Asphalt-treated permeable-base (ATB) construction process

A construction technique, asphalt macadam technology, applied to roads, on-site coagulation pavements, roads, etc., can solve the problem of large shrinkage (temperature shrinkage and dry shrinkage) of semi-rigid materials, affecting the use function of the road surface, and road reflection cracks and other problems, to achieve the effect of reducing maintenance costs, significant economic and social benefits, and delaying reflection cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

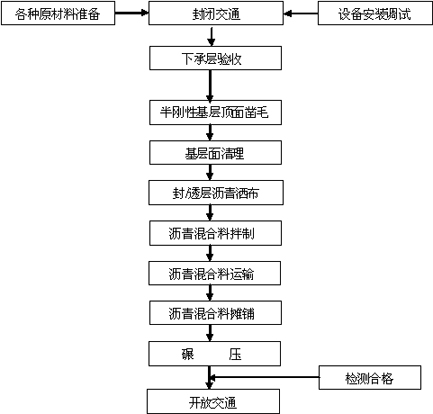

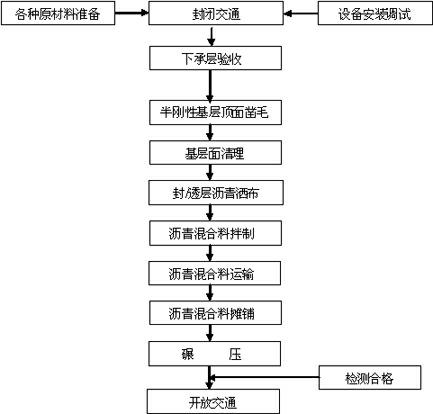

[0017] Such as figure 1 As shown, a construction process of ATB asphalt macadam base includes the following processes:

[0018] 1. Selection of raw materials:

[0019] The quality requirements and technical indicators of asphalt, permeable coal tar pitch, viscous layer emulsified asphalt, coarse and fine aggregates, fillers, etc. shall be determined according to the structural type of the asphalt concrete surface layer design and its corresponding technical specification requirements and construction methods. The quality of asphalt mixture The indicators mainly refer to "Technical Specifications for Construction of Highway Asphalt Pavement" (JTG F40-2004), the owner's design documents or related technical specifications.

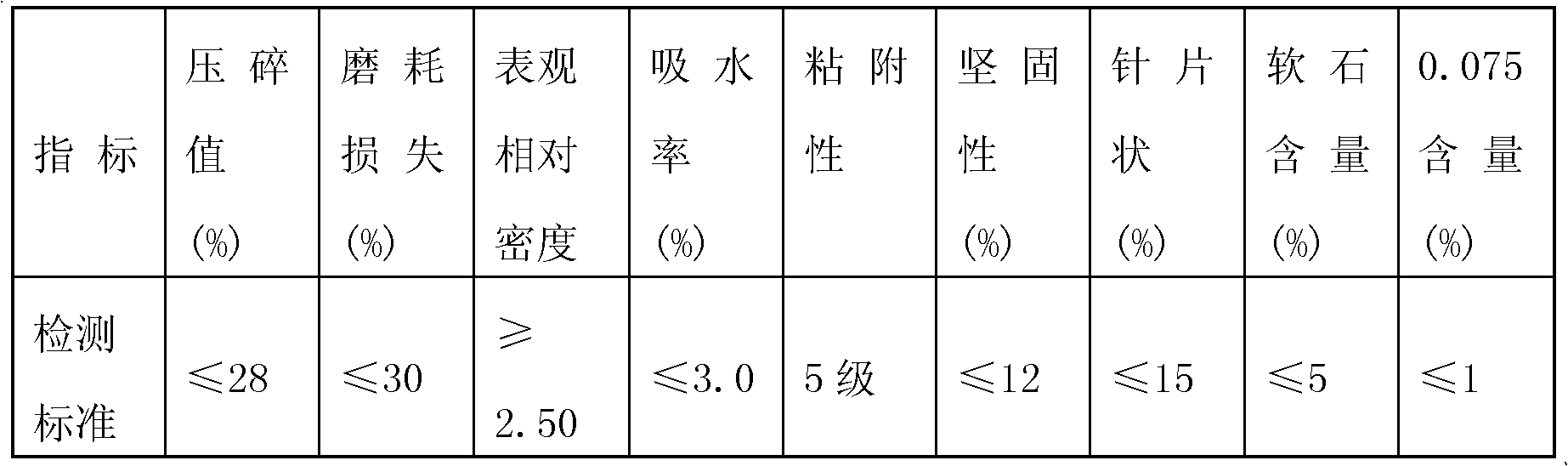

[0020] 1) coarse aggregate

[0021] The limestone gravel produced by the impact crusher is clean, free of miscellaneous rocks, large in size, rough in surface, square in shape and good in adhesion, with less flat and needle-like particles.

[0022] Strict...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com