Automatic clamping jig for mobile phone production and clamping method

A mobile phone and clamping technology, which is applied in the field of automatic clamping fixtures and clamping for mobile phone production, can solve problems such as manual operation, increased labor costs and time costs, and inability to clamp samples to be tested, so as to reduce the time used , reduce labor costs and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

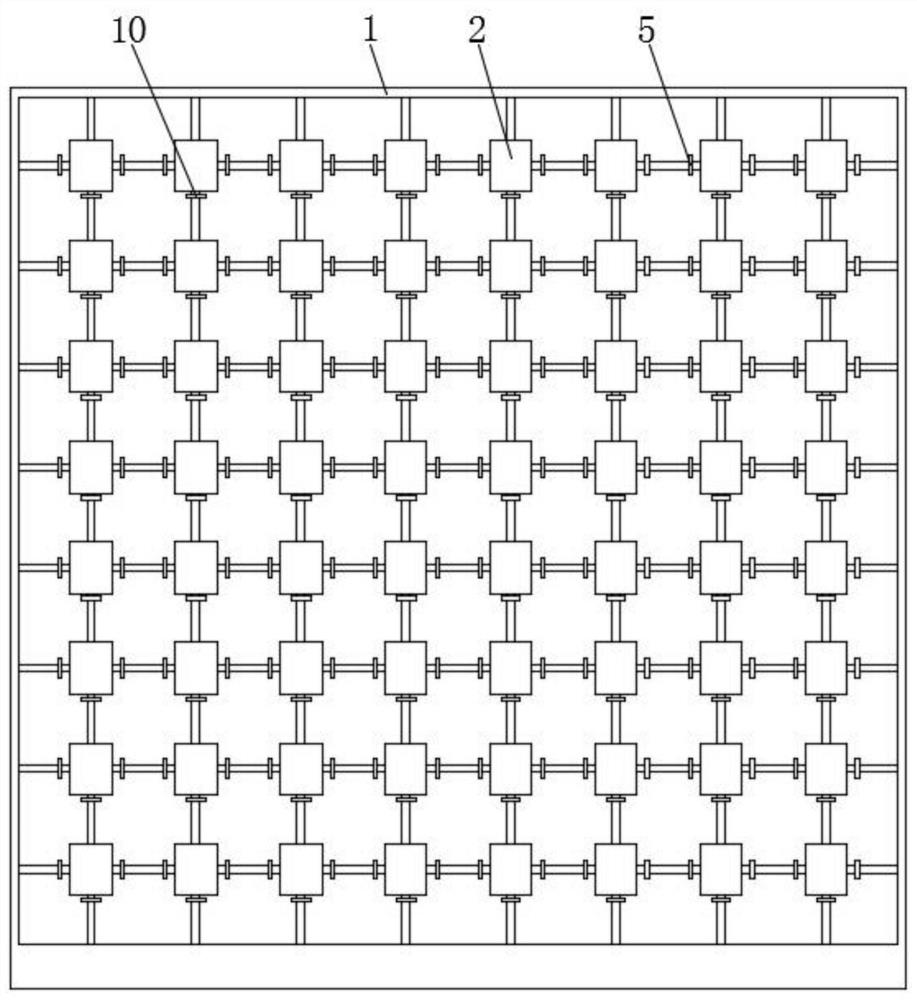

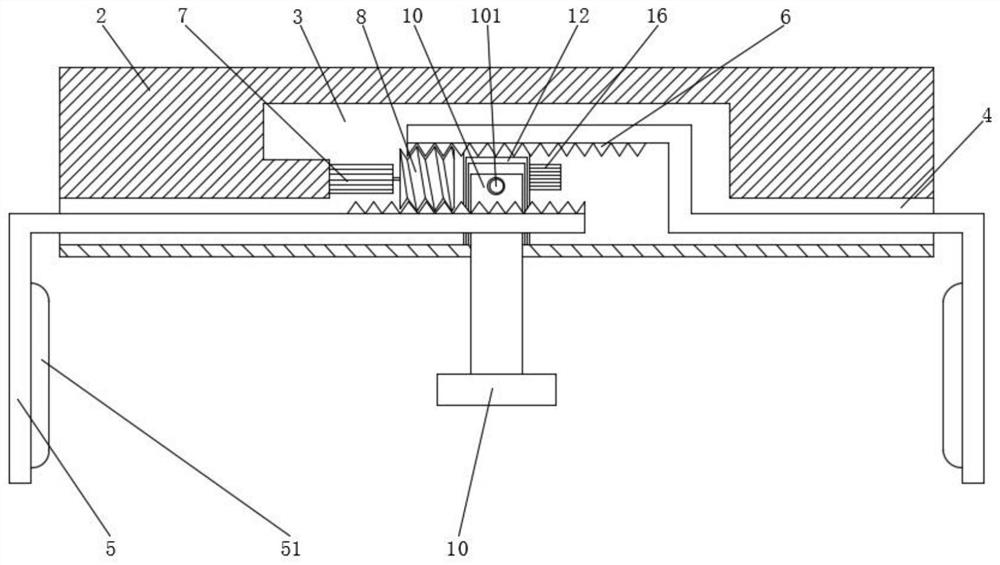

[0027] see Figure 1-5 , the present embodiment provides an automatic clamping jig for mobile phone production, including a vertically fixed mounting frame 1, a plurality of mounting plates 2 distributed in an array are fixed on the front of the mounting frame 1, and the interior of the mounting plate 2 A movable chamber 3 is provided, and the two sides of the placement plate 2 are far away from each other and near the middle, there is a movable port 4 connected with the movable chamber 3, and a splint 5 is installed inside the movable port 4, and the splint 5 extends into the side of one end of the movable port 4 A rack 6 is fixed, and a telescopic motor 7 is fixed inside the movable chamber 3. The power output shaft of the telescopic motor 7 is fixed with a worm 8 meshing with the rack 6. Through telescopic mouth 9, the inside of telescopic mouth 9 is equipped with support plate 10, and the inner wall of movable cavity 3 bottom side is extended to be provided with slideway 1...

Embodiment 2

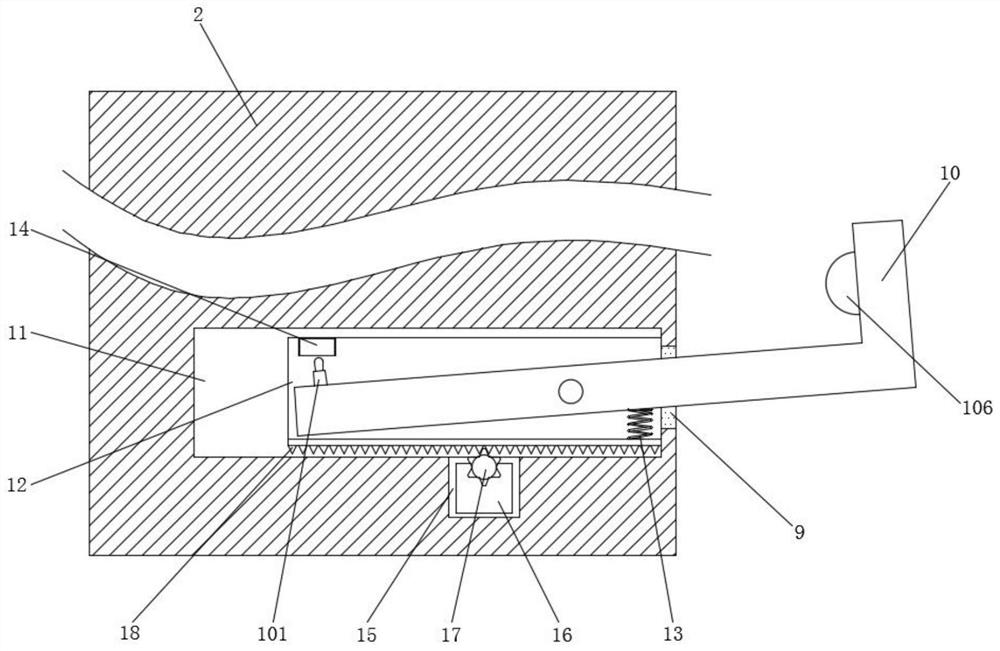

[0041] see Figure 3-4 A further improvement has been made on the basis of Embodiment 1: a movable cylinder 101 is integrally provided on the top side of the end of the support plate 10 directly below the pressure sensor 14, and a movable rod 102 is installed inside the movable cylinder 101, and the movable cylinder 101 is far away from the opening end. A back-moving spring 103 is installed between the inner wall and the movable rod 102, and the inner wall of the movable cylinder 101 near the open end is integrally provided with a limit ring 104, and the outer wall at the bottom end of the movable rod 102 is provided with a limit ring 105 matched with the limit ring 104, and the movable rod 102 The top of the movable rod 102 is one-half of a spherical structure, and the pressure sensor 14 can measure a stable pressure in a relatively long period of time by sliding inside the movable cylinder 101 after the top of the movable rod 102 touches the pressure sensor 14 value, which c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com