Vibrational finishing machining method for high-temperature alloy disc parts

A technology for disc parts and superalloys, applied in the field of vibrating finishing of superalloy disc parts, can solve the problems of poor surface integrity, large polishing workload, long cycle, etc., achieve low surface roughness value, solve surface quality problems Poor, uniform surface texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the drawings and embodiments, but the protection scope of the present invention is not limited by the drawings and embodiments.

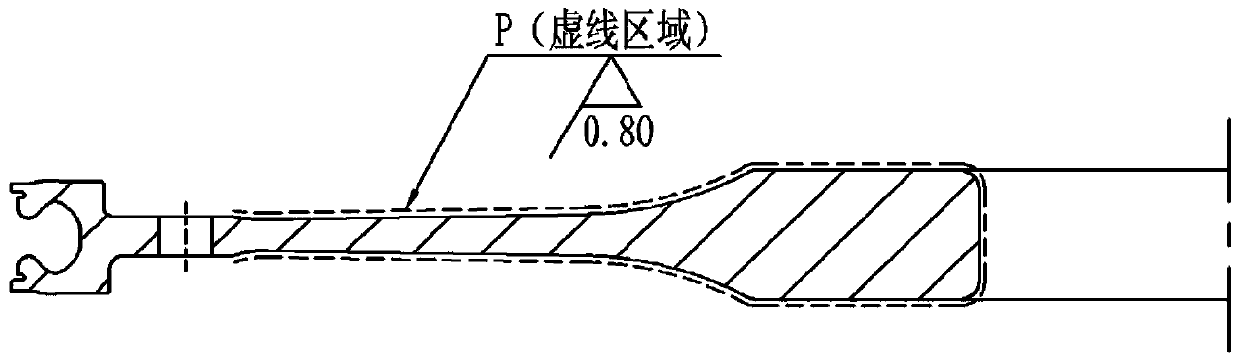

[0035] (1) Select the appropriate vibration finishing machine tool. Aeroengine superalloy disc parts, usually with a diameter of 400mm-700mm. figure 1 It is a schematic diagram of a high-temperature alloy compressor disk. As shown in the figure, the diameter of the compressor disk is 580mm, its volume is relatively large, and its overall quality is high. Therefore, a vibration finishing machine tool with parts fixed and clamped in the machine tool should be selected to only realize the contact between the abrasive and the parts, so as to avoid the tumbling and collision caused by the free movement of the parts, resulting in bump damage.

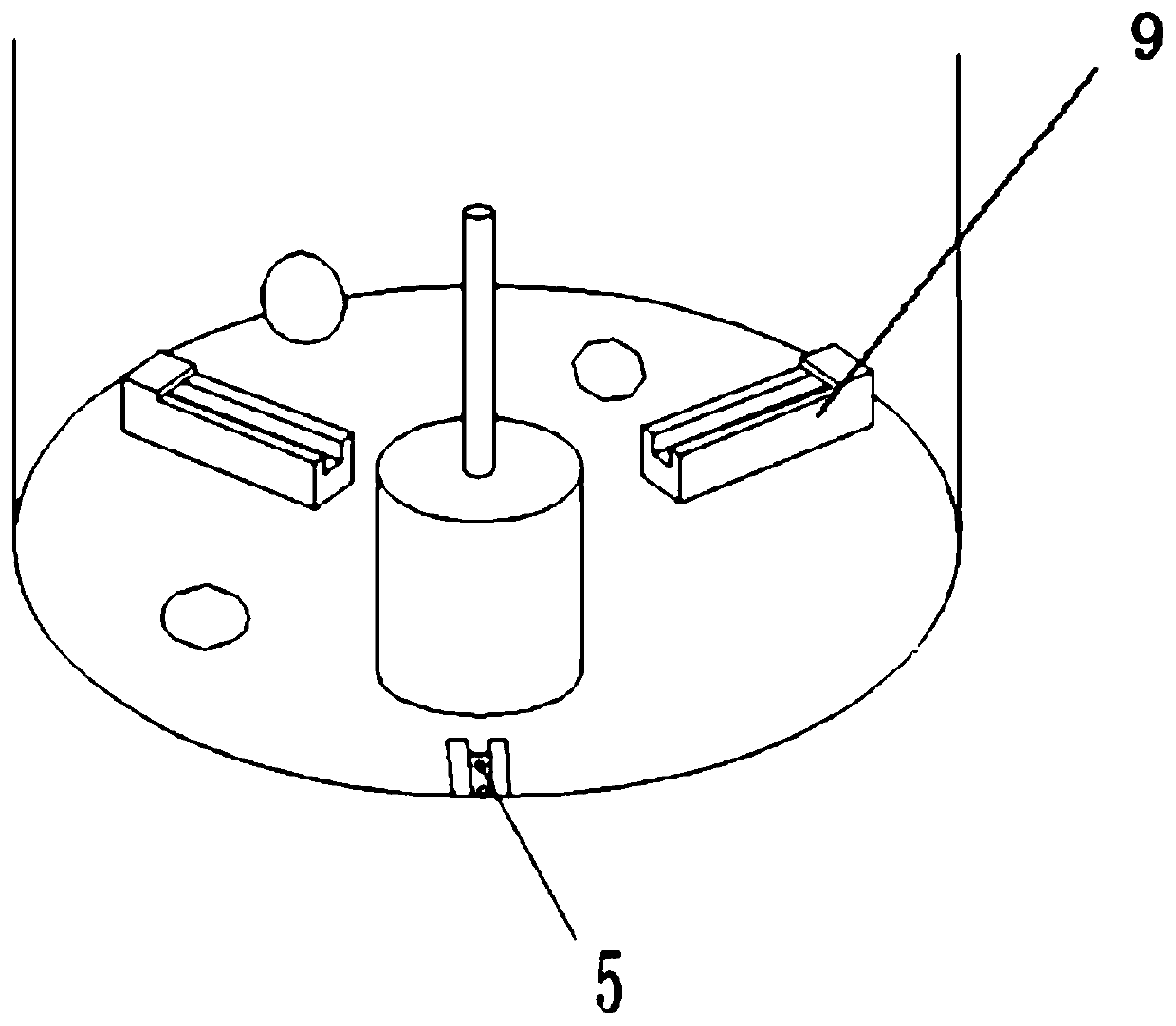

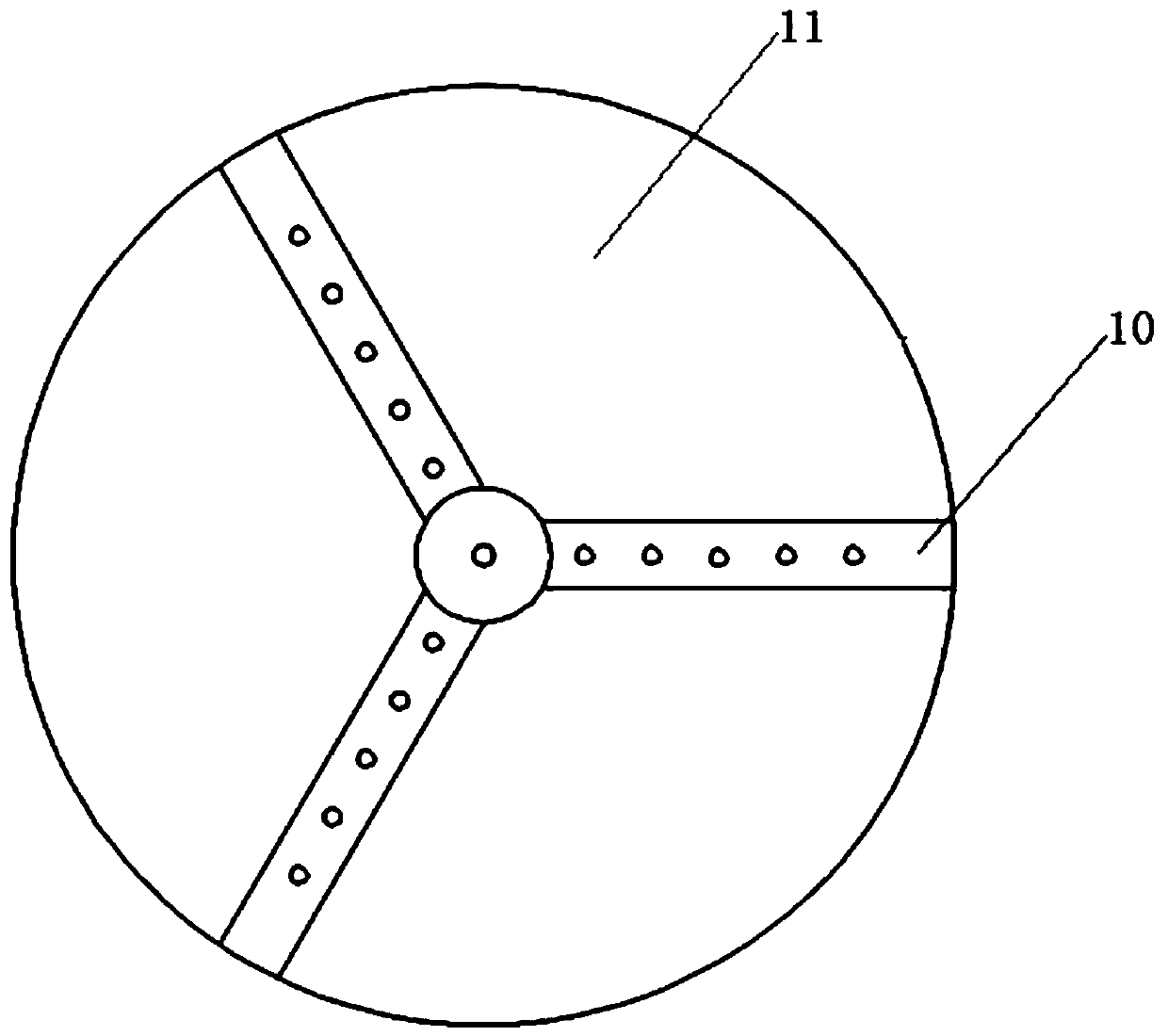

[0036] The vibration finishing machine is a rotary vibration finishing machine with no island in the center, and its unbalanced moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com