Recycled pavement structure and road construction process thereof

A technology of pavement structure and process, applied in roads, roads, buildings, etc., can solve the problems of polluted environment, less comprehensive recycling and utilization of various construction wastes, and waste of resources, etc., to enhance durability, reduce road construction costs, and prolong use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

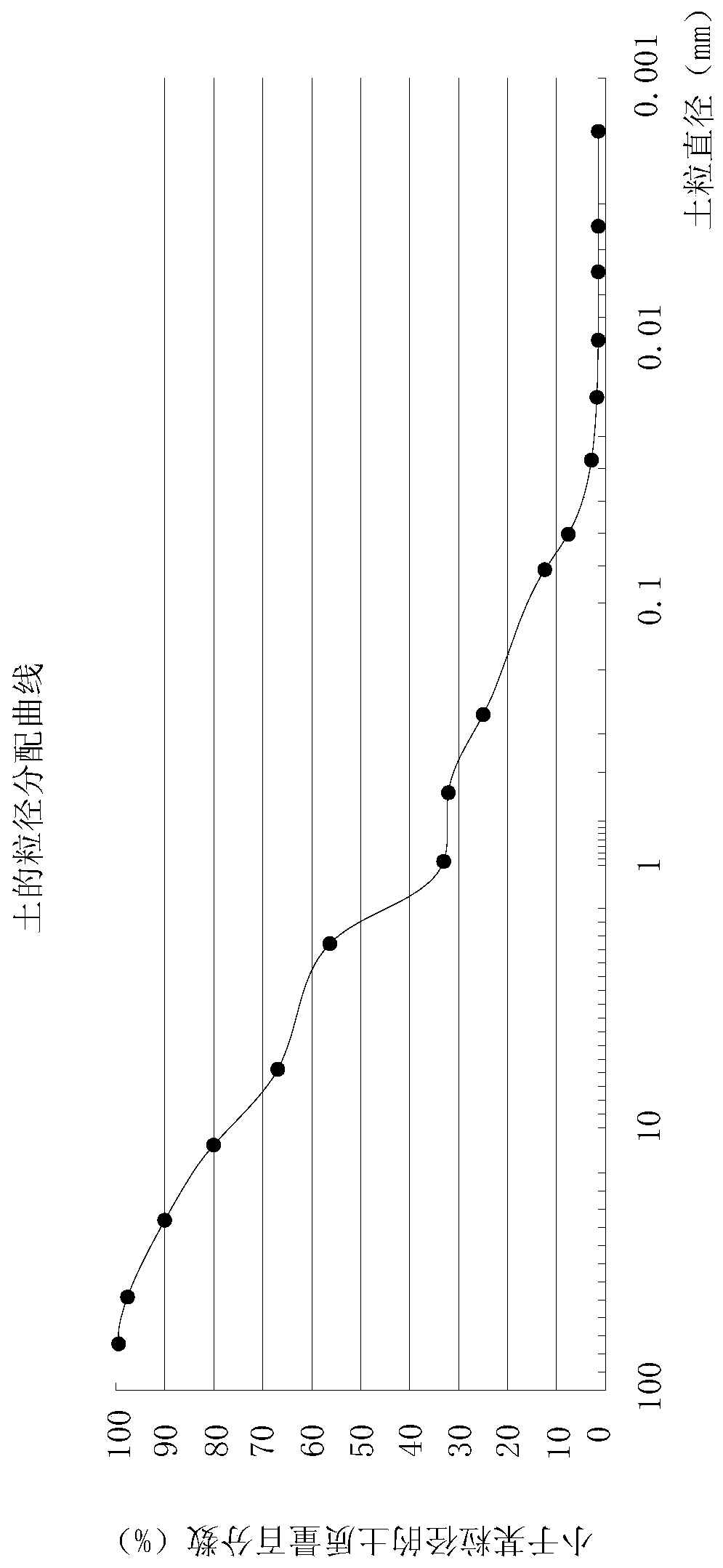

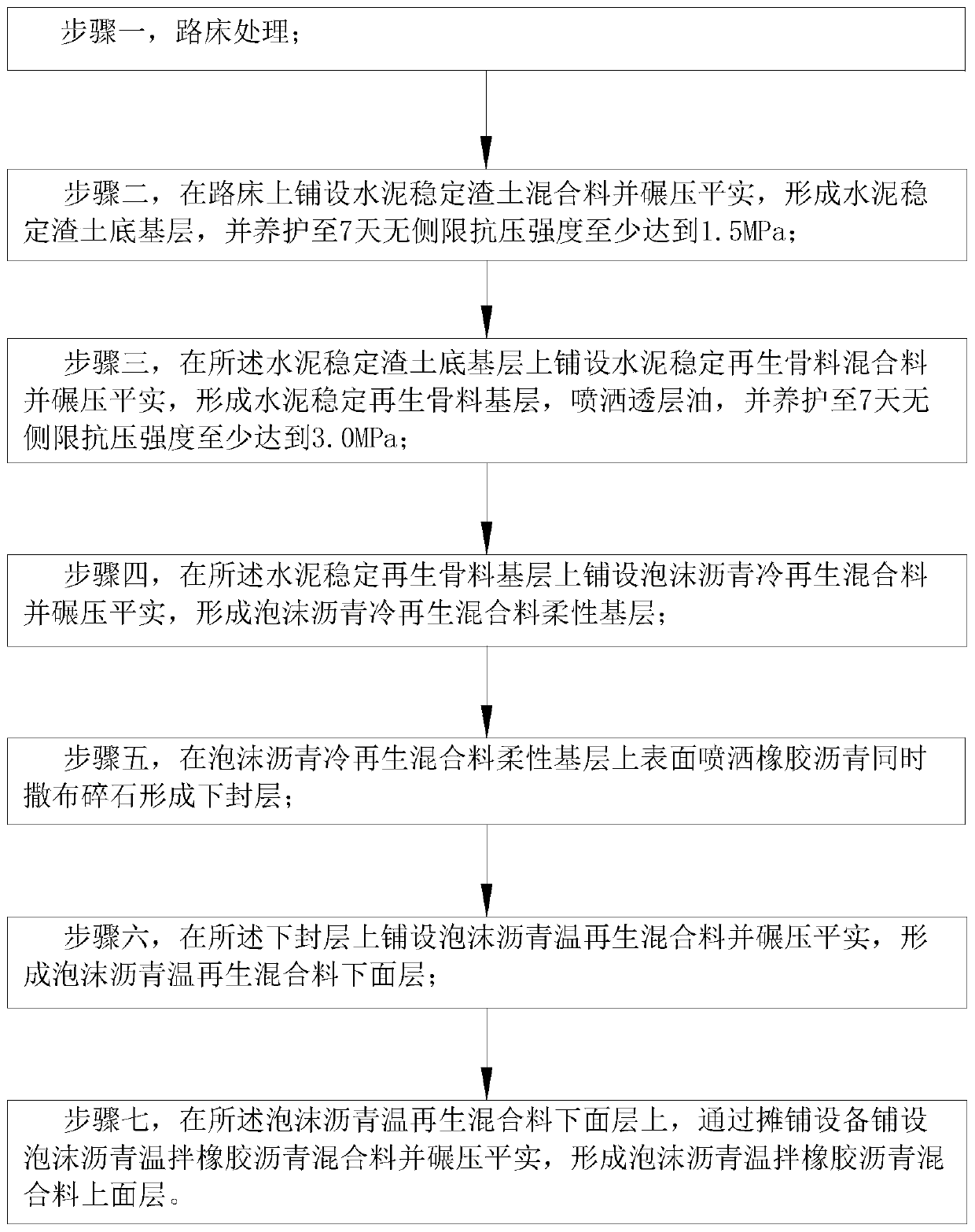

[0042] As an embodiment of the present invention, the muck content in the cement-stabilized muck subbase is 93% to 96%, and the cement content is 4% to 7%; the recycled aggregate content in the cement-stabilized recycled aggregate base is 94% to 96%, the cement content is 4% to 6%; the recycled aggregate content of the waste asphalt pavement in the flexible base of the foamed asphalt cold recycled mixture is 70% to 80%, and the new aggregate content is 20% to 30% %, the foamed asphalt content is 1.5% to 3.5%, the cement content is 1% to 1.5%; the waste and old asphalt pavement recycled aggregate content in the lower layer of the warm-mixed recycled asphalt mixture is 10% to 40%, and the new aggregate content The content of new asphalt is 3% to 6%; the upper layer of the warm-mix rubber asphalt mixture, the content of waste tire rubber powder is 18% to 25% of that of rubber asphalt, and the asphalt ratio is 5.5% to 6.5%, the mixing temperature is 140℃~160℃; the thickness range ...

Embodiment 1

[0063] The pavement structure of a roadway in a certain city is as follows: After the roadbed 100 is treated, a 32cm thick cement-stabilized muck subbase (7-day unconfined compressive strength is 1.5-2.5MPa) is successively laid on the roadbed 100, and a 18cm-thick Cement-stabilized recycled aggregate base (7-day unconfined compressive strength is 3.0-4.0MPa), spray oil for penetration, lay 12cm thick foam asphalt cold recycled mixture, spray rubber asphalt and spread gravel to form a lower seal layer, lay The lower layer of foamed asphalt warm recycled mixture is 8cm thick, and the upper layer of foamed asphalt warm rubber asphalt mixture is laid 4cm thick.

[0064] 1 Cement-stabilized slag-soil subbase mix design and production construction technology

[0065] 1.1 Cement-stabilized muck subbase mix design

[0066] Take certain technical measures to eliminate the variability of muck. When sampling, use a loader to select samples from different piles and stack them together, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com