Powder spraying, marking and blank cutting method for aluminum alloy components with ribs

An aluminum alloy strip and cutting method technology, applied in the field of shipbuilding, can solve the problems of unsuitable numerical control cutting, many pipe holes, large expansion coefficient, etc., so as to improve the scribing efficiency and accuracy, reduce the amount of positioning scribing, and improve the production efficiency. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the content, implementation process and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

[0035] 1. Formulate the production process of powder spraying, scribing, blanking and cutting of aluminum alloy ribbed parts

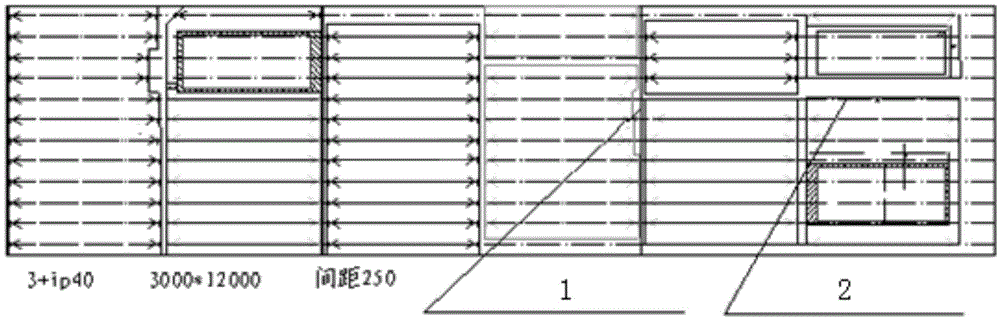

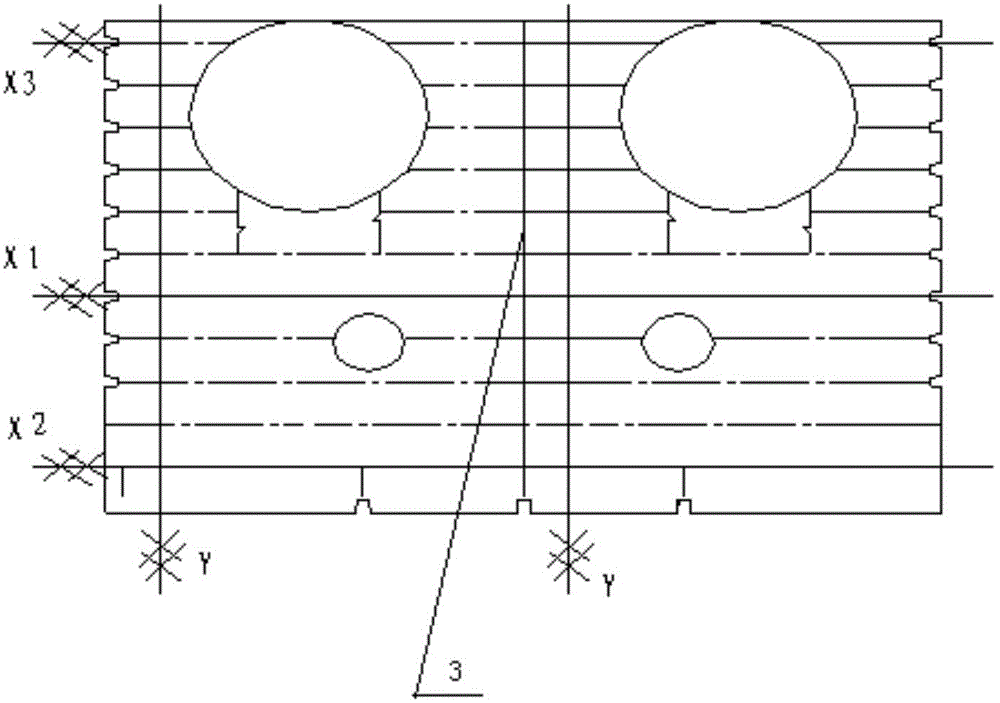

[0036] The design department and the assembly department jointly determine the production process, including providing the electronic version of the part sketch (the part is turned over on the smooth surface) to implement CNC nesting, draw the inspection line reference line on the block surface, and draw the part graphics by spraying powder on the CNC cutting machine to draw the inspection reference Line, check the reference line before on-site cutting and then blank cutting.

[0037] 2. CNC nesting of aluminum alloy ribbed parts

[0038]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com