A long-life flexible base asphalt pavement structure

A technology of flexible base and asphalt pavement, which is applied to cohesive pavement paved on site, roads, roads, etc., can solve the problems of water damage to the asphalt layer, poor economic benefits, and inconsistent structural values, etc., to improve service life, Improved rutting resistance, effect of increased stress levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

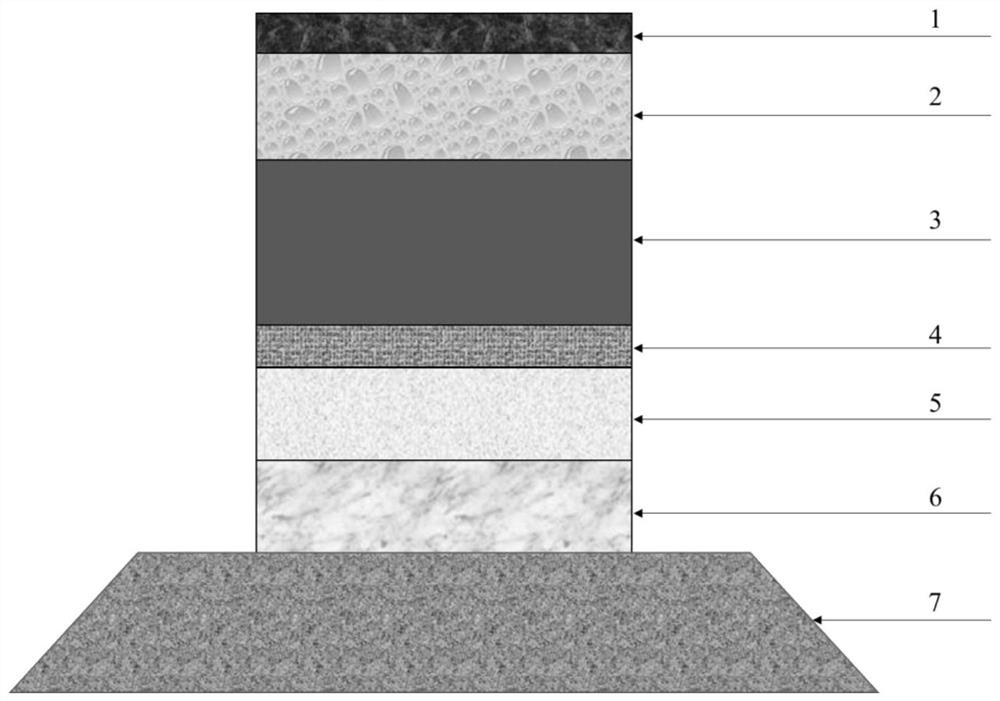

[0059] The long-life flexible base asphalt pavement structure of this embodiment, such as figure 1 As shown, the composition is as follows:

[0060] Asphalt concrete upper layer 1, its material is SMA-13;

[0061] High modulus anti-rutting asphalt concrete middle surface layer 2, the material is SUP-20;

[0062] The lower layer 3 of high modulus asphalt concrete is made of SUP-25;

[0063] Anti-fatigue asphalt concrete layer 4, the material of which is AC-10;

[0064] Graded crushed stone base 5;

[0065] Reinforced graded crushed stone subbase 6;

[0066] The roadbed improved soil layer 7 is composed of a 6% cement improved soil roadbed, a 4% cement improved soil upper embankment and a 4% cement improved soil lower embankment.

[0067] The thickness, modulus, Poisson's ratio and other parameters of each layer are shown in the table below:

[0068] Material Thickness / m Modulus / MPa Poisson's ratio SMA-13 0.04 11000 0.25 SUP-20 0.08 12000 0....

Embodiment 2

[0073] The long-life flexible base asphalt pavement structure of this embodiment, such as figure 1 As shown, the composition is as follows:

[0074] Asphalt concrete upper layer 1, its material is SMA-13;

[0075] High modulus anti-rutting asphalt concrete middle surface layer 2, the material is SUP-20;

[0076] The lower layer 3 of high modulus asphalt concrete is made of SUP-25;

[0077] Anti-fatigue asphalt concrete layer 4, the material of which is AC-10;

[0078] Graded crushed stone base 5;

[0079] Reinforced graded crushed stone subbase 6;

[0080] The roadbed improved soil layer 7 is composed of a 6% cement improved soil roadbed, a 4% cement improved soil upper embankment and a 4% cement improved soil lower embankment.

[0081] The thickness, modulus, Poisson's ratio and other parameters of each layer are shown in the table below:

[0082] Material Thickness / m Modulus / MPa Poisson's ratio SMA-13 0.03 11000 0.25 SUP-20 0.06 12000 0....

Embodiment 3

[0087] The long-life flexible base asphalt pavement structure of this embodiment is composed as follows:

[0088] Asphalt concrete upper layer 1, its material is SMA-13;

[0089] High modulus anti-rutting asphalt concrete middle surface layer 2, the material is SUP-20;

[0090] The lower layer 3 of high modulus asphalt concrete is made of SUP-25;

[0091] Anti-fatigue asphalt concrete layer 4, the material of which is AC-10;

[0092] Graded crushed stone base 5;

[0093] Reinforced graded crushed stone subbase 6;

[0094] The roadbed improved soil layer 7 is composed of a 6% cement improved soil roadbed, a 4% cement improved soil upper embankment and a 4% cement improved soil lower embankment.

[0095] The thickness, modulus, Poisson's ratio and other parameters of each layer are shown in the table below:

[0096] Material Thickness / m Modulus / MPa Poisson's ratio SMA-13 0.06 11000 0.25 SUP-20 0.12 12000 0.25 SUP-25 0.16 12000 0.25 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com