LED flexible light bar glue dispensing tool and assembly method and application thereof

A technology of LED flexible light bar and dispensing, which is applied to the device and coating of the surface coating liquid, which can solve the problems of wasting semi-closed dispensing grooves, poor uniformity and stability, and easy spillage of glue , to prevent contamination of the operating platform, improve stability, and avoid spillage of rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

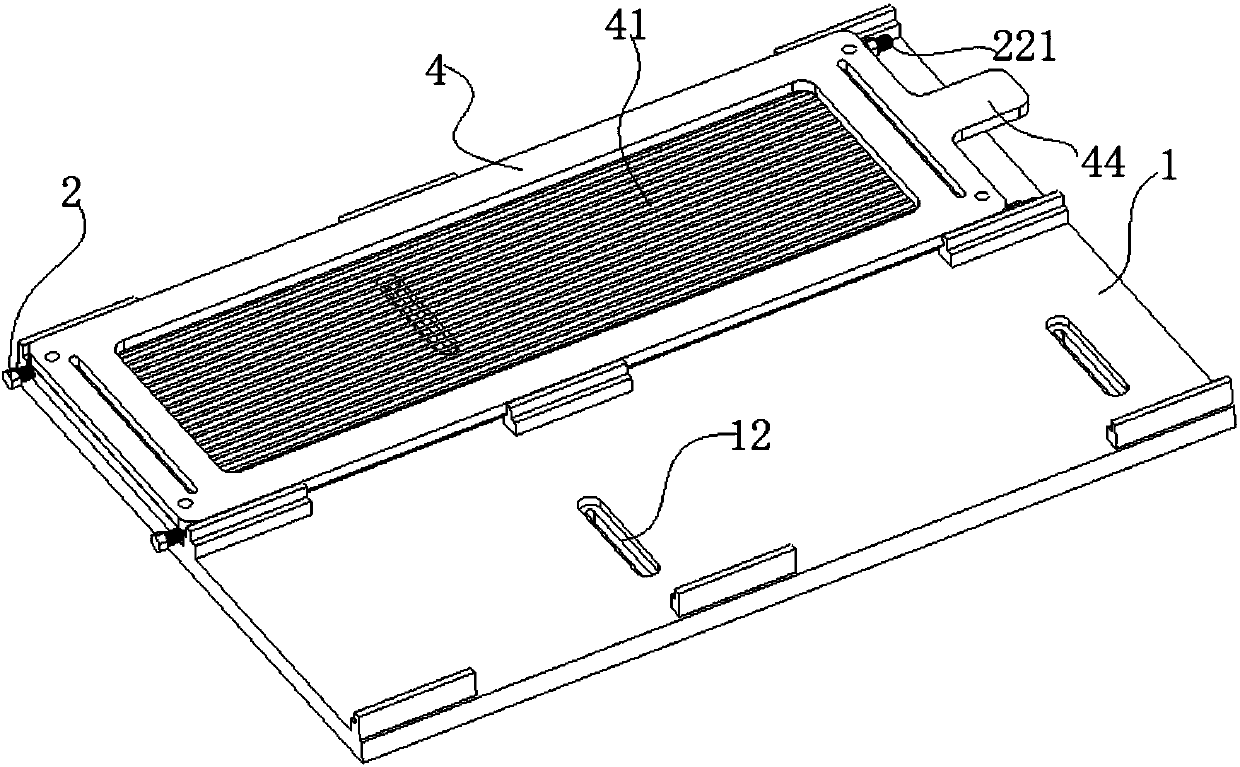

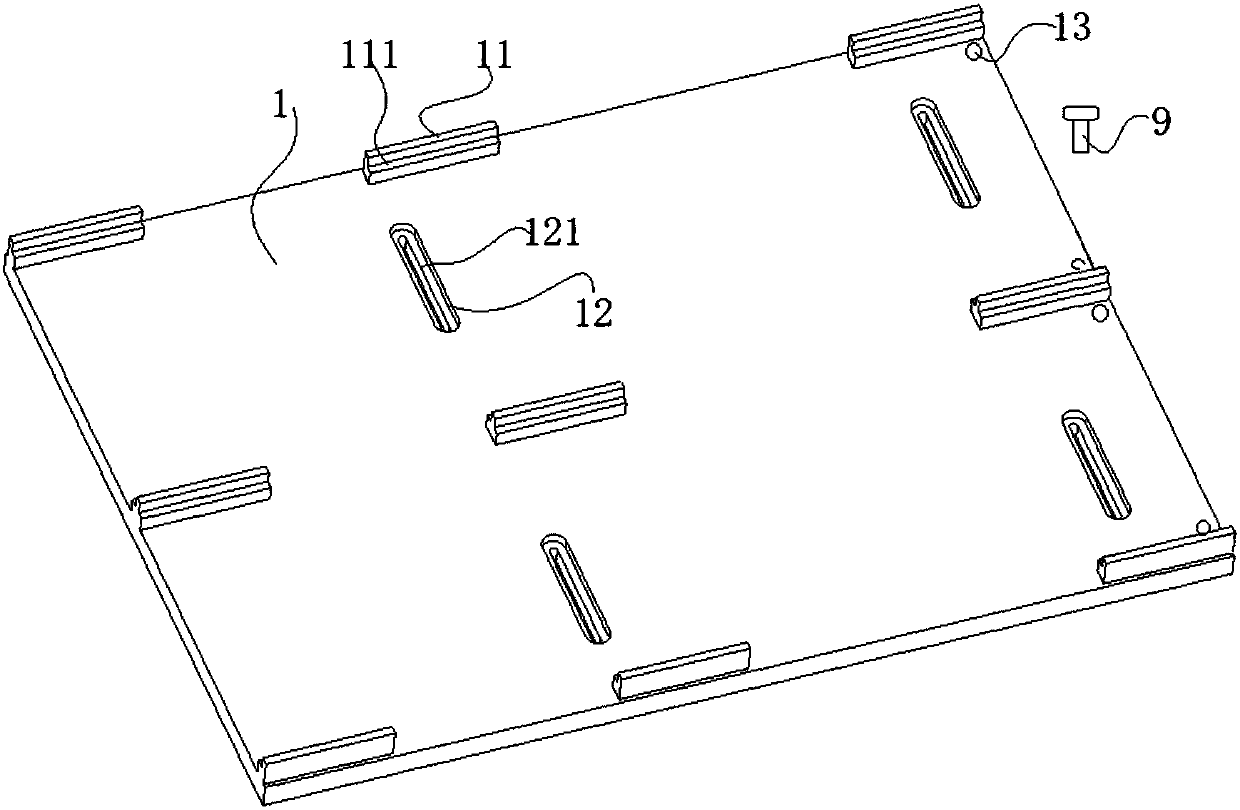

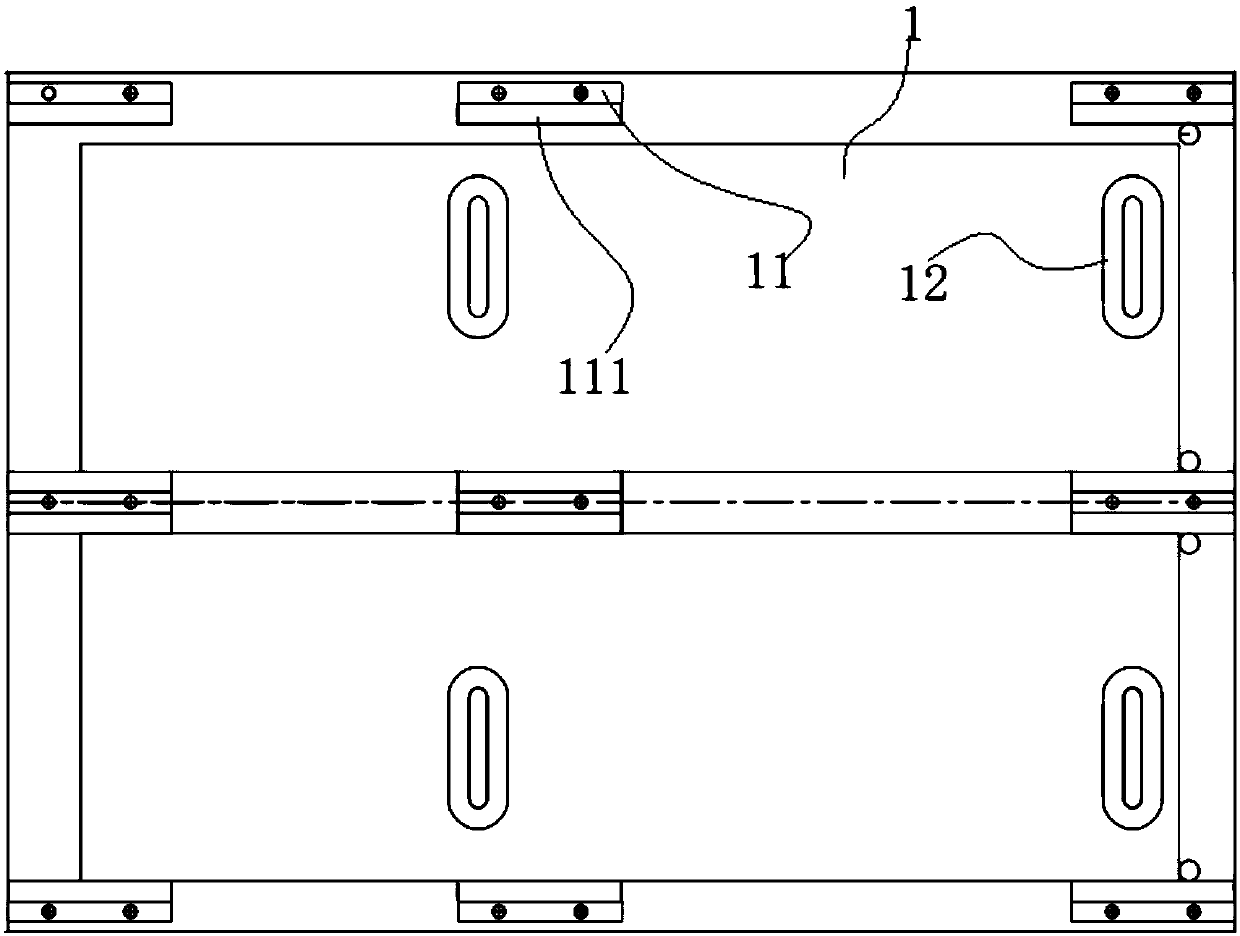

[0051] The LED flexible light strip dispensing tooling of this embodiment, such as figure 1 As shown, it includes a square plate-shaped bottom plate 1, a bracket 2 and a pressing plate 4 covering the bracket 2, wherein: as figure 2 , 3 As shown, the two sides of the two ends of the base plate 1 protrude with symmetrically distributed limiting platforms 11, and the inner side of the limiting platform 11 is a step-shaped limiting step 111; as Figure 6 As shown, the bracket 2 includes a fixed piece 23 and two square adjustment blocks 21 arranged parallel to each other, and the two side ends of the two adjustment blocks 21 are fixedly connected by two connecting rods 22; There are fixed columns 211 uniformly protruding from the upper surface; both ends of the LED flexible light bar row 10 are fixedly connected with the fixed piece 23; on the fixed column 211; the bracket 2 is fastened to the limit step 111 through the two sides of the adjustment block 21; as Figure 8 As show...

Embodiment 2

[0054] The basic structure of the LED flexible light bar dispensing tool of this embodiment is the same as that of Embodiment 1, the difference and improvement are that two symmetrically distributed limiting platforms 11 protrude from both ends and the middle of the bottom plate 1, A total of 6 limit platforms 11 are opposite to each other and arranged in parallel, which further improves the stability of the entire tooling; the connecting rod 22 is a screw, and the two side ends of the adjustment block 21 are pierced with screw holes 212, and the screw Set in cooperation with the screw hole 212, one end of the screw rod is sleeved with an adjusting nut 221, through the cooperation between the screw rod and the adjusting nut 221, it can be adaptively adjusted according to the length of the LED flexible light bar; the two long ends of the pressure plate 4 are square frames Limiting slots 42 are opened horizontally in each area, and the limiting slots 42 are arranged in cooperatio...

Embodiment 3

[0056] The basic structure of the LED flexible light strip dispensing tool of this embodiment is the same as that of Embodiment 2, the difference and improvement are: there are two bottom plates 1, which are combined into a whole flat plate to achieve the technical effect of alternate dispensing; There are several LED flexible light strips and bracket fixing holes 231 in the LED flexible light strip row 10, and there are also several corresponding fixing columns 211, so as to improve dispensing efficiency and further improve production efficiency; near the four corners of the pressure plate 4, The positioning hole 43 of the pressure plate is pierced downward, which is set in cooperation with the positioning hole 213 of the bracket, and the coordinated positioning improves the stable and uniform technical effect in the dispensing process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com