various actual production conditions and accurately know the tax burden of the enterprise, and the platform facilitates subsequent adjustmentof the production work target, and solves the problem that tax software can only be conveniently used by tax authorities and does not go deep into an enterprise operation layer.

Owner:武汉微麦互联网络科技有限公司

Finished product automatic packaging equipment for hair product production

The invention discloses finished product automatic packaging equipment for hair product production. The finished product automatic packaging equipment comprises a packaging box storage box, a finishedproduct storage box and a slide rail, wherein slide slots are formed in the two sides inside the packaging box storage box, and cut-off structures are arranged in the slide slots; the two sides of the right end of each cut-off structure are fixedly connected with telescopic poles, and springs sleeve the telescopic poles; a packaging box conveyor belt is arranged below the packaging box storage box; a front wheel of the packaging box conveyor belt is axially connected with a rotary shaft; the rotary shaft is fixedly equipped with a cam; a belt wheel of the packaging box conveyor belt is spacedwith a positive blocking claw and a negative blocking claw; the rear side of the packaging box conveyor belt is equipped with a dual-fan-shaped plate; a motor is mounted below the dual-fan-shaped plate; the right side of the dual-fan-shaped plate is fixedly equipped with a gear lever; and a packaging conveyor belt is arranged below the right side of the packaging box conveyor belt. The finished product automatic packaging equipment adopts an automatic single placing structure to replace the original sucking mechanism, ensures precise placing, saves labor power, and avoids the operation risk.

Owner:邵阳至泰发制品有限公司

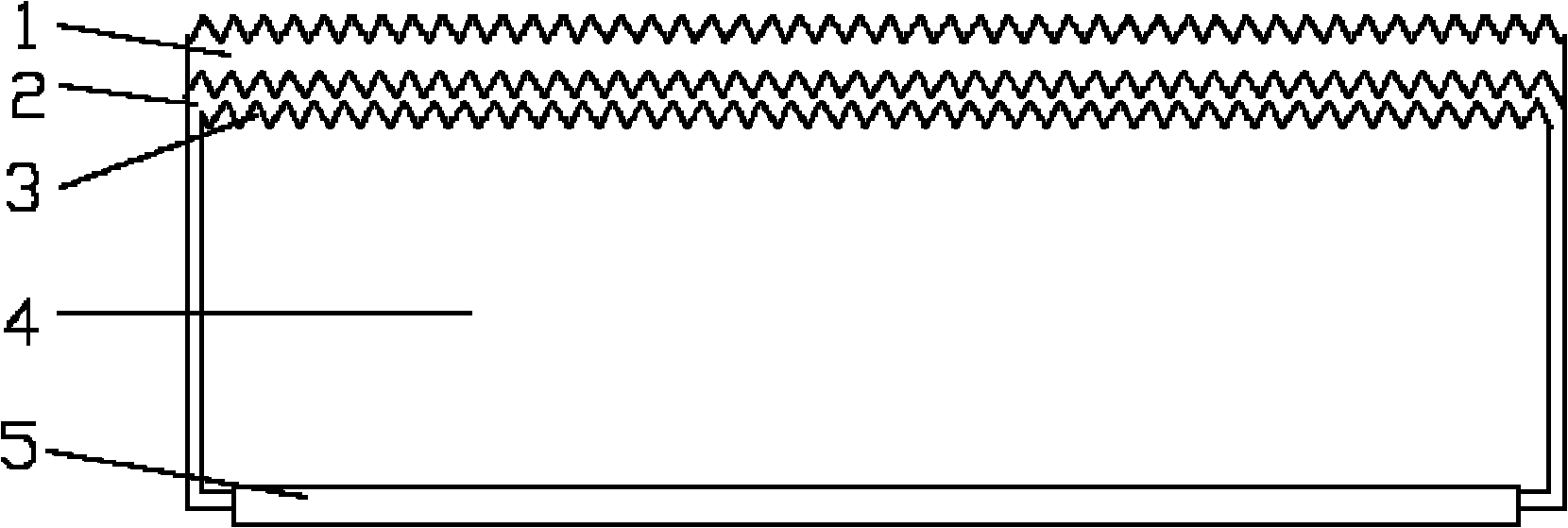

Production process of N-type back contact solar cell

InactiveCN102569518ARealize thermal diffusionReduce etchingFinal product manufactureSemiconductor devicesScreen printingSolar cell

The invention relates to a production process of an N-type back contact solar cell. The production process comprises the following steps of: flocking a silicon substrate so that a light reflective surface has a flock surface; oxidizing the silicon substrate; manufacturing a diffusion window on a back side of the silicon substrate; carrying out selective boron source thermal diffusion to enable the exposed silicon to be doped by boron to form a PN junction; removing an oxide layer and impurities; oxidizing the silicon substrate again; plating an anti-reflecting film on the light reflective surface of the silicon substrate; carrying out screen printing by using metal electrode paste; and sintering to obtain a metal electrode to finish the manufacturing of the cell. The production process disclosed by the invention is artful in concept, compatible with conventional industrial cell production and easy to realize industrial manufacturing; meanwhile, relative to the conventional solar cell, the N-type back contact solar cell manufactured by the production process disclosed by the invention has the advantages that: an etching step with higher cost is saved, and metal electrode screen printing is changed into a one-step screen printing from three-step metal electrode screen printing of the conventional solar cell. The production process disclosed by the invention is widely applied in the photovoltaic field and has favorable market prospect.

Owner:杨正刚

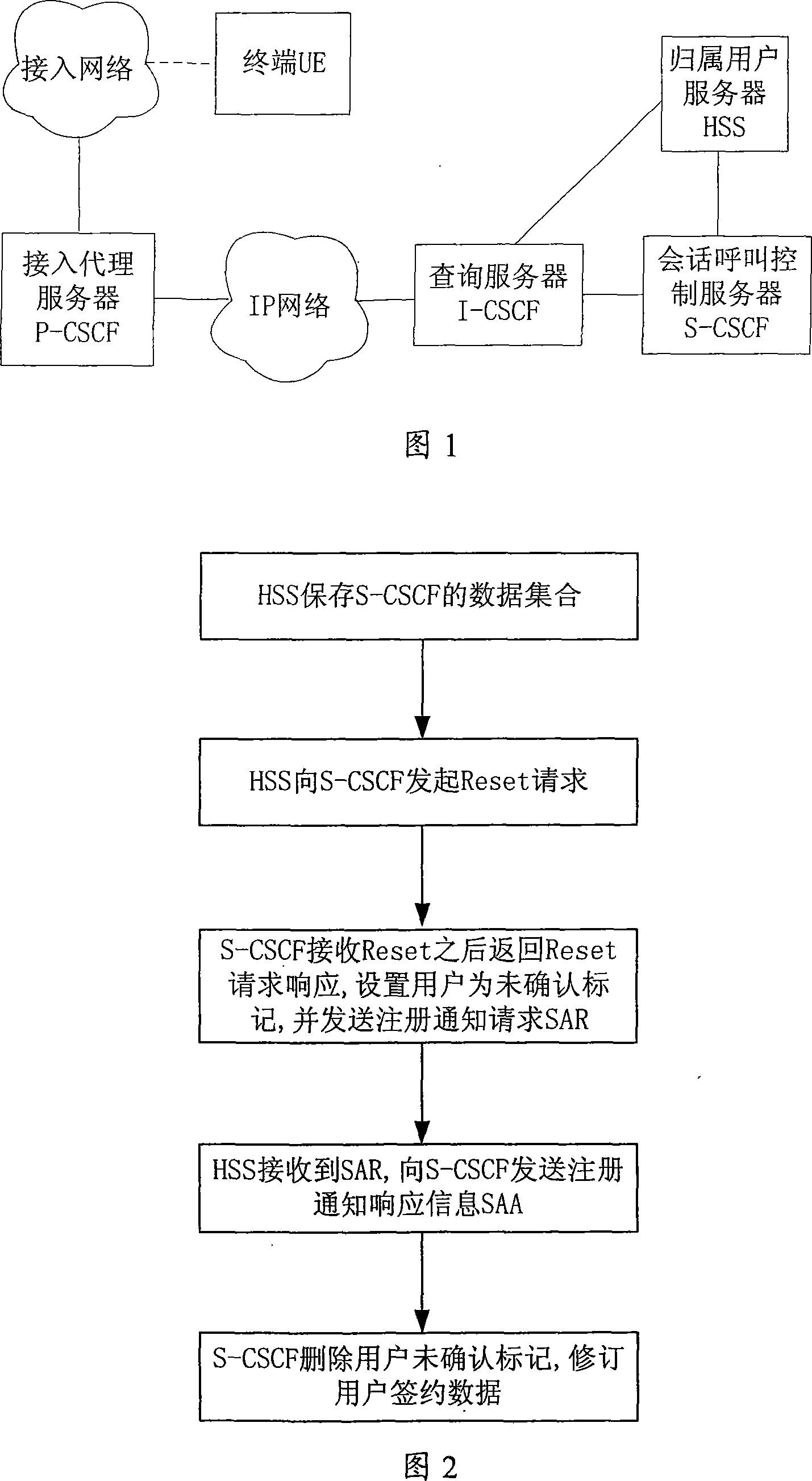

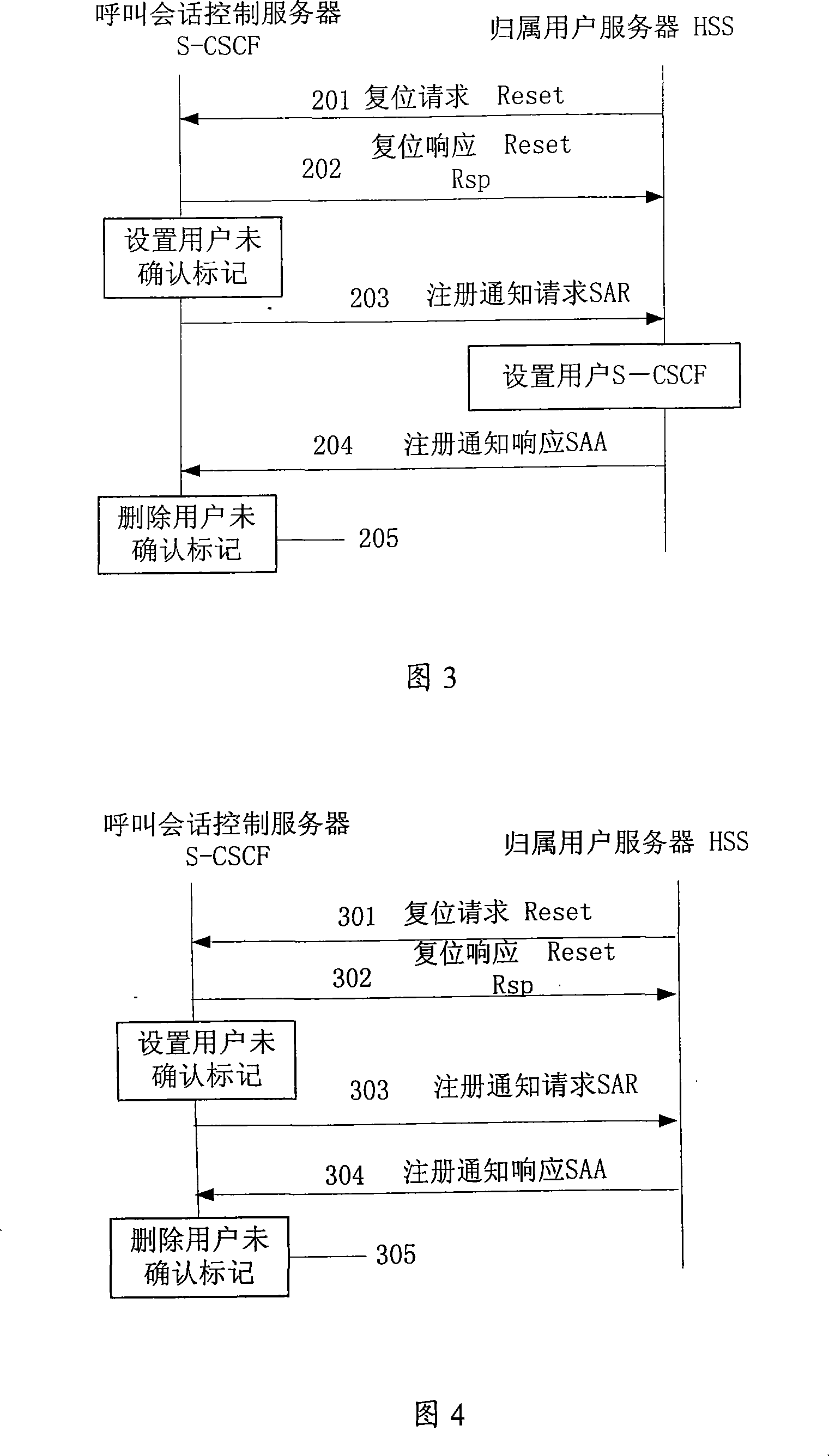

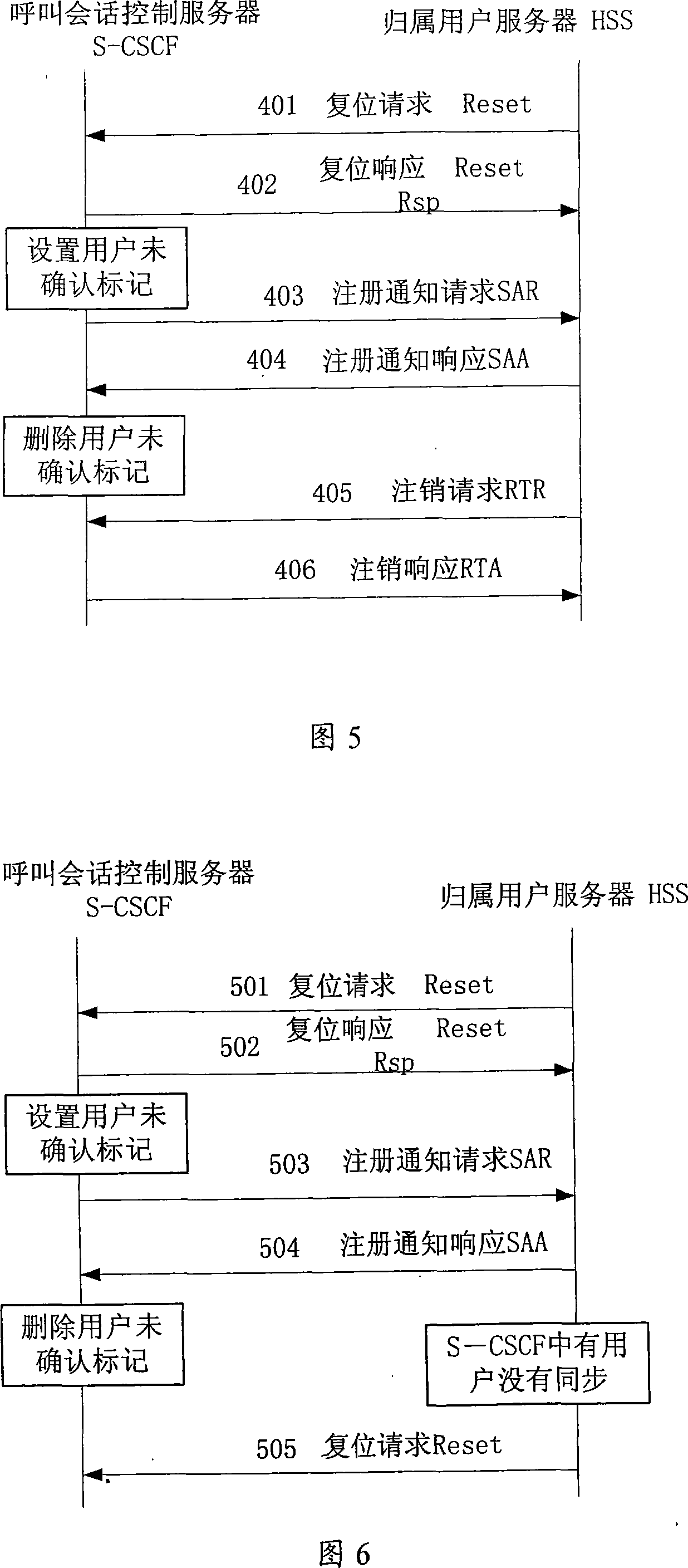

A method for realizing data consistency of home user server

InactiveCN101123480AMaintain stabilityReduce monitoring costsError preventionData switching networksSession controlComputer science

The present invention discloses a method realizing the data consistency of a home subscriber server. The method is divided into five steps. Firstly, a method realizes the data consistency of the homesubscriber server; secondly, the home subscriber server sends a reset request to a call session control server; thirdly, the call session control server returns a reset response and a registration notification request message to the home subscriber server; fourthly, the home subscriber server sends a registration notification response message to the call session control server; and fifthly, afterreceiving the registration notification response message, the call session control server revises the subscription data of user. Compared with the prior art, by applying the method, a home subscriberserver (HSS) can actively and efficiently detect and correct the abnormality of data, avoid the operation risk caused by the data inconsistency and maintain the stability of services; and meanwhile, the method provides a means of monitoring and correcting the HSS data consistency, reducing the monitoring cost and increasing the quality of management of operators.

Owner:ZTE CORP

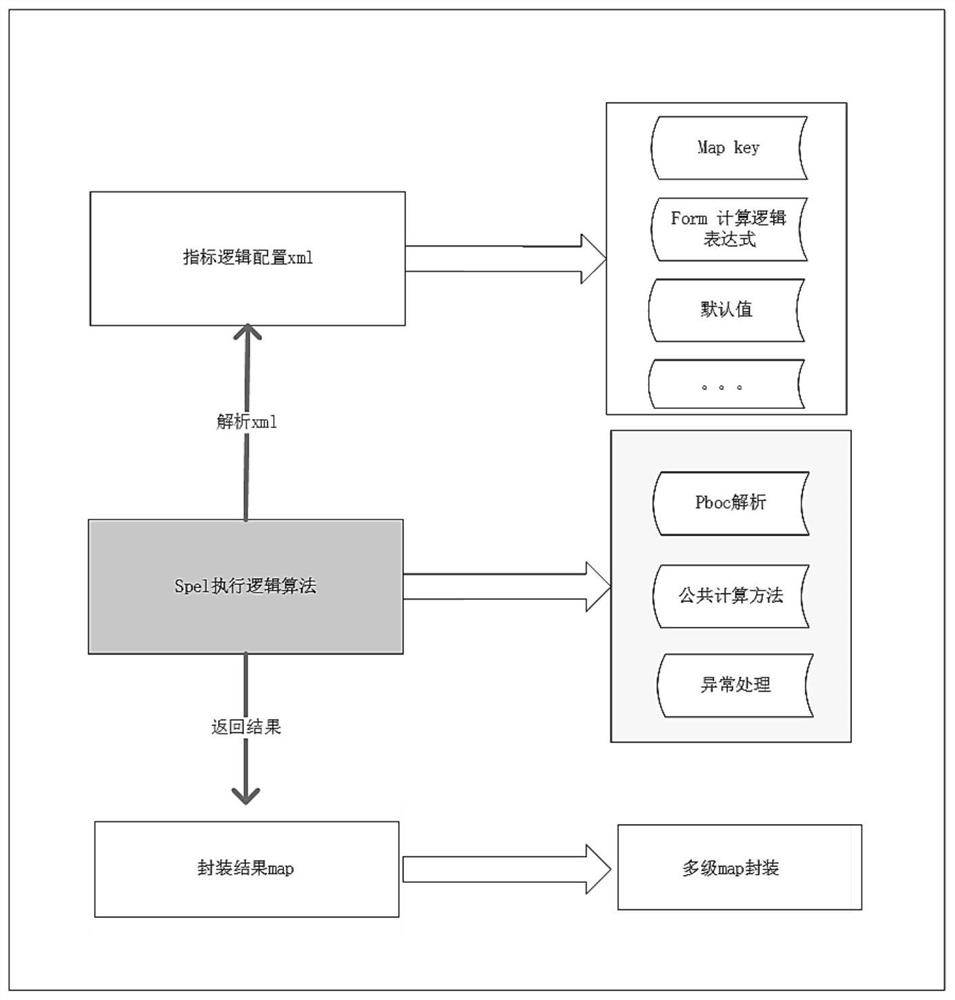

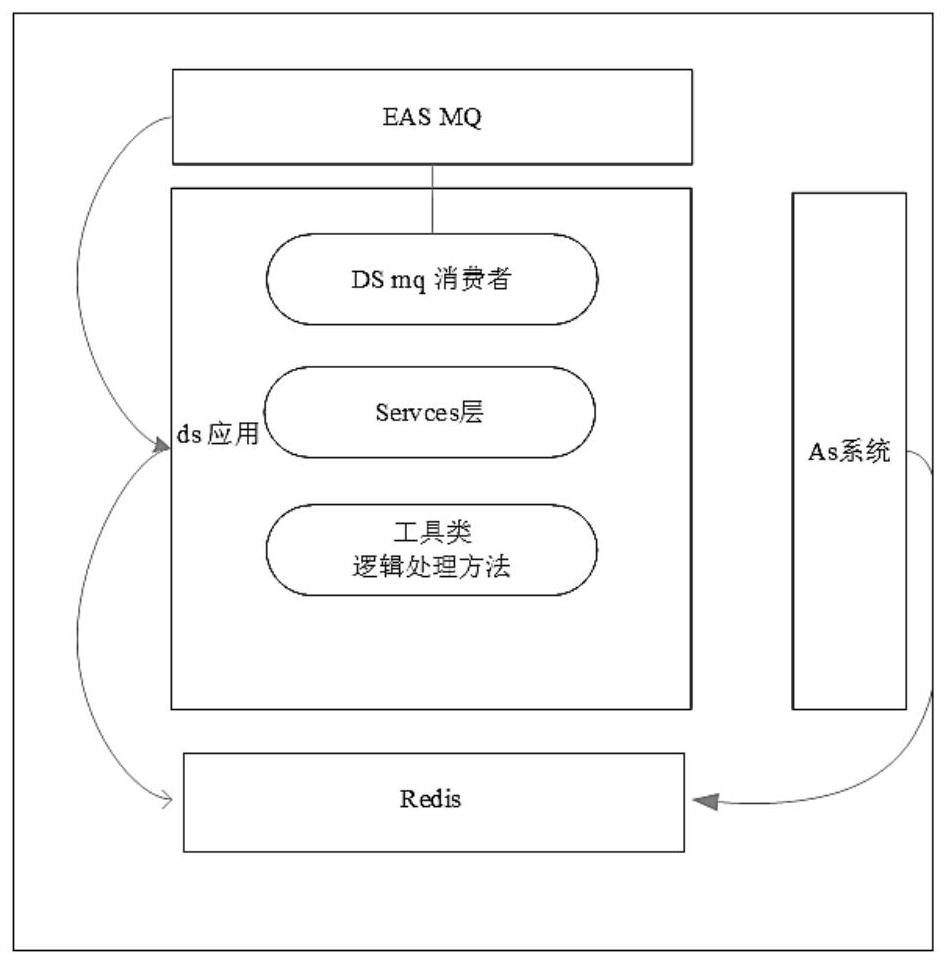

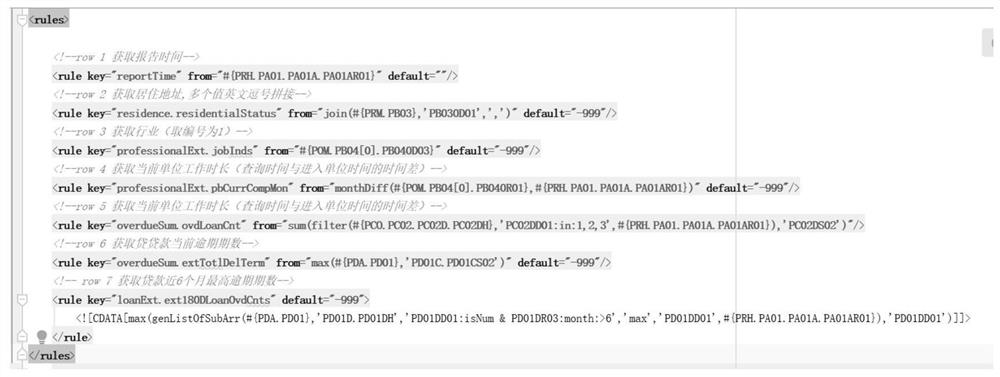

Credit investigation second-generation credit report derivative variable processing method

PendingCN112883689AEasy to processReduce developmentFinanceText processingComputational logicData mining

The invention discloses a credit investigation second-generation credit report derivative variable processing method, which comprises the following steps of: 1, analyzing and classifying a use scene of a credit investigation report derivative variable in an existing credit process based on a credit investigation report; 2, defining a common calculation logic fixed telephone as a standard calculation expression in combination with an in-stack technology; and 3, based on the standard calculation expression, configuring the processing logic of the derivative variables. Code development is reduced, developers only need to pay attention to implementation of business logic, if requirements are changed, general logic only needs to modify configuration of an xml expression needs, the accuracy and preciseness of index calculation are guaranteed, operation risks are avoided, if variables with complex logic cannot be output through configuration, the calculation expression can be self-defined, an existing expression library is expanded, and subsequent derivative variable processing is facilitated.

Owner:SUNING CONSUMER FINANCE CO LTD

Manual and electric switching type double-terminal change-over switch

PendingCN110783119ASimple processCompact structureMake-before-break contact arrangementControl cellTransfer switch

The invention relates to the control switch technology field and especially relates to a manual and electric switching type double-terminal change-over switch. The switch comprises a pedestal, a leftplectrum, a right plectrum and a driving mechanism, wherein the left plectrum and the right plectrum are slidably arranged on the pedestal, and the driving mechanism is used for driving the left plectrum and the right plectrum to move. The driving mechanism comprises a rotating driver, a cam disc rotatably arranged on the pedestal, a left driving component used for driving the left plectrum to move, a right driving component used for driving the right plectrum to move, a control unit electrically connected with the rotating driver, a starting piece used for starting and stopping the control unit, and a control component used for driving the starting piece to ascend and descend. The control unit is used for making the rotating driver be started and stopped, and an output shaft of the rotating driver is used for driving the control component and the cam disc to rotate synchronously. Manual control and electric control are integrated, manual and electric switching is convenient, an operation process is simplified, operation efficiency is improved, a manual state and an electric state are interlocked, and operation safety performance is improved.

Owner:DONGGUAN JIYE ELECTRICAL EQUIP CO LTD

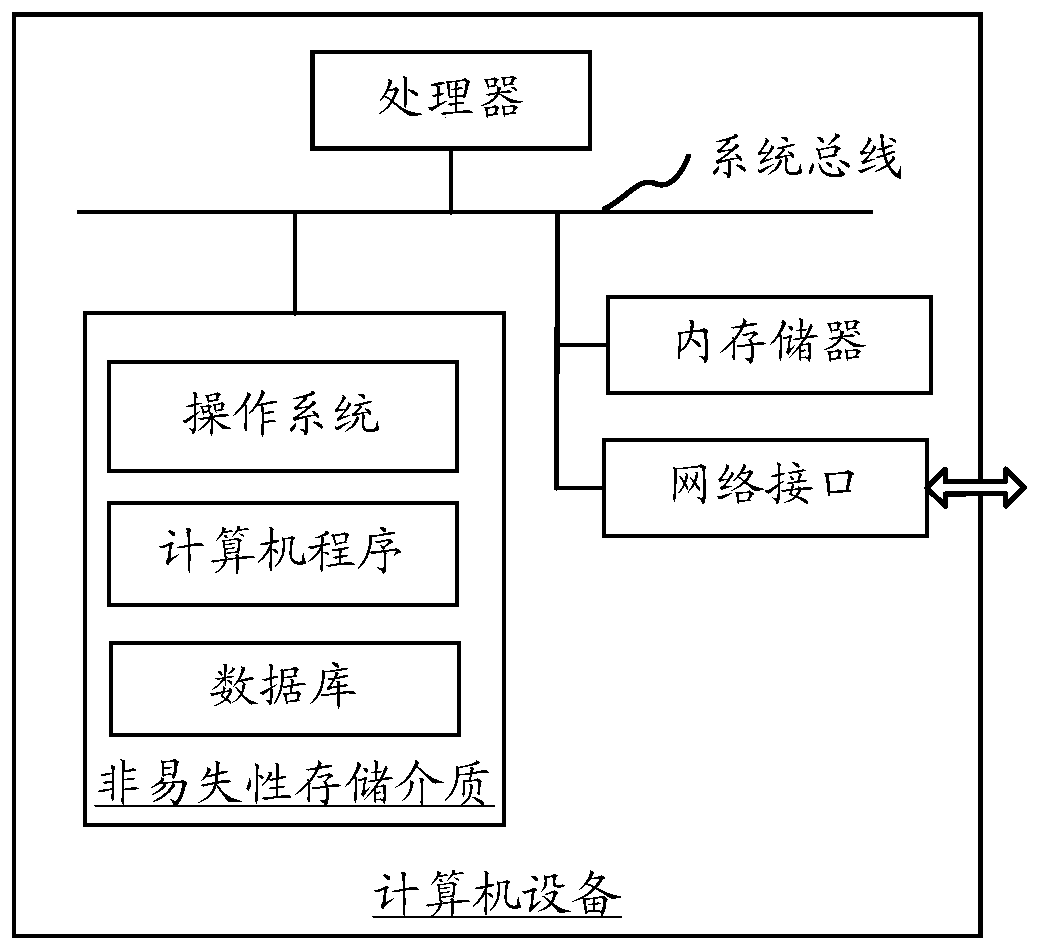

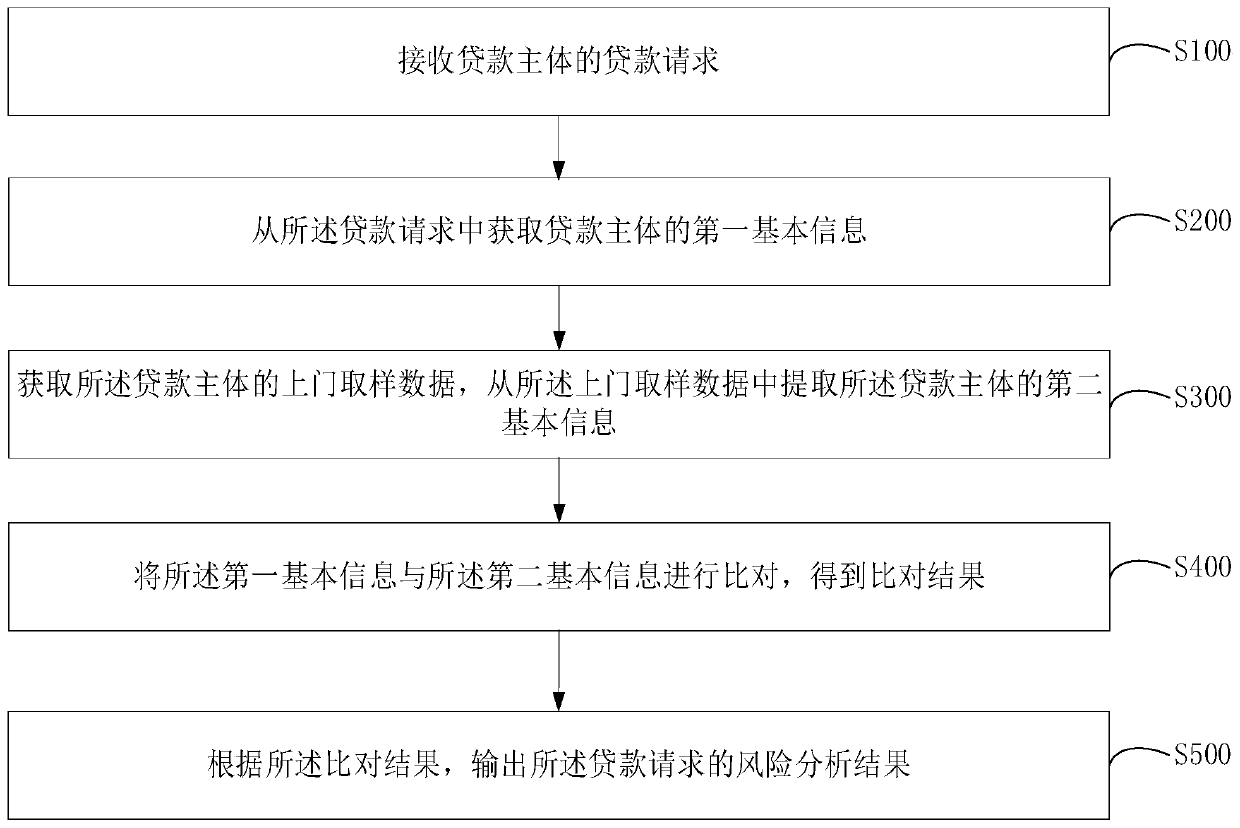

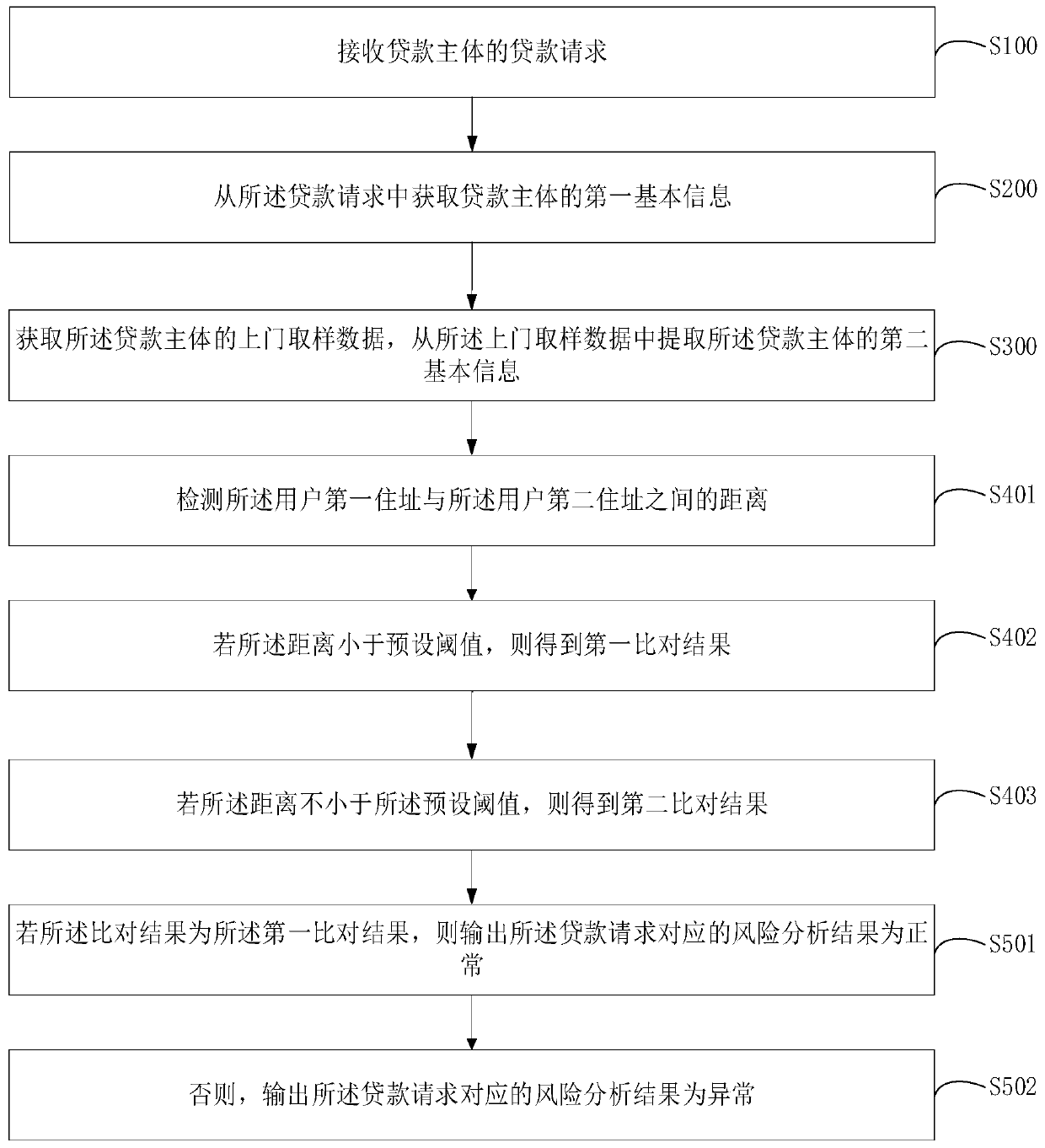

Loan risk analysis method and device, computer device and readable storage medium

PendingCN110458694AConducive to controlling credit riskAvoid operational riskFinanceBusiness PersonnelRisk profiling

The invention relates to a loan risk analysis method and device, a computer device and a readable storage medium. The method comprises the following steps: receiving a loan request of a loan subject;obtaining first basic information of a loan subject from the loan request; obtaining door-to-door sampling data of the loan subject, and extracting second basic information of the loan subject from the door-to-door sampling data; wherein the physical meanings represented by the first basic information and the second basic information are the same; comparing the first basic information with the second basic information to obtain a comparison result; and outputting a risk analysis result of the loan request according to the comparison result. By adopting the method, the operation risk caused bythe fact that business personnel manually verify the basic information of the loan main body can be avoided, and the credit risk of a credit institution can be controlled.

Owner:浙江大搜车软件技术有限公司

Foreign trade service system

PendingCN109685512AMeet needsReduce loss rateBuying/selling/leasing transactionsProtocol authorisationPaymentPattern recognition

The invention discloses a foreign trade service system which comprises a management system, a return point cleaning system, a safety verification module and a payment rejection processing module. Thereturn point cleaning system comprises an acquisition module, a calculation module, a preprocessing module and a return point processing module. The payment rejection processing module comprises an initiating module, a receiving module, a processing module and an executing module; The safety verification module comprises a fingerprint recognition module, a voice recognition module, a face recognition module, an iris recognition module and a GPS positioning module.

Owner:宁波和丰科技服务有限公司

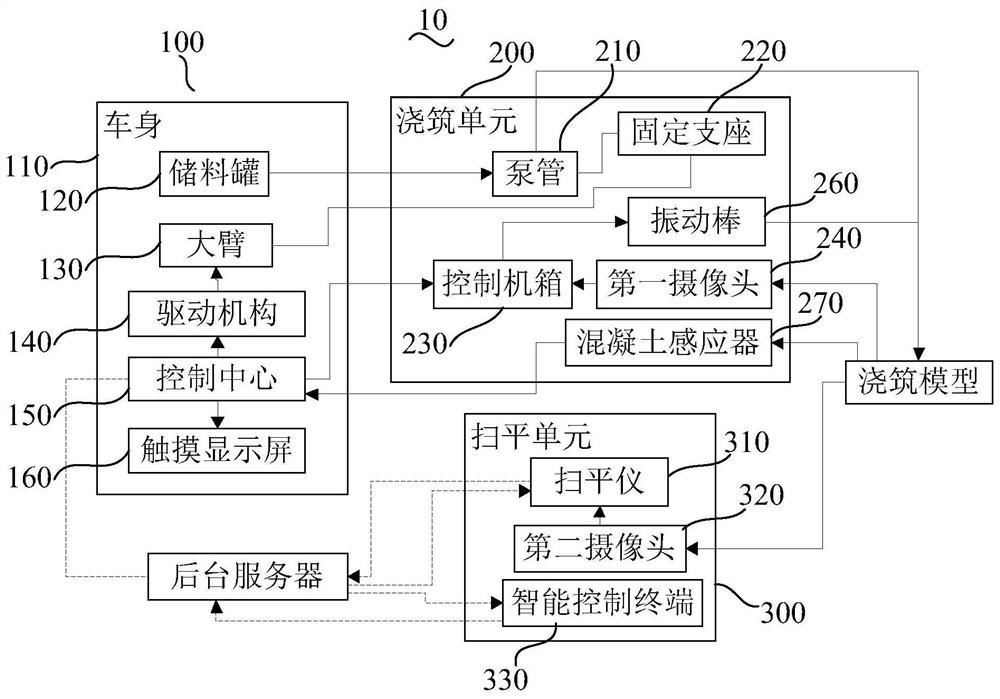

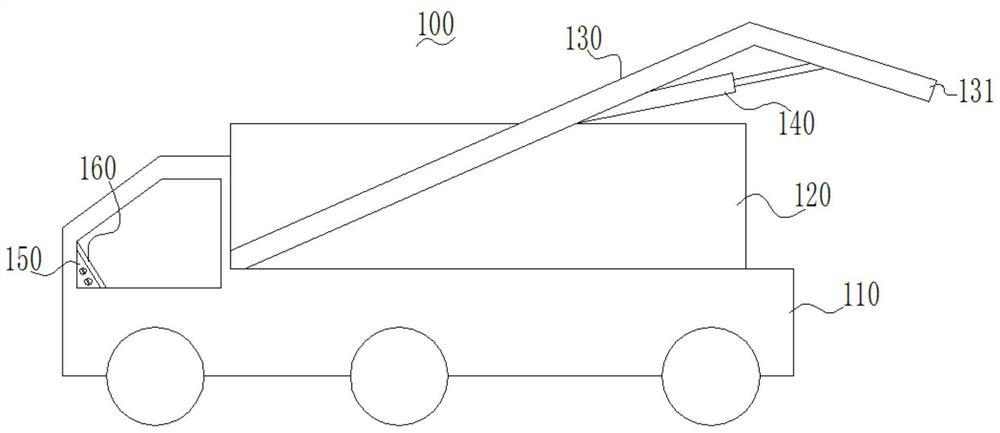

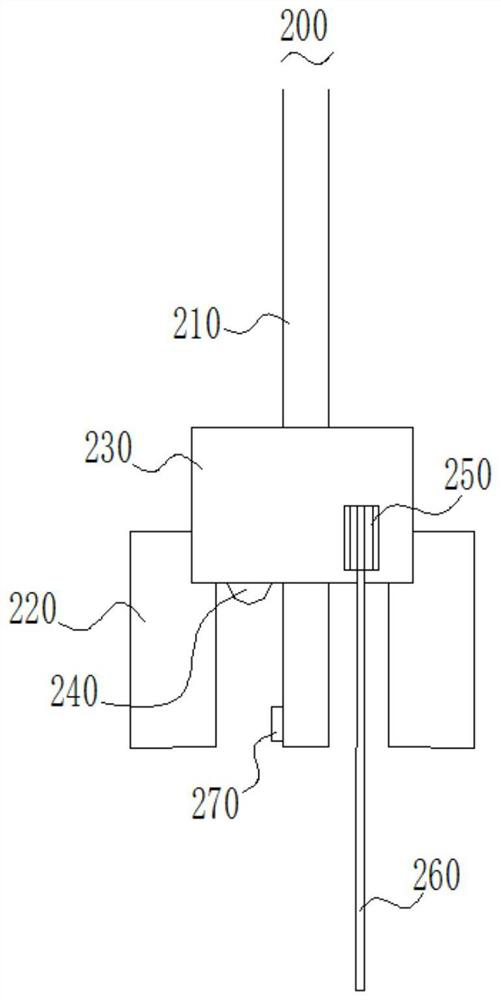

Full-automatic concrete delivery pump truck pouring system

PendingCN112663960AReduce labor costsAvoid operational riskTelevision system detailsColor television detailsTruckElectric machinery

The invention relates to the technical field of building construction, and particularly discloses a full-automatic concrete delivery pump truck pouring system. The full-automatic concrete delivery pump truck pouring system is low in labor cost, good in operation safety and high in operation efficiency and comprises a pump truck body, a pouring unit and a leveling unit. The pouring unit comprises a pump pipe communicating with a storage tank of the pump truck body, a fixing support arranged on a pouring part of the pump truck body and used for fixing the pump pipe, a control case arranged on the fixing support and connected with a control center of the pump truck body, a first camera arranged at the bottom of the control case, a motor arranged in the control case and connected with the control center, a vibrating bar being in driving connection with the motor and a concrete sensor arranged on the side surface of a pump pipe ring. The control center is used for receiving image information collected by the first camera and sent by the control case, and receiving pouring qualification information sent by the concrete sensor and controlling a driving mechanism to act; and the leveling unit comprises a leveling instrument which is provided with a second camera and is used for finishing the concrete surface and an intelligent control terminal which is used for sending an instruction to the leveling instrument.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

Unlocking method of shared bicycle and system and device thereof

InactiveCN107221053APrevent password leakageAvoid operational riskIndividual entry/exit registersEmbedded systemSingle vehicle

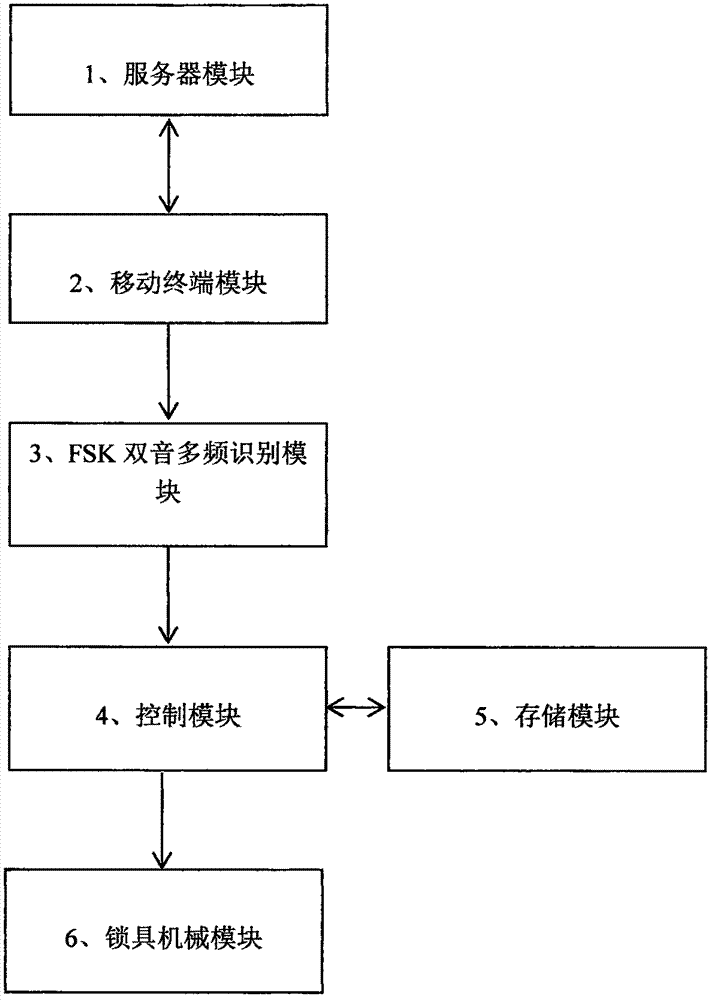

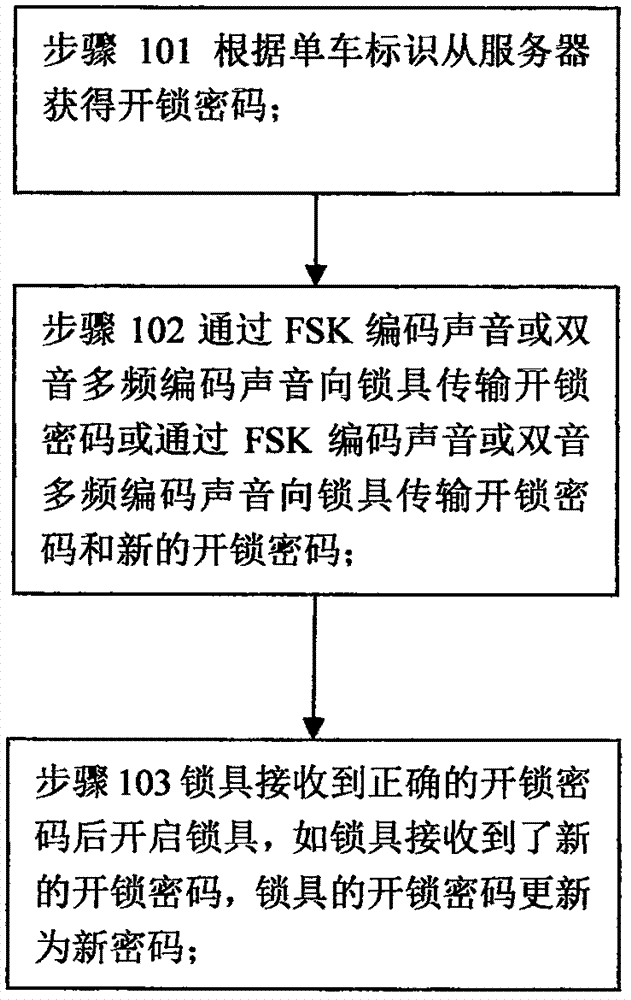

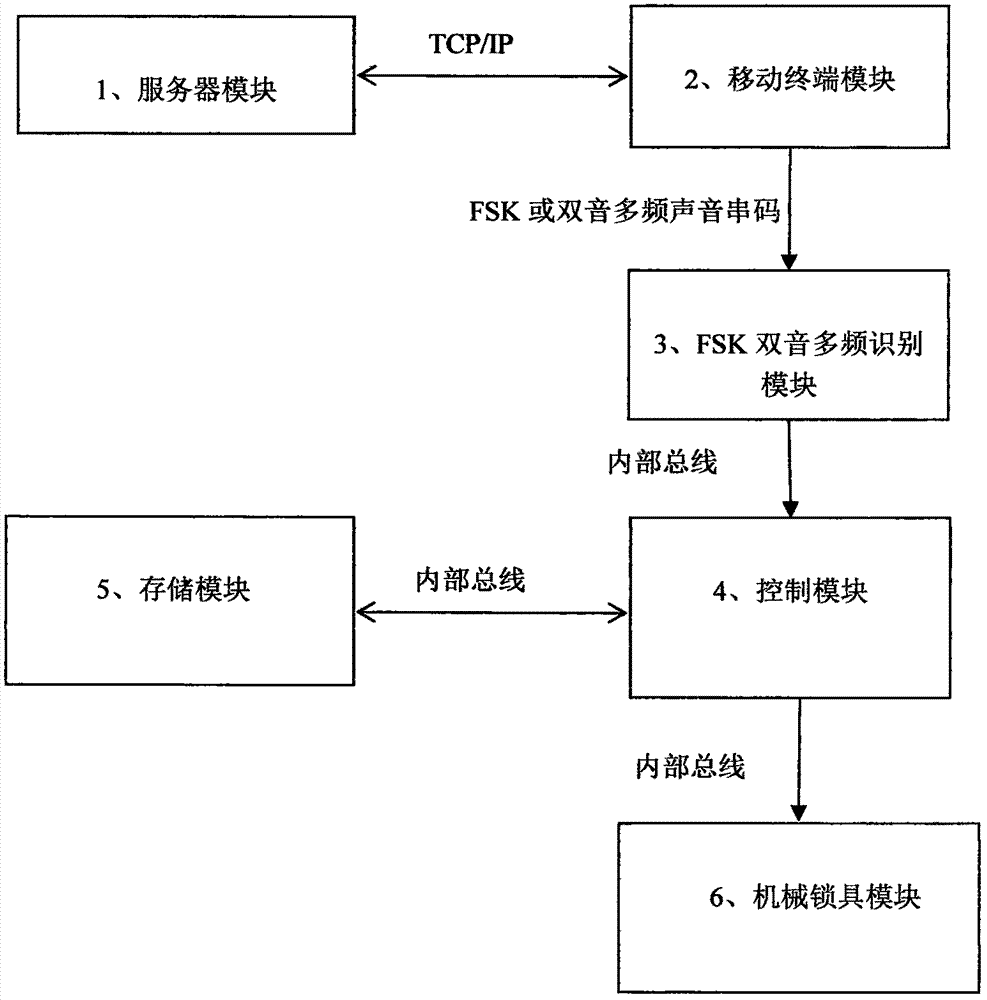

A lock system for shared bicycles, characterized in that it includes: a lock mechanical module, a control module, a storage module, an FSK dual-tone multi-frequency identification module, a mobile terminal module and a server module; the lock mechanical module is used to receive the control module instruction to complete the unlocking of the bicycle lock; the control module is used to judge whether the unlock password is correct, and controls the opening of the lock mechanical module; the storage module is used to store the unlock password of the lock; the FSK dual-tone multi- A frequency recognition module is used to receive the FSK or dual-tone multi-frequency sound string codes sent by the mobile terminal module, and identifies the password content contained in the FSK or dual-tone multi-frequency sound string codes; the mobile terminal module is used to request to the server Unlock password, and send FSK or DTMF sound string code to FSK dual-tone multi-frequency identification module; Described server module is used for pushing the unlock password to mobile terminal module according to the unlocking request of mobile terminal module.

Owner:张磊 +1

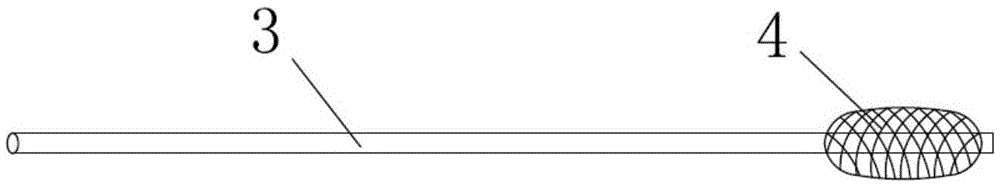

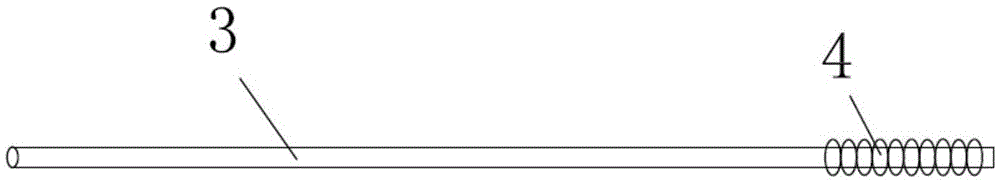

Anchoring micro-catheter capable of accurately puncturing intracoronary complete occlusion lesion

InactiveCN106308892AReduce the difficulty of surgeryImprove the success rate of surgeryCannulasSurgical needlesAlloyCatheter

The invention relates to the technical field of clinical medicine cardiovascular medicine interventional therapy surgical instruments, in particular to an anchoring micro-catheter capable of accurately puncturing an intracoronary complete occlusion lesion. The anchoring micro-catheter capable of accurately puncturing the intracoronary complete occlusion lesion comprises an inner tube which is arranged inside an outer tube, wherein the length of the inner tube is greater than that of the outer tube; the inner tube is provided with a positioning and orienting device; the positioning and orienting device is a silk-woven mesh cage arranged at the working end of an inner tube in a sleeving way; the silk-woven is made of a memory alloy. By adopting the anchoring micro-catheter, a chronic complete occlusion lesion can be successfully opened by a forward strategy, the operation difficulty is lowered, the operation success rate is increased, the operation time is shortened, various corresponding expenses are reduced, radioactive ray dosage is lowered for doctors and patients, the intra-operative operation risk is avoided, a standardized operational program is built, and the operation quality can be ensured.

Owner:祝金明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com