Composite pavement structure and construction method thereof

A composite pavement and overlay technology, which is applied to roads, roads, pavement details, etc., can solve the problems of not using the structure of the board, accelerating the destruction of the overlay, and unsatisfactory use effects, so as to ensure road performance and service life, improved construction efficiency, and simple and easy construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

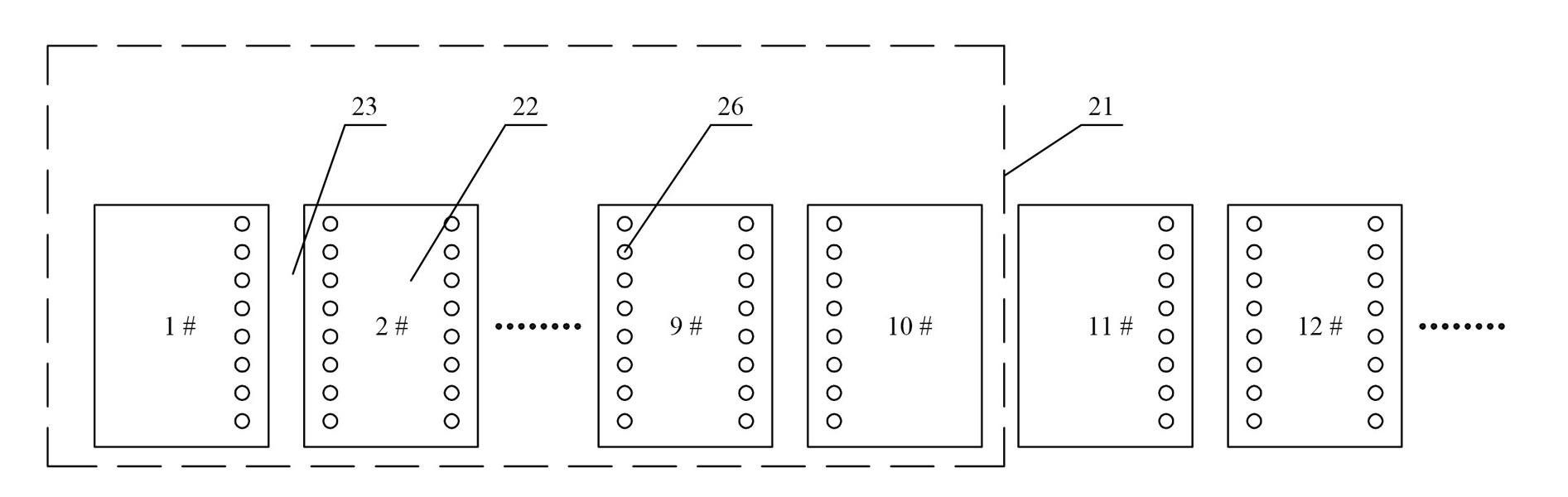

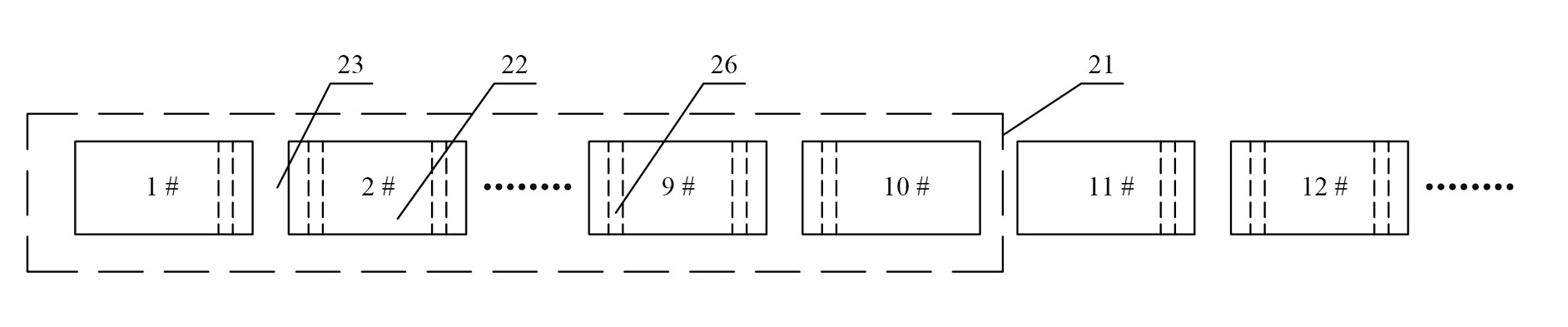

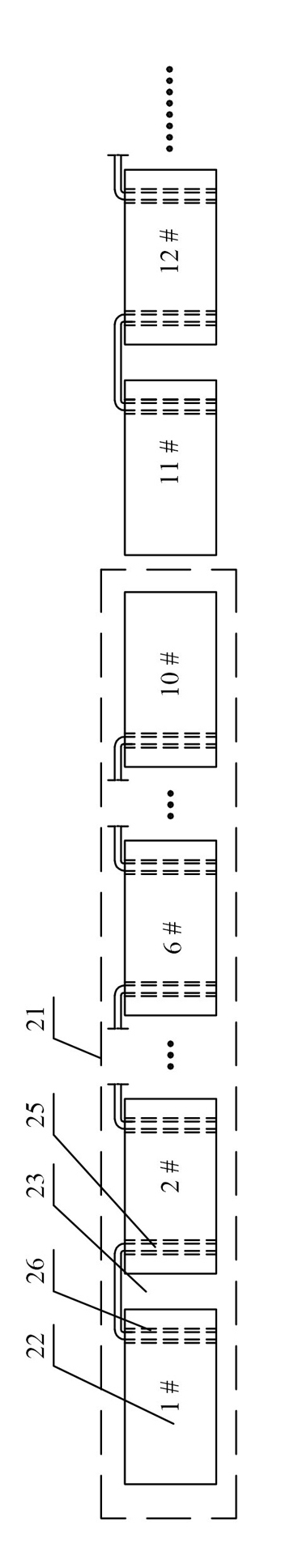

[0032] a kind of like Figure 5 The composite pavement structure of the present invention shown, this composite pavement structure comprises the bituminous concrete overlay 1 that is positioned at the upper layer and the old cement concrete panel layer 2 that is positioned at the lower floor, and the old cement concrete panel layer 2 is made of four old cement concrete slabs Composed of connection groups 21, each old cement concrete slab connection group 21 is set by ten old cement concrete slabs 22 (the length of the concrete slab 22 in this embodiment is 5 meters, and the width is 3.75 meters). The connectors 24 are connected, and the groups are not connected by connectors, and the seams are directly left blank. The connectors used in this embodiment are eight rake nails 25 (φ18) arranged side by side along the joint 23, and the left and right teeth of each rake nail 25 are respectively nested at the edge of the adjacent old cement concrete slab 22. Rake nail hole 26. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com