Piezoelectric drive type electric spindle chip mingling detection device used for numerical control machine tool

A technology of CNC machine tools and detection devices, which is applied in the directions of measuring/indicating equipment, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of waste of tool holder resources, long measurement time, expensive installation costs, etc., and reduce the manufacturing process. and manufacturing difficulty, the alarm threshold is stable, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

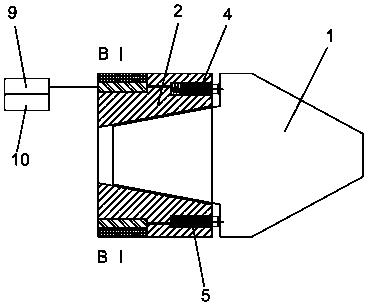

[0027] Such as Figure 1-5 As shown, a piezoelectric-driven electric spindle chip detection device for CNC machine tools, including a fixture body 2 for clamping a tool handle 1, a tapered groove is provided in the fixture body 2, and the fixture body 2 is coaxially fixed At one end of the electric spindle of the CNC machine tool.

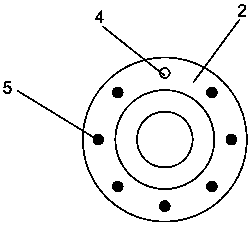

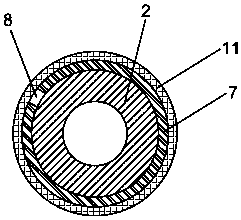

[0028] A number of piezoelectric ceramic blocks that can extend out of the clamp body 2 are evenly distributed in the end of the fixture body 2 that is in contact with the tool handle 1. The end of the piezoelectric ceramic block that can extend out of the clamp body 2 is provided with a conductive touch terminal 3. The electric ceramic block includes a movable piezoelectric ceramic block 4 and seven fixed piezoelectric ceramic blocks 5, the conductive touch terminal 3 at the end of the movable piezoelectric ceramic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com