Balance weight loading device and loading method thereof

A counterweight device and counterweight technology, which is applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve problems such as reduced work efficiency, increased test costs, and limited application range of loading test methods. Achieve convenient operation, reduce material and labor costs, and increase load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

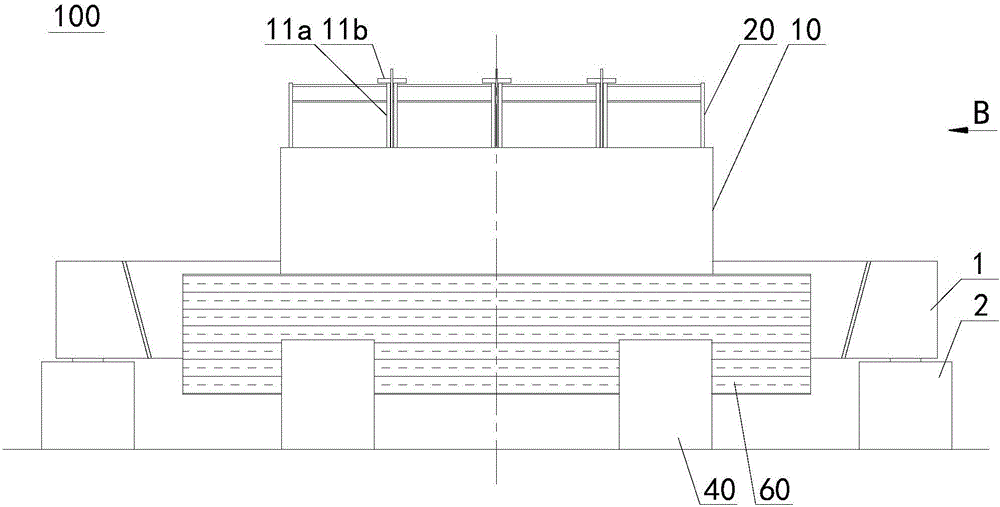

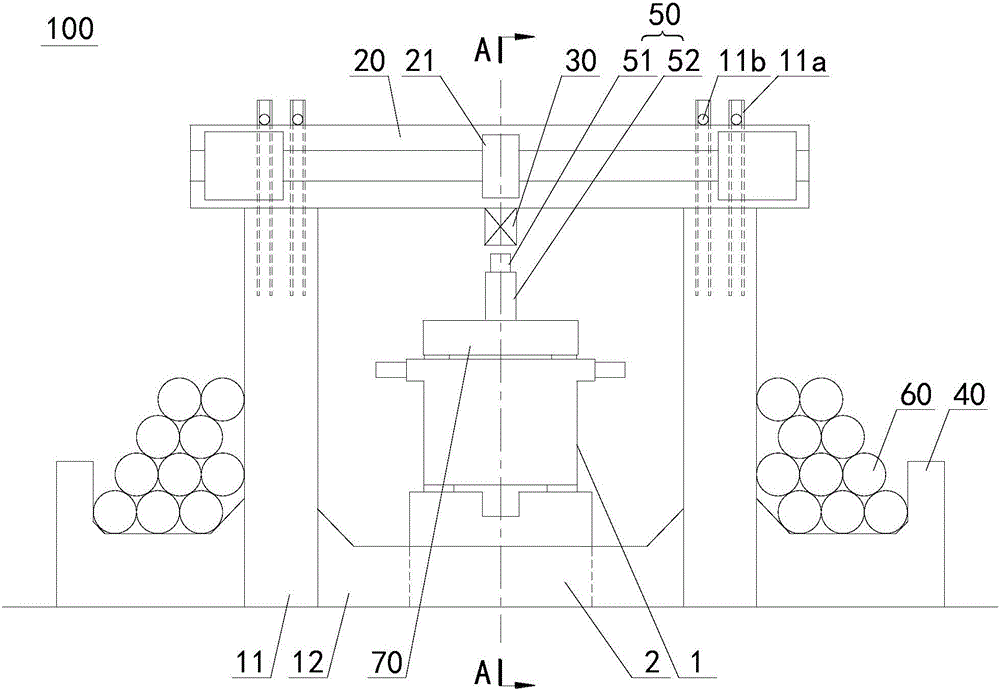

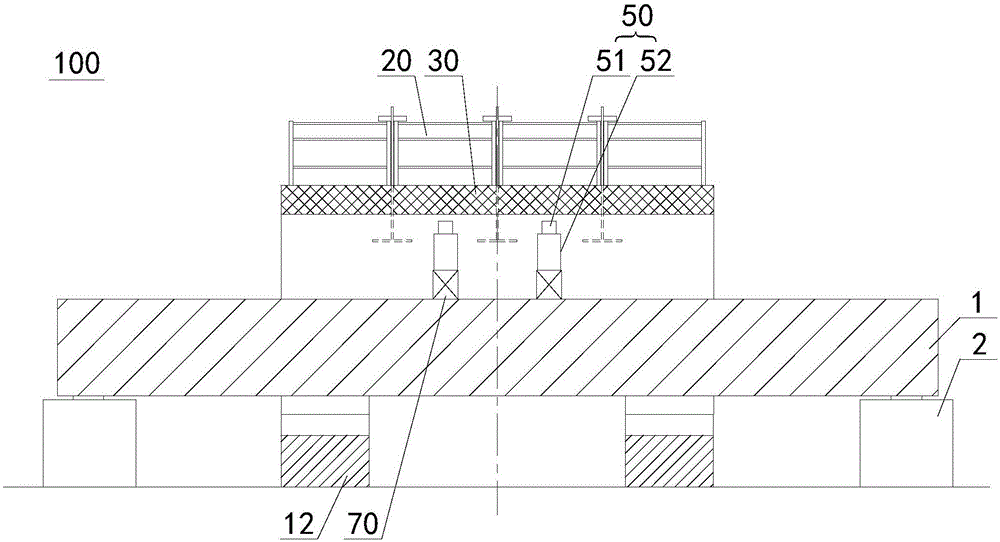

[0028] Example 1: Combining Figure 1 to Figure 3 Illustrate that the loading counterweight device 100 of the present invention is used to carry out the loading test on the test beam 1 placed horizontally on the pier 2 at both ends, and the above-mentioned loading counterweight device 100 includes a reinforced concrete reaction force frame 10, which consists of vertical and A pair of columns 11 oppositely arranged, some tie beams 12 connected to the bottom of the columns 11, spanning and affixed to the code beam 20 at the top of a pair of columns 11, and fixed at the bottom of the code beam 20 and connected to the column 11 parallel auxiliary beams 30;

[0029] The above-mentioned loading counterweight device 100, the reinforced concrete reaction force frame 10 as the main structure is composed of a pair of columns 11 vertically and oppositely arranged and some tie beams 12 connected to the bottom of the columns 11 to form a U-shaped frame, the yard beam 20 and The auxiliary ...

Embodiment 2

[0035]Embodiment 2: Different from Embodiment 1, the loading counterweight device 100 of this embodiment also includes an anti-jacking device 50 resting on the top of the test beam 1. The above-mentioned anti-jacking device 50 includes a jack 52 and is installed on the top of the jack 52. The pressure sensor 51. Lift the jack 52 to tighten the auxiliary beam 30, and then realize the loading on the test beam 1. In this embodiment, both the jack 52 and the pressure sensor 51 can be purchased through commercial channels.

Embodiment 3

[0036] Example Three: Combining Figure 1 to Figure 3 Illustrate the loading method of the loading counterweight device of the present invention, concrete steps are as follows:

[0037] 1. Lift the test beam 1 and erect it on the pier 2 located on both sides of the test beam 1, and make the test beam 1 between the two columns 11 of the reinforced concrete frame 10;

[0038] 2. Place the reverse jacking device 50 between the test beam 1 and the auxiliary beam 30, and reserve a gap between the reverse jacking device 50 and the auxiliary beam 30;

[0039] Three, start the anti-jacking device 50, load the test beam 1 by the anti-jacking device 50, load the counterweight object 60 to the maximum load once or step by step on the corbel 40 on both sides of the column body 11, and record the corresponding load The data measured by the lower anti-jack device 50.

[0040] In the loading method of the above-mentioned loading counterweight device, at first the test beam 1 is erected bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com