Method for texturing large-area silicon surface in multipoint contact mode

A technology of multi-point contact and processing method, which is applied in the process of producing decorative surface effects, microstructure technology, gaseous chemical plating, etc., and can solve problems such as slow processing speed, difficult texture processing, and harsh processing environment , to achieve the effect of improving processing efficiency, reducing operation difficulty and reducing processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

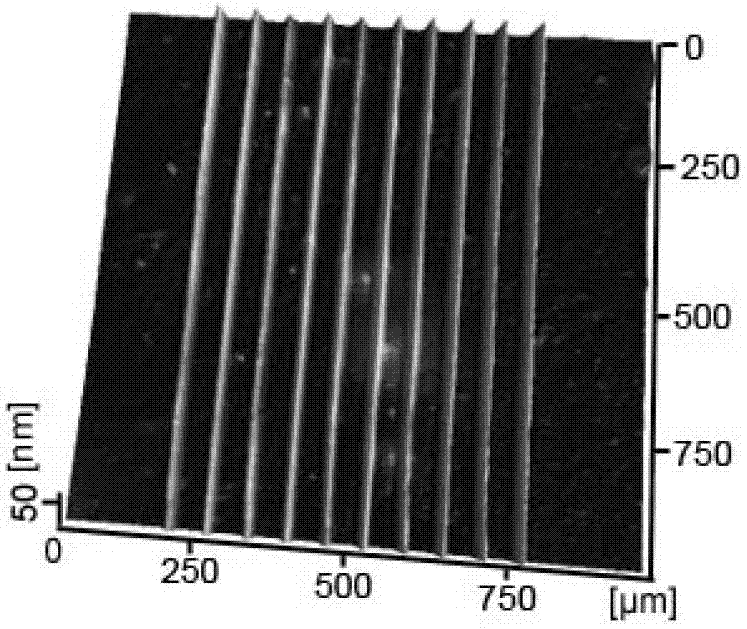

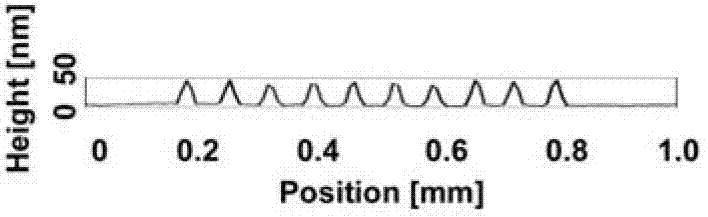

Embodiment 1

[0025] A large-area silicon surface texturing processing method in a multi-point contact mode, the steps are:

[0026] (1) Place the silicon (100) single wafer at the vertical lower position of the multi-point contact plate, and then make the silicon (100) single wafer and the multi-point contact plate move vertically relative to each other until contact occurs, and reach the set contact load F ; Wherein, the specific composition of the multi-point contact plate is: a plurality of microspheres with a radius of curvature of 160 μm are fixed on the substrate, and the vertices of the plurality of microspheres are on the same plane.

[0027] The contact load F set in this example is 250mN / microsphere. The number of microspheres on the multi-point contact plate is ten, and the material is steel.

[0028] (2) Under the set contact load F, make the multi-point contact plate and the silicon (100) single wafer move relative to each other according to the set track, so that the multi-p...

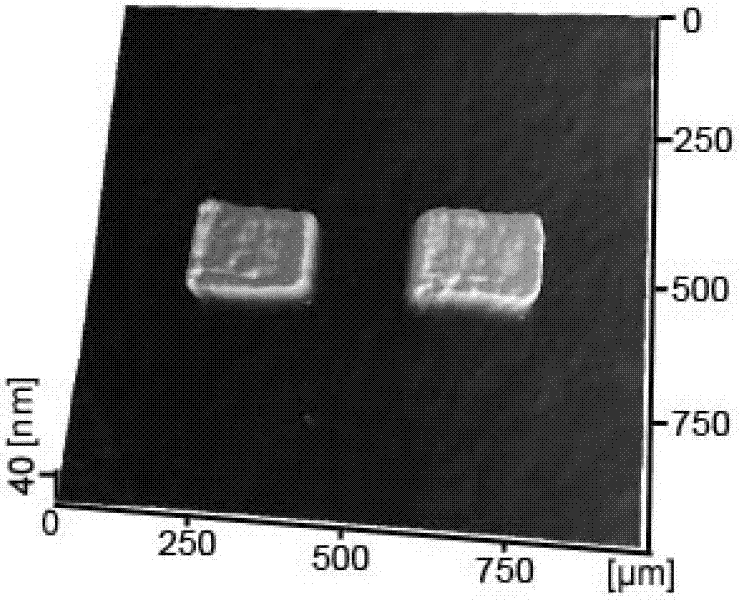

Embodiment 2

[0033] A large-area silicon surface texturing processing method in a multi-point contact mode, the steps are:

[0034] (1) Place the silicon (100) single wafer at the vertical lower position of the multi-point contact plate, and then make the silicon (100) single wafer and the multi-point contact plate move vertically relative to each other until contact occurs, and reach the set contact load F ; Wherein, the specific composition of the multi-point contact plate is: a plurality of microspheres with a radius of curvature of 160 μm are fixed on the substrate, and the vertices of the plurality of microspheres are on the same plane.

[0035] The contact load F set in this example is 450mN / microsphere. The number of microspheres on the multi-point contact plate is two, and the material is steel.

[0036] (2) Under the set contact load F, make the multi-point contact plate and the silicon (100) single wafer move relative to each other according to the set trajectory, so that the mu...

Embodiment 3

[0041] A large-area silicon surface texturing processing method in a multi-point contact mode, the steps are:

[0042] (1) Place the silicon (100) single wafer at the vertical lower position of the multi-point contact plate, and then make the silicon (100) single wafer and the multi-point contact plate move vertically relative to each other until contact occurs, and reach the set contact load F ; Wherein, the specific composition of the multi-point contact plate is: a plurality of microspheres with a radius of curvature of 160 μm are fixed on the substrate, and the vertices of the plurality of microspheres are on the same plane.

[0043] The contact load F set in this example is 250mN / microsphere. The number of microspheres on the multi-point contact plate is seven, and the material is steel.

[0044] (2) Under the set contact load F, make the multi-point contact plate and the silicon (100) single wafer move relative to each other according to the set track, so that the multi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com