Extreme ultraviolet recessed surface reflector coated film uniformity assessing method

A concave mirror, extreme ultraviolet technology, applied in the application field of extreme ultraviolet optical technology, can solve the problems of expensive coating substrate, high experiment cost, high risk, etc., to avoid inconvenience in testing and operation risks, and improve reliability and convenience. , the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A point-selected sampling patch method to evaluate the coating uniformity of extreme ultraviolet concave mirrors, the evaluation method includes the following basic steps:

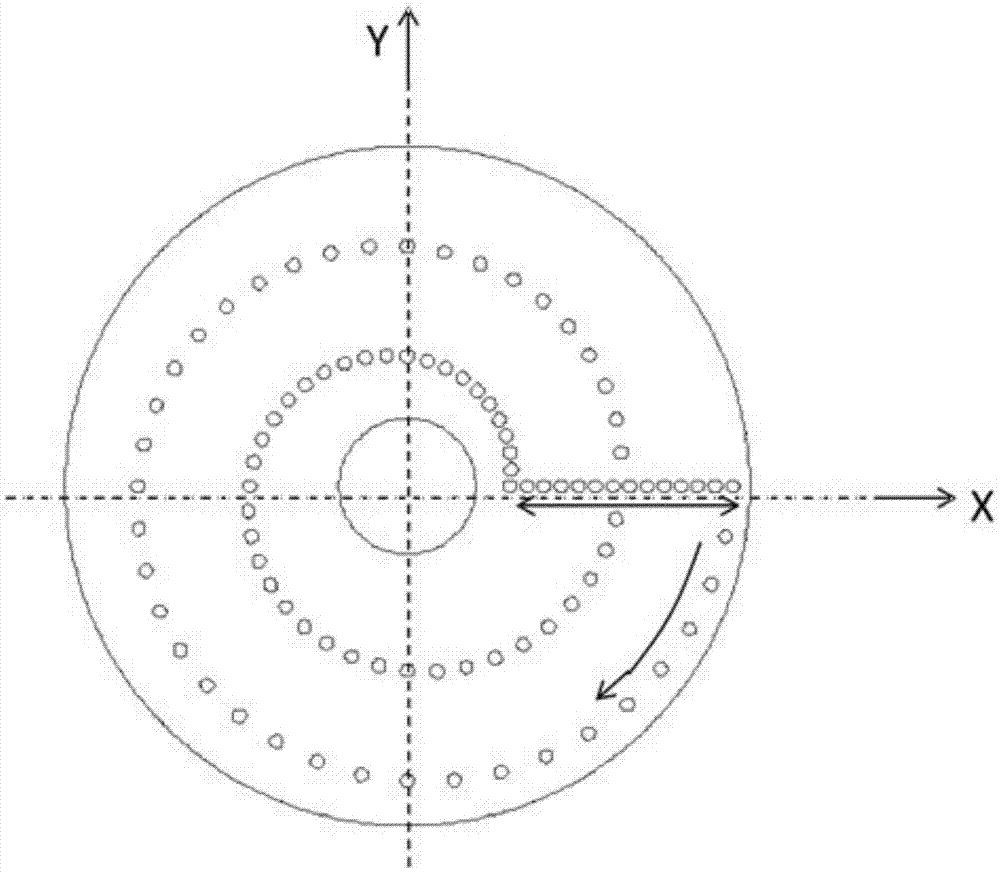

[0017] Step 1. Process and evaluate the EUV concave mirror with the same shape as the coating mold, such as figure 1 As shown, starting from a point on the outer edge of the coating mold, holes are drilled on the coating mold according to the shape of the spiral line. The last intersection point between the spiral line and the radius of the starting point is the end point of the hole punching, and each point is coded according to the coordinate position. . Points are sequentially drilled on the radial straight line between the start point and the end point, and each point is coded according to the coordinate position. Ultrasonic cleaning, slow dehydration, and alcohol drying are performed on the mechanically processed coating molds to ensure the cleanliness of the coating molds before entering the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com