Full-pressure tiny leak precision measurement system

A precision measurement and full pressure technology, applied in the field of measurement, can solve the problems of high leak detection cost, inconvenient portability, and complicated process of leak detectors, and achieve the effects of easy promotion, portability, and stable values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

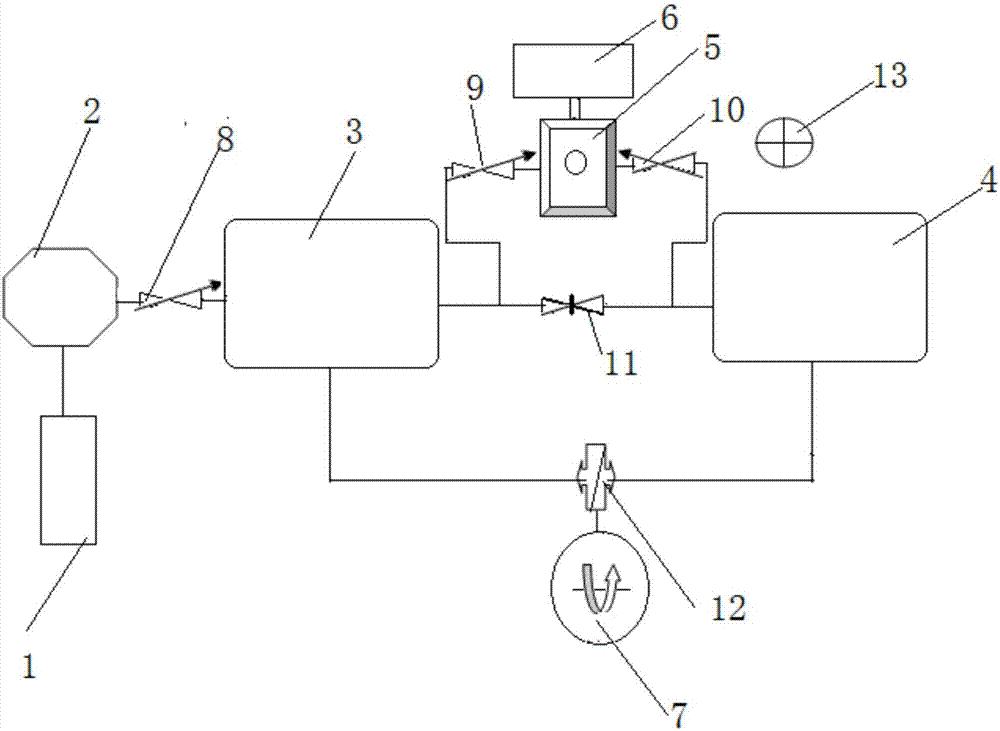

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0033] from figure 1 It can be seen that the present invention is a full pressure micro-leakage precision measurement system, mainly including ball valve V411, stop valve V18, stop valve V29, stop valve V310 and three-way sealing valve V512, high-precision differential pressure gauge 5, instrument control unit 6 , Constant volume chamber 3, gas distribution chamber 4, vacuum pump 7, timer 13, gas source 1 and pipeline.

[0034] The constant volume chamber 3 is connected to the gas distribution chamber 4 through the pipeline and the ball valve V411; the constant volume chamber 3 is used to store gas at a given pressure; the gas distribution chamber 4 is used to configure the gas with the same pressure as the constant volume chamber 3; the high precision difference The pressure gauge 5 is connected in parallel to the inlet and outlet of the ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com