Ultrathin composite structure layer for preventing reflection cracks and preparation method of ultrathin composite structure layer

A composite structure, anti-reflection technology, applied in the field of transportation, can solve the problem of insufficient tensile strength, stability and waterproof ability of geogrid, high elongation at break of epoxy asphalt binder, toughness and strength, etc. Problems, to achieve the effect of improving anti-peeling and waterproof performance, improving tear resistance, and preventing relative movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

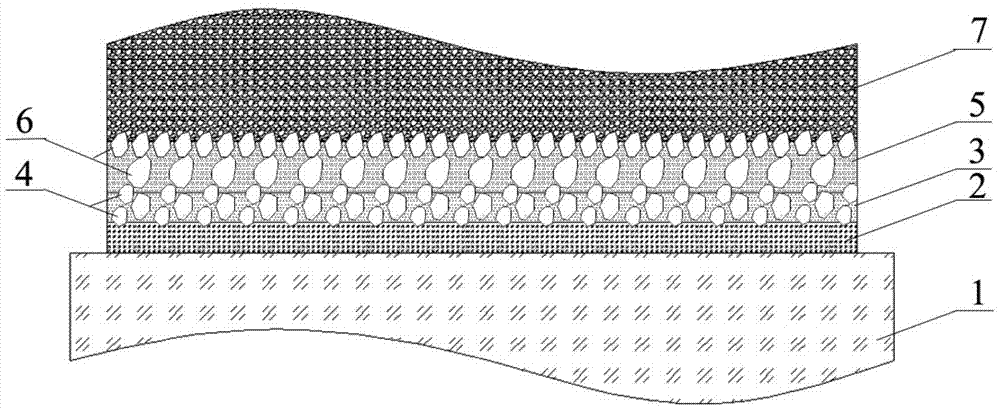

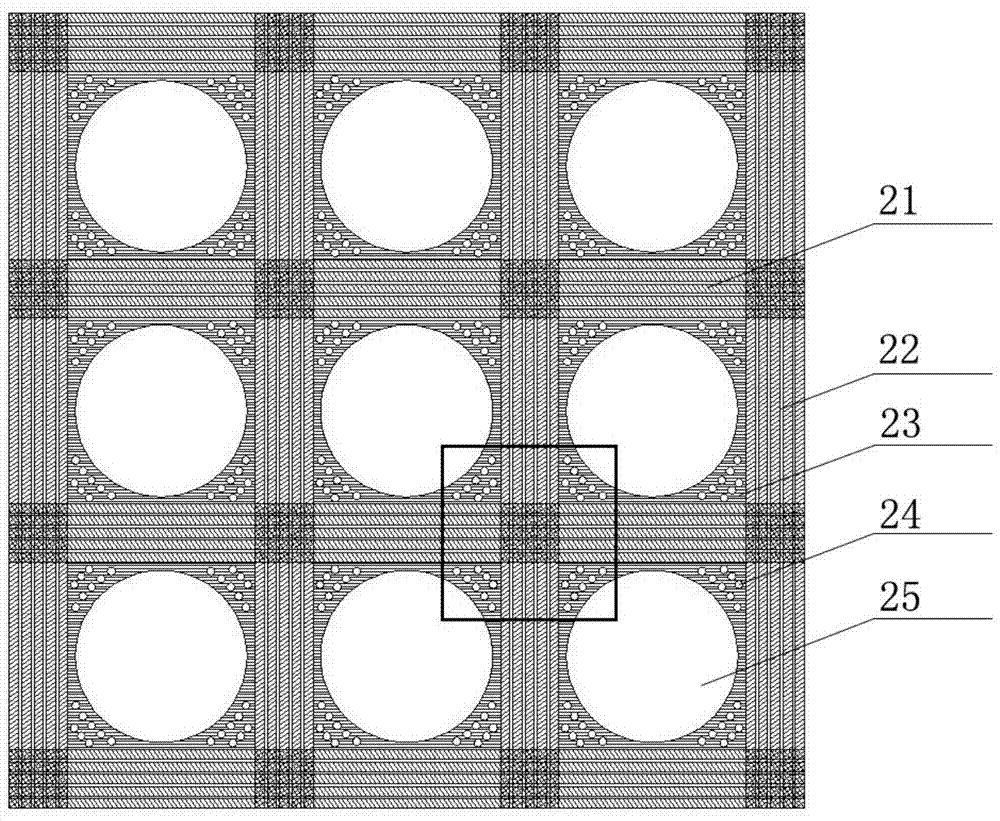

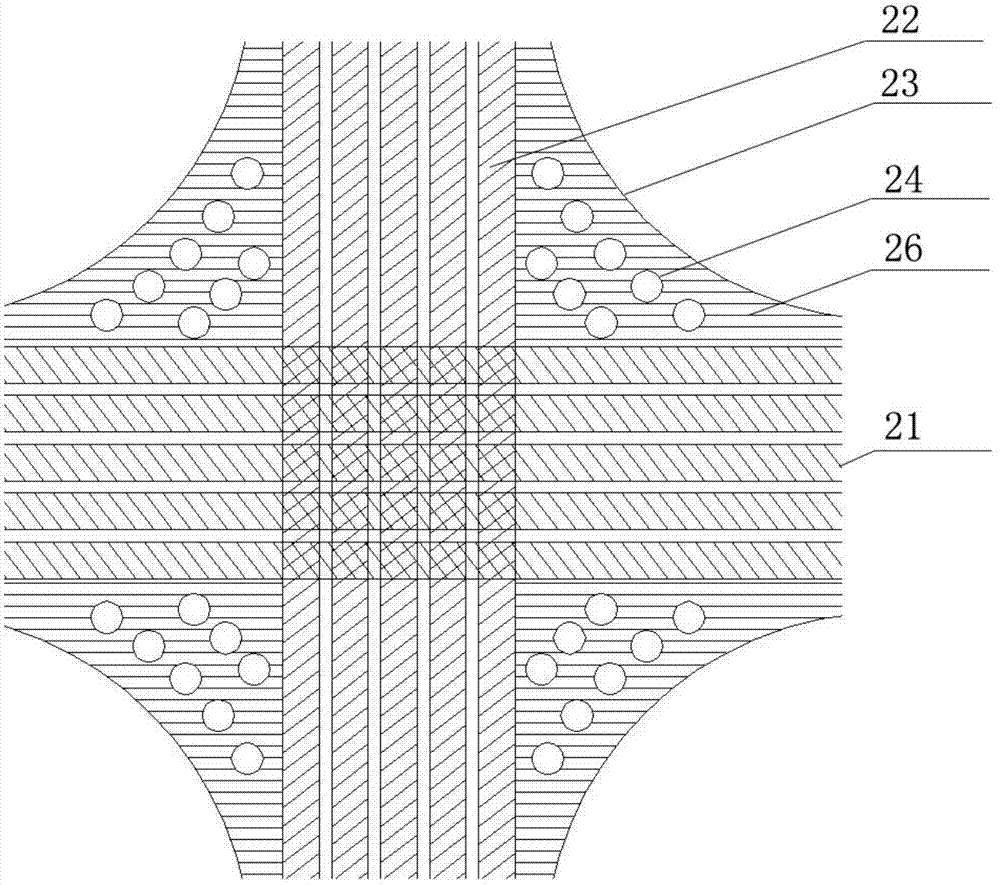

[0043] Such as figure 1 As shown, it is an ultra-thin composite structural layer for anti-reflection cracks, including the anti-slip high-strength geogrid layer 2, the lower layer of toughened epoxy asphalt graded gravel layer and the upper layer of reinforced ring Oxygen asphalt graded gravel layer; the anti-reflection crack is set between the cement pavement 1 and the asphalt concrete overlay layer 7 with an ultra-thin composite structure layer, and the anti-reflection crack passes between the cement pavement 1 and the asphalt concrete overlay layer 7 Bonded with an ultra-thin composite structure layer; the lower toughened epoxy asphalt graded gravel layer includes the lower toughened epoxy asphalt layer 3 and the lower graded gravel 4, and the lower graded gravel 4 is laid on the lower layer On the toughened epoxy asphalt layer 3, and embedded in the lower toughened epoxy asphalt layer 3, contacting the anti-slip high-strength geogrid layer 2 and the upper reinforced epoxy ...

Embodiment 2

[0061] Such as figure 1 As shown, it is an ultra-thin composite structural layer for anti-reflection cracks, including the anti-slip high-strength geogrid layer 2, the lower layer of toughened epoxy asphalt graded gravel layer and the upper layer of reinforced ring Oxygen asphalt graded gravel layer; the anti-reflection crack is set between the cement pavement 1 and the asphalt concrete overlay layer 7 with an ultra-thin composite structure layer, and the anti-reflection crack passes between the cement pavement 1 and the asphalt concrete overlay layer 7 Bonded with an ultra-thin composite structure layer; the lower toughened epoxy asphalt graded gravel layer includes the lower toughened epoxy asphalt layer 3 and the lower graded gravel 4, and the lower graded gravel 4 is laid on the lower layer On the toughened epoxy asphalt layer 3, and embedded in the lower toughened epoxy asphalt layer 3, contacting the anti-slip high-strength geogrid layer 2 and the upper reinforced epoxy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com