A recycled asphalt pavement

A technology of reclaimed asphalt and recycled asphalt, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of long construction period, easy expansion and reflection of base cracks, and waste of resources, so as to improve the comprehensive road performance and solve the two problems. Sub-aging, reduce the effect of construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

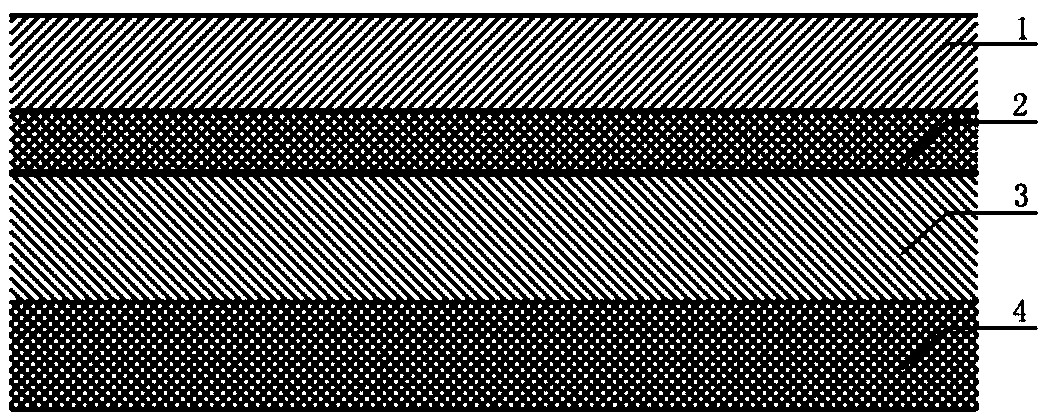

[0031] refer to figure 1, The regenerated asphalt pavement structure of this embodiment is the surface layer 1, the sealing layer 2, the base layer 3 and the cushion layer 4 from top to bottom.

[0032] The surface layer of this embodiment is a factory-mixed heat-recycled asphalt concrete with a single-layer layered structure, and the thickness is 4cm; the surface layer material consists of:

[0033] 70% of recycled asphalt pavement materials, 1% of modified asphalt materials, 1% of admixtures, and 28% of modified stone materials, among which recycled asphalt pavement materials are divided into 2 grades: 0mm~9.5mm and >9.5mm;

[0034] Composition and ratio of modified asphalt materials: modifier 3%, warm mix agent 2%, regenerant 5%, petroleum asphalt 90%, modifier is styrene-butadiene latex (SBR); warm mix agent is polyethylene wax; The regeneration agent is furfural extract oil; the petroleum asphalt is No. 70 road petroleum asphalt.

[0035] Admixture composition and ratio...

Embodiment 2

[0040] This embodiment differs from Embodiment 1 in that:

[0041] The sealing layer of this embodiment is a single-layer spraying modified emulsified asphalt; the modified emulsified asphalt material of the sealing layer consists of 40% petroleum asphalt, 1% asphalt emulsifier, 2% modifier, 57% water, the mark of petroleum asphalt No. 70; the asphalt emulsifier is alkylphenol polyoxyethylene ether OP series alkylphenol polyoxyethylene ether OP-9, the modifier is styrene-butadiene latex (SBR), and the spraying amount of modified emulsified asphalt for the sealing layer is 1.2 kg / m 2 .

[0042] The base of this embodiment is the in-situ cement-stabilized cold recycled mixture of single-layer layered structure, and the thickness is 20cm; Portland cement, the label is 32.5; the admixture is styrene-butadiene latex (SBR). The recycled material is a mixture of recycled asphalt pavement surface material and recycled asphalt pavement base material in any mass ratio.

[0043] The ...

Embodiment 3

[0045] The difference with embodiment 1 is:

[0046] The thickness of the surface layer in this embodiment is 8cm, and the material composition of the surface layer is: 90% of recycled asphalt pavement materials, 3% of modified asphalt materials, 3% of admixtures, and 4% of modified stone materials, wherein the recycled asphalt pavement materials are divided into 3 grades: 0mm~4.75mm, 4.75mm~9.5mm, ≥9.5mm.

[0047] The composition and ratio of modified asphalt materials: modifier 7%, warm mix agent 16%, regenerant 15%, petroleum asphalt 62%, modifier is natural rubber latex (NR), warm mix agent is microcrystalline wax, The regeneration agent is aromatic hydrocarbon oil, and the petroleum asphalt is No. 90 road petroleum asphalt.

[0048] Admixture composition and ratio: recycled asphalt mixture modifier 40%, recycled asphalt mixture warm mix agent 60%, recycled asphalt mixture modifier is rubber-plastic compound produced by Shaanxi Changboyuan Highway Maintenance Technology C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com