Patents

Literature

79results about How to "Numerically stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

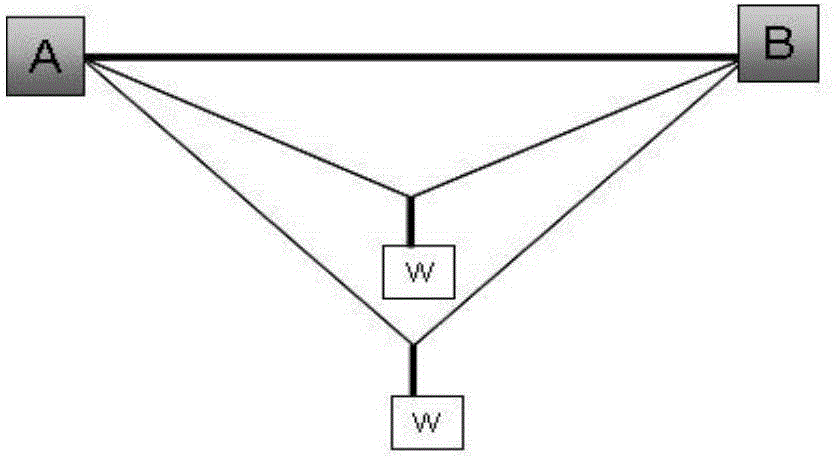

Real time precision rail fixing method of navigational satellite

InactiveCN101435863AProcessing speedOvercoming the problem of reduced or even wrong estimation accuracyBeacon systems using radio wavesEarth's rotationSlide window

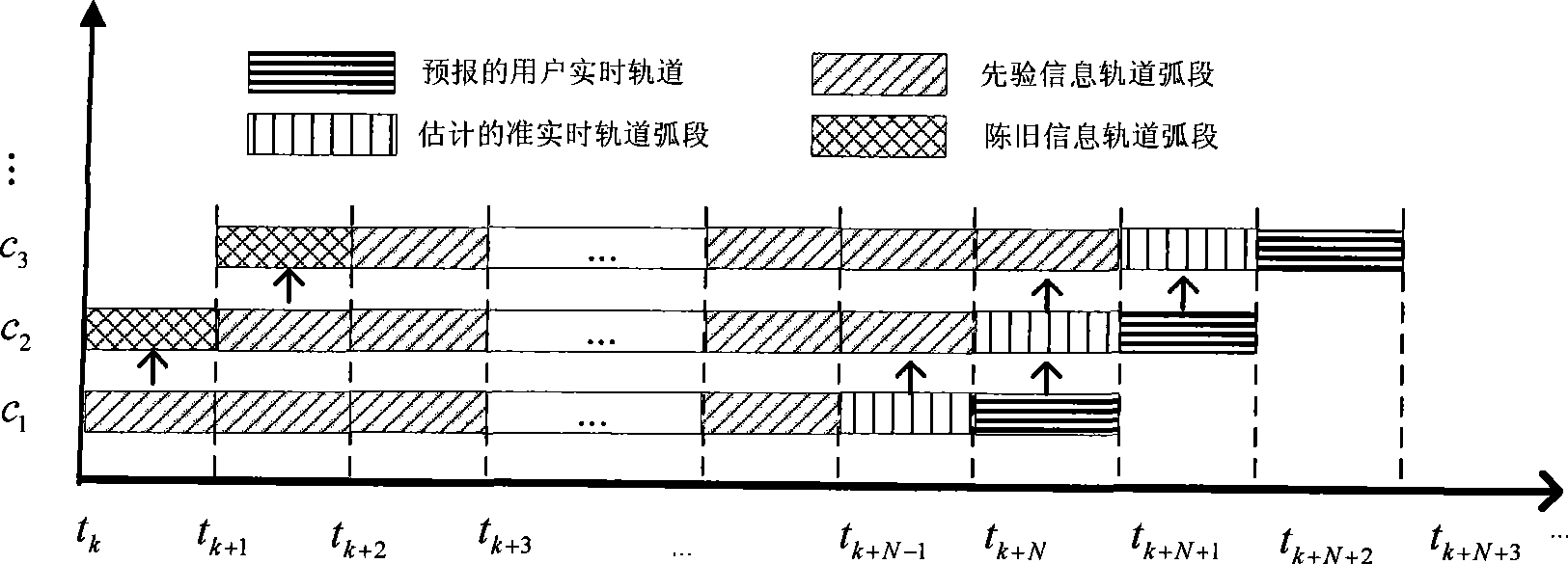

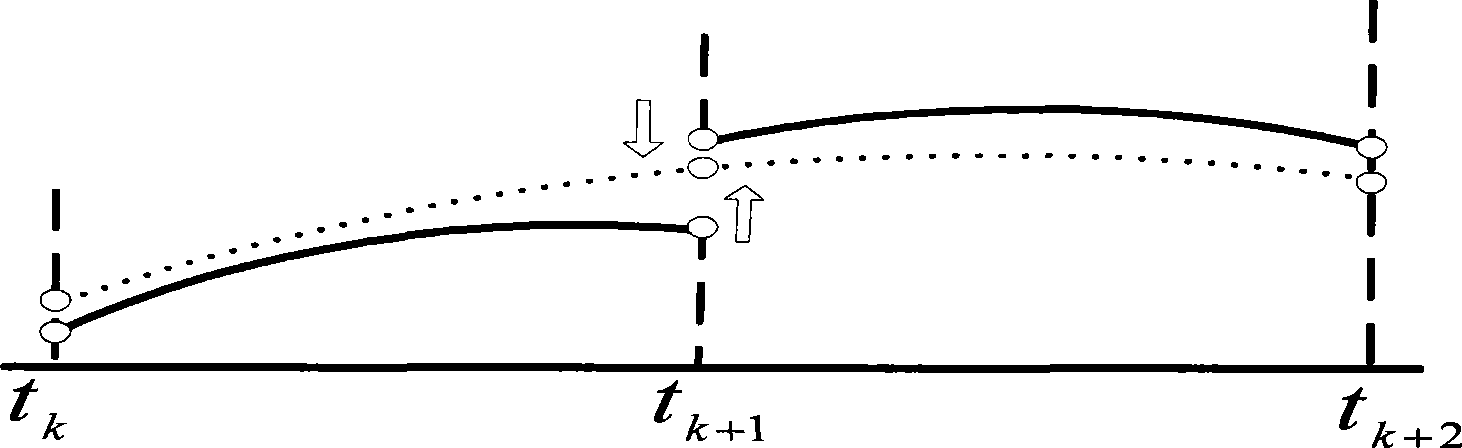

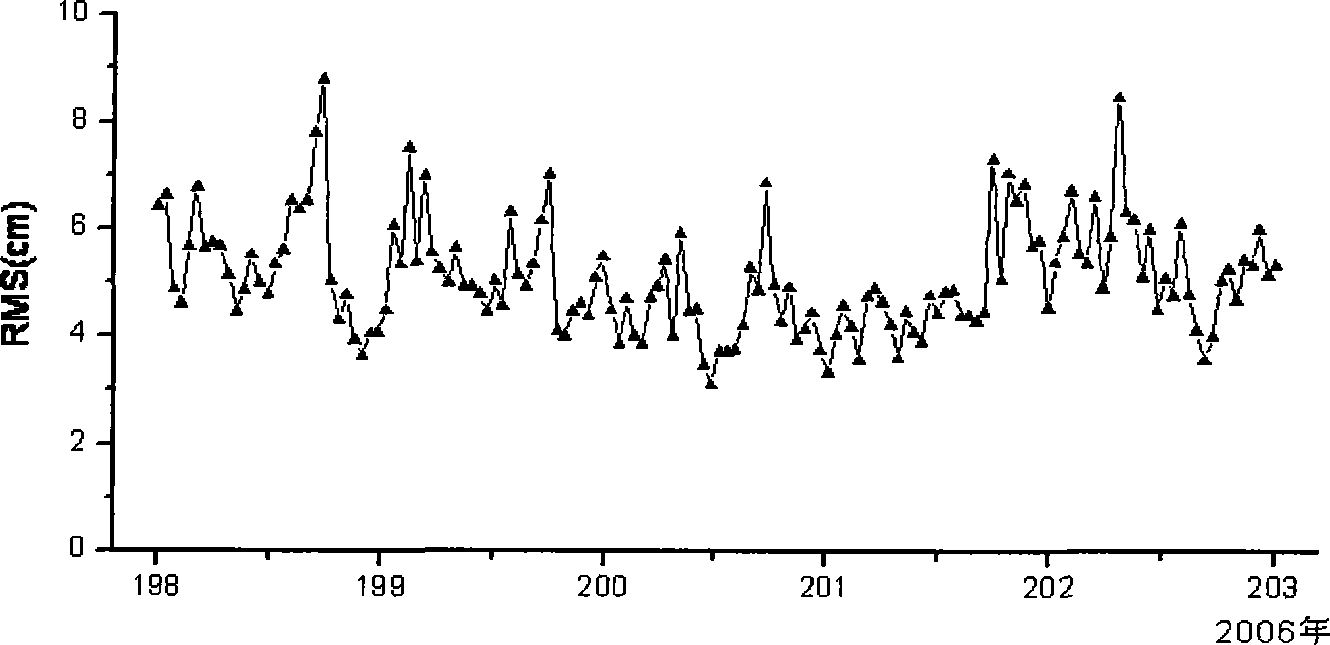

The invention discloses a method for precisely determining an orbit of a navigational satellite in real time based on a sliding data window. The main concept of the method is that when an estimation is carried out on a state Xk including an initial state of the satellite, a force model parameter, an earth rotation parameter, an atmospheric parameter, a station coordinate and the like; only first N measurements which are closest to k moment are utilized, while other measurements are completely abandoned, wherein N is a predetermined length of the sliding window; a precise satellite orbit initial value and the precise force model parameter of the Nth segmental arc can be acquired through establishing, combining, solving a normal equation and other steps; and a predicted orbit of the next moment can be acquired through an orbit integral and taken as a real-time orbit to be transmitted to a user. The method for determining the orbit of the satellite has the advantages of high speed of data processing, high orbit precision, stable numerical value and the like.

Owner:WUHAN UNIV

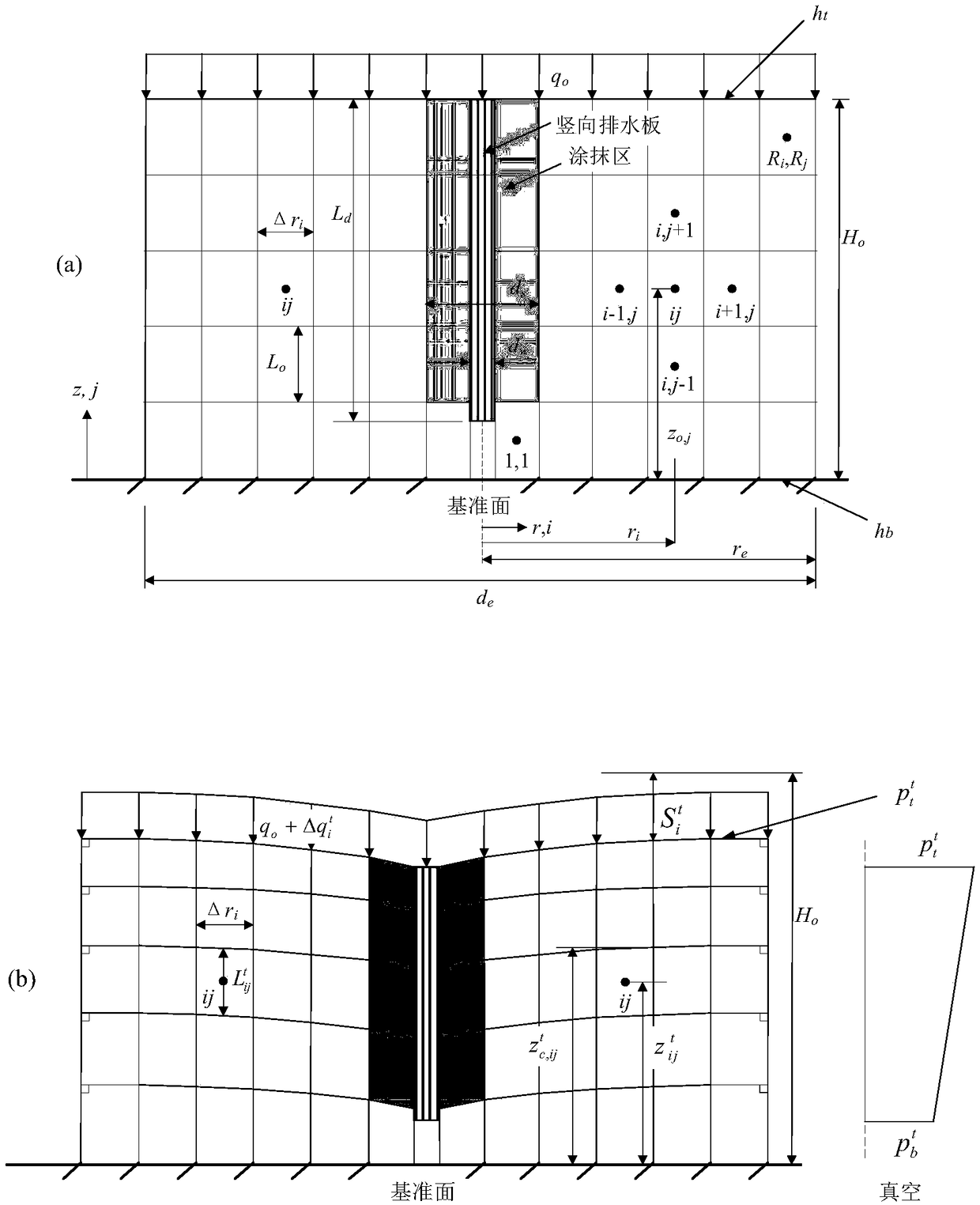

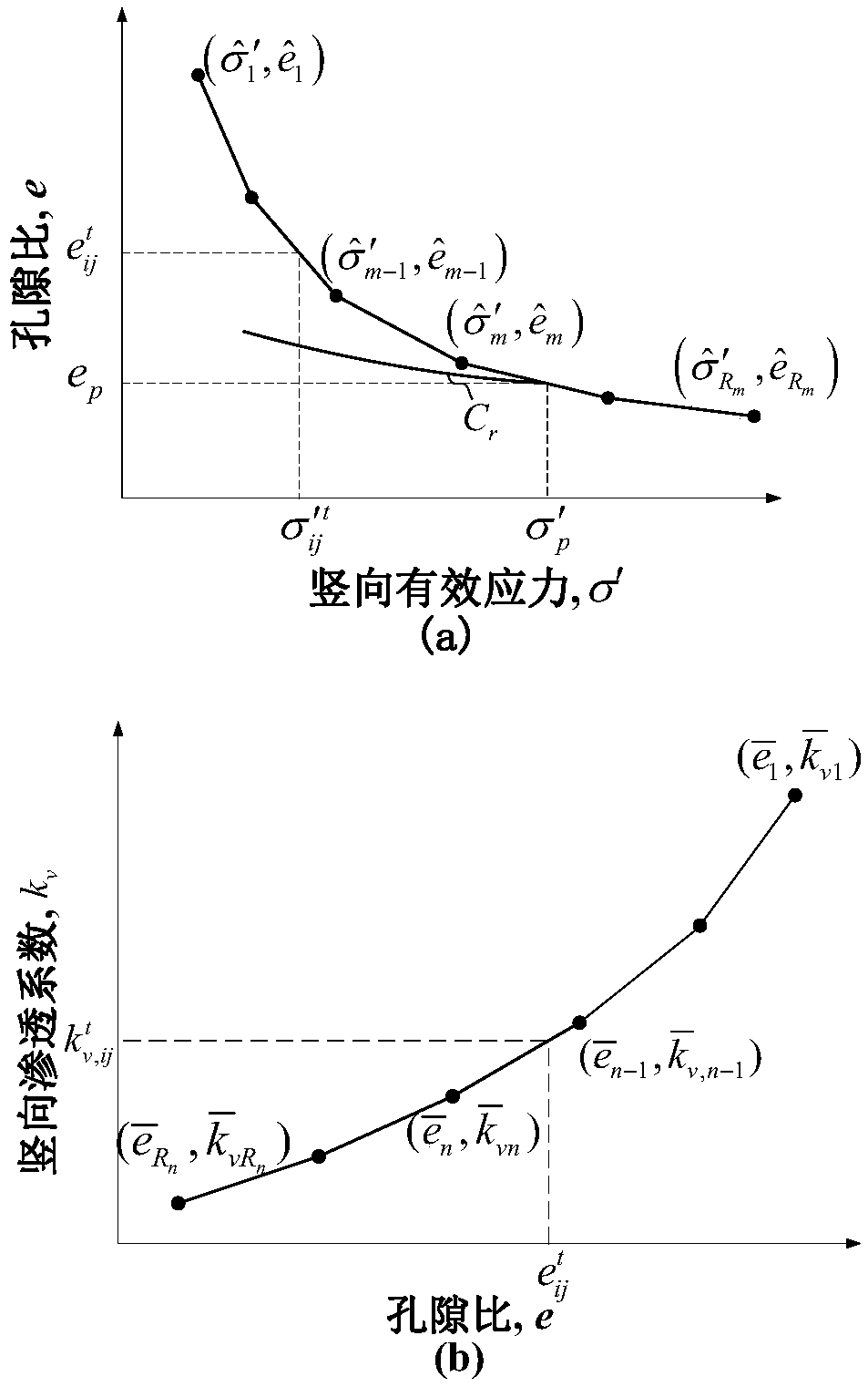

A method for predicting the settlement process of saturated soft soil consolidated by vertical drainage board

ActiveCN109145473AReduce mistakesImprove calculation accuracyForecastingDesign optimisation/simulationExperimental researchPredictive methods

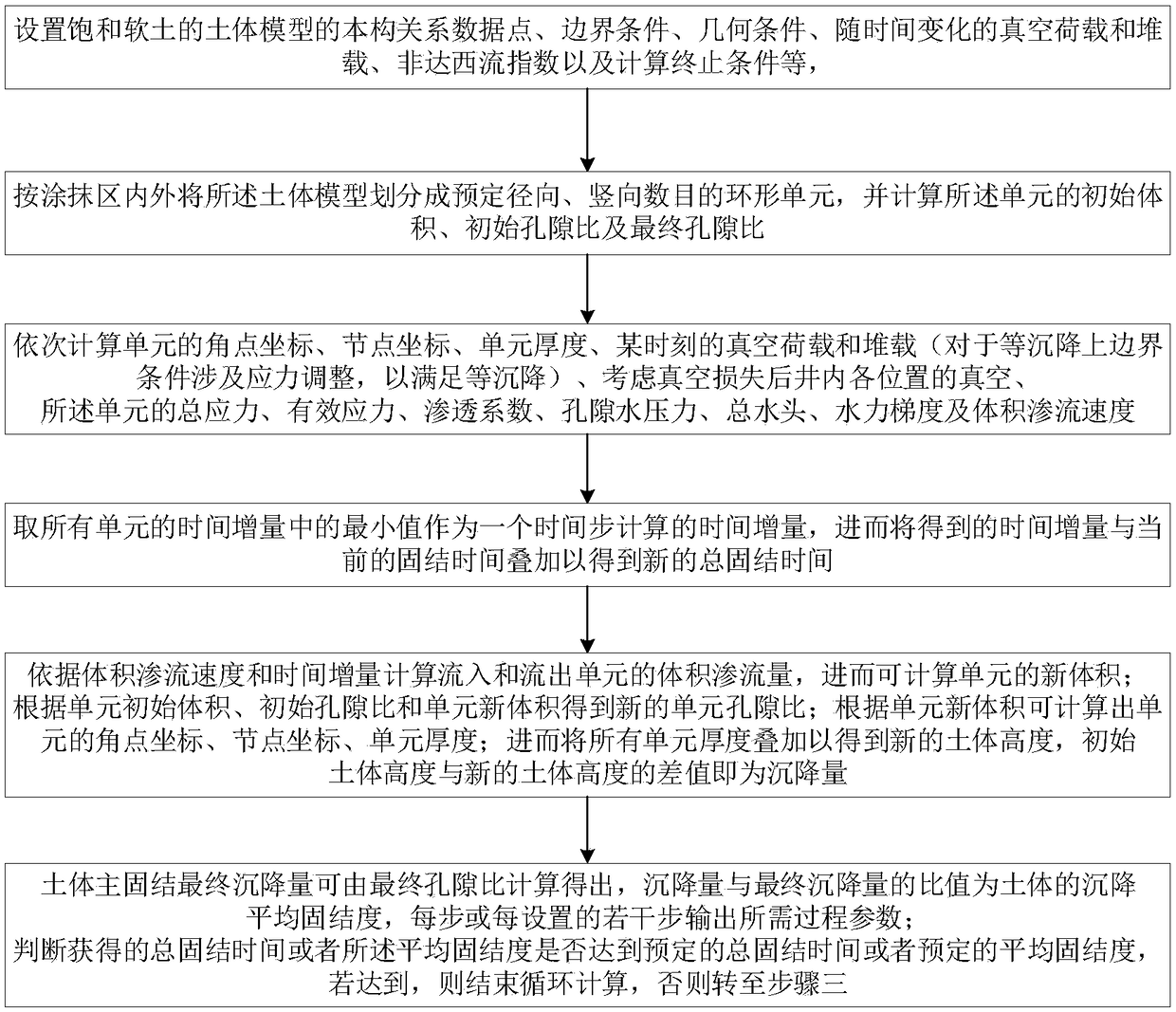

The invention discloses a vertical drainage plate consolidation saturated soft soil settlement process prediction method, which belongs to the research field of foundation treatment technology in geotechnical engineering. Considering the large deformation, the nonlinearity of material parameters, the boundary conditions, the time-varying vacuum load and surcharge, the unloading / reloading, the non-penetration of the shaft, the loss of vacuum along the well, the non-Darcy flow, the vertical and radial two-dimensional seepage flow and so on, the error is effectively reduced and the calculation precision is improved. The advantage of the method is more obvious for large strain problems. At the same time, the prediction method is simple and flexible, and the constitutive relation can be set flexibly according to the user's wishes, which solves the problems of incomplete considerations and inappropriate material parameters, which lead to large error in calculation results and difficult to beapplied in complex engineering environment. Therefore, the invention can be used for assisting the experimental research of a scientific research unit and predicting the consolidation of the engineering site.

Owner:HUAZHONG UNIV OF SCI & TECH

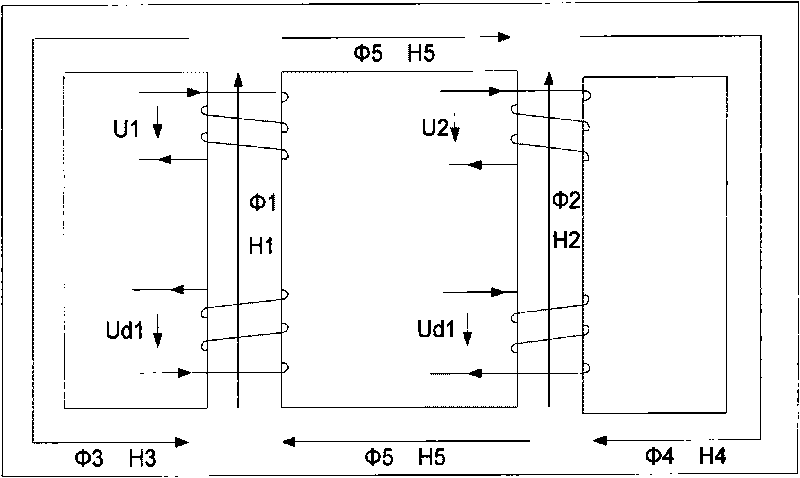

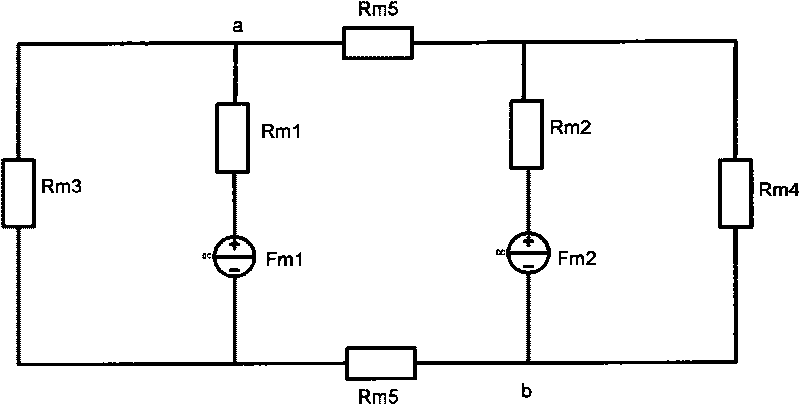

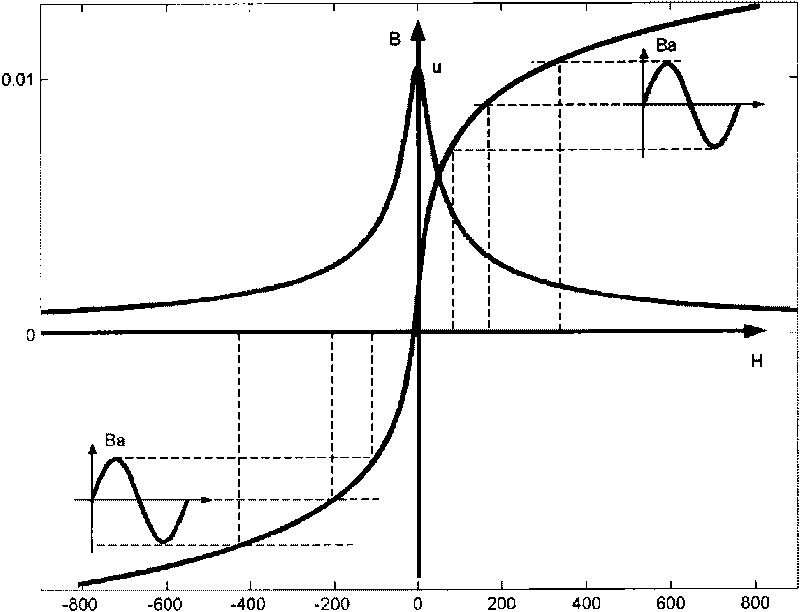

Dynamic magnetic resistance based equivalent reactance transient state modeling method of magnetically controlled shunt reactor

ActiveCN101719185ANo truncation errorSolve problemsSpecial data processing applicationsShunt reactorMagnetic reluctance

The invention provides a practical decoupling electromagnetic transient state modeling method for describing the nonlinear magnetic saturation property of a super / extreme-high voltage magnetically controlled shunt reactor (MCSR), comprising the steps of: providing a transient equivalent reactance algorithm on the basis of a dynamic magnetic resistance idea under AC / DC mixed excitation; reflecting the real-time dynamic change property of the saturated equivalent reactance under the condition of the AC / DC mixed excitation; accurately describing the magnetizing and demagnetizing effect of network side AC current on a reversely series-wound DC excitation saturation magnetic circuit in two main magnetic circuits of the super / extreme-high voltage magnetically controlled shunt reactor (MCSR); describing nonlinear magnetic circuit property with arc hyperbolic functions; decoupling a coupling magnetic circuit equation; differencing transient equivalent reactance by an implicit trapezoid integration algorithm with damping; and establishing an electromagnetic transient state model. The invention not only accurately reflects the continuously smooth regulation property of the saturated magnetic circuit of the super / extreme-high voltage magnetically controlled shunt reactor (MCSR) and prevents the numerical oscillation of piecewise linearization algorithm, but also can meet the requirements of real-time / faster-than-real-time simulation computation under the condition of large-range continuous regulation.

Owner:CHINA ELECTRIC POWER RES INST +1

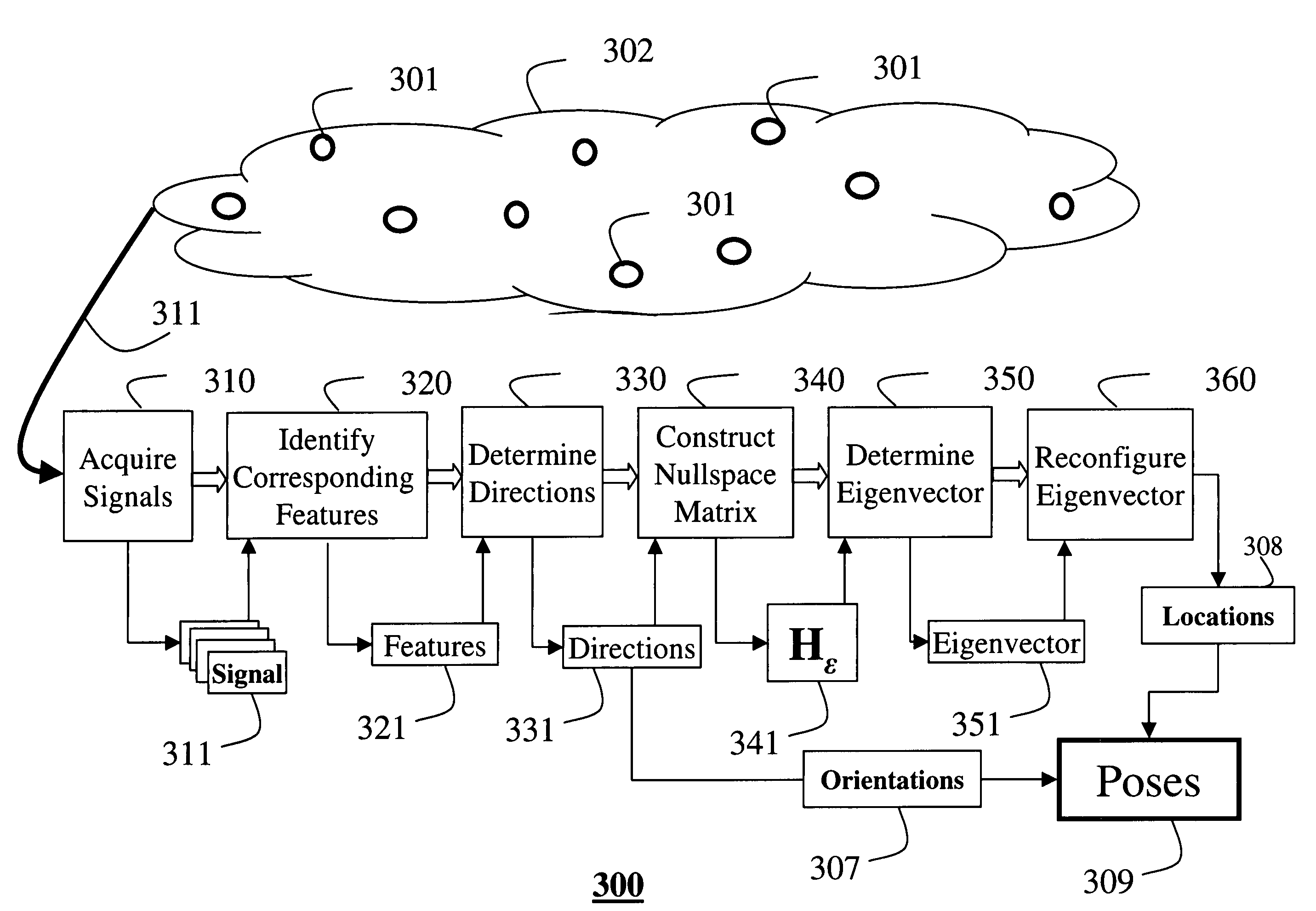

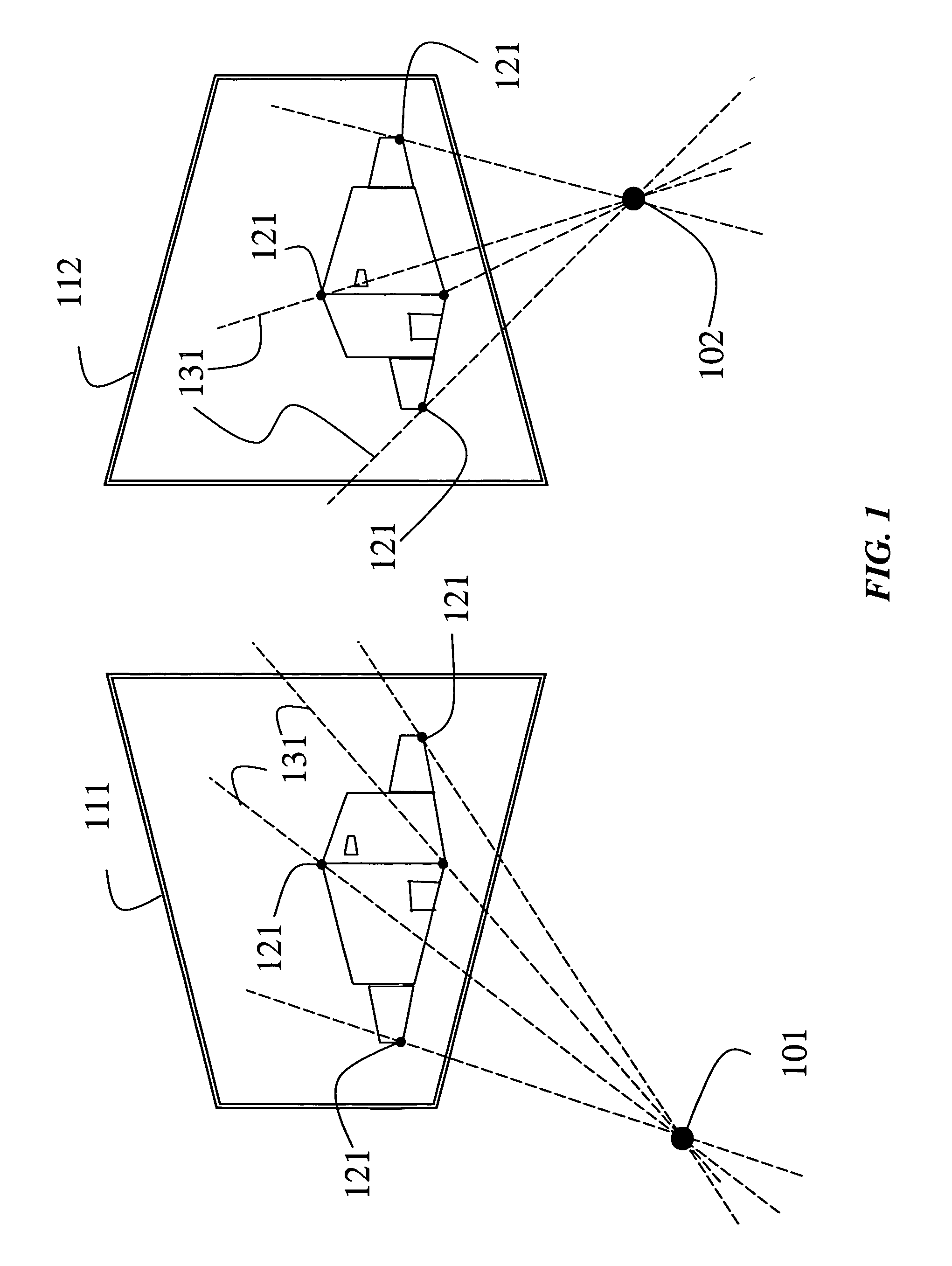

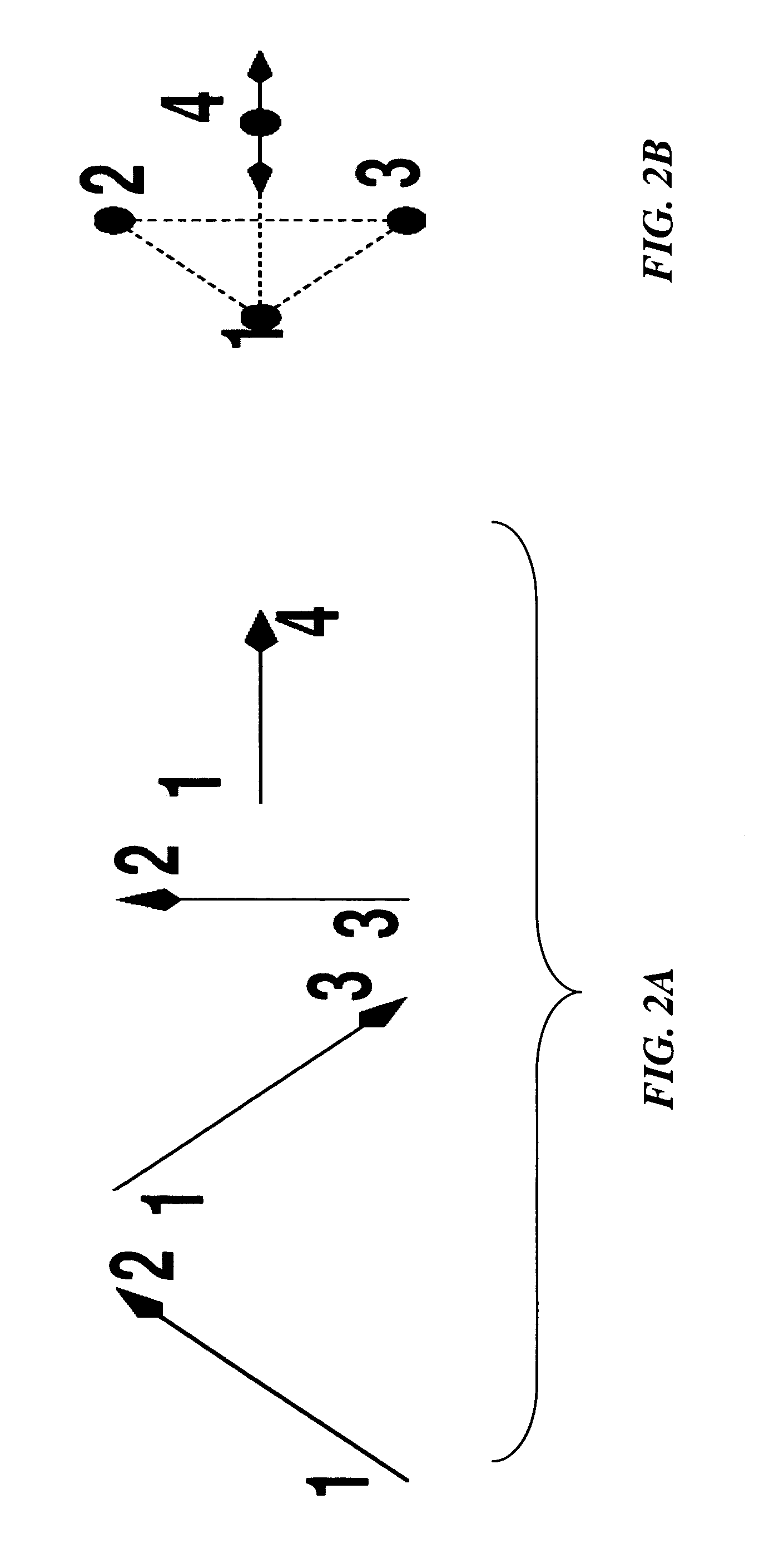

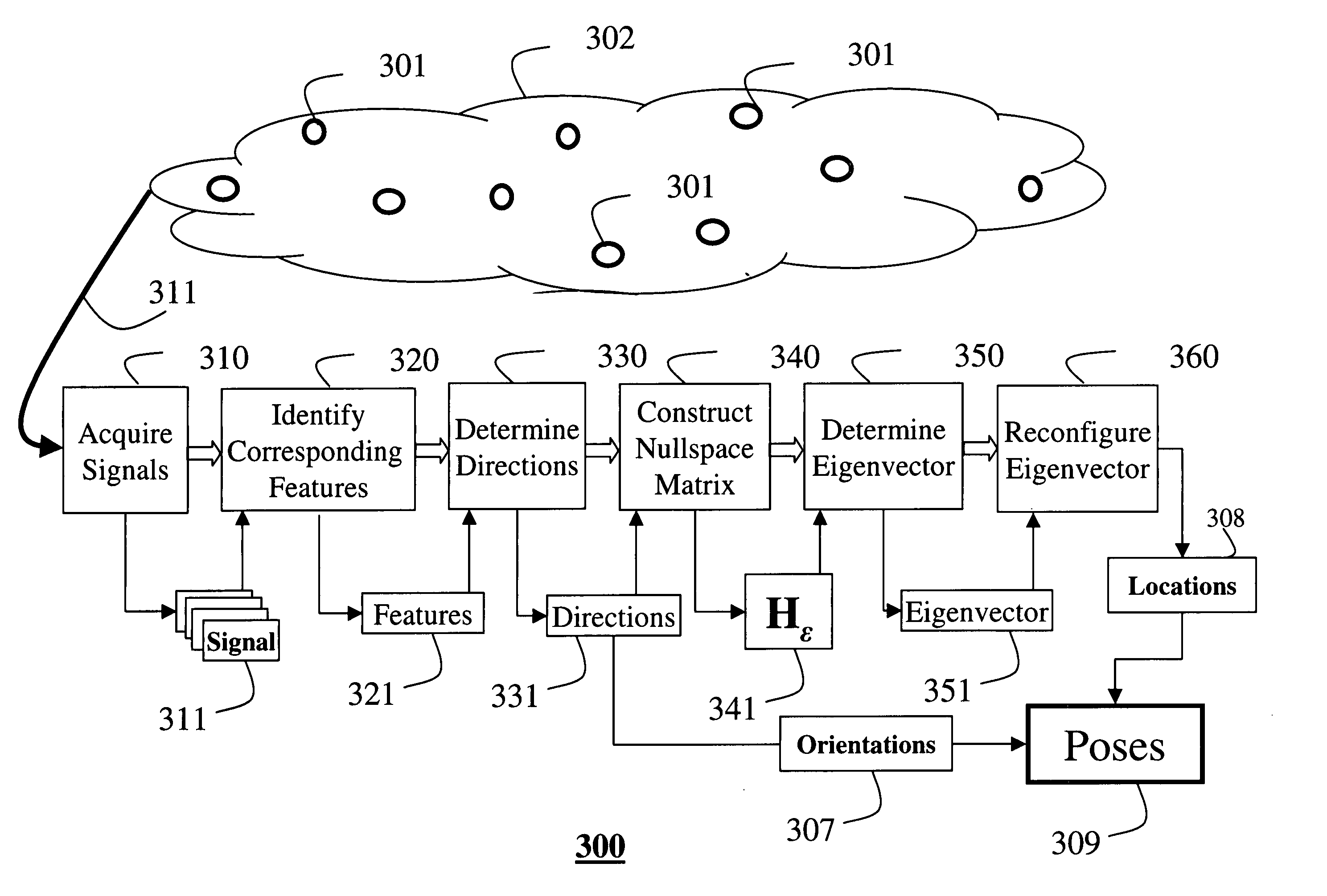

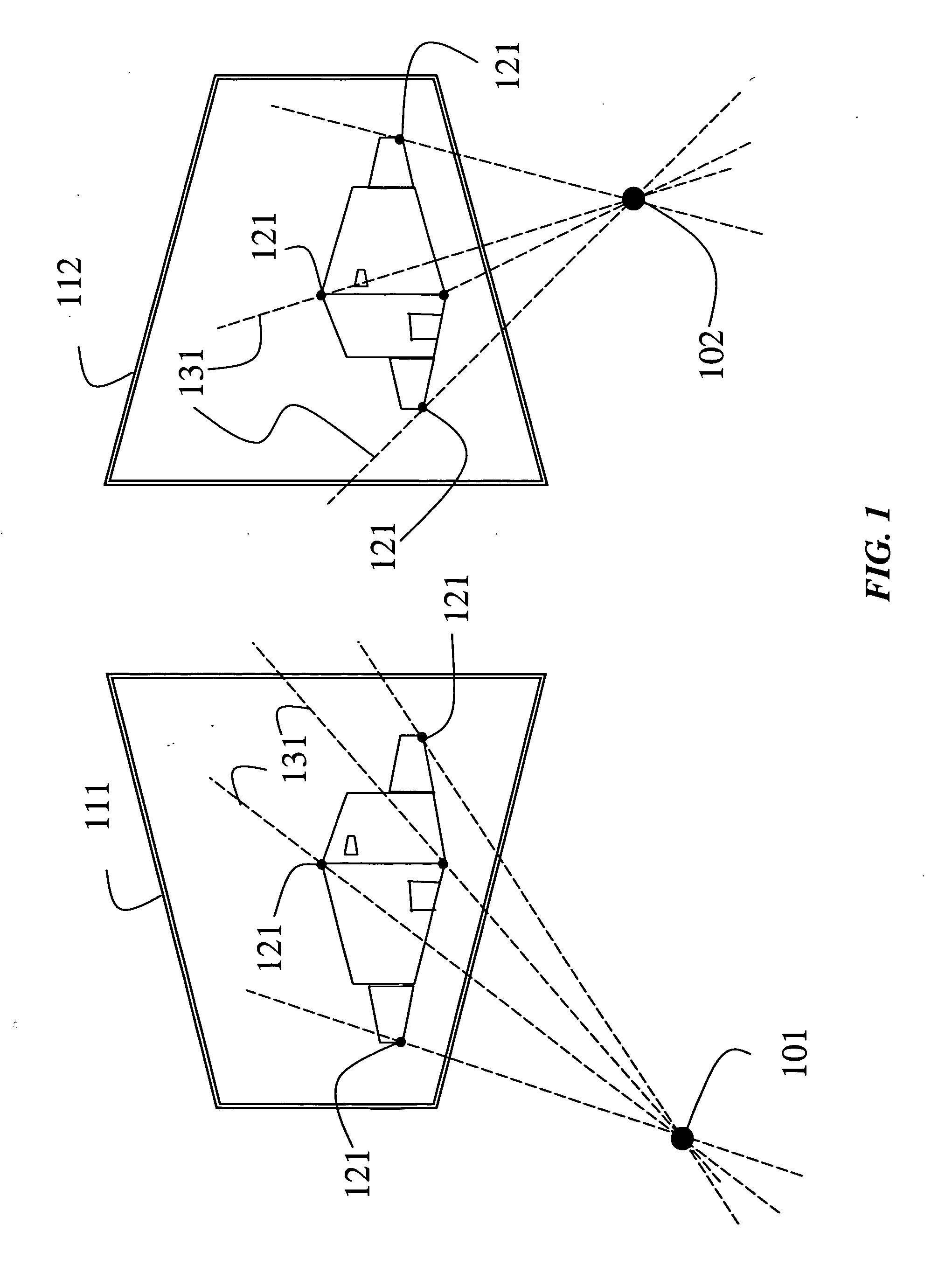

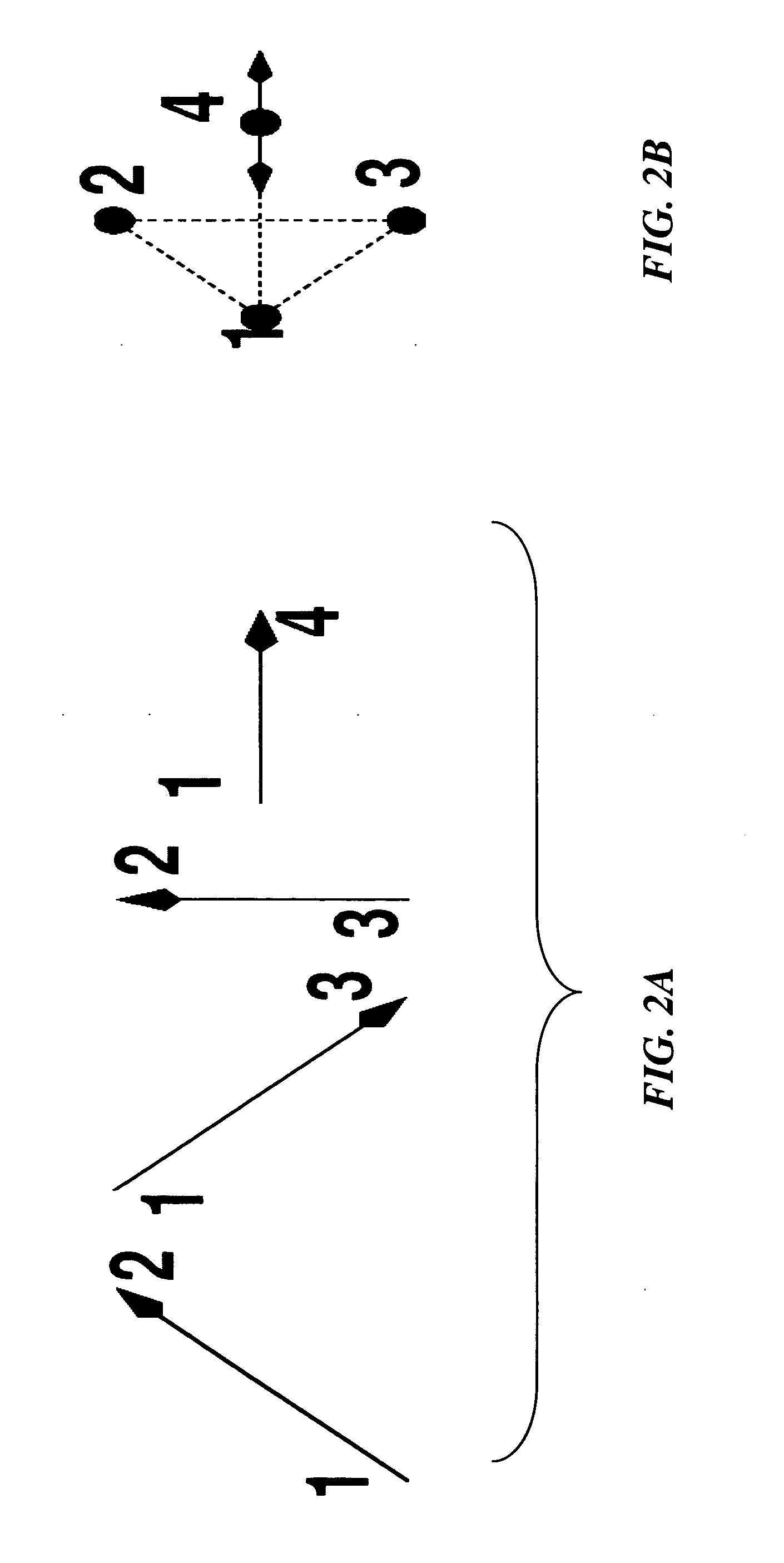

Method for determining poses of sensors

ActiveUS7006944B2Numerically stableFast to implementDirection finders using radio wavesAmplifier modifications to reduce noise influencePattern recognition

A method determines poses of a sensors distributed in an environment. A signal of the environment is acquired by each sensor. Features in each signal that correspond to the features in at least one other signal are identified. Directions between the sensors and the corresponding features are determined. Nullspaces of the directions are used to construct a matrix. A nullspace eigenvector is determined of the matrix, and then the nullspace eigenvector is reconfigured to a matrix specifying the locations of the sensors.

Owner:MITSUBISHI ELECTRIC RES LAB INC

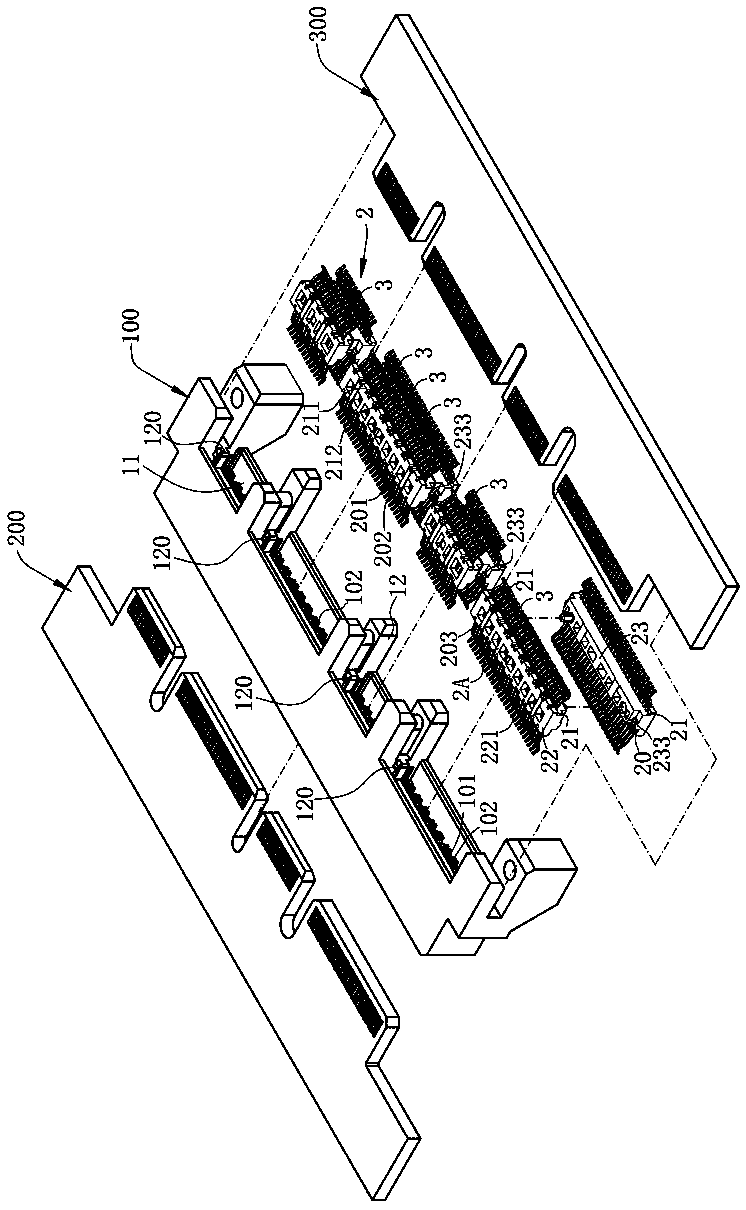

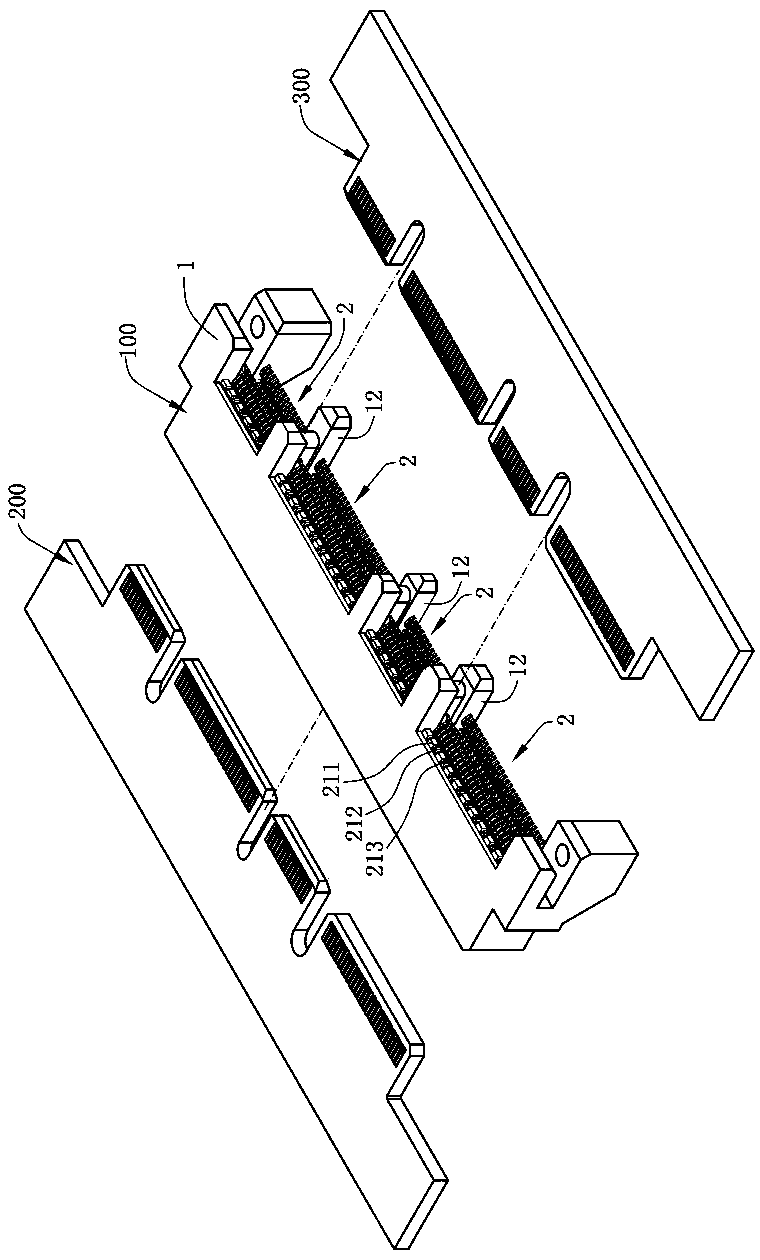

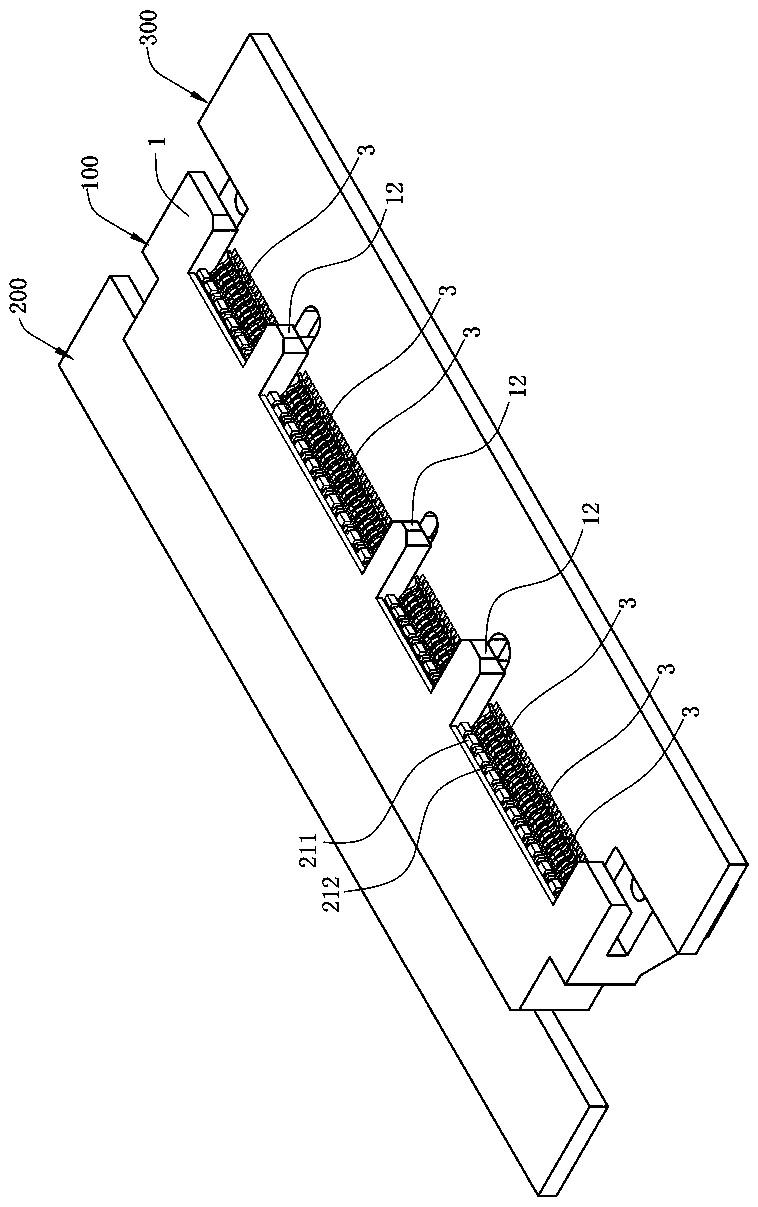

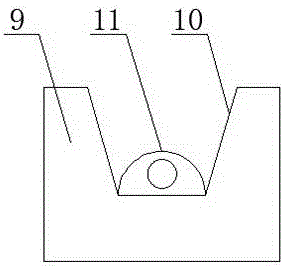

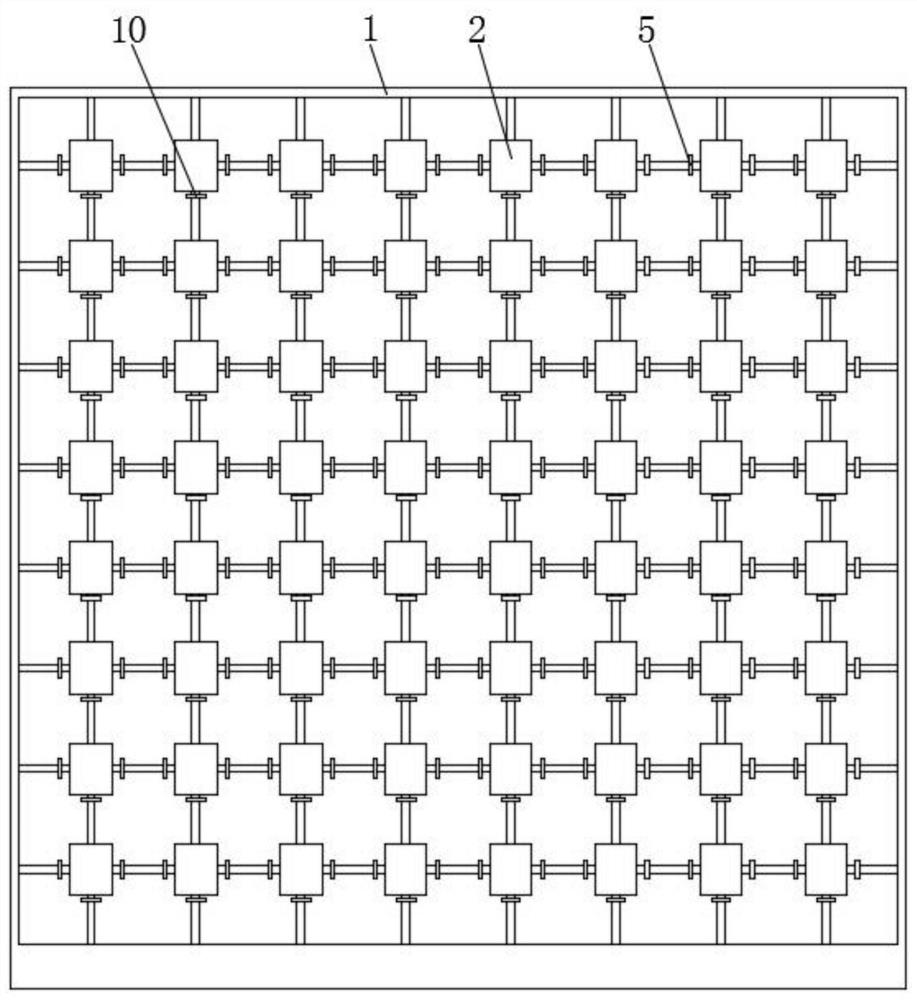

Electric connector

ActiveCN108832339AIncrease the facing areaSuppress volatilitySecuring/insulating coupling contact membersCouplings bases/casesElectricityDifferential signaling

The invention discloses an electric connector which is used for being inserted and connected into a butt joint element forwardly. The electric connector is characterized by comprising an insulating block, a plurality of pairs of differential signal terminals and a plurality of grounding terminals, wherein a plurality of first protruding blocks and a plurality of second protruding blocks are arranged on the front surface of the insulating block in a protruding mode; the first protruding block and the second protruding block are adjacently arranged, and a groove is formed between every two adjacent first protruding blocks and the second protruding blocks; the plurality of pairs of differential signal terminals and the plurality of grounding terminals are embedded in the insulating blocks; each differential signal terminal is embedded in the corresponding first protruding block and extends out of the first protruding block, and is used for electrically contacting the butt joint element; afirst side surface is arranged on each of the left side and the right side of the pair of differential signal terminals separately; the grounding terminals are arranged between the two adjacent pairsof differential signal terminals; each grounding terminal is embedded in the corresponding second protruding block and extends out of the second protruding block, and is used for electrically contacting the butt joint element; a second side surface is arranged on each of the left side and the right side of the grounding terminal separately; and the medium between the first side surface and the second side surface is air.

Owner:DEYI PRECISION ELECTRONIC IND CO LTD PANYU

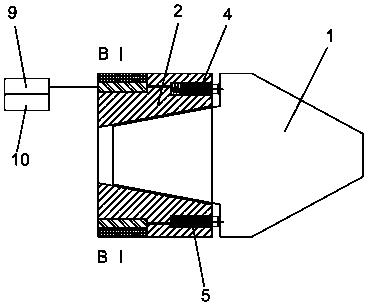

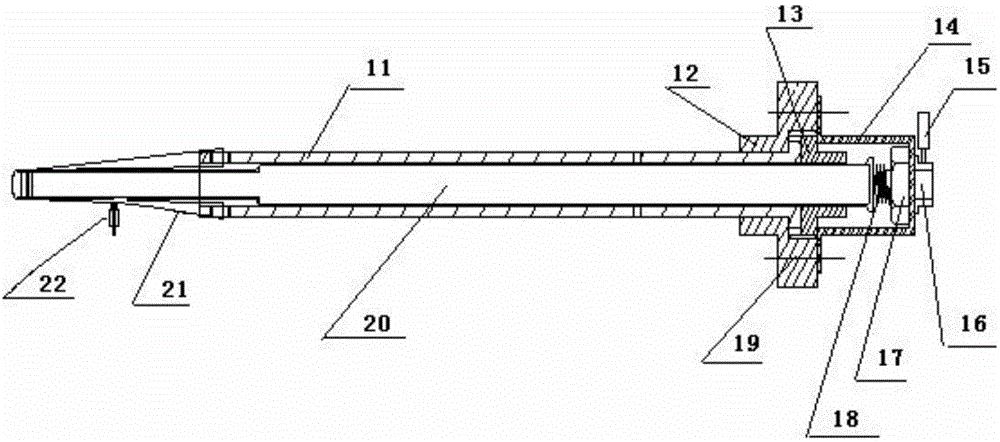

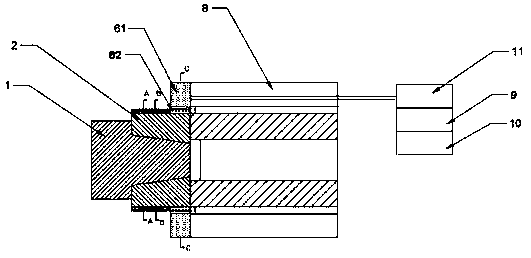

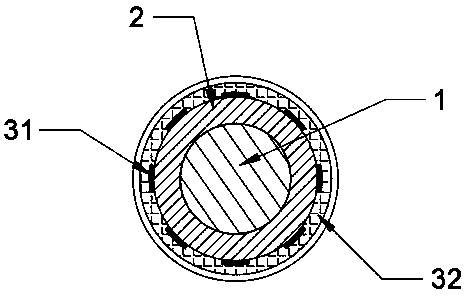

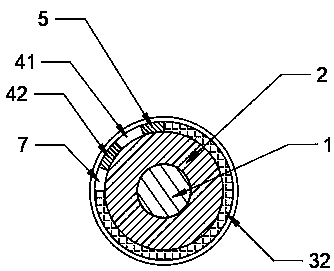

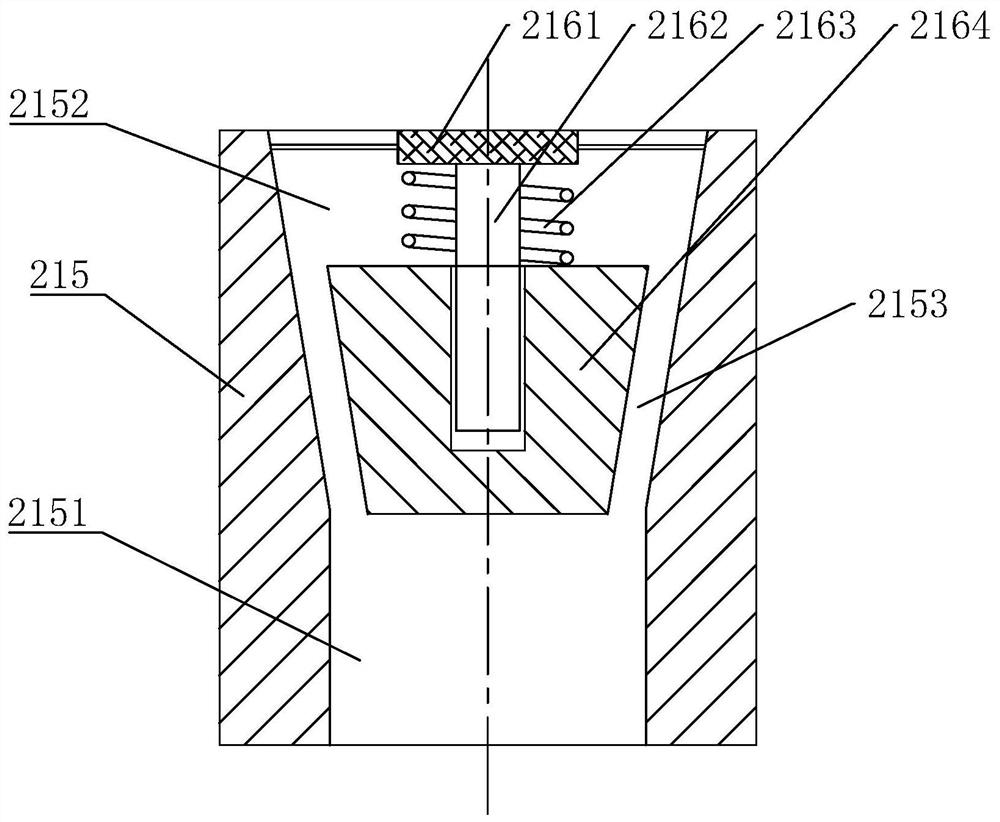

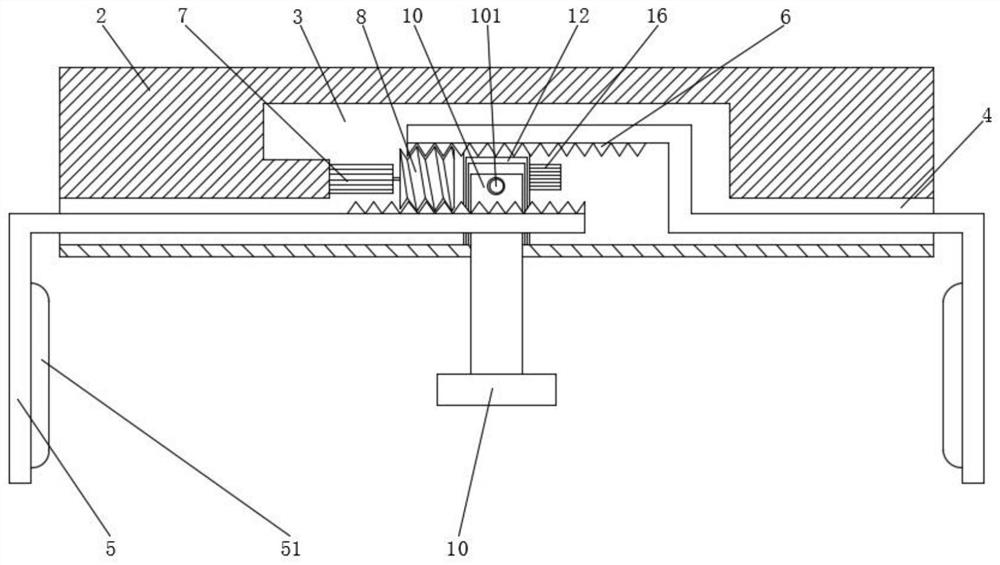

Piezoelectric drive type electric spindle chip mingling detection device used for numerical control machine tool

ActiveCN110695765AImprove detection accuracyAlarm Threshold StabilityMeasurement/indication equipmentsMaintainance and safety accessoriesNumerical controlEngineering

The invention relates to the technical field of machine tool parts, in particular to a piezoelectric drive type electric spindle chip mingling detection device used for a numerical control machine tool. The piezoelectric drive type electric spindle chip mingling detection device comprises a conical clamp body used for clamping a tool handle and is characterized in that piezoelectric ceramic blockswhich can stretch out of the clamp body after being electrified are evenly distributed in the end, making contact with the tool handle, of the clamp body; the ends, being capable of stretching out ofthe clamp body, of the piezoelectric ceramic blocks are provided with electric conduction touch terminals; and the piezoelectric ceramic blocks include one movable piezoelectric ceramic block and multiple fixed piezoelectric ceramic blocks, and different electric properties are applied to the electric conduction touch terminals at the end portions of the fixed piezoelectric ceramic block and themovable piezoelectric ceramic blocks. During tool feeding of the numerical control machine tool, whether iron chips are mingled between the faces, making contact with the two end faces and two positions of a conical face of the tool handle clamp installed on the electric spindle of the numerical control machine tool, of the tool handle or not is detected, the detected alarming critical value can be preset, the numerical value is stable, and the detection accuracy, stability and reliability are improved.

Owner:YANTAI UNIV

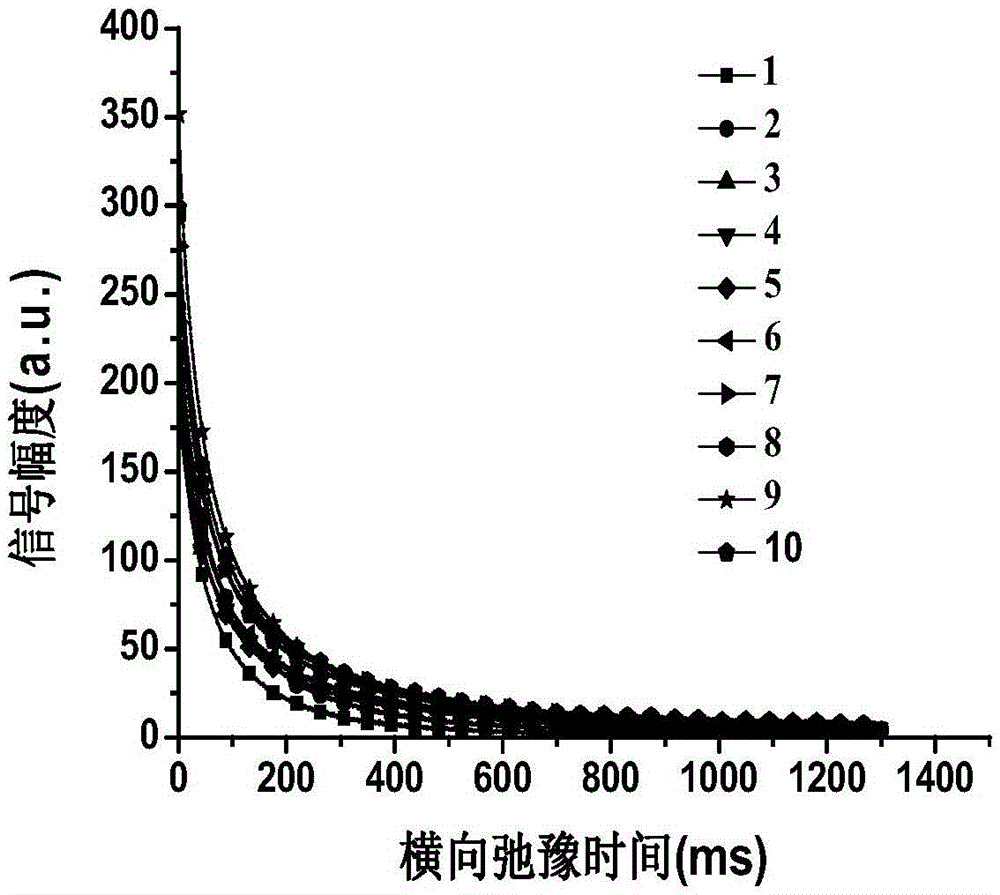

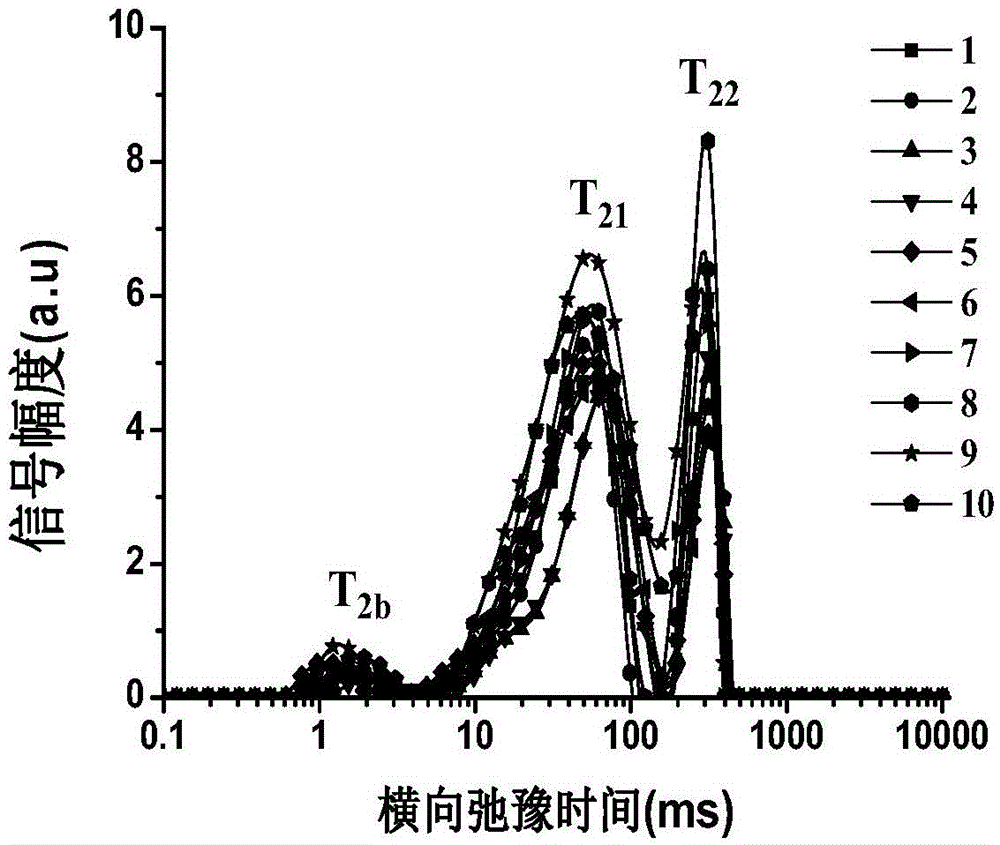

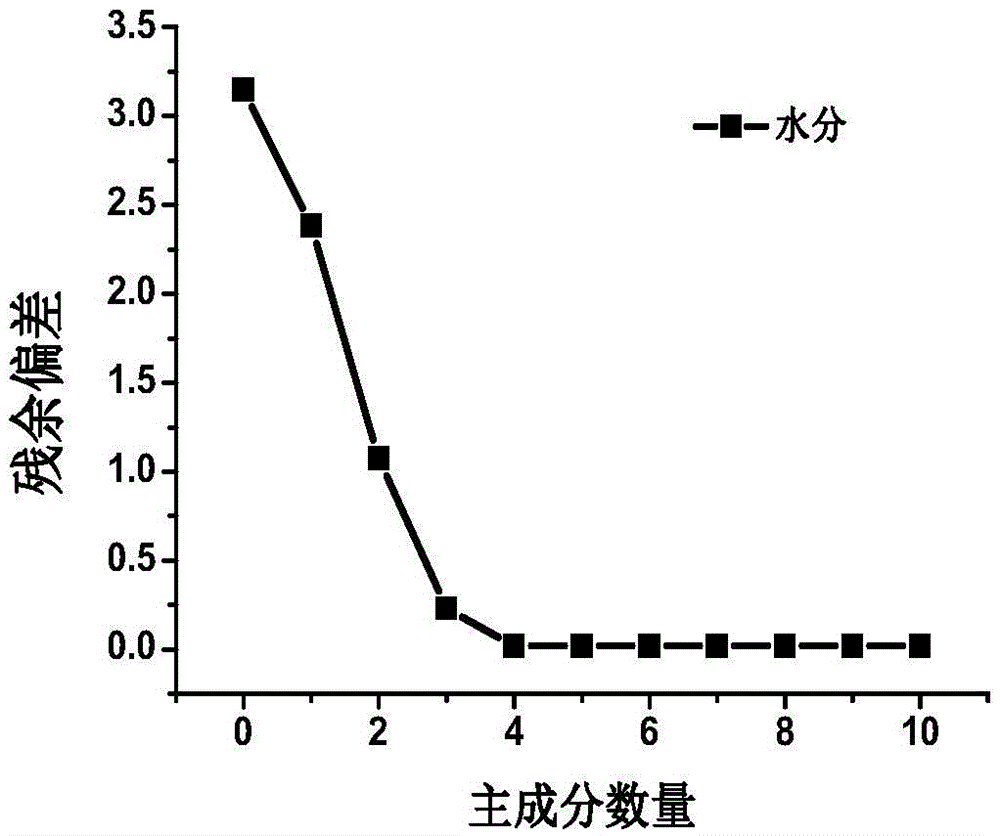

Method for detecting water content and fat content in abalone through low-field nuclear magnetic resonance technology

ActiveCN105606637AEasy to operateMeet the needs of rapid analysisAnalysis using nuclear magnetic resonanceLow field nuclear magnetic resonanceFat content

The invention provides a method for detecting the water content and fat content in abalone through a low-field nuclear magnetic resonance technology. The method comprises the following first step of collecting samples, the second step of carrying out low-field nuclear magnetic analysis on the sample, the third step of measuring the samples, the fourth step of establishing a model, the fifth step of evaluating the model, and the sixth step of measuring the water content and the fat content of the samples to be detected. By means of the method, the water content and fat content in abalone can be measured at the same time, detection is rapid and accurate and free of the influence of the surface feature of abalone, and abalone is not damaged in the measuring process.

Owner:DALIAN POLYTECHNIC UNIVERSITY

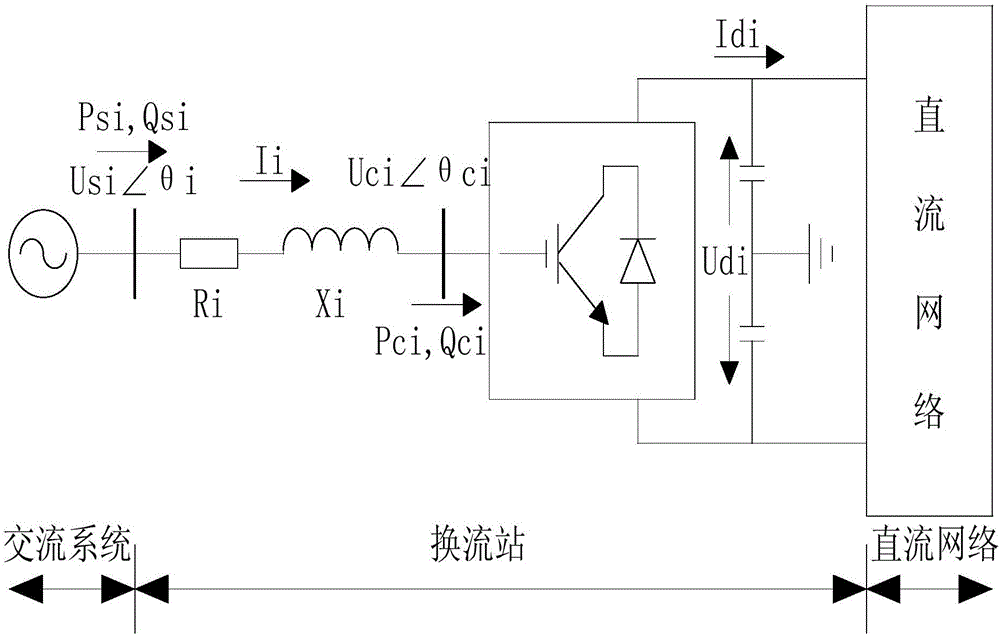

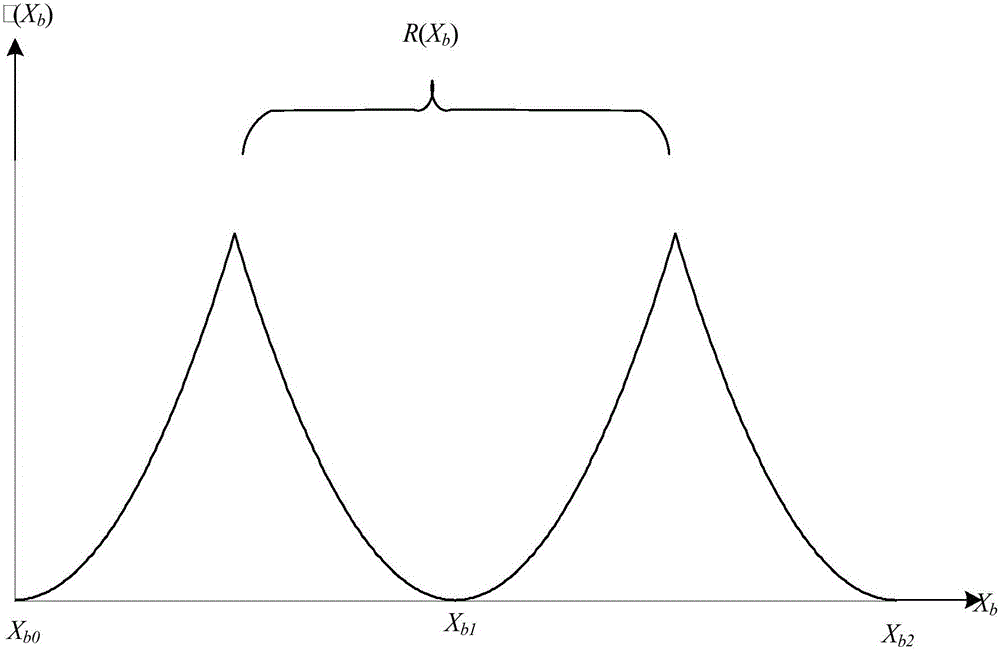

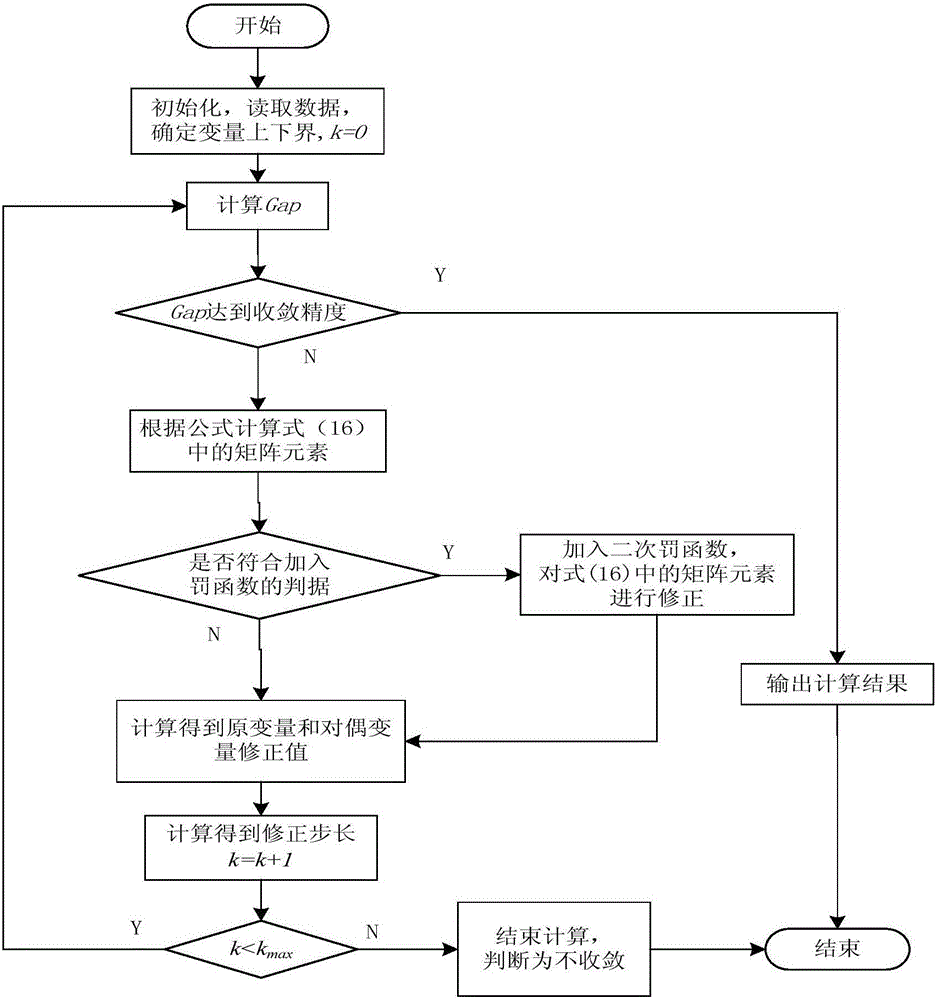

Precision discrete optical power flow calculation method of VSC-HVDC (voltage source converter based high voltage direct current) containing AC/DC system

InactiveCN105978046AEasy to handleImprove search abilityElectric power transfer ac networkForecastingOptical powerVoltage source

The invention relates to a precision discrete optical power flow calculation method of a VSC-HVDC (voltage source converter based high voltage direct current) containing AC / DC system. The calculation method is characterized by comprising the steps of firstly analyzing a power steady-state equation and other modified equations of the VSC-HVDC containing AC / DC system, then setting equality constraints and inequality constraints, and finally introducing a positive curvature quadratic penalty function into an interior point method. According to the calculation method, the interior point method is adopted to carry out optimization on continuous variables of the AC / DC system, the penalty function is introduced when a certain condition is reached, and discrete variables are constrained and optimized. Meanwhile, parameter values of the penalty function are continuously adjusted according to variations of the iteration quantity, and finally a purpose of optimizing the continuous variables and the discrete variables simultaneously is achieved.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD JIAXING POWER SUPPLY CO

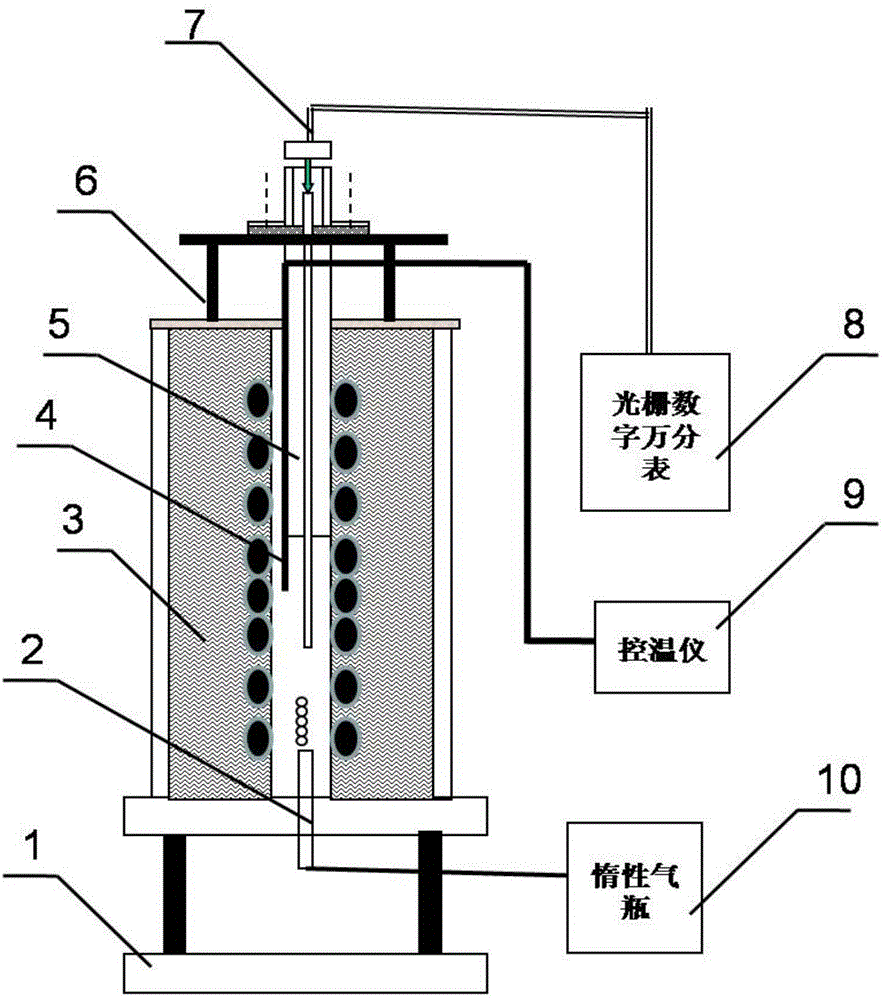

Fiber medium-temperature longitudinal coefficient-of-linear-expansion testing device

ActiveCN103983658ASimple structureStable structureMaterial thermal coefficient of expansionTemperature controlFiber

The invention discloses a fiber medium-temperature longitudinal coefficient-of-linear-expansion testing device, the temperature range of which is from a room temperature to 800 DEG C. The fiber medium-temperature longitudinal coefficient-of-linear-expansion testing device comprises a grate, a gas tube, an electric heating furnace, a thermocouple, a quartz differential sensor unit, a quartz differential sensor unit bracket, a raster digital displacement sensor probe, a raster digital universal meter, a temperature-controlled instrument, and an inert gas cylinder. The fiber medium-temperature longitudinal coefficient-of-linear-expansion testing device has a technical core of the design of the quartz differential sensor unit and a connecting method of a fiber sample to be tested. The fiber medium-temperature longitudinal coefficient-of-linear-expansion testing device is capable of effectively solving all main technical problems and difficulties of the prior art, and remarkably improving the longitudinal coefficient-of-linear-expansion testing precision of fiber materials with low coefficient-of-linear-expansion characteristic.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

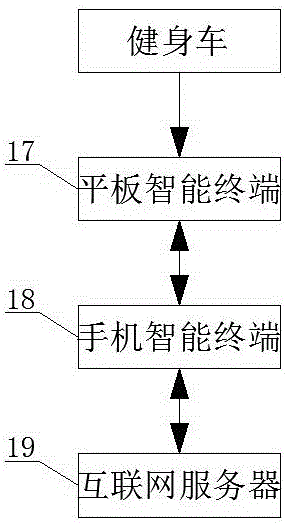

Intelligent riding training system

InactiveCN106693289AGood stabilityLow costMovement coordination devicesCardiovascular exercising devicesInternet serversData migration

The invention discloses an intelligent riding training system, and relates to the field of exercise and fitness. The intelligent riding training system comprises an exercise bicycle, a tablet intelligent terminal, a mobile phone intelligent terminal and an internet server. As a conventional training system of an exercise bicycle is optimized, the exercise data acquisition accuracy is improved, multiple actually tested data meaningful for exercise can be directly acquired, different fitting data standards can be unified and referable, data migration can be conveniently implemented, the individual training efficiency can be specifically improved, the activeness of training on schedule and exercise attention can be improved, the exercise injury risk can be reduced, relatively real riding experience can be provided, and thus the exercise effect of the exercise bicycle can be ultimately improved.

Owner:林卿

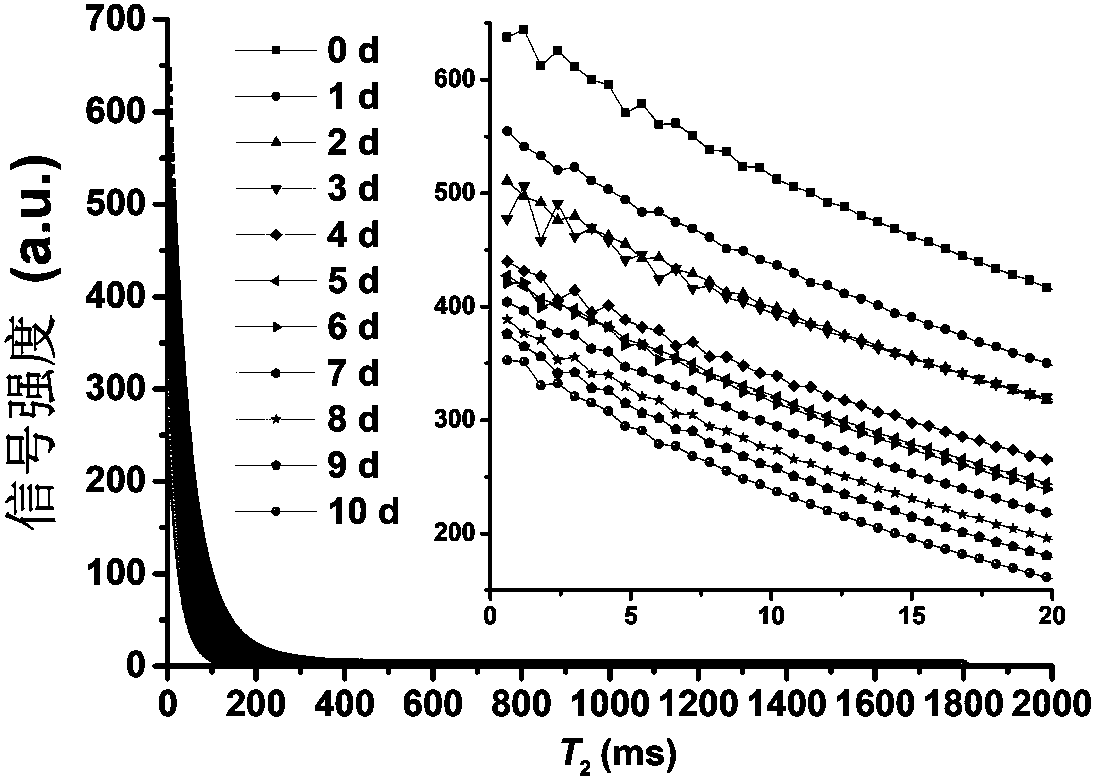

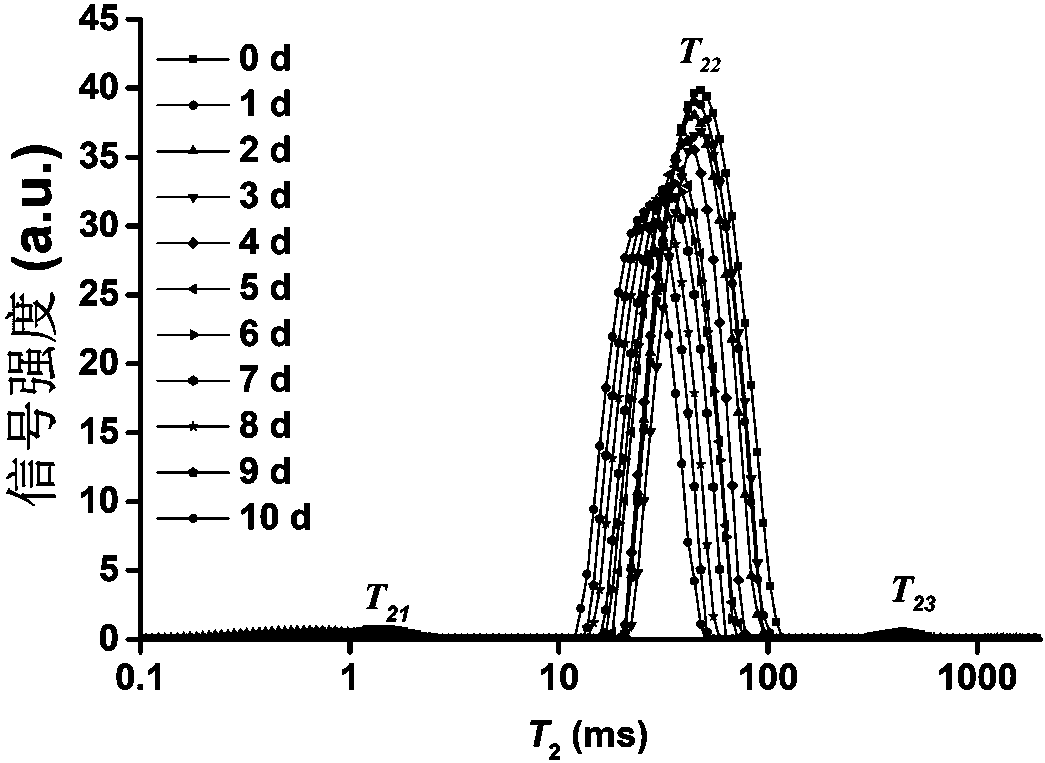

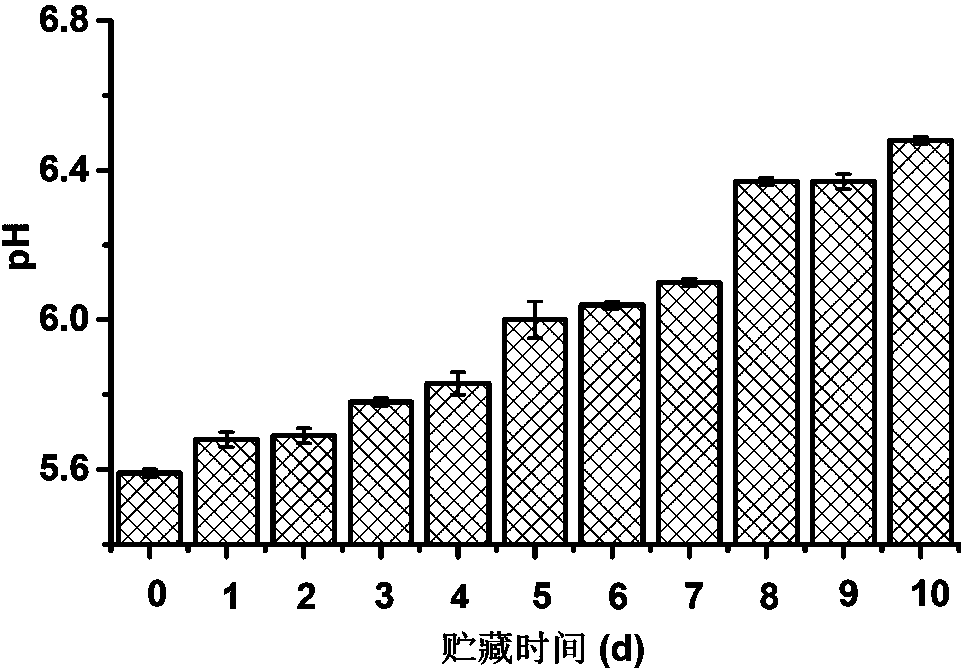

Low field nuclear magnetic resonance-applied frozen beef freshness nondestructive testing method

InactiveCN109444199AMeet the needs of rapid analysisBeef bustingAnalysis using nuclear magnetic resonanceNitrogenThiobarbituric acid

The invention discloses a low field nuclear magnetic resonance-applied frozen beef freshness nondestructive testing method. The low field nuclear magnetic resonance-applied frozen beef freshness nondestructive testing method comprises the following steps of (A) sample collection, (B) sample measurement, (C) sample low field nuclear magnetic analysis, (D) multiple freshness-related index measurement, (E) model establishment, (F) model assessment and (G) measurement of freshness of samples to be detected. By establishing a mathematical predication model reflecting fresh beef moisture content relaxation spectrum information and multiple indexes related to fresh beef freshness to accurately and reliably detect multiple indexes of an unknown fresh beef simultaneously such as thiobarbituric acidreactive substances (TBARS), volatile basic nitrogen (TVB-N) and pH, the low field nuclear magnetic resonance-applied frozen beef freshness nondestructive testing method can help predict the storagetime of the beef and achieve rapid and nondestructive detection and assessment of the freshness of the fresh beef. The low field nuclear magnetic resonance-applied frozen beef freshness nondestructivetesting method is rapid and accurate, avoids influence of beef surface properties, and during measurement, has no damage to the beef.

Owner:DALIAN POLYTECHNIC UNIVERSITY

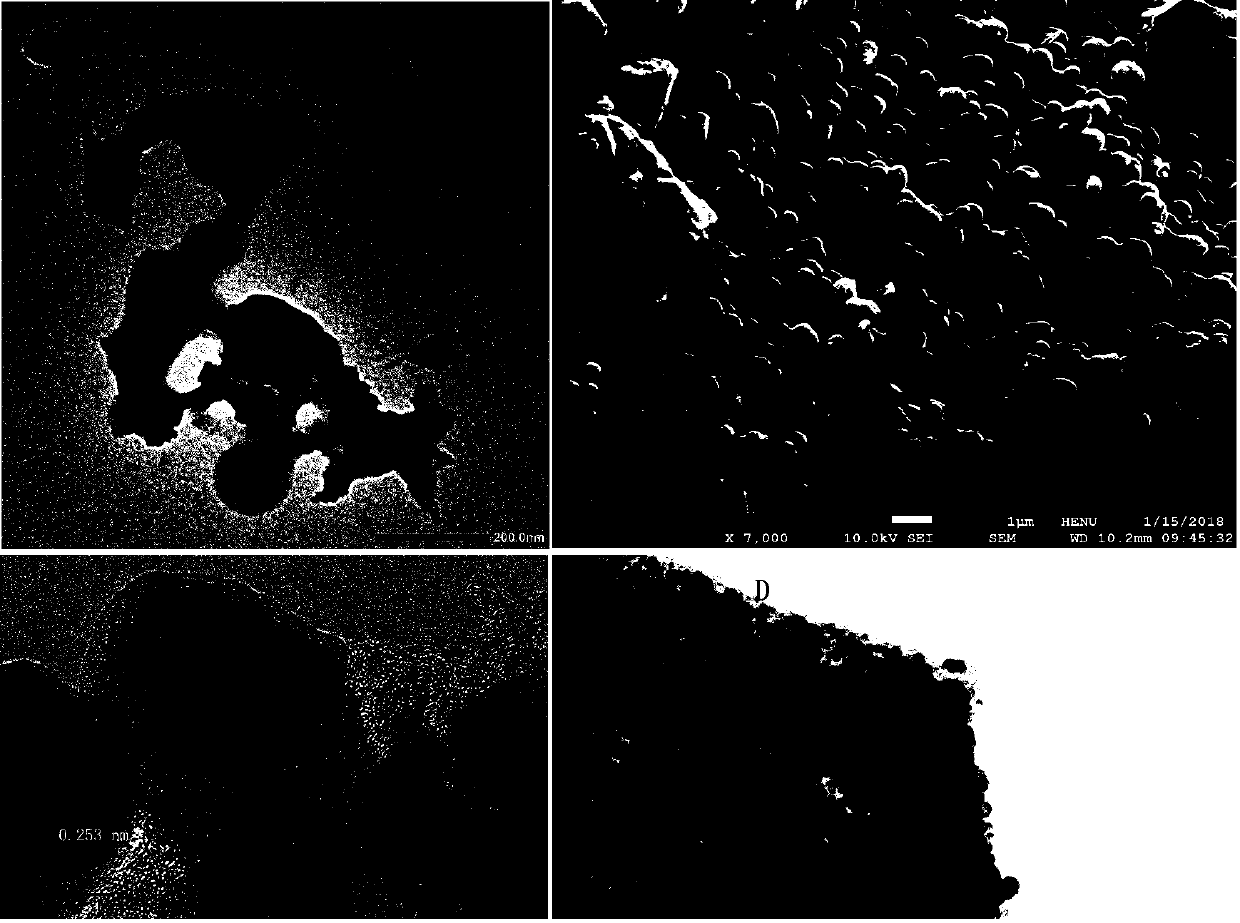

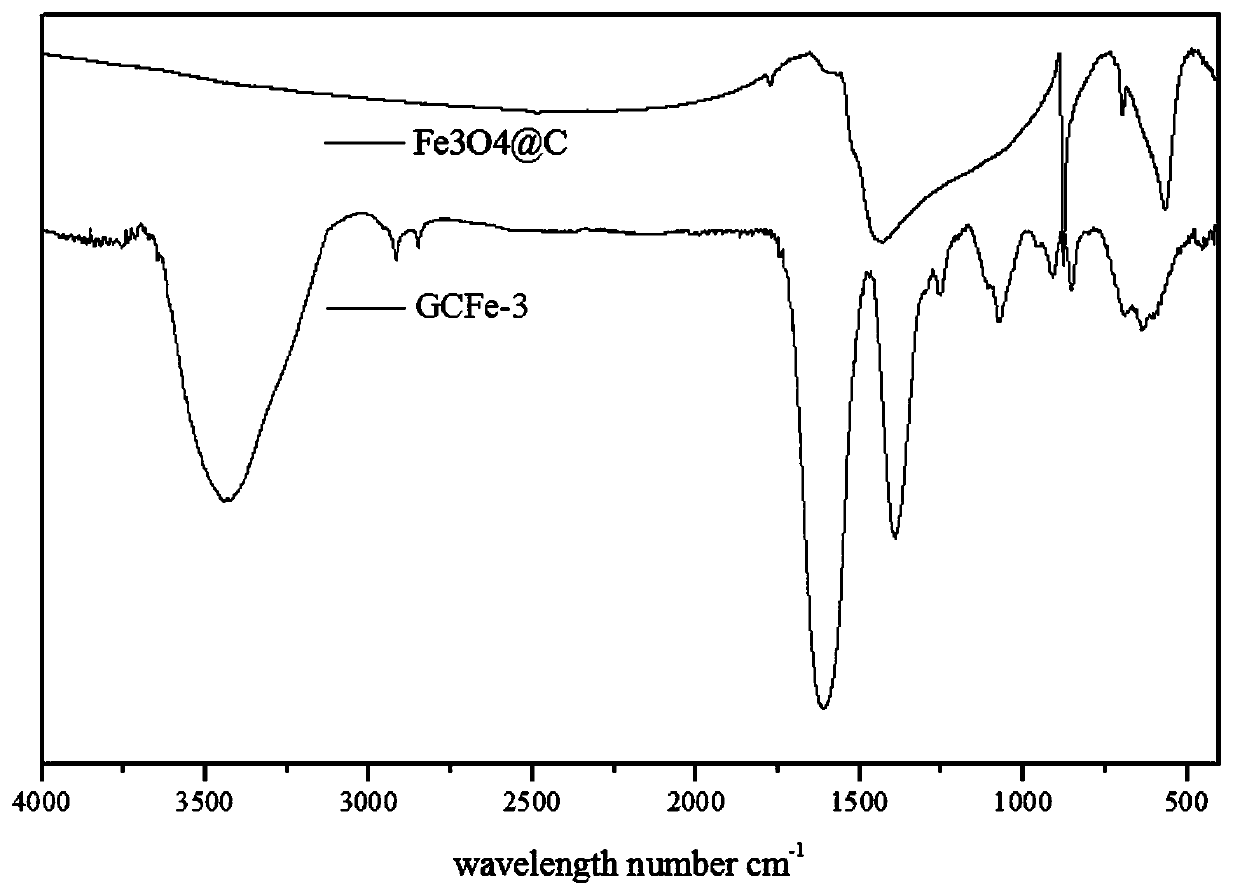

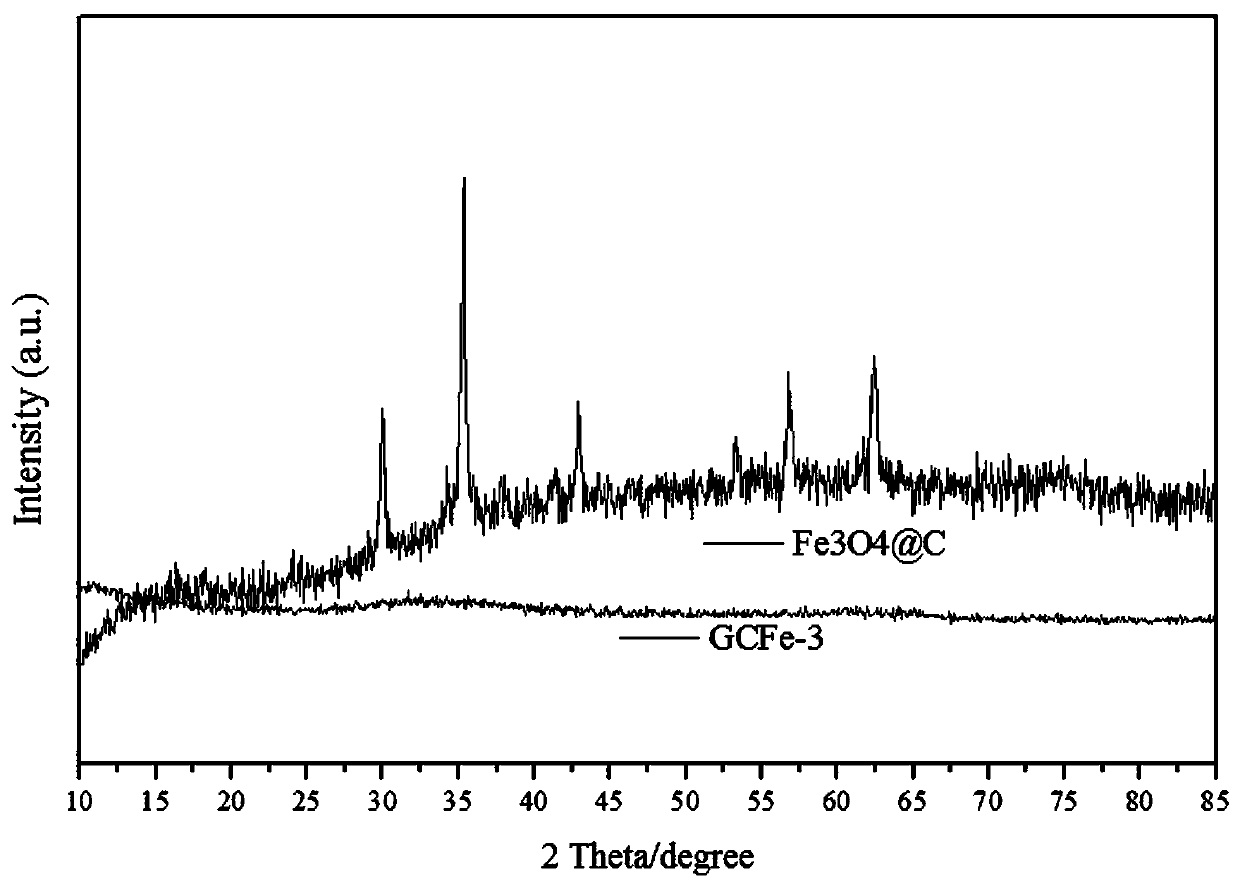

Carbon coated layer thickness adjustable nanometer ferroferric oxide composite material, preparation method and application thereof

InactiveCN110212192APlay a covering roleInhibition of agglomerationMaterial nanotechnologyCell electrodesCarbon layerOxide composite

The invention relates to the field of electrochemical materials, in particular to a carbon coated layer thickness adjustable nanometer ferroferric oxide composite material, a preparation method and application thereof. The preparation method comprises the following steps: firstly, taking sugar, a catalyst and a ferric salt solution as raw materials, reacting for 0.1 to 24 h under the conditions that the pH is 5 to 10 and the temperature is 5 to 90 DEG C, preparing an iron-sugar complex, and thus preparing the carbon coated layer thickness adjustable nanometer ferroferric oxide composite material from the iron-sugar complex through in situ calcinations or a hydrothermal method. The nanometer ferroferric oxide composite material with a carbon coated layer is prepared through different in situ calcinations conditions or the hydrothermal method by using the iron-sugar complex as a precursor, and due to the fact that a multi-stage carbon structure array can play the role of a fixed frame for ferroferric oxide, the volume effect in the charge and discharge cycle process is reduced, and when the composite material serves as the negative electrode of a battery, the performance of the battery can be improved obviously. The thickness of the carbon coated layer inside the carbon coated ferroferric oxide composite material can be changed by changing the additive amounts of sugar and the catalyst.

Owner:HENAN UNIVERSITY

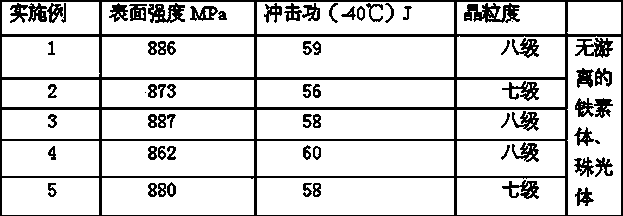

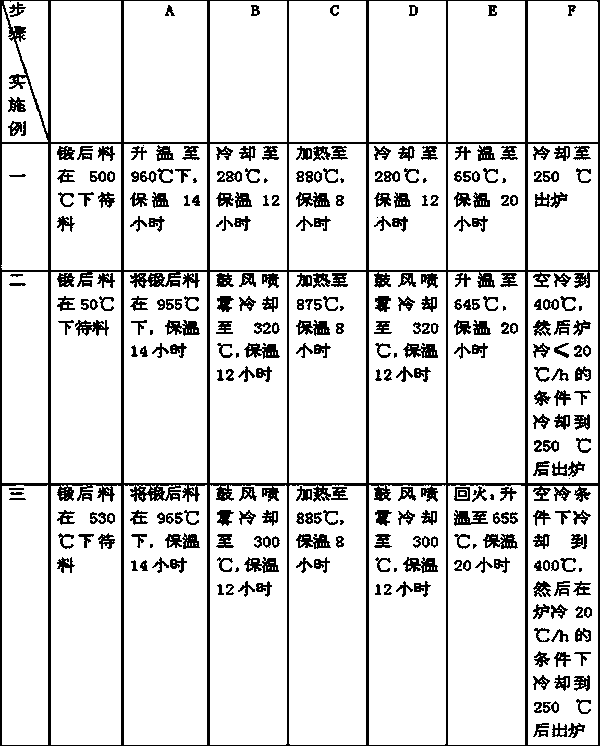

Method for performing heat treatment on wind power main shaft after forging

InactiveCN103409606AImprove mechanical propertiesNumerically stableFurnace typesHeat treatment furnacesElectricityForge

The invention discloses a method for performing heat treatment on a wind power main shaft after forging. The method is characterized by adopting twice normalizing and once tempering, wherein normalizing for the first time is carried out, namely, performing heat preservation on a forge piece at 960+ / -5 DEG C for 14 hours, and cooling to 280 to 320 DEG C and preserving heat for 12 hours; normalizing for the second time is carried out, namely, heating to 880+ / -5 DEG C and preserving heat for 8 hours, and cooling to 280 to 320 DEG C and preserving heat for 12 hours; tempering is carried out, namely, heating to 650+ / -5 DEG C and preserving heat for 20 hours, and cooling to 250 DEG C and discharging out of a furnace. By adopting the method for performing heat treatment after forging, the wind power main shaft has the advantages of uniform components, tiny grain crystals, good mechanical properties and good impact-resistant effect.

Owner:SHANDONG LAIWU JINLEI WIND POWER TECH

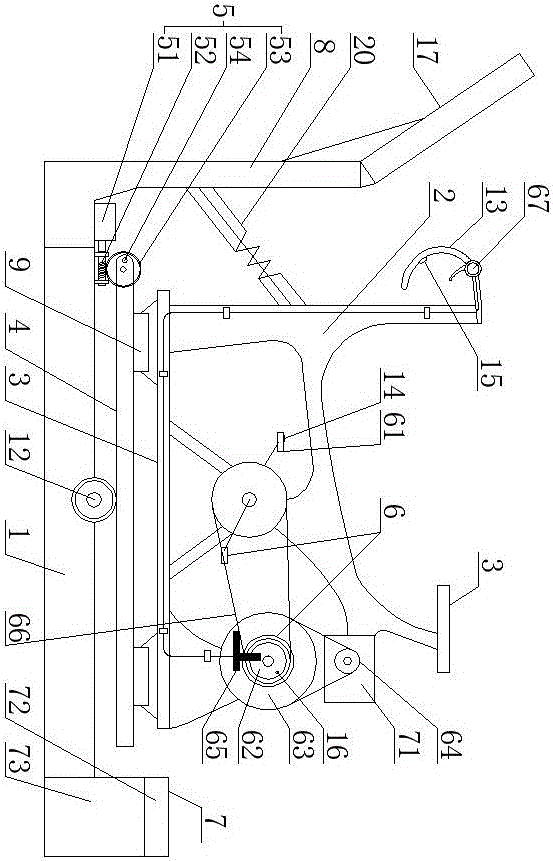

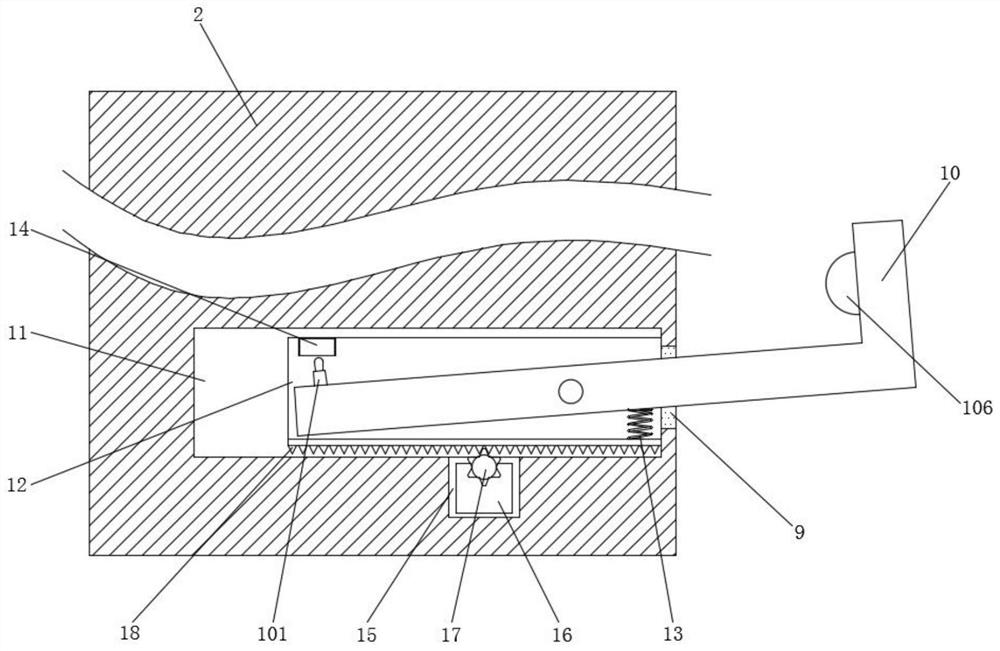

Detection system for chips adhering to electric spindle of numerical-control machine tool

ActiveCN109290850ASave resourcesReduce manufacturing costMeasurement/indication equipmentsElectrical resistance and conductanceNumerical control

The invention discloses a detection system for chips adhering to an electric spindle of a numerical-control machine tool. The detection system comprises a conical clamp body, a power supply module, asensor module, a signal processing module and a signal transmitting module. The power supply module, the sensor module, the signal processing module and the signal transmission module are arranged onthe outer surface of the conical clamp body. The sensor module is formed by at least four resistance strain gauges which are connected into a full-bridge circuit. The resistance strain gauges are evenly distributed on the outer circular surface of the conical clamp body. The signal processing module is used for converting a weak analog signal detected by the sensor module into a digital signal. The signal transmission module is used for wirelessly transmitting detected data. A detection device is integrated on a conical clamp of the spindle, and the full-bridge detection circuit is used, so that the detection sensitivity is high; and an alarm critical value can be preset, so that frequent value calibration is not needed, and the detection stability and reliability are improved.

Owner:YANTAI UNIV

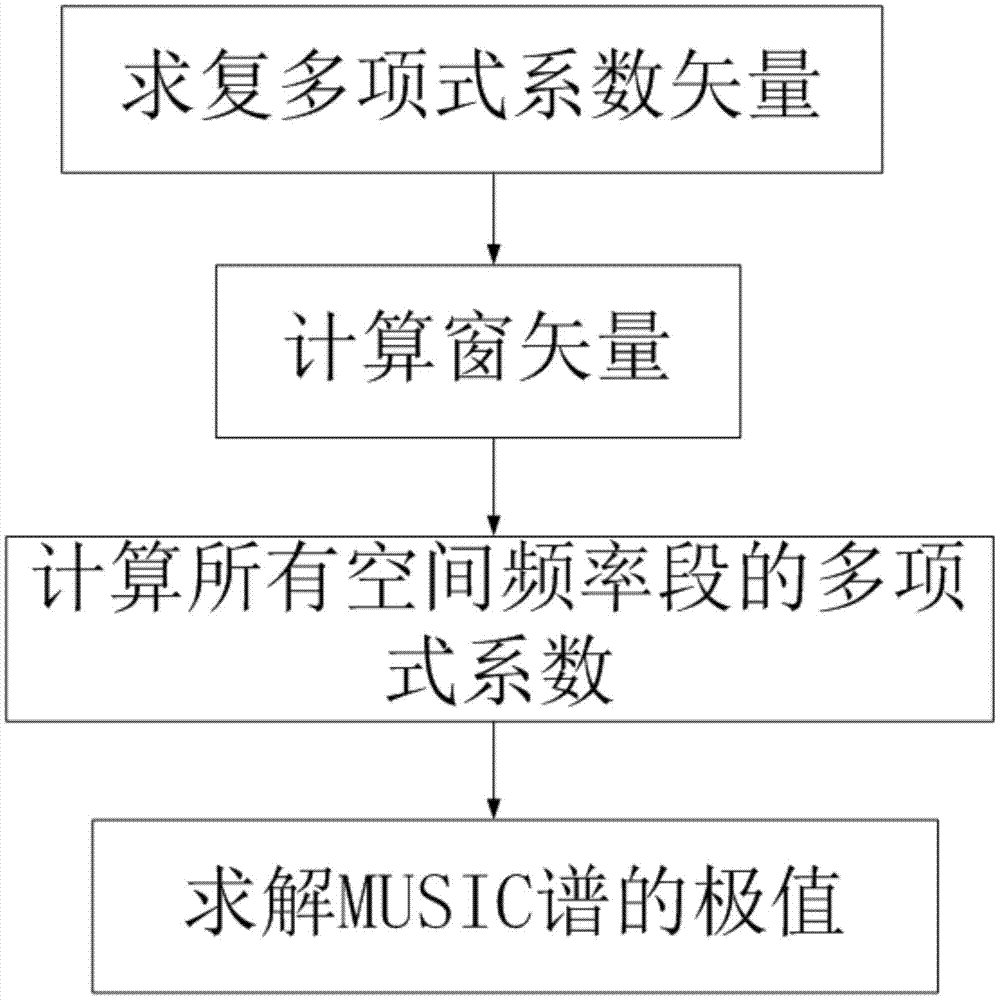

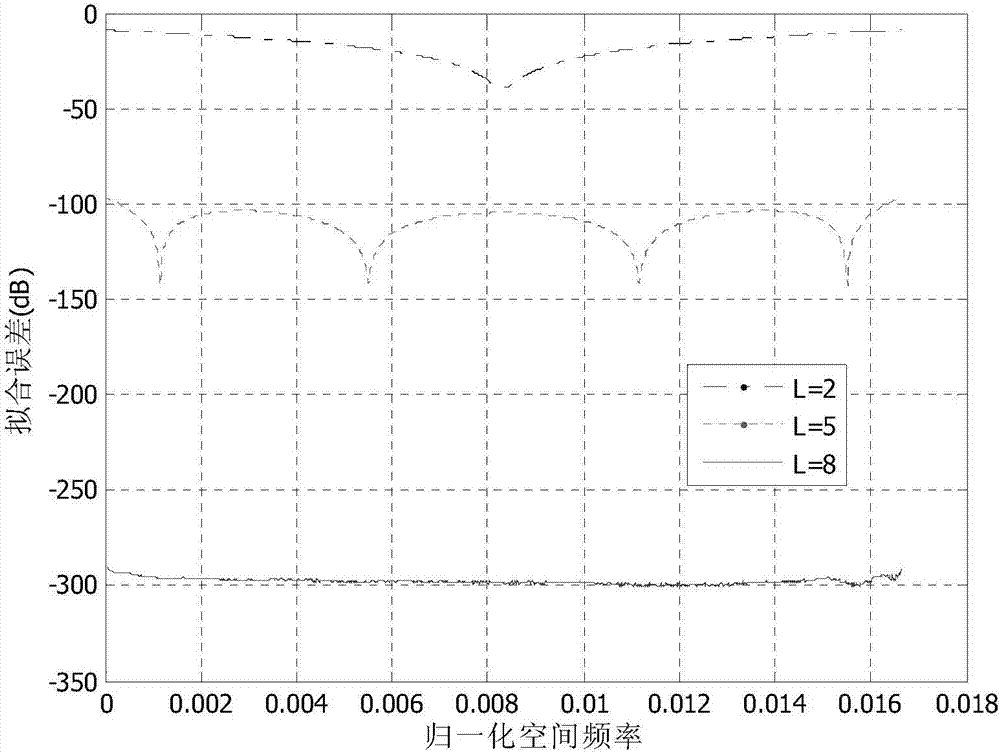

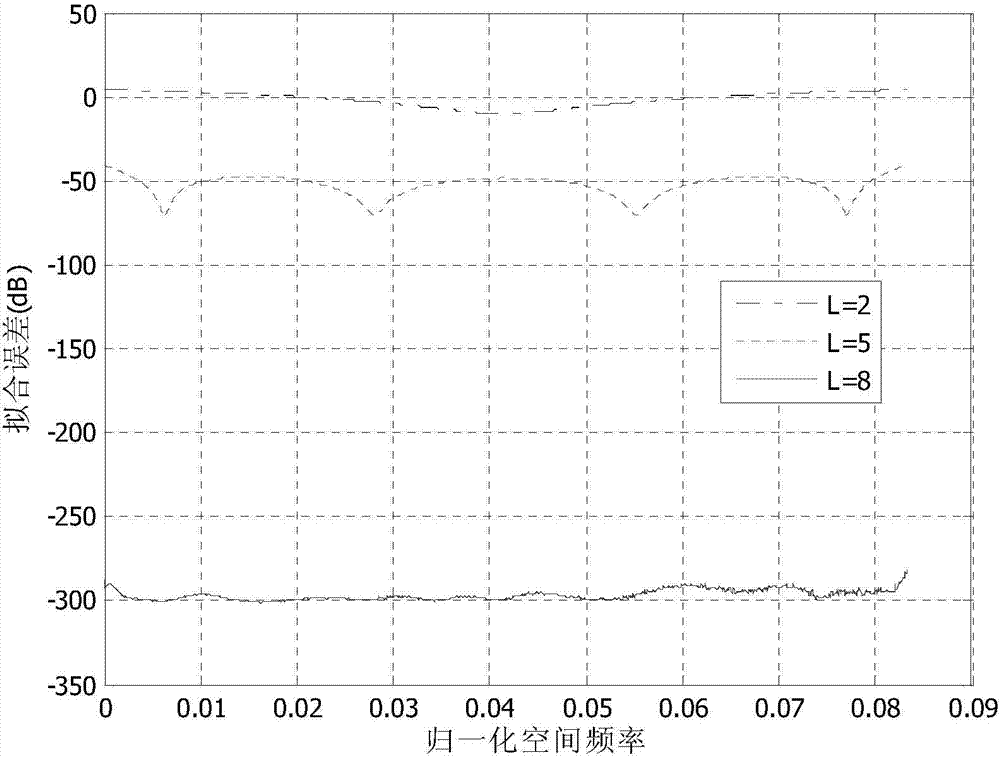

Spectrum MUSIC method for achieving uniform linear array by means of root computing of real polynomials

InactiveCN104123462AComputationally efficientReduce computational complexityWave based measurement systemsSpecial data processing applicationsNumerical stabilityComputation complexity

The invention belongs to the technical field of radar signal processing, and particularly relates to a spectrum MUSIC method for achieving a uniform linear array by means of root computing of real polynomials. The spectrum MUSIC method includes the following steps of (1) computing coefficient vectors of the complex polynomials, (2) computing a window vector, (3) computing coefficients of the polynomials of all intervals, and (4) computing extreme values of MUSIC spectrums. According to the method, the coefficient vectors of the complex polynomials are computed quickly through Fourier transformation, the method of computing the extremities of the MUSIC spectrums is changed into the method of computing roots of multiple sets of low-order polynomials, and windowing Fourier transformation is carried out on related vectors of a signal subspace so that the coefficients of all the sets of the polynomials can be obtained. The defects that in the prior art, elaborate angle searching algorithms are needed, computation complexity is high and value stability is poor are overcome, and the method has the advantages that computation complexity is low and value stability is good and has great potential in estimation of the direction of arrival in low complexity.

Owner:XIDIAN UNIV

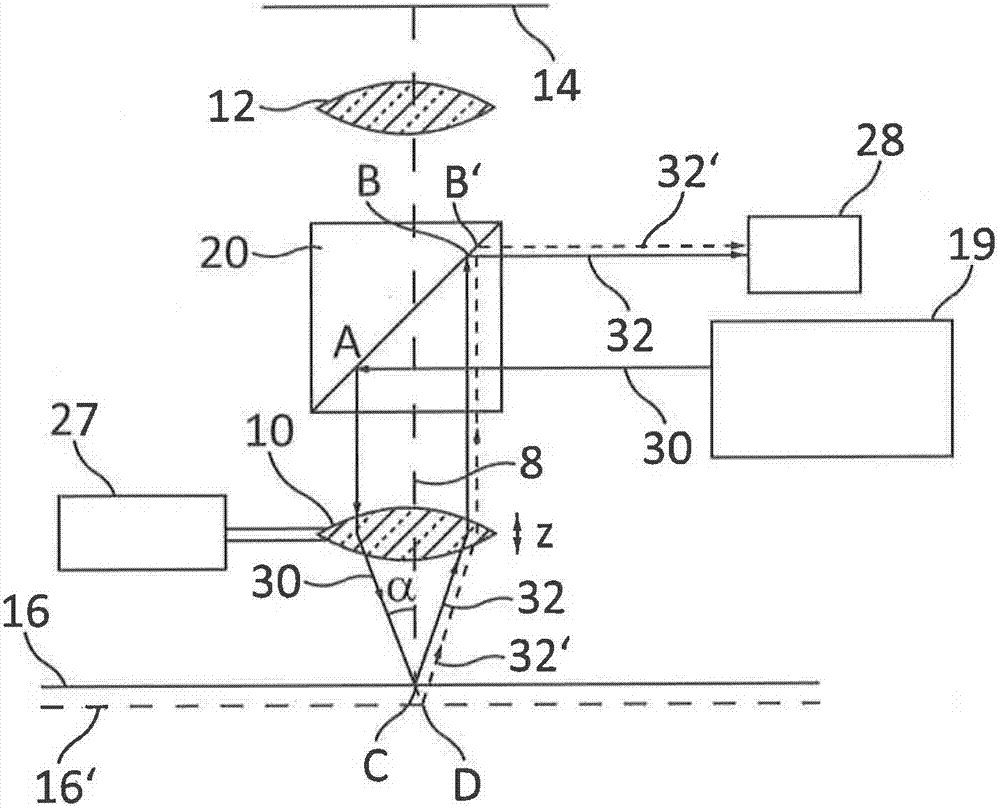

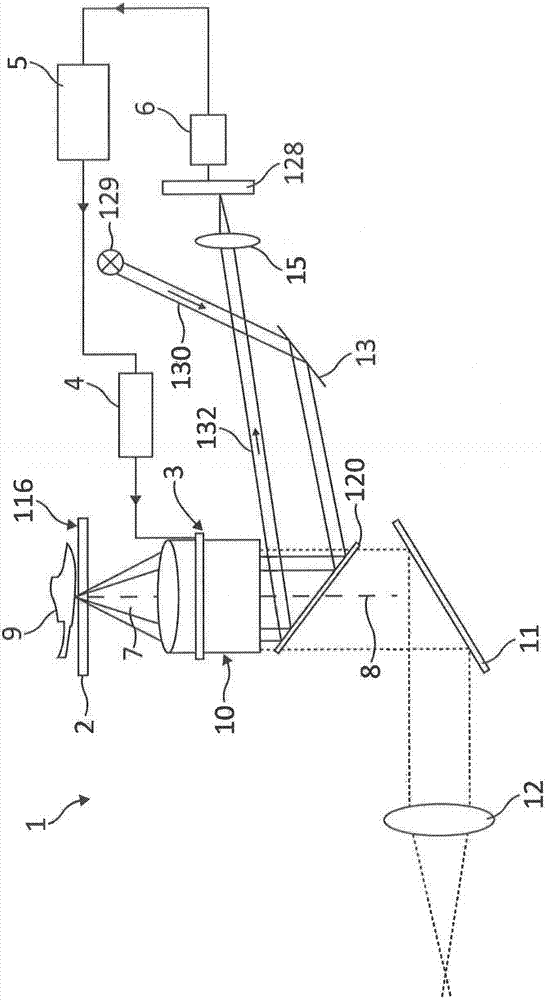

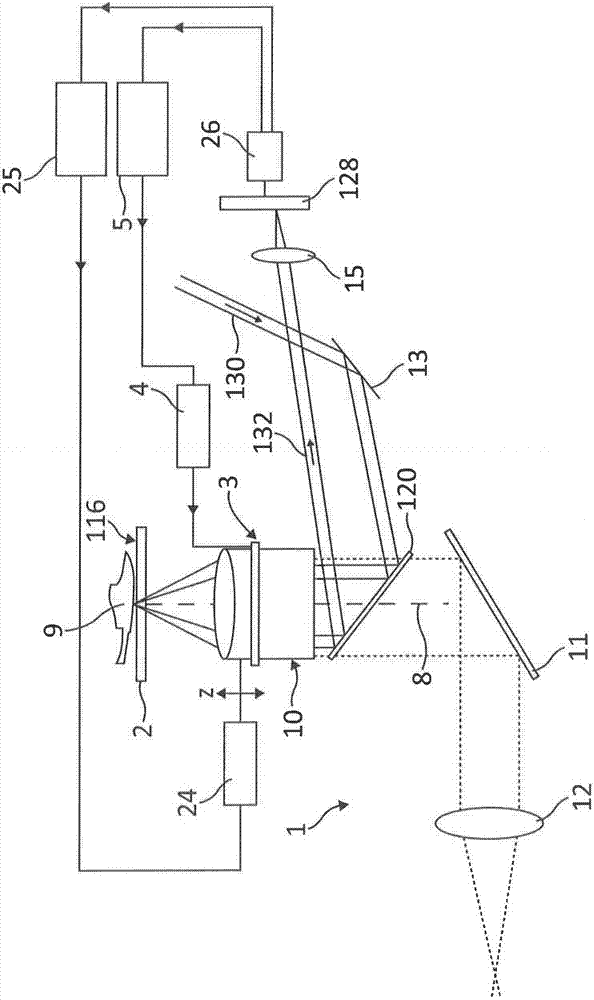

Method and apparatus for identifying and correcting spherical aberrations in a microscope imaging beam path

InactiveCN103048779AEliminate spherical aberrationIncrease overheadMicroscopesTesting optical propertiesOptical axisLight beam

A method and apparatus provide identification of a spherical error of a microscope imaging beam path in a context of microscopic imaging of a sample using a microscope having an objective. A coverslip that carries or covers the sample is arranged in the imaging beam path. A measurement beam is guided through the objective onto the sample in a decentered fashion that is outside an optical axis of the objective. The measurement beam is reflected at an interface of the coverslip with the sample and the reflected measurement beam is guided through the objective onto a detector. An intensity profile of the reflected measurement beam is detected with the detector and a presence of a spherical error from the intensity profile is determined qualitatively and / or quantitatively.

Owner:LEICA MICROSYSTEMS CMS GMBH

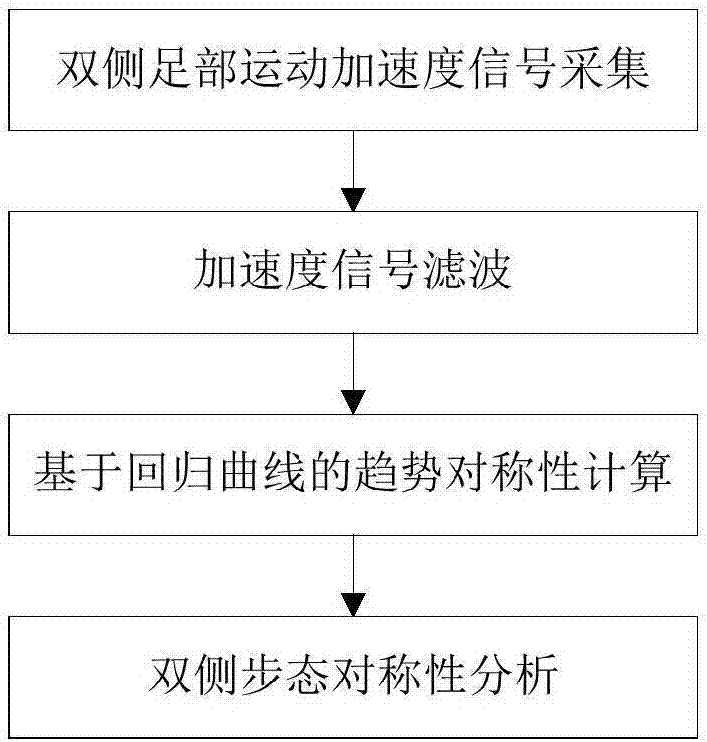

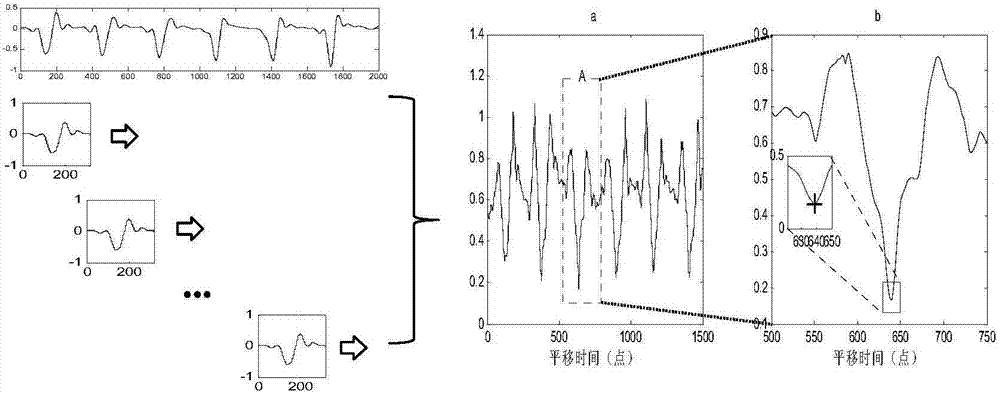

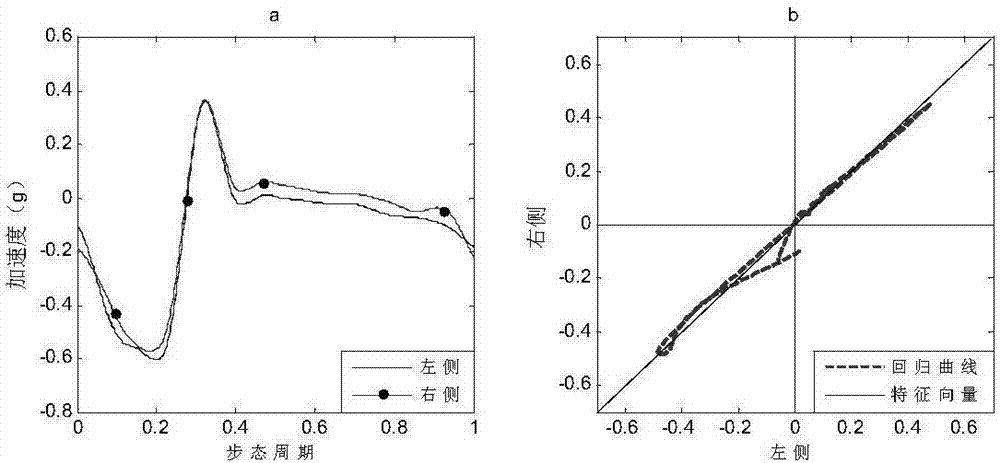

Gait double-side symmetric evaluation method based on regression curve

ActiveCN106937872ASmall random fluctuationsNumerically stableDiagnostic signal processingSensorsGait cycleAcceleration Unit

The invention discloses a gait double-side symmetric evaluation method based on a regression curve. The gait double-side symmetric evaluation method comprises the following steps of utilizing an acceleration sensor to obtain foot three-axis acceleration information in the gait movement, and denoising and pretreating the obtained acceleration information; extracting a denoised acceleration signal, respectively calculating double-side symmetric indexes in a continuous gait cycle, and quantitatively analyzing the symmetry of the gait. The gait double-side symmetric evaluation method has the characteristics that the simplicity and accuracy are realized; the broad application prospect is realized in the field of gait balance ability analysis and the like.

Owner:HANGZHOU DIANZI UNIV

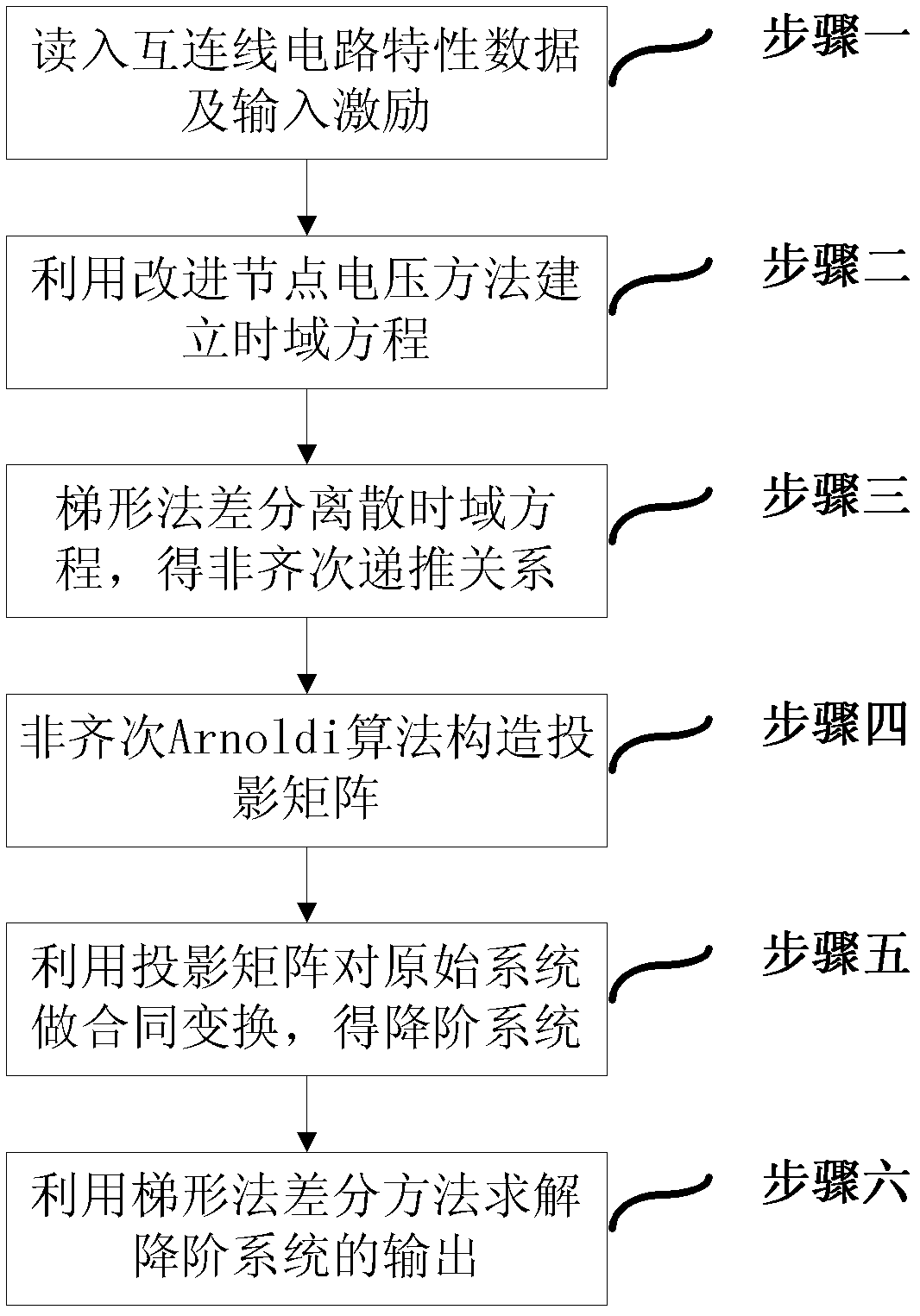

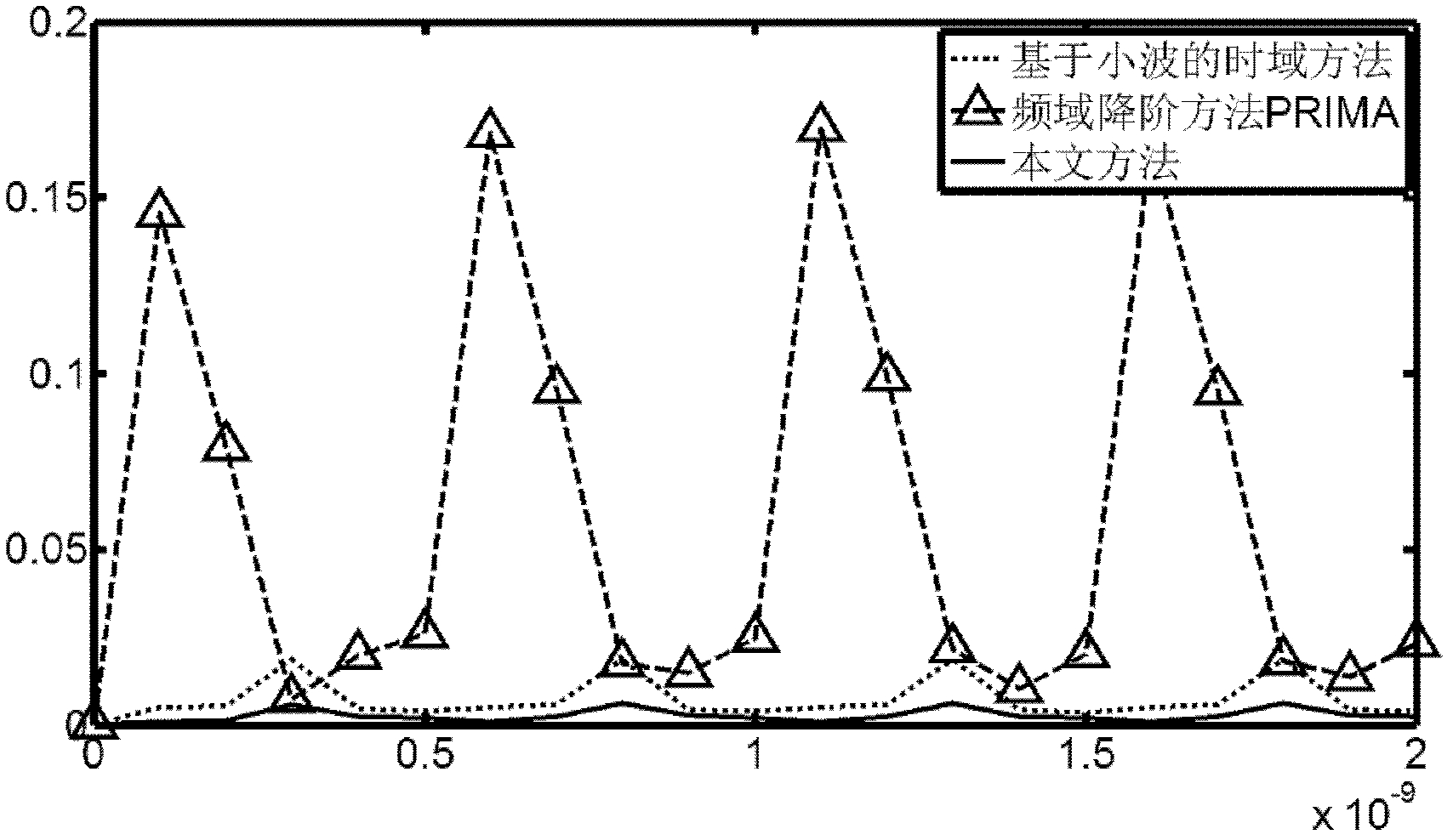

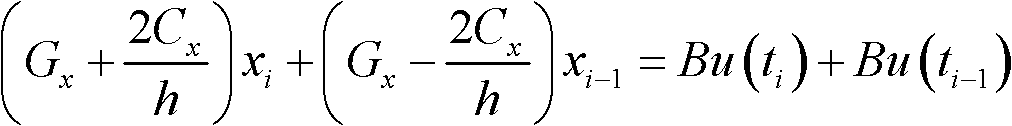

Interconnection line model reduction method based on time-domain trapezoidal method difference

ActiveCN102915385AGuaranteed passivityAvoid conversion errorsSpecial data processing applicationsHat matrixNumerical stability

The invention belongs to the field of integrated circuits, and relates to an interconnection line model reduction method based on time-domain trapezoidal method difference. The method comprises the steps as follows: reading performance data of an interconnection circuit, utilizing an improved node voltage method to build a corresponding time-domain equation; utilizing a trapezoidal method to discretize the time-domain equation of the interconnection circuit and obtain a nonhomogeneous recurrence relation; using a nonhomogeneous Arnoldi algorithm to construct a projection matrix, and then using the projection matrix to perform contragradient transformation on the time-domain equation of the interconnection circuit to obtain a reduction system; and finally, using the trapezoidal method to discretize the reduction system to obtain time-domain output. By virtue of the method, the matching of state variables between the reduction system after the time-domain trapezoidal method difference and the original system is ensured; the time-domain reduction precision is ensured; and the numerical stability during the reduction process and the passivity of the reduction system are ensured. Compared with the original time-domain model reduction method, the computing complexity is greatly reduced; and the method has higher precision in time-domain compared with a frequency-domain reduction method.

Owner:FUDAN UNIV

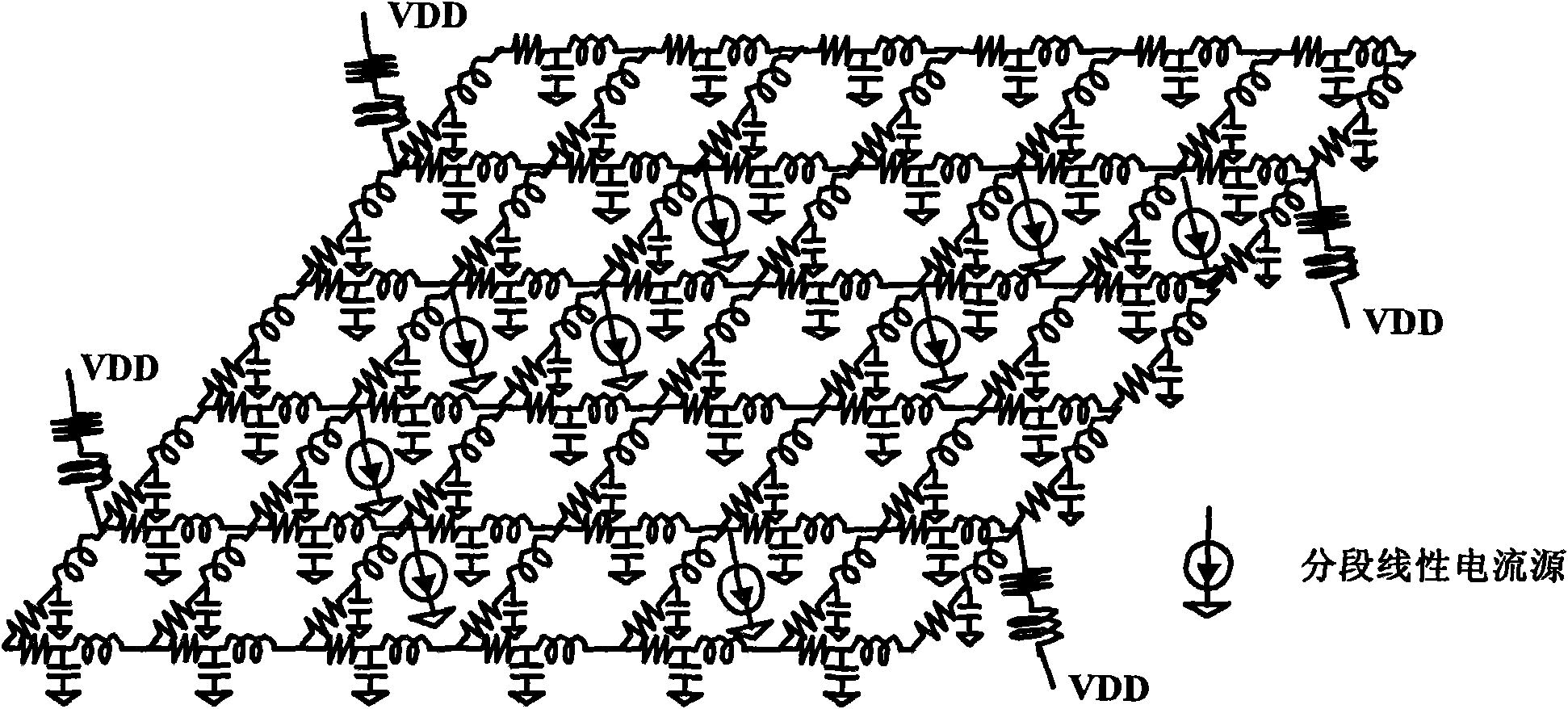

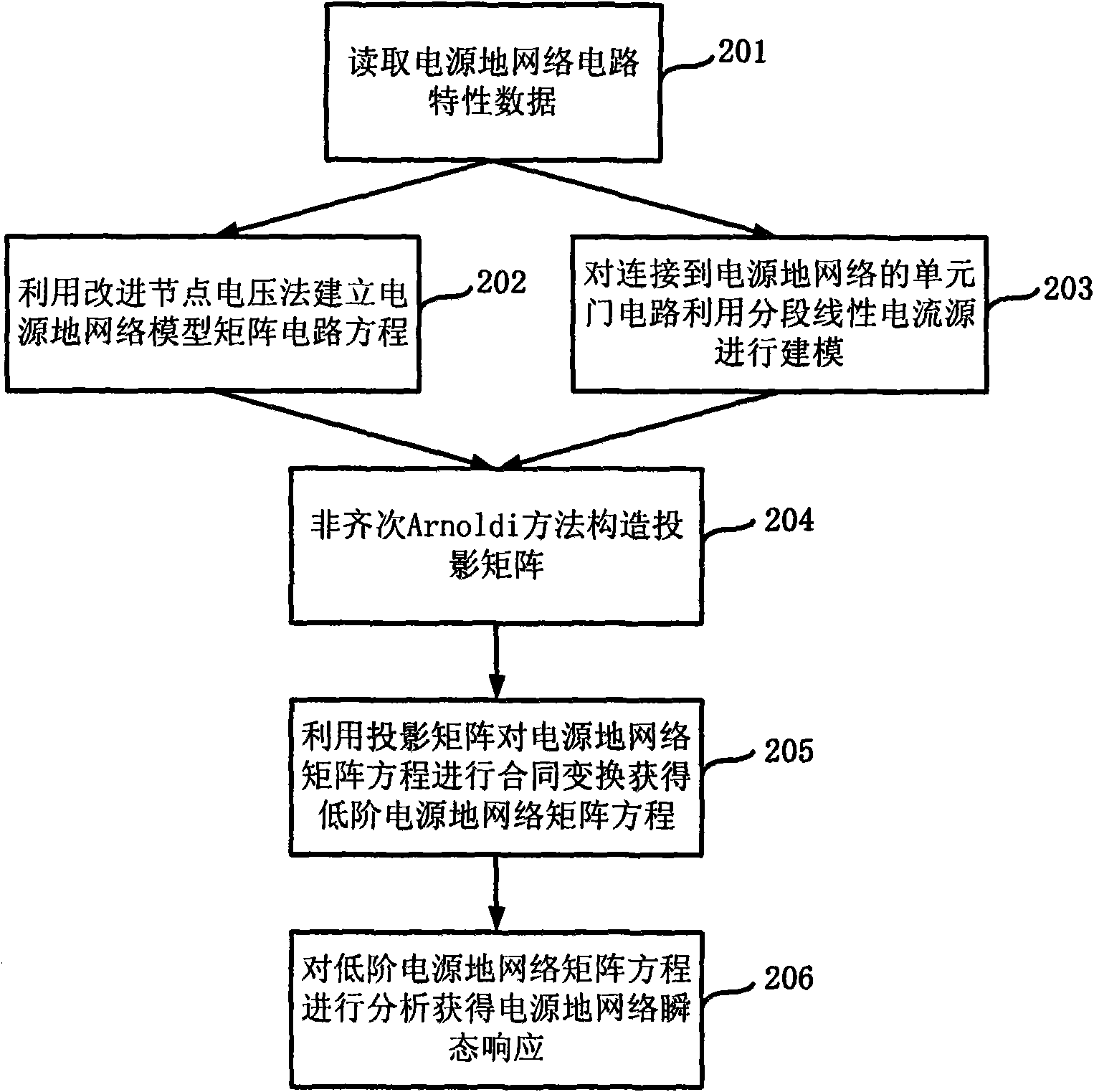

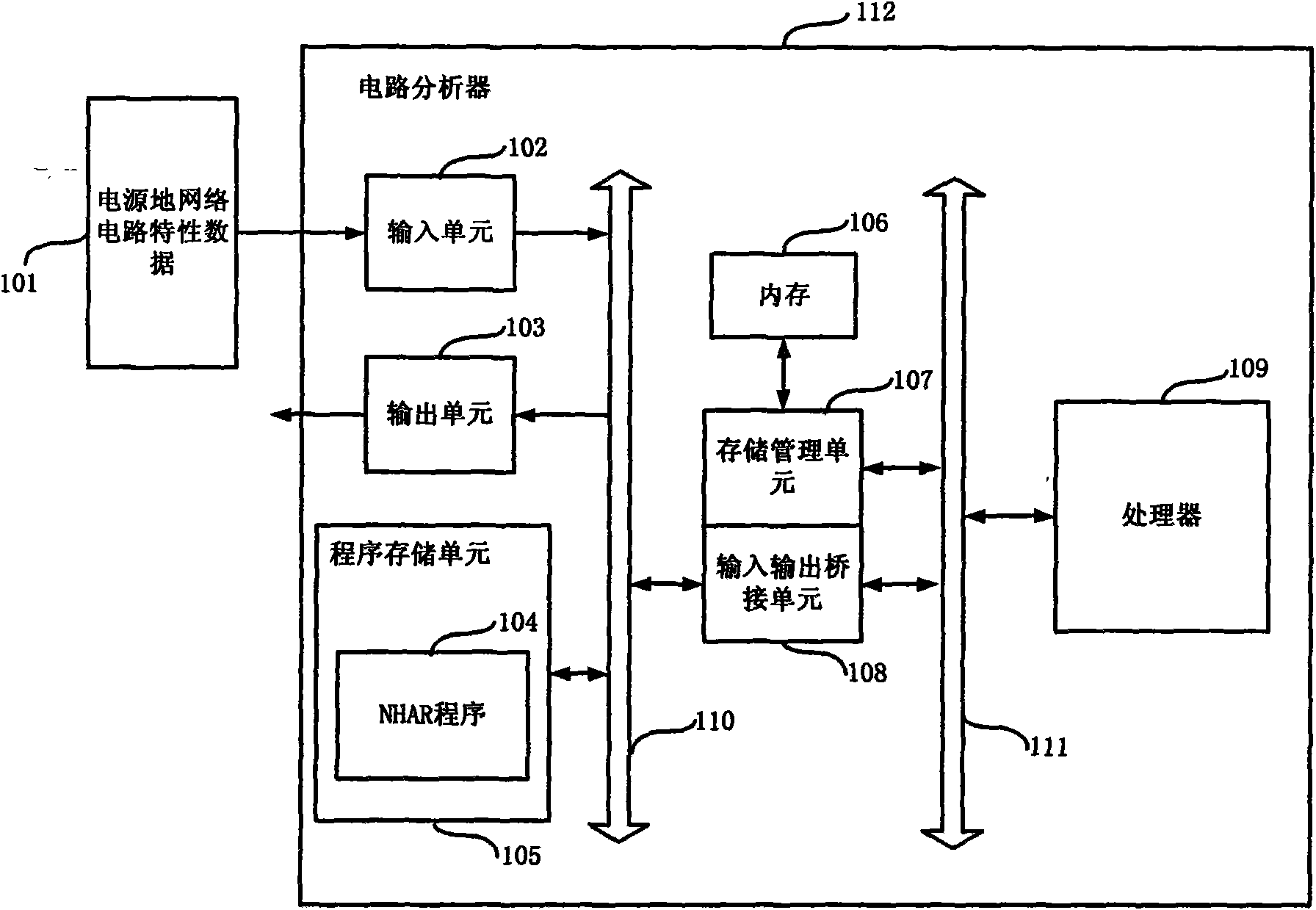

Analytical method and device for power ground network of integrated circuit

InactiveCN101901279AGood numerical stabilityImprove calculation accuracySpecial data processing applicationsAnalysis methodIntegrated circuit layout

The invention relates to an analytical method and a device for a power ground network of an integrated circuit. The method comprises the following steps: firstly, establishing a matrix circuit equation of the power ground network; then constructing a projection matrix by a nonhomogeneous Amoldi method, and carrying out contragradient transformation on the matrix circuit equation of the power ground network to obtain a reduced order system; and finally, solving the transient response of the reduced order system to obtain the analytical result. The device applying the method comprises an input unit, an output unit, a program storage unit, an external bus, a memory, a storage management unit, an input / output bridging unit, a system bus and a processor. NHAR programs realizing the analytical method of the invention are stored in the program storage unit, and the circuit characteristic data of the power ground network are analyzed through the NHAR program. By analyzing the power ground network by the invention, numerical values can be ensured to be stable in the computational process, and very high computational accuracy can be achieved by very low complexity of computation, thereby solving the problem that the stableness of the numerical value and the computational efficiency can not be compromised in the computational process of the current methods.

Owner:FUDAN UNIV

Method for determining poses of sensors

ActiveUS20050110679A1Numerically stableFast to implementDirection finders using radio wavesAmplifier modifications to reduce noise influencePattern recognition

A method determines poses of a sensors distributed in an environment. A signal of the environment is acquired by each sensor. Features in each signal that correspond to the features in at least one other signal are identified. Directions between the sensors and the corresponding features are determined. Nullspaces of the directions are used to construct a matrix. A nullspace eigenvector is determined of the matrix, and then the nullspace eigenvector is reconfigured to a matrix specifying the locations of the sensors.

Owner:MITSUBISHI ELECTRIC RES LAB INC

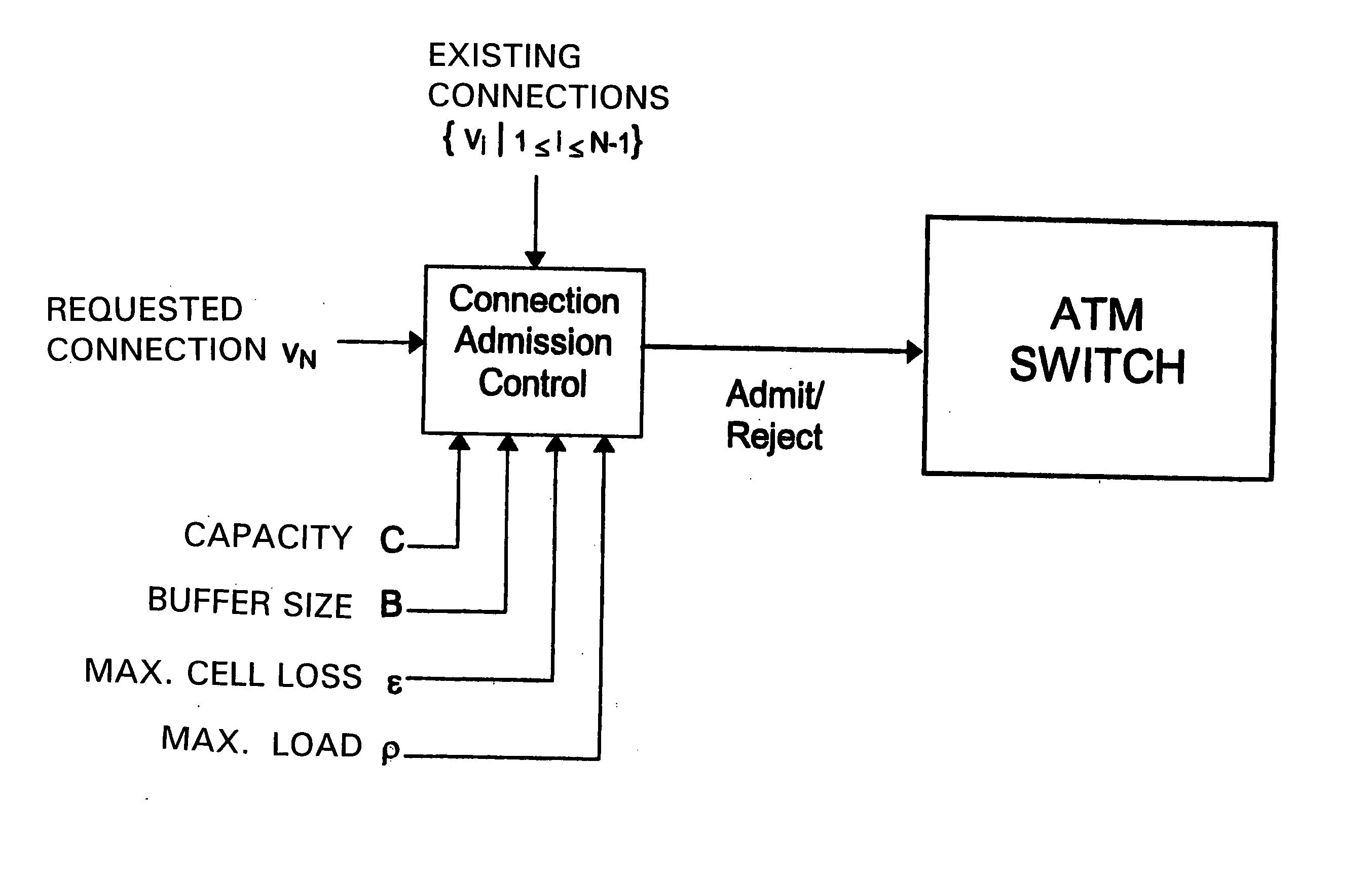

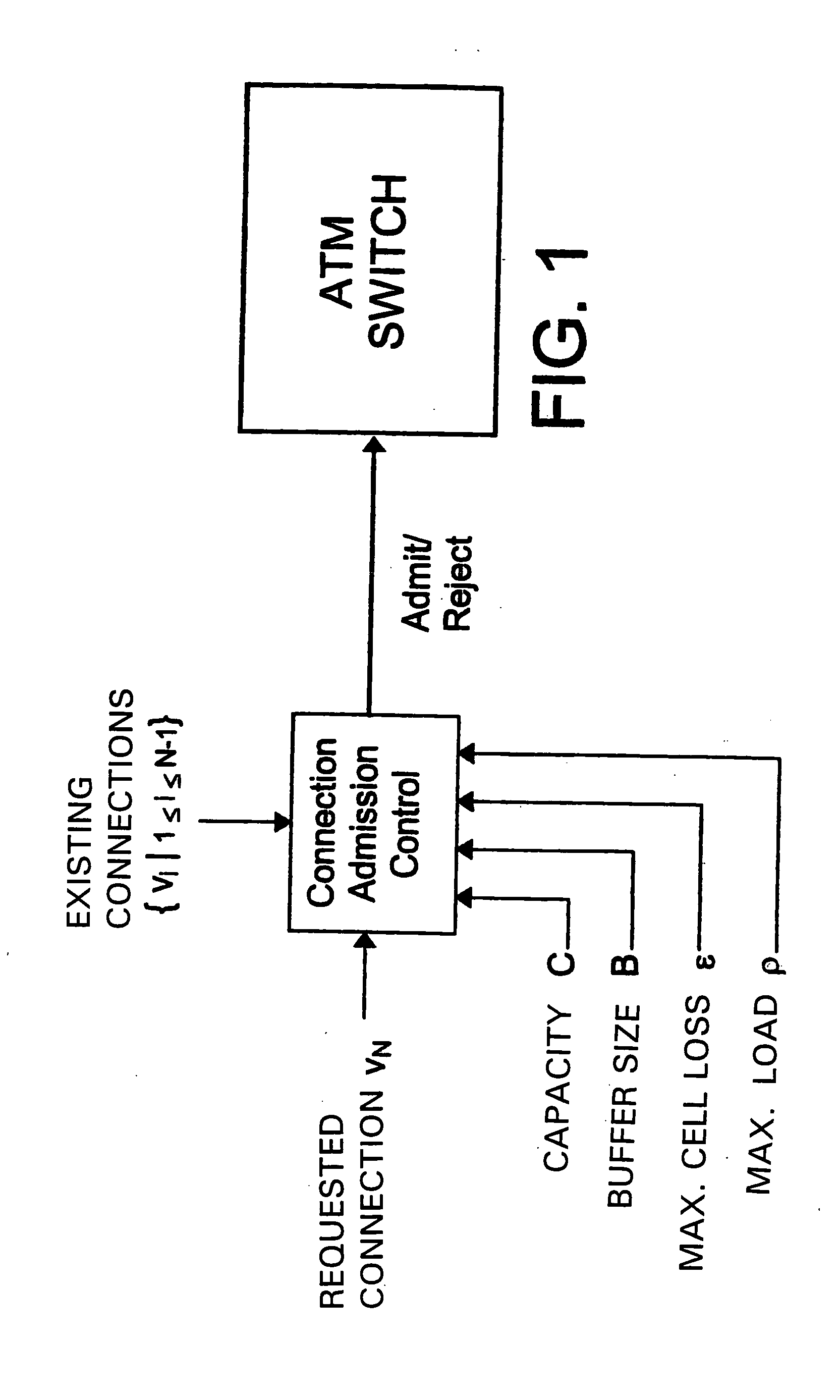

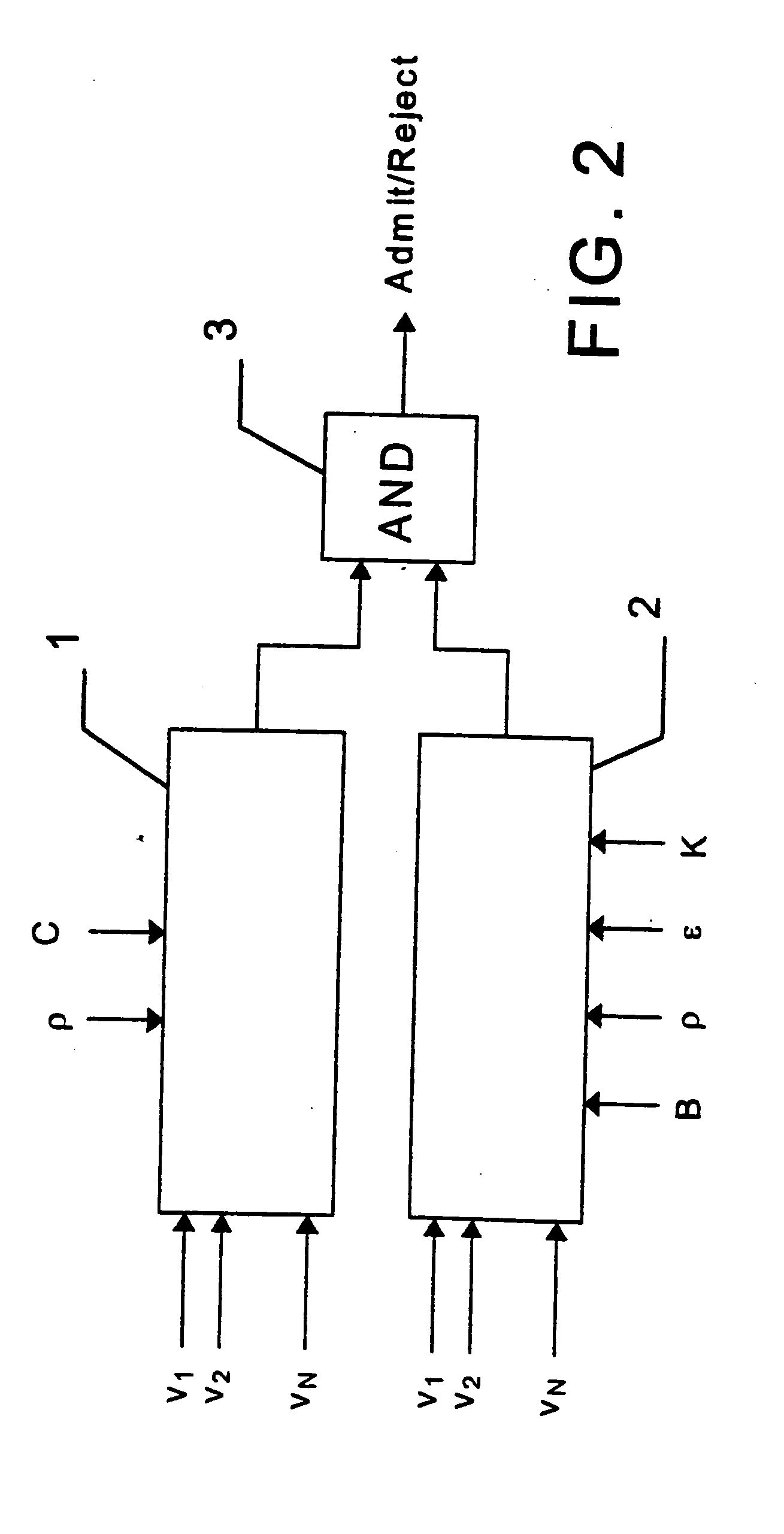

ATM connection admission control device for DBR connections

InactiveUS20050038903A1Improve practicalityNumerically stableMultiple digital computer combinationsStore-and-forward switching systemsTraffic volumeAdmission control

Owner:KONINK KPN NV

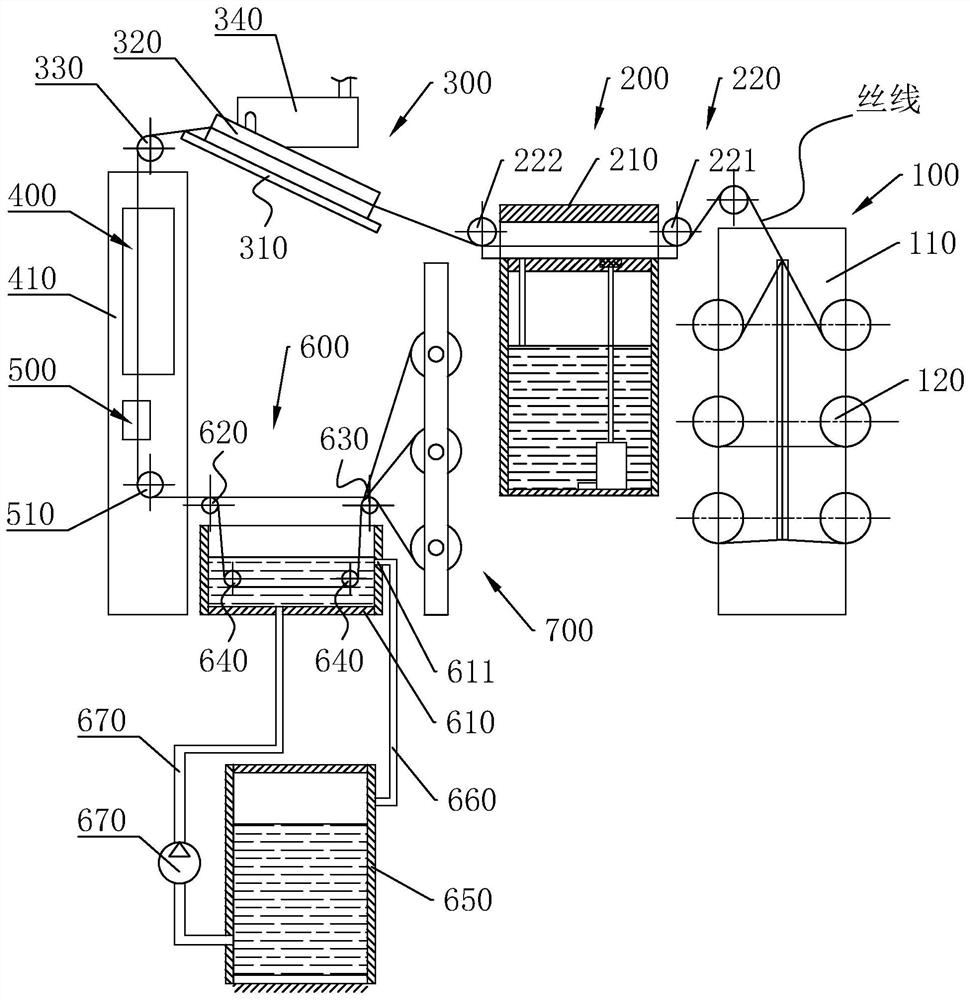

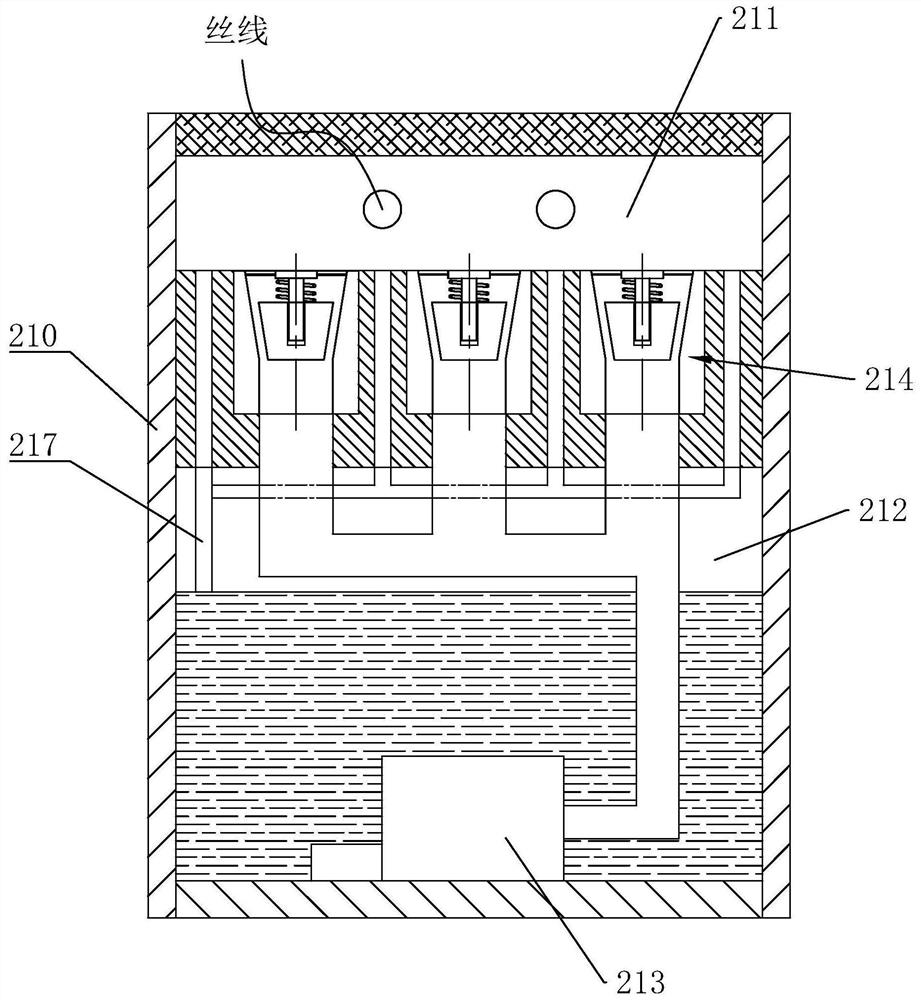

Chemical fiber spinning elasticizing device

ActiveCN112011866AImprove the lubrication effectShorten the production cycleLiquid/gas/vapor removalTextile treatment machine arrangementsYarnPolymer science

The invention belongs to the technical field of textile machinery, and particularly relates to a chemical fiber spinning elasticizing device which is characterized by comprising a yarn feeding system,a heating system, a cooling system, a false twister, an oiling system and a winding device which are arranged in sequence; the yarn feeding system is used for placing silk thread raw material and unwinding silk threads; the heating system is used for heating the unwound silk threads; the cooling system is used for cooling high-temperature silk threads; the false twister is used for false twistingof the silk threads; the oiling system is used for oiling and lubricating the silk threads; the winding device is used for winding the oiled silk threads; and an elasticizing device further comprisesa dyeing system which is located between the yarn feeding system and the heating system and used for dyeing the unwound silk yarn. Dyeing can be completed while the silk threads are elasticized, so that the production period is shortened, and the production cost is reduced.

Owner:诸暨市双冠化纤有限公司

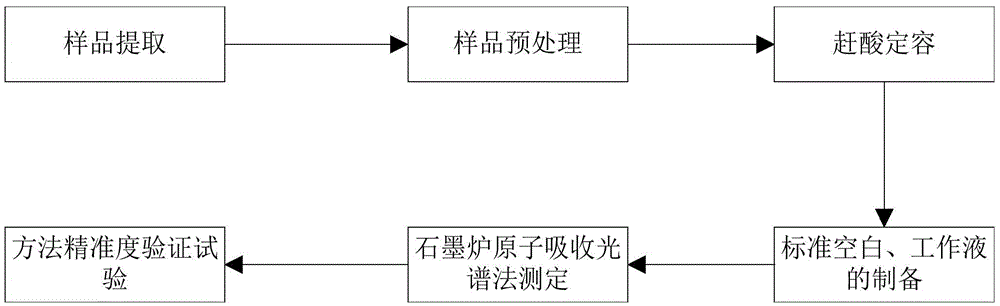

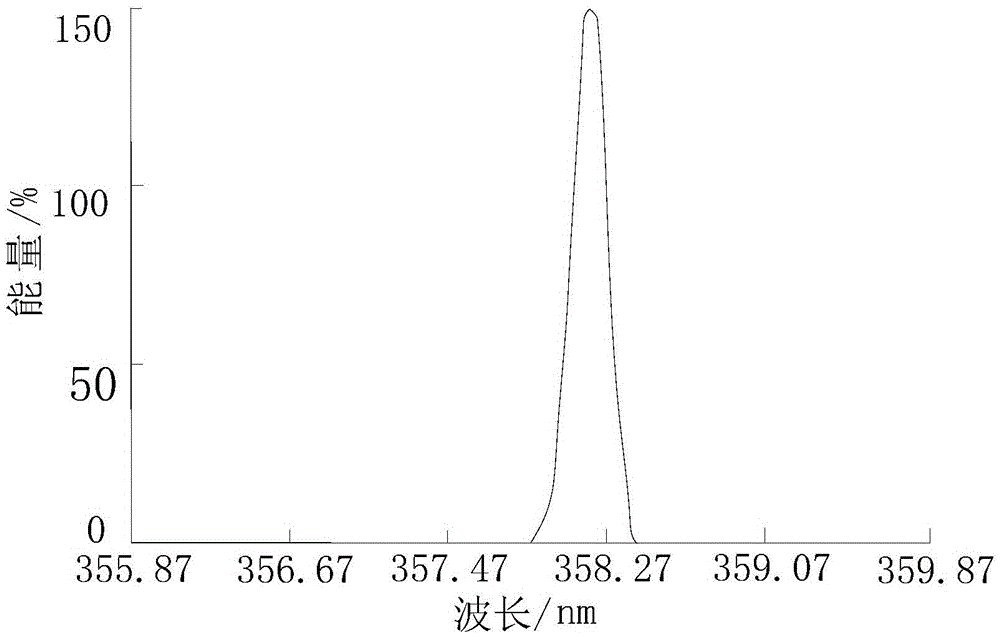

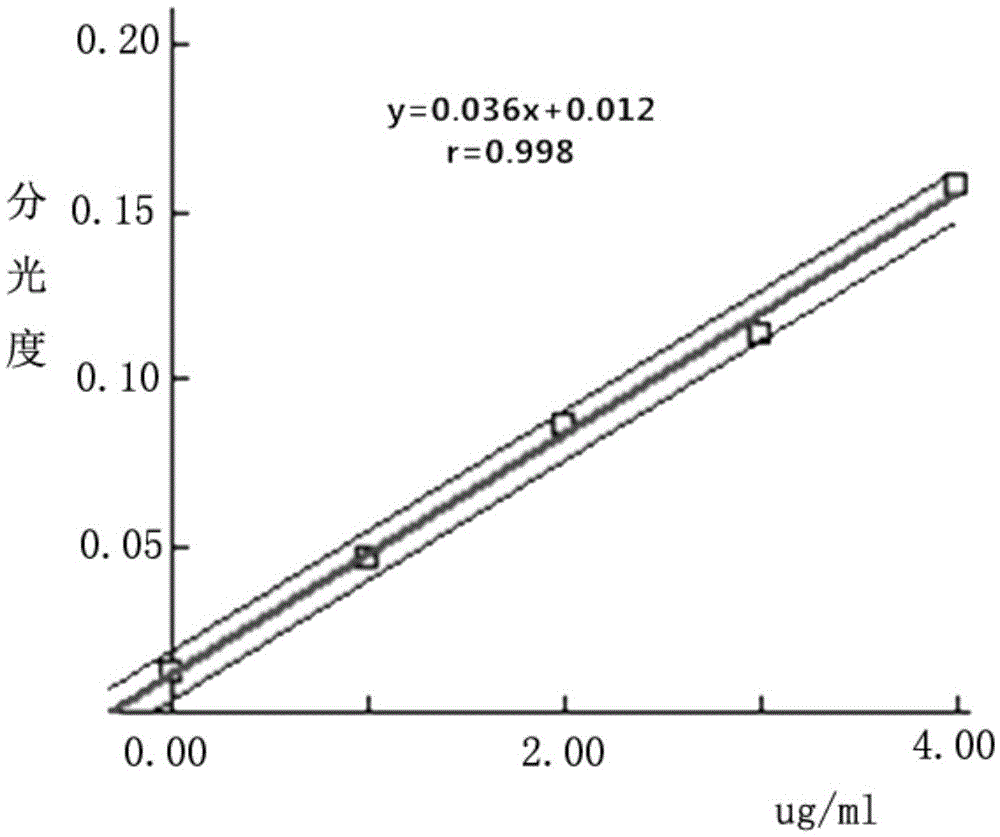

Determination method for chromium content of inhalable particles in soil dust and detection method

InactiveCN105651543AEasy to operateShort sampling periodWithdrawing sample devicesColor/spectral properties measurementsInhalable particlesNational standard

The invention discloses a determination method for the chromium content of inhalable particles in soil dust. The determination method includes the following steps of sample extraction, sample pretreatment, acid removal and volume metering, preparation of a standard blank solution and a standard working solution, and graphite furnace atomic absorption spectrometry determination. The invention further discloses a detection method for the accuracy of the determination method for the chromium content of inhalable particles in soil dust. The detection method includes the following steps that a national standard substance with the known chromium content is prepared into five parts of sample solutions to be detected, wherein the concentrations of the sample solutions to be detected are different; the chromium content in each sample solution to be detected is detected with the determination method for the chromium content of inhalable particles in soil dust so that the precision of the determination method for the chromium content of inhalable particles in soil dust can be verified. The determination method and the detection method have the advantage that sampling time is short, digestion is fast, little interference exists in determination, and the result is accurate and reliable.

Owner:SHANDONG UNIV OF SCI & TECH

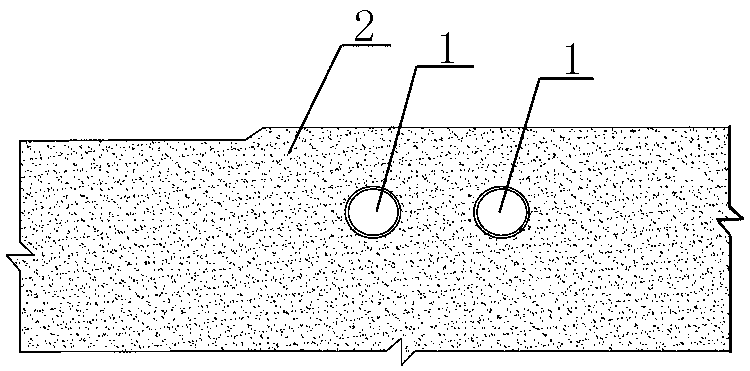

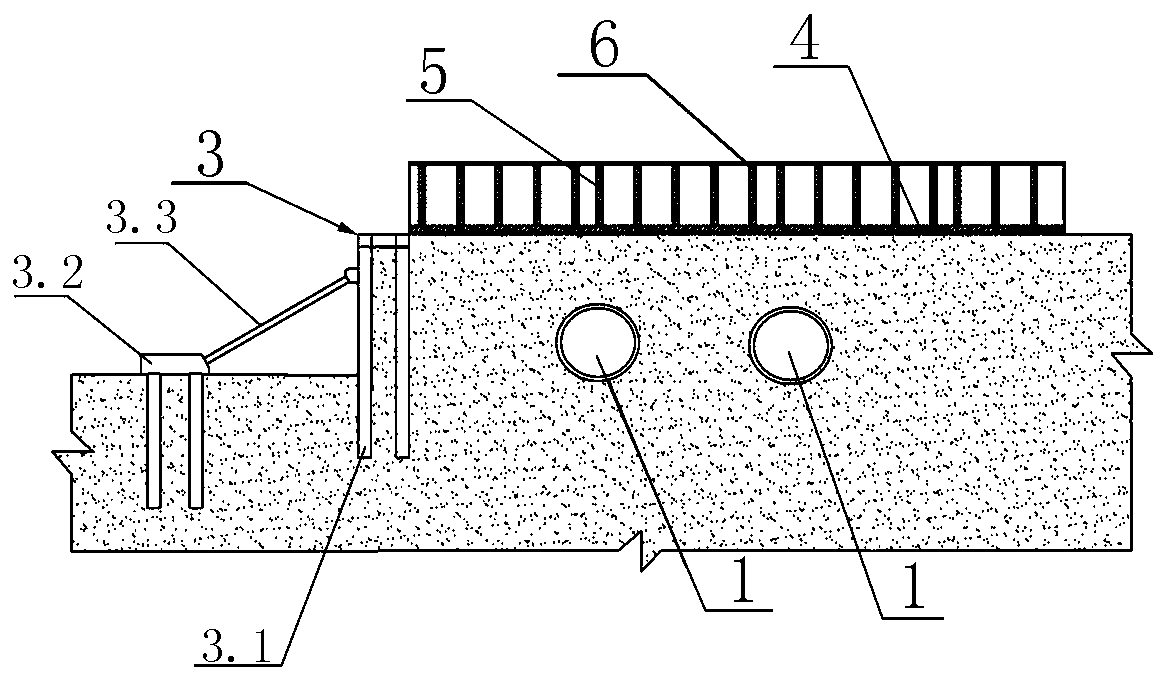

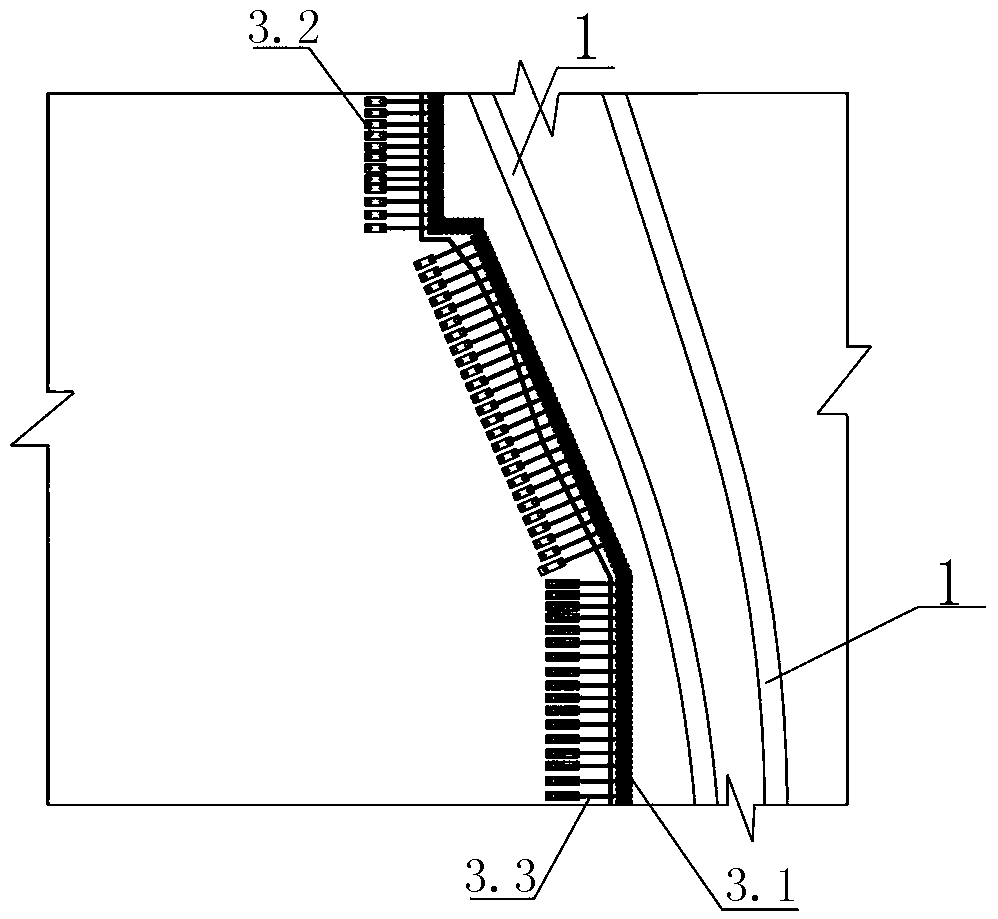

Structure system for controlling deformation of subway shield tunnels and construction method thereof

PendingCN110159296AIncrease horizontal forceSideways deformation preventionUnderground chambersExcavationsStructure of the EarthStructure system

The invention provides a structure system for controlling deformation of subway shield tunnels and a construction method of the structure system for controlling deformation of the subway shield tunnels. The structure system comprises a foundation pit support, a base structure, a group of wall bodies and a structure top plate. The foundation pit support is arranged on one side of the subway shieldtunnels and comprises double rows of piles, a group of diagonal bracings and diagonal bracing foundations. The double rows of piles are arranged at intervals in the extension direction of the subway shield tunnels, and an interval exists between the double rows of piles and the subway shield tunnels. The elevation of the top face of the double rows of piles is not lower than the elevation of the bottom face of the base structure. The diagonal bracing foundations are parallel to and spaced with the double rows of piles. The top face of the diagonal bracing foundations is lower than the top faceof the double rows of piles. The group of diagonal bracings are arranged in parallel at intervals between the diagonal bracing foundations and the double rows of piles. The base structure is arrangedon the upper side of the subway shield tunnels. The group of wall bodies are arranged on the top of the base structure in a spaced manner. The structure top plate covers the tops of the group of wallbodies. The structure system for controlling deformation of the subway shield tunnels solves the technical problems that by the adoption of a traditional foundation pit construction method, a dug area can generate large upward floating deformation, and the safety of a to-be-constructed building is harmed.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD

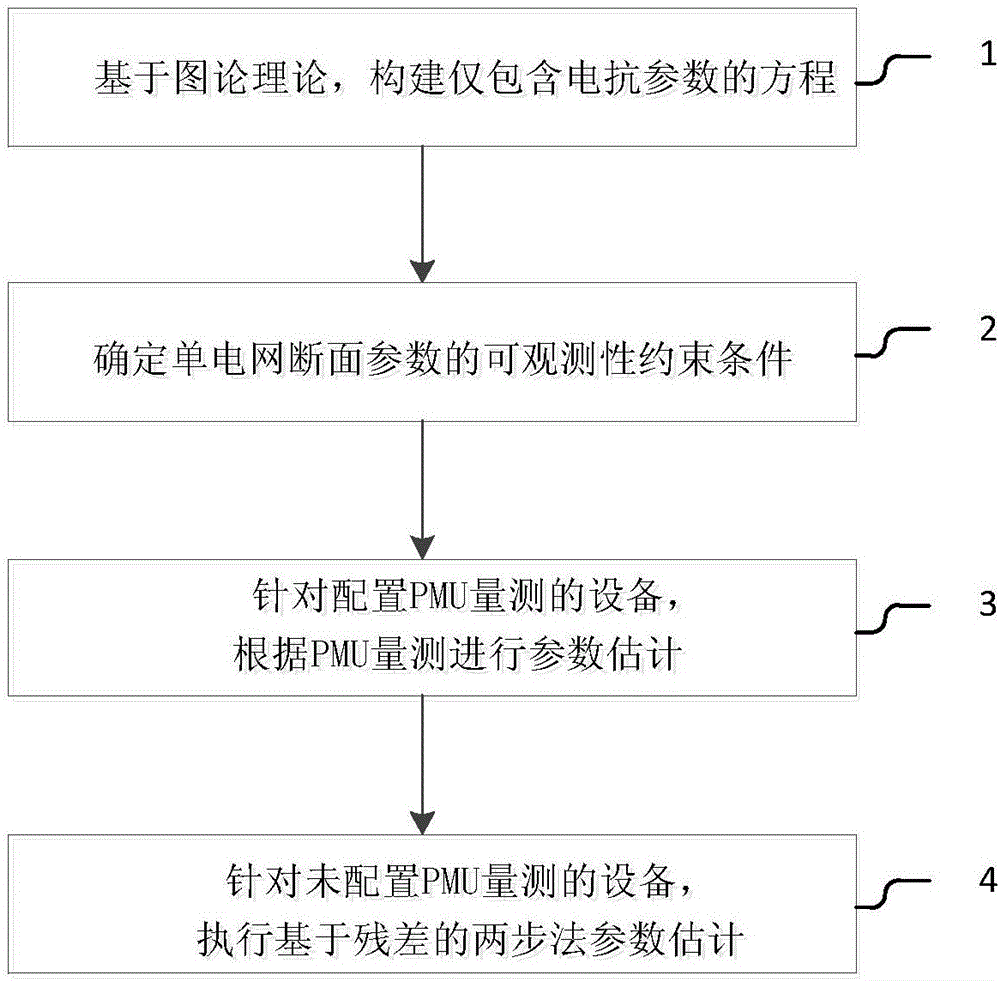

Parameter identification method based on graph theory and device

PendingCN106570345AEfficient identificationNumerically stableSpecial data processing applicationsInformaticsElectric power systemHigh pressure

The invention provides a parameter identification method based on graph theory and a device. an equation only comprising reactance parameters is established based on the graph theory; constrained conditions of observability of single power grid section parameters are determined; PMU measurement is adopted for parameter estimation for the devices which are equipped with PMU measurement; two-step parameter estimation is executed on the basis of residual error for the devices which are not equipped with PMU measurement. The pre-estimation of parameter values is quick and accurate; by means of the method, effective identification of high voltage loop grid parameters is achieved; suspicious device parameters can be accurately positioned so that the power grid technical data quality is improved and the practical level of electric power system network analysis is increased.

Owner:CHINA ELECTRIC POWER RES INST +4

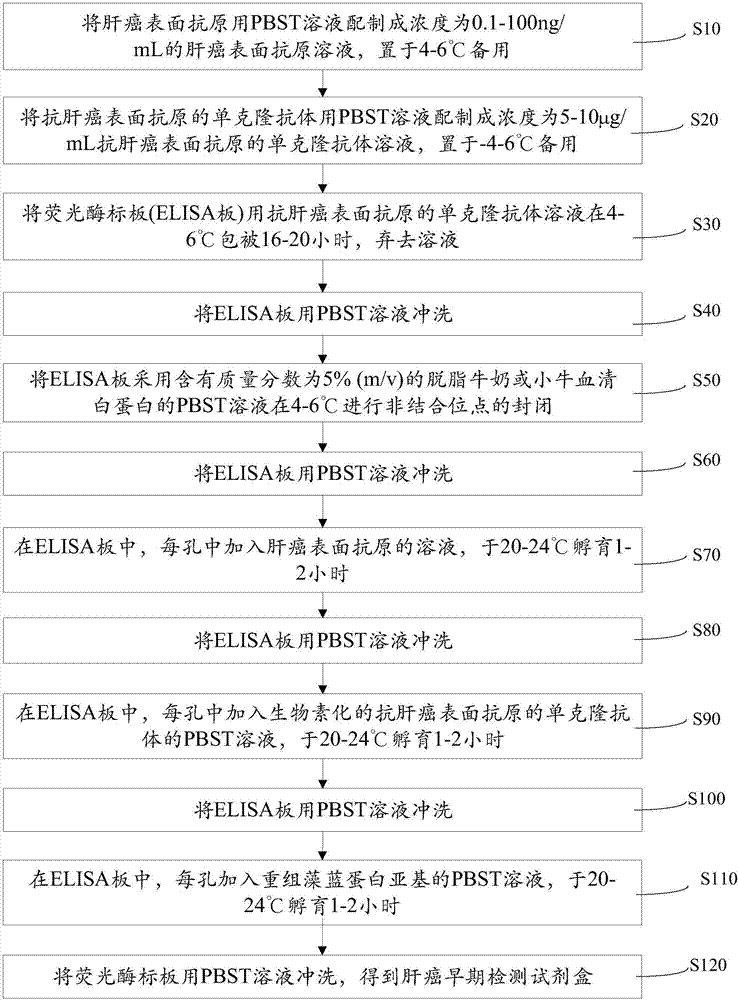

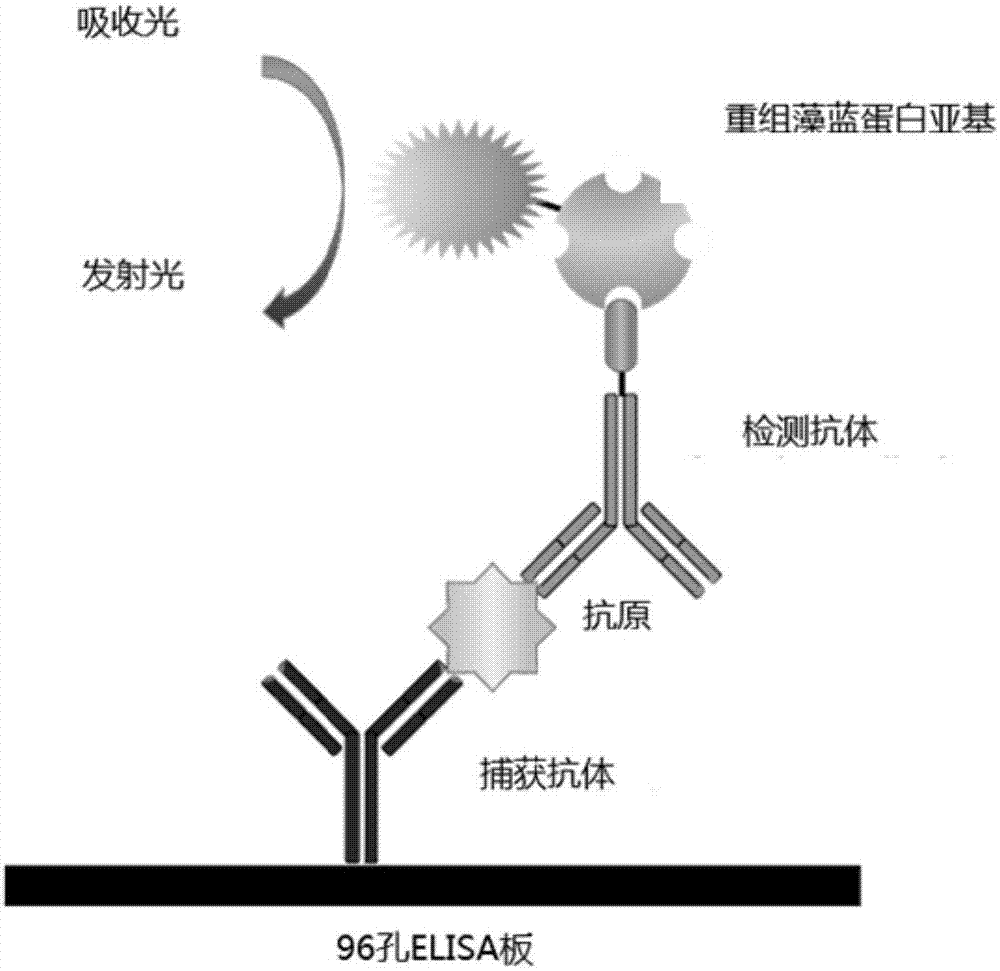

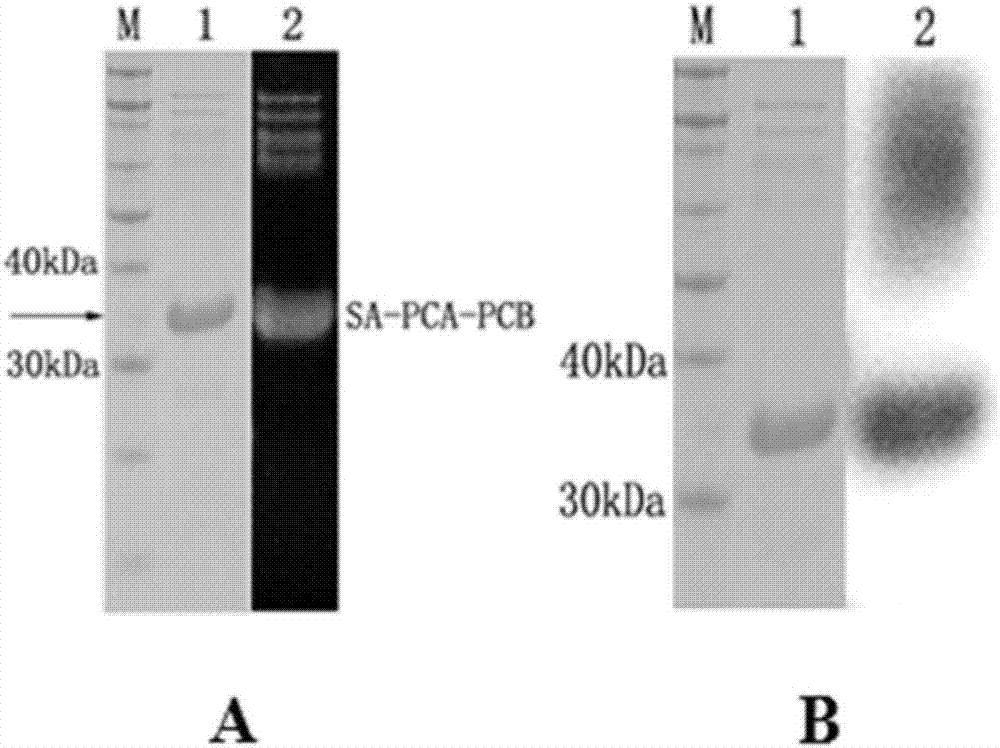

Preparation method of liver cancer early detection kit

PendingCN107271661AImprove stabilityHigh fluorescence quantum efficiencyMaterial analysisAntigenBinding site

The invention discloses a preparation method of a liver cancer early detection kit. The preparation method comprises the following steps: coating an ELISA (Enzyme-Linked Immunosorbent Assay) plate with a monoclonal antibody solution of an anti-liver-cancer surface antigen, and flushing with a PBST (Phosphate Buffered Solution-Tween) solution; enclosing a non-binding site of the ELISA plate with a 5 percent by mass PBST solution of skimmed milk or bovine serum albumin, and flushing with the PBST solution; in the ELISA plate, adding a liver cancer surface antigen solution into each hole for incubation, and flushing with the PBST solution; in the ELISA plate, adding a PBST solution of a monoclonal antibody of a biotinylated anti-liver-cancer surface antigen into each hole for incubation, and flushing with the PBST solution; in the ELISA plate, adding a PBST solution of recombinant phycocyanin subunit into each hole for incubation, and flushing with the PBST solution to obtain the liver cancer early detection kit. The preparation method for preparing the liver cancer early detection kit from the recombinant phycocyanin subunit is simple, is easy to operate, and is less in side products; moreover, the obtained liver cancer early detection kit has high stability, high fluorescence property and high sensitivity.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

Automatic clamping jig for mobile phone production and clamping method

ActiveCN112040043AFully automatedImprove efficiencyUsing optical meansApparatus for force/torque/work measurementControl engineeringElectric machinery

The invention discloses an automatic clamping jig for mobile phone production and a clamping method. The jig comprises a placement frame fixed in a vertical direction, a placement plate is fixed to the front surface of the placement frame, a movable cavity is formed in the placement plate, movable openings are formed in the two sides, away from each other, of the placement plate, clamping plates are installed in the movable openings, and racks are fixed to the side surfaces of the clamping plates. A telescopic motor is fixed in the movable cavity, a sliding way is formed in the movable cavity,a sliding groove is formed in the sliding way, the supporting plate is hinged to the interior of the sliding groove, a pressure sensor is arranged right above one end of the sliding groove, a fixed cavity is formed in the bottom side of the sliding way, a reset motor is installed in the fixed cavity, and the output end of the pressure sensor is connected with a single-chip microcomputer. A distance sensor is installed at the top end of the placement plate. Through cooperative use of the devices, clamping and fixing of a mobile phone during testing can be automatically completed, a labor expenditure is reduced, time for clamping and fixing a mobile phone sample is shortened, and mobile phone testing efficiency is improved.

Owner:南京雷石电子科技有限公司

Full-pressure tiny leak precision measurement system

PendingCN107991033AFirmly connectedEasy to carryMeasurement of fluid loss/gain rateDifferential pressureGas cylinder

The invention belongs to the technical field of measurement, and in particular relates to a full-pressure tiny leak precision measurement system which is composed of a ball valve, a stop valve, a three-way sealing valve, a high-precision differential pressure gauge, an instrument control unit, a timer, a vacuum pump, a constant volume chamber, a gas distribution chamber, a gas cylinder and a pipejoint. The ball valve is adopted to cause the constant volume chamber with a known volume to be connected with the gas distribution chamber through a pipe, the stop valve is used to be connected withthe high-precision differential pressure gauge, and the three-way sealing valve is connected with the vacuum pump. After a part to be measured, the high-precision differential pressure gauge, the constant volume chamber and the gas distribution chamber reach the pressure balance, the ball valve is switched off, the stop valve is switched on to enable tiny leaked gas to be introduced into the constant volume chamber through a pipe, the gas flows to the gas distribution chamber through the high-precision differential pressure gauge, and the accumulated pressure change of the part to be measuredover time can be obtained. The full-pressure tiny leak precision measurement system has the advantages of being convenient to operate, small in size, wide in measurement range, high in measurement precision, not subjected to interference of gas source medium, capable of performing full pressure measurement, convenient to carry and low in cost.

Owner:西安航天计量测试研究所

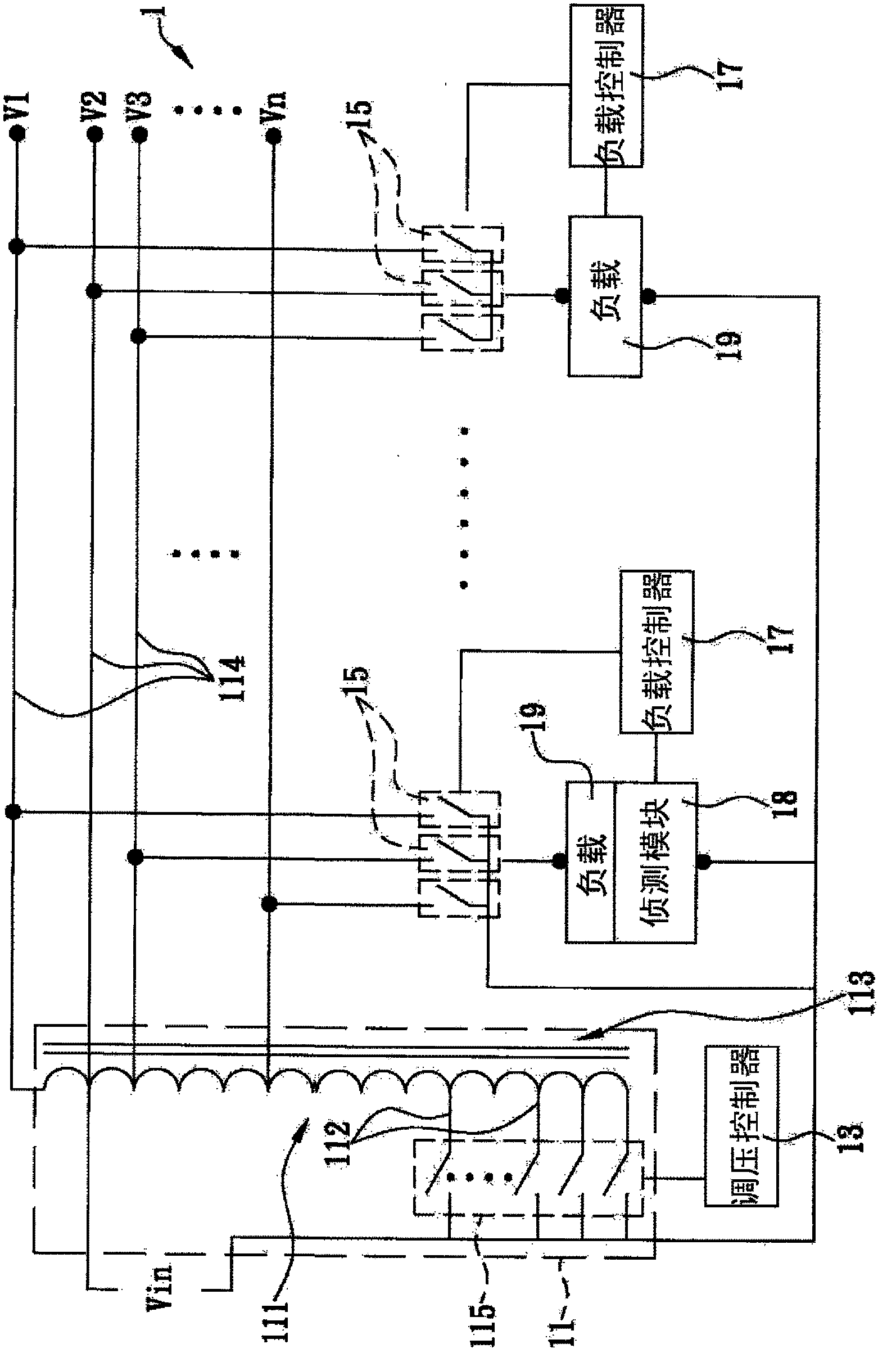

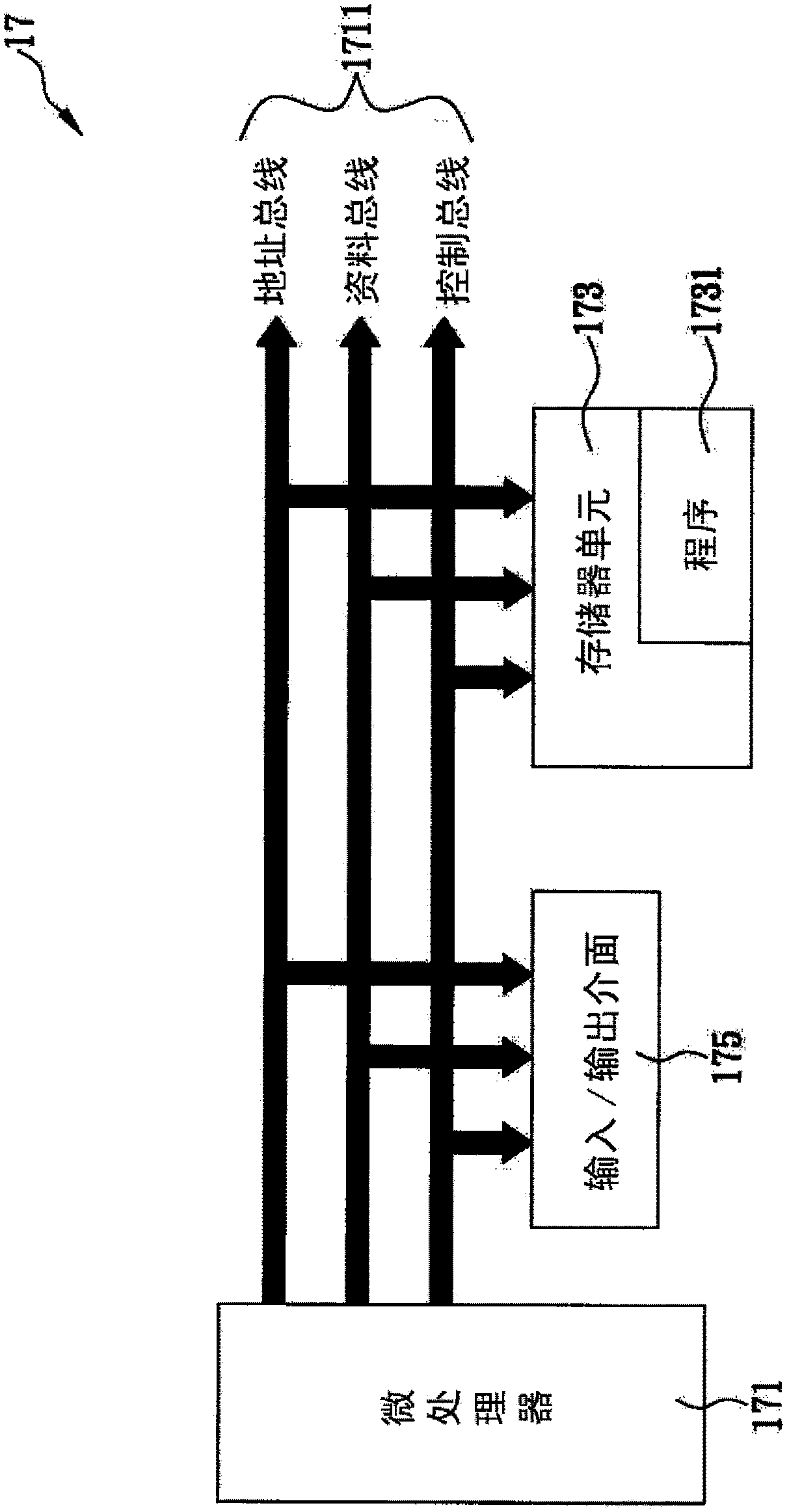

Electricity-saving system capable of selecting and stably outputting voltage

InactiveCN104078980ANumerically stableReduce power consumptionAc network voltage adjustmentElectricityTransformer

An electricity-saving system capable of selecting and stably outputting voltage comprises a multi-output voltage transformer, a voltage regulation controller, a plurality of voltage selection switches and at least one load controller. The primary winding side of the multi-output voltage transformer is connected to an input voltage through a plurality of tap switches. At the same time, only one tap switch is in an on state at each phase. The secondary winding side of the multi-output voltage transformer is provided with a plurality of output leads so that a plurality of output voltages with different voltage magnitudes can be generated. The voltage regulation controller can change the state of the tap switches so that the output voltages can accord with default voltage magnitudes. The voltage selection switches are connected between loads and the output leads respectively. At the same time, one load receives the output voltage of only one output lead. Input ends and output ends of the load controller are connected to the loads and the voltage selection switches respectively. The load controller switches the voltage selection switches according to the operation states of the loads so that the voltage magnitudes of the output voltages transmitted to the loads can be changed.

Owner:王广富

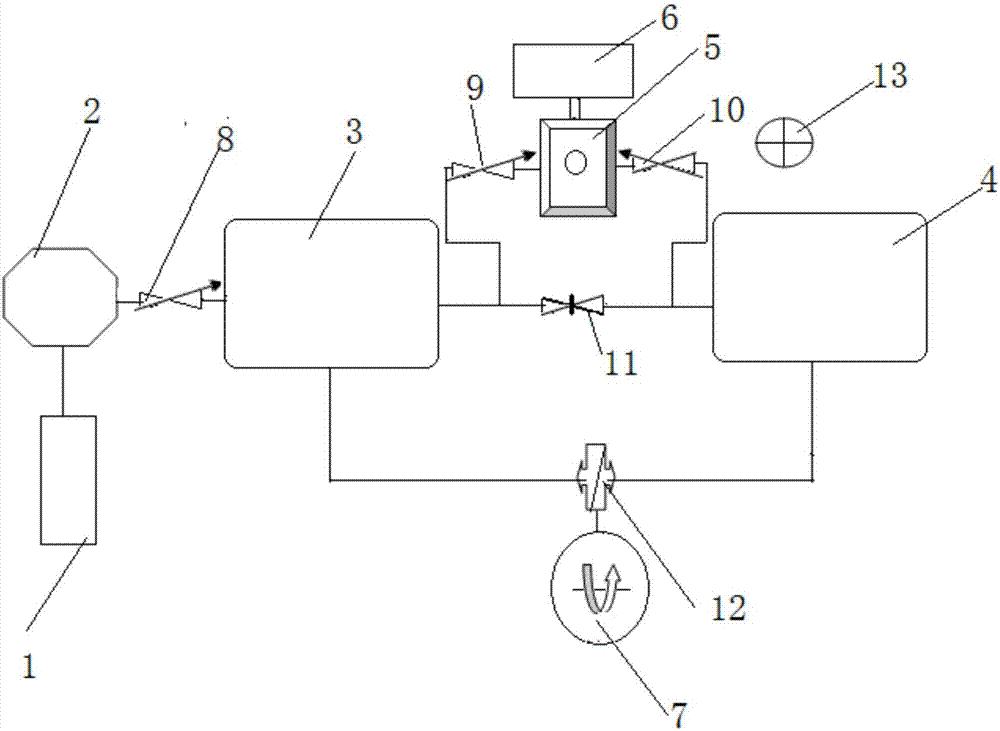

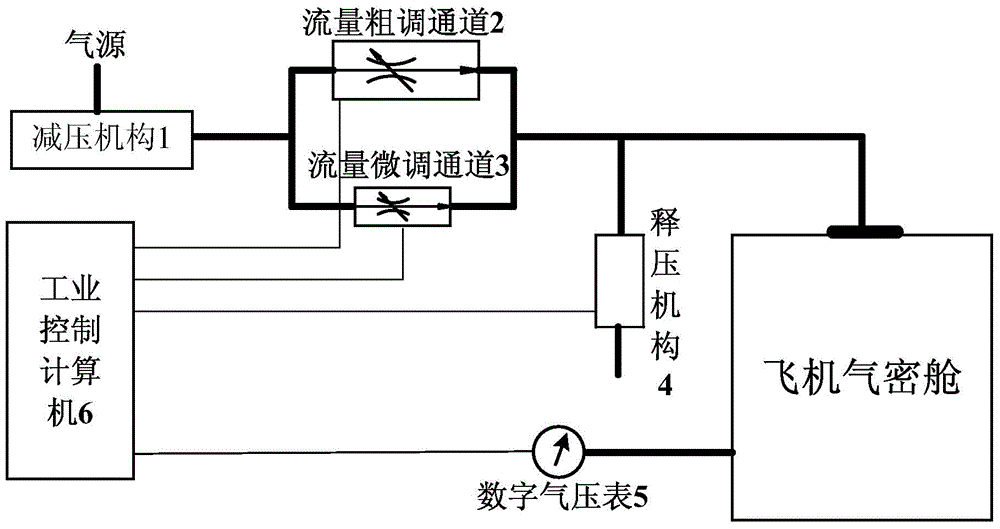

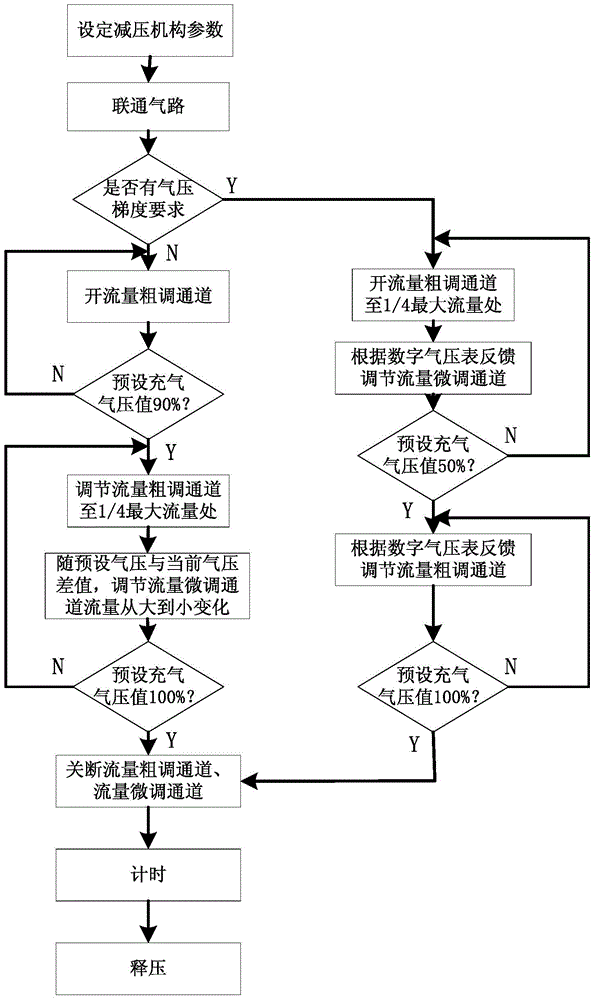

Airplane air tightness test method

InactiveCN105628305ANumerically stableGuaranteed accuracyFluid-tightness measurement using fluid/vacuumPore pressure gradientAtmospheric pressure

A method is used for a low-pressure large-volume air tightness test for testing airplane air tightness, and the invention relates to an airplane air tightness test method. The method is characterized in that an industrial control computer (6) is used to control the gas flow injected into an airtight cabin of an airplane, and two control modes, coarse tuning control and fine tuning control, are adopted. When gas charging of the airplane airtight cabin has no air pressure gradient requirement, the method mainly comprises the steps that: the industrial control computer 6 opens a flow coarse tuning path 2 to a largest flow, gas is rapidly injected until the air pressure reaches 90% of a set air pressure; and a flow coarse tuning path 2 is controlled so as to reduce the gas flow to 1 / 4 of the original value. When gas charging of the airplane airtight cabin has an air pressure gradient requirement, the method comprises the following steps that: the industrial control computer 6 controls the gas flow of the flow coarse tuning path to the 1 / 4 maximum value, and a flow fine tuning path 3 is adjusted according to an air pressure value fed back by a digital air gauge 5 so as to stabilize the air pressure gradient. According to the invention, the air tightness detection can be carried out on the low-pressure large-volume airplane airtight cabins of different precision requirements.

Owner:CHINESE FLIGHT TEST ESTAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com