Hot in-plant reclaimed asphalt mixture

A technology of asphalt mixture and recycled asphalt, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as unsatisfactory effects and shortages, and achieve environmental protection, economic efficiency, and obvious social benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The project overview of this example is: the test section of AC-25S asphalt mixture mixed with regenerant plant and hot regeneration is selected at the lower level of the connecting line of Jiangning Binjiang Development Zone in Nanjing. The project adopts the first-class highway standard, two-way six-lane, and the design speed 80 km / h, the pavement structure adopts: 4cm asphalt mixture (AC-13C) + 5cm asphalt mixture (AC-20S) + 7cm asphalt mixture (AC-25S), the recycled layer is the lower layer, and the milling material is mixed The amount is 50%. The lower layer adopts the hot recycled asphalt mixture of the present invention

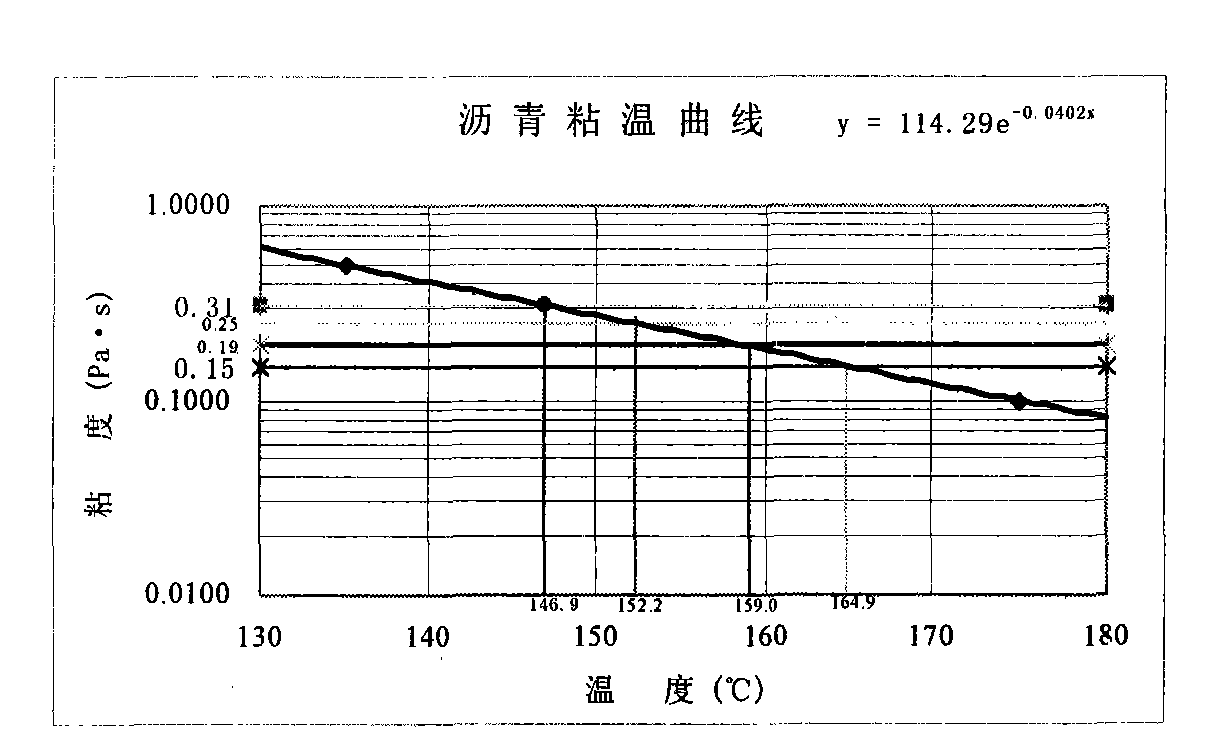

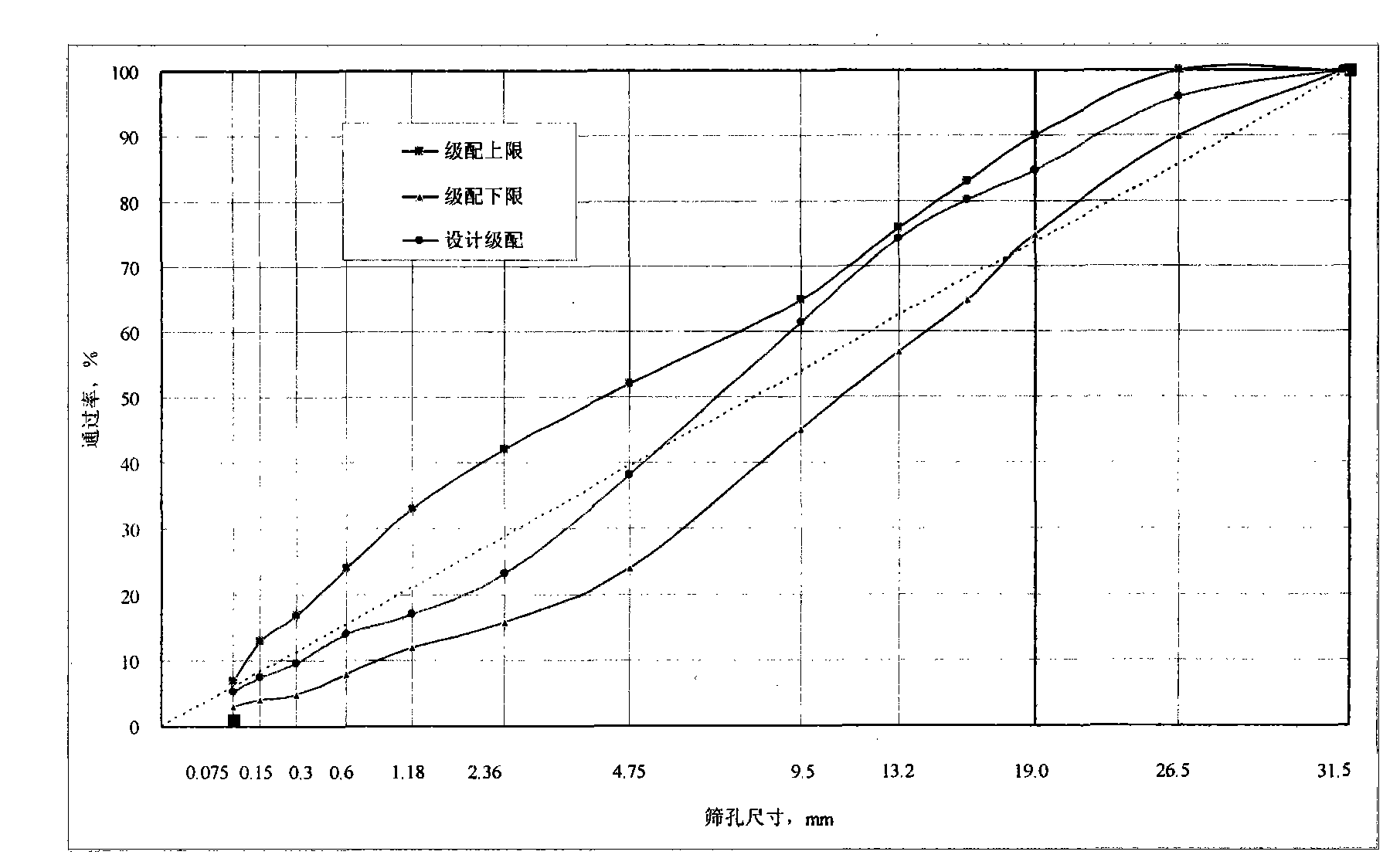

[0036] First, take a sample of the milling material, and use the Absen method to perform the extraction and decomposition test of the aggregate and asphalt. After the milling material is extracted, the aggregate is sieved by a 2.36mm screen and divided into two parts: coarse aggregate and fine aggregate, and then the density test is carried out re...

Embodiment 2

[0070] The plant-mixed hot regenerated asphalt mixture of this embodiment is also used for the regeneration layer as the middle surface layer. The milling material of the recycled asphalt mixture accounts for 40% of the total mass. That is, the middle surface layer adopts the hot recycled asphalt mixture of the present invention.

[0071] First, take a sample of the milling material, and use the rotary evaporator method to conduct the extraction and decomposition test of aggregate and asphalt. After the milling material is extracted, the aggregate is sieved by a 2.36mm screen and divided into two parts: coarse aggregate and fine aggregate. For the gradation and oil-stone ratio, please refer to Table 2-1.

[0072] Table 2-1 Extraction test results of asphalt mixture

[0073]

[0074] The above-mentioned extracted recycled asphalt was measured for related property indicators, and the properties of the new asphalt with the same label were also tested. The results are shown in Table 2-...

Embodiment 3

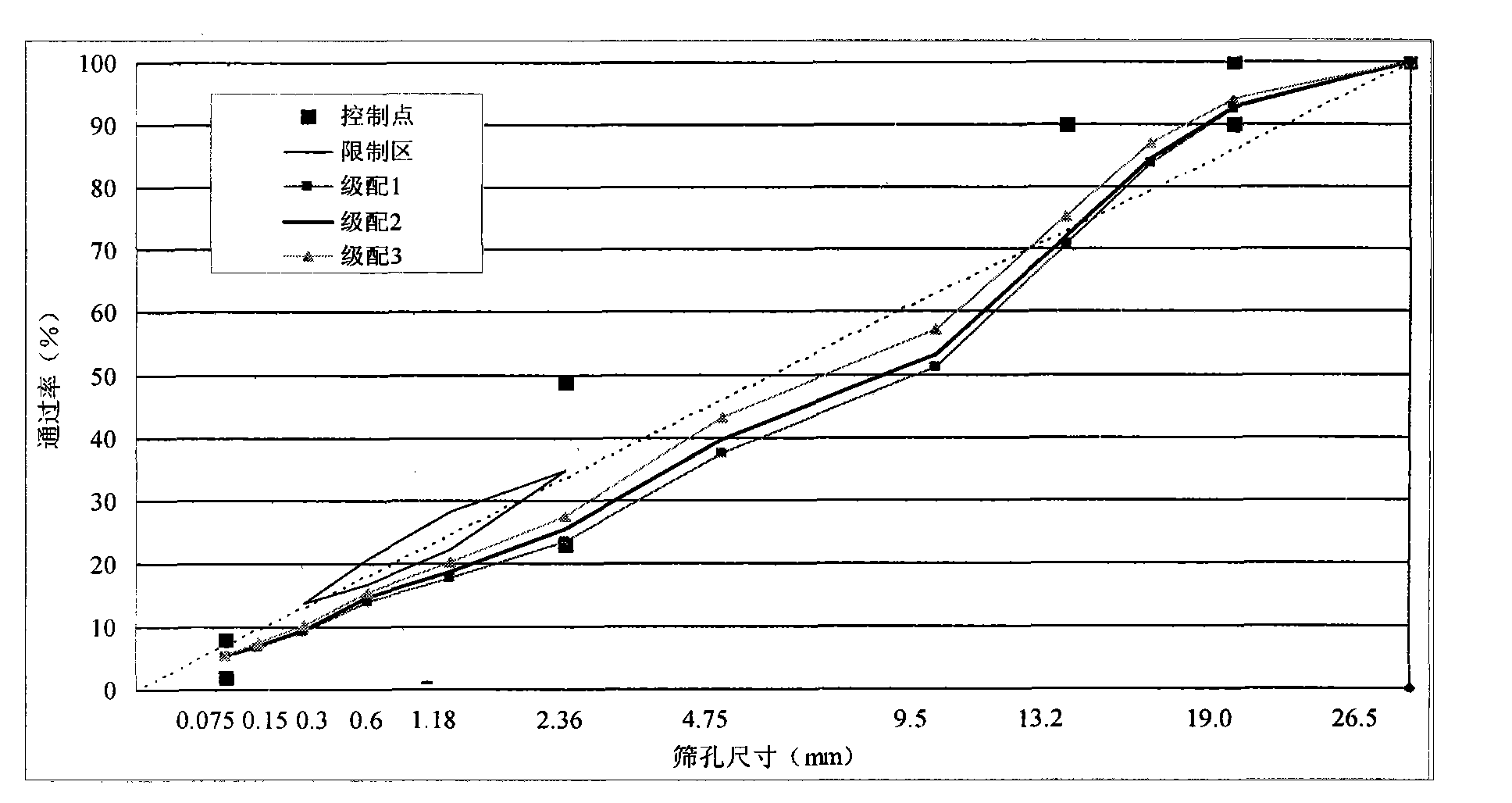

[0101] The test section was selected on the Dongshan-Qilin highway in Jiangning District, Nanjing. The starting point was the construction end point of Hongyun Avenue, and it crossed the Nanjing-Hangzhou Expressway to the east. The end point was connected to Kaicheng Lushun, Qilin Town. The entire route was about 9.7km. SUP-20 is mainly used for the middle surface layer. The milling material RAP content of the recycled asphalt mixture accounts for 30% of the total mass, and no regenerating agent is added.

[0102] First, sample the milling material RAP, and use the rotary evaporator method to carry out the extraction and decomposition test of aggregate and asphalt. After the milling material is extracted, the aggregate is sieved by a 2.36mm screen and divided into two parts: coarse aggregate and fine aggregate, and then the density test is carried out respectively, and the oil-stone ratio of the milling material is determined, please refer to the table 3-1. Table 3-2.

[0103] Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com