Chemical fiber spinning elasticizing device

A technology of chemical fiber and guiding device, which is applied in the processing of textile material equipment configuration, textile and papermaking, and textile material processing. It can solve the problems affecting the effect of texturing, prolonging the production cycle, and reducing product quality, so as to improve the filtering effect. , Reduce production costs, shorten the production cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to enable those skilled in the art to better understand the technical solutions in the present invention, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings:

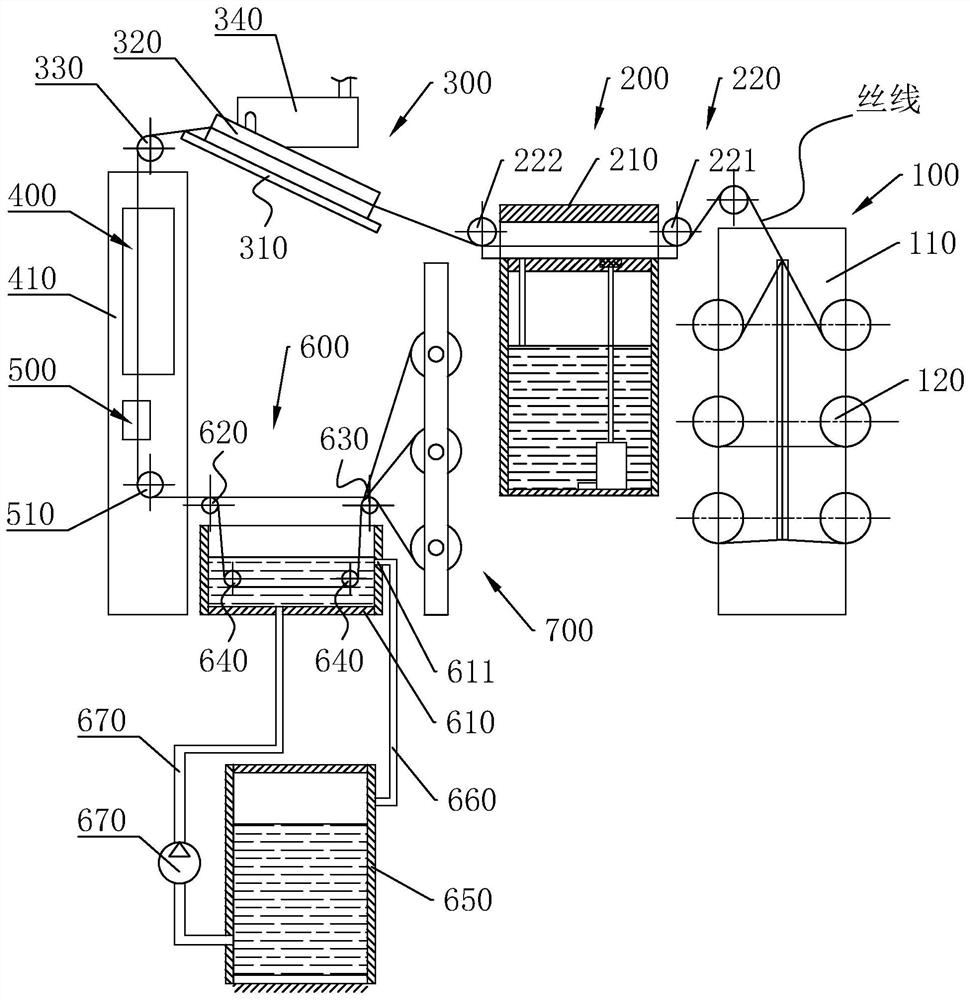

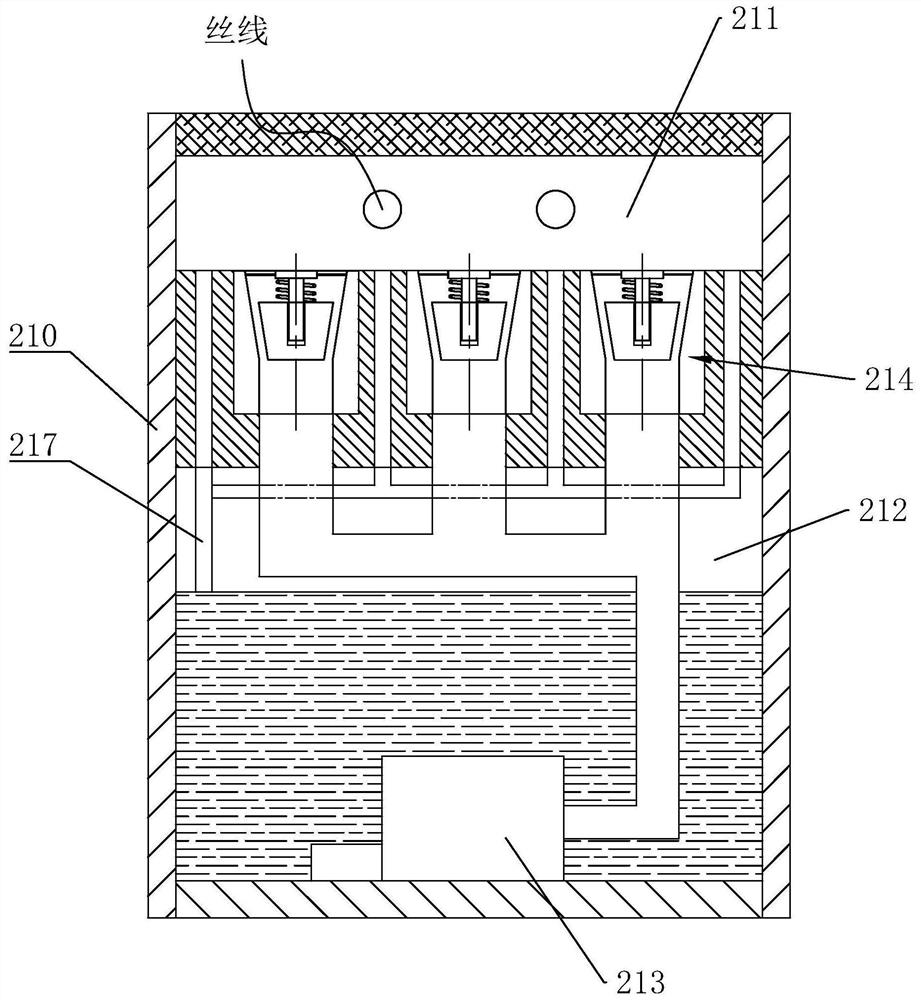

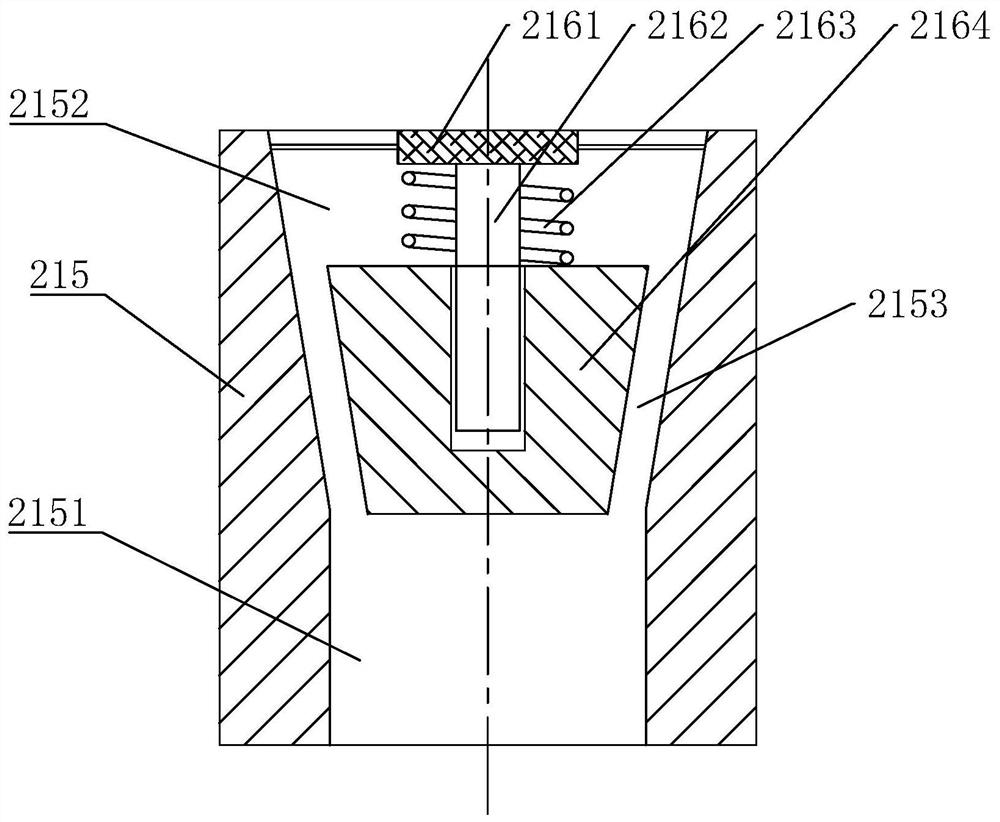

[0047] A chemical fiber spinning texturing device, such as figure 1 As shown, it includes a yarn feeding system 100 arranged in sequence, which is used to place the raw material silk and unwind it; a heating system 300, which heats the unrolled silk; a cooling system 400, which cools the high-temperature silk; a false twister 500, false-twisting the silk thread; the oiling system 600, oiling and lubricating the silk thread; and the winding device 700, winding the oiled silk thread; the texturing device also includes a yarn feeding system 100 and a heating system 300 Among them is a dyeing system 200 for dyeing unwound silk threads.

[0048] By adding the dyeing system 200 between the yarn feeding sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com