Airplane air tightness test method

A test method and aircraft technology, applied in the field of aviation flight test, can solve the problem that it is difficult to keep the pressure gradient constant, and achieve the effects of improving measurement accuracy and work efficiency, increasing speed, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

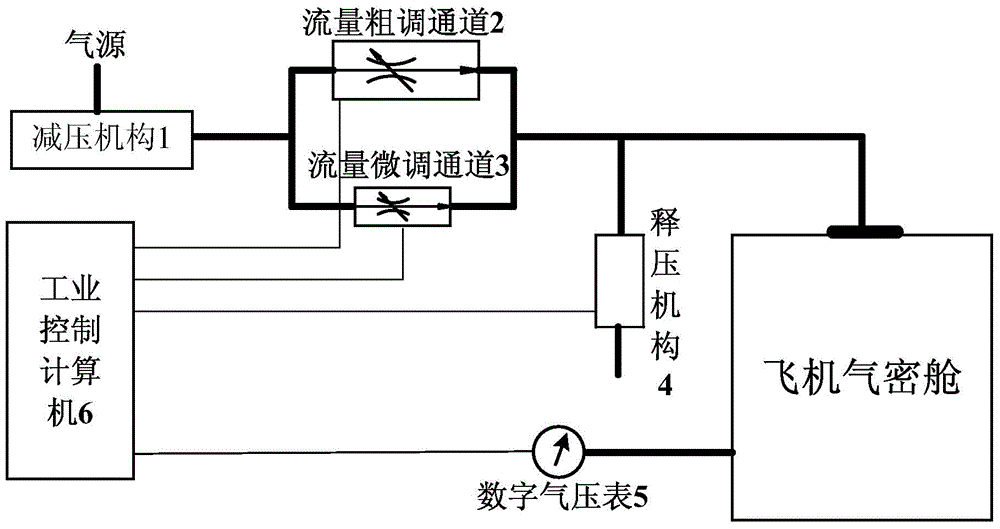

Method used

Image

Examples

Embodiment Construction

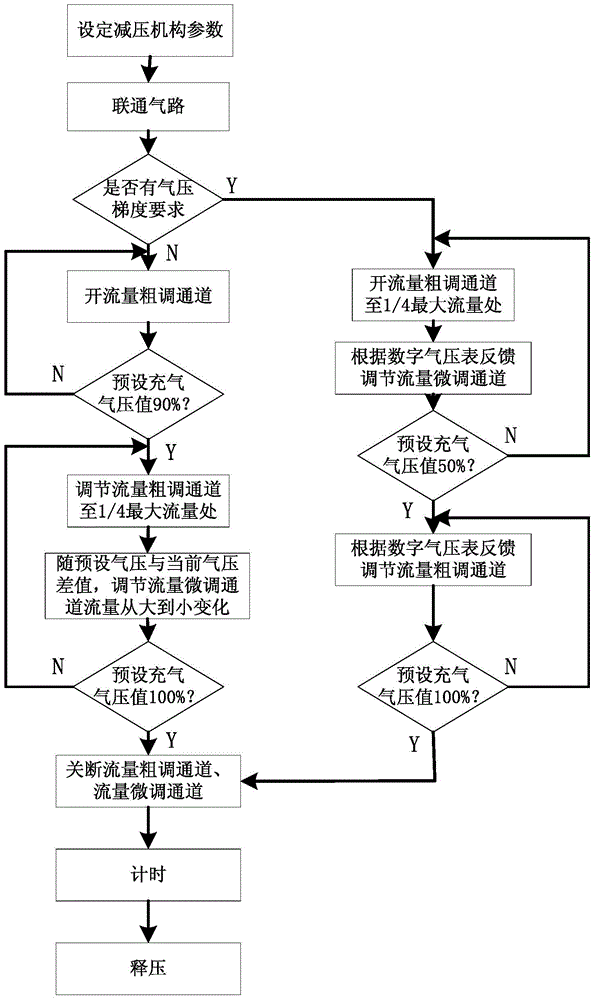

[0025] When there is no pressure gradient requirement in the test process, the industrial computer 6 controls the opening of the coarse flow adjustment channel 2 to the maximum flow, and quickly injects air to 90% of the set air pressure. At this time, the flow rate of the coarse flow adjustment channel 2 is reduced to 1 / 4 of the maximum At the flow rate, this gas flow is used to counteract the natural discharge flow of the airtight cabin of the aircraft, adjust the flow and fine-tune the flow of channel 3, so that the air pressure in the airtight cabin of the aircraft slowly reaches the set pressure value.

[0026] When the test process requires a pressure gradient, the industrial computer 6 controls the coarse flow adjustment channel 2 to 1 / 4 of the maximum flow, and adjusts the flow fine adjustment channel 3 according to the pressure value fed back by the digital barometer 5 to stabilize the pressure gradient. When the air pressure rises to 50% of the set air pressure value,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com