Method and apparatus for identifying and correcting spherical aberrations in a microscope imaging beam path

An imaging optical path and microscopic imaging technology, applied in the field of spherical aberration devices, can solve problems such as insufficient elimination of spherical aberration, and achieve the effect of eliminating spherical aberration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

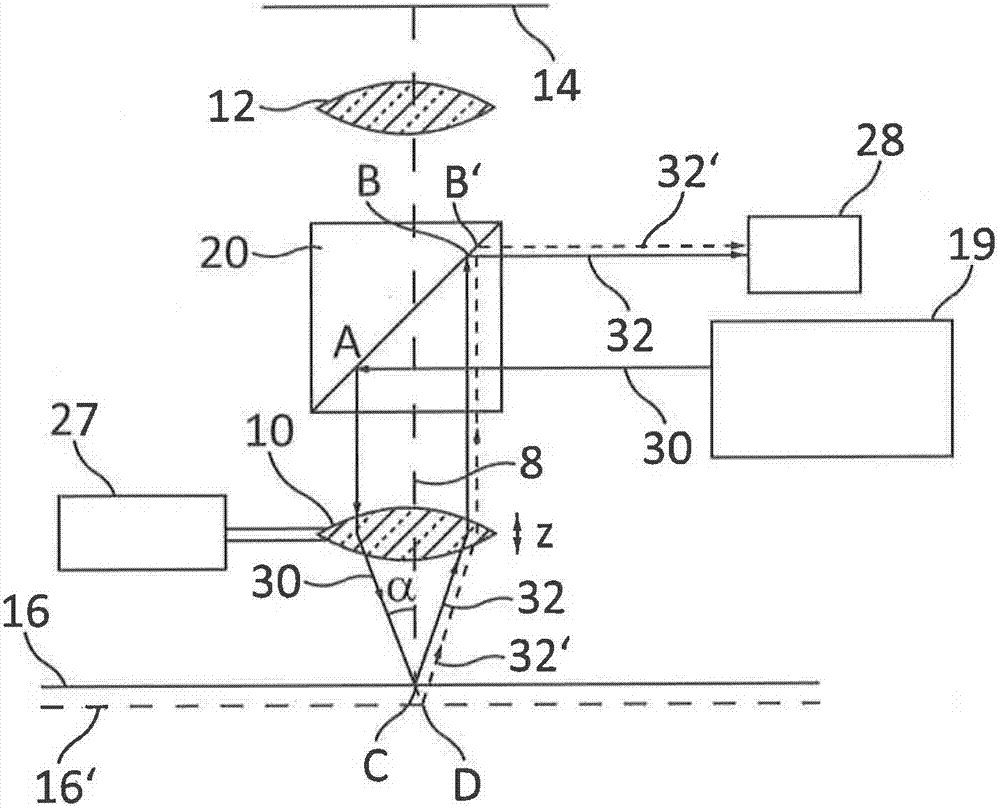

[0045] Fig. 1 shows a triangularized self-focusing device according to the prior art US5136149B1, which has been described in detail in conjunction with a particularly advantageous embodiment of the present invention.

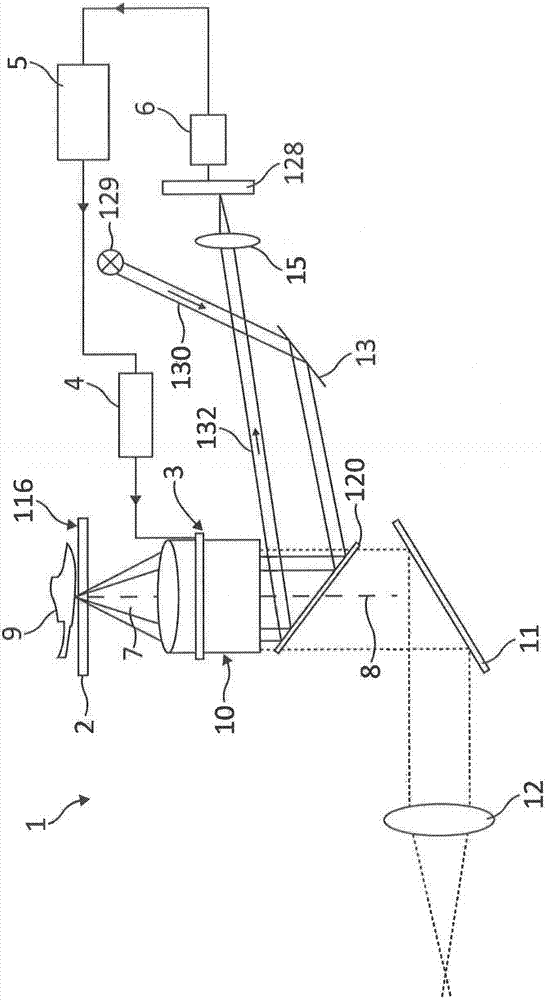

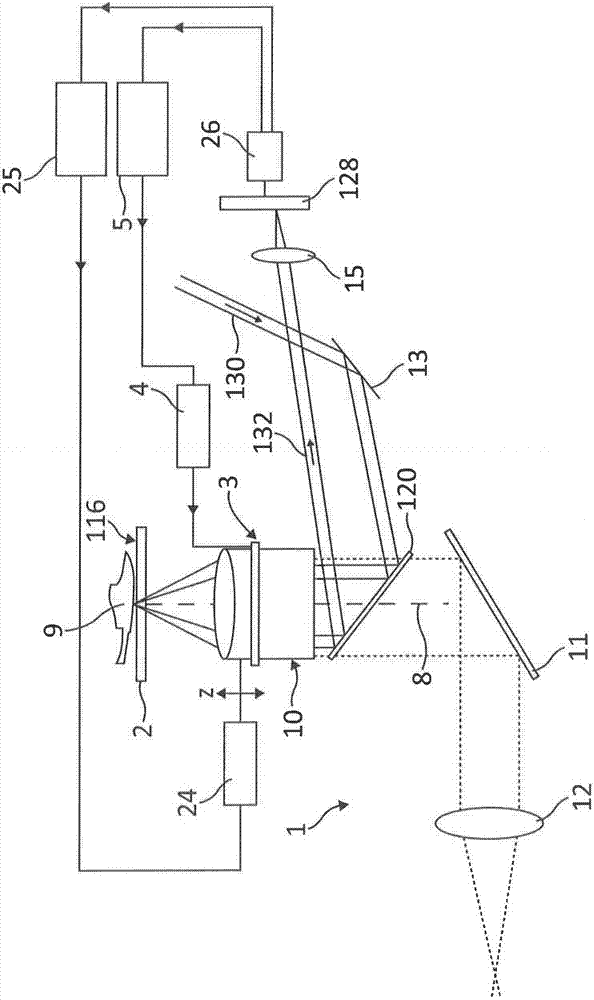

[0046] figure 2 A preferred embodiment of the device according to the invention for determining spherical aberration in microscopic imaging of a microscope 1 is schematically shown, wherein only necessary components (to be described below) are shown. The sample 9 is placed on the cover glass 2 carrying the sample 9 . The cover glass 2 is placed in the imaging optical path 7 of the microscope 1 . Microscope objectives are numbered 10. The tube lens 12 is only schematically drawn. Other details such as eyepieces, image acquisition detectors, zoom systems etc. are not shown as they are not essential to the invention. These units are known to those skilled in the art from the prior art.

[0047] Sample 9 may involve live cells that are observed over a longer p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com