Hot-distribution rubber bituminous pavement and construction method thereof

A rubber asphalt and construction method technology, applied in the field of asphalt pavement construction, can solve problems such as poor shear strength, poor fatigue resistance, and difficulty in guaranteeing construction quality, and achieve the effects of reducing road surface diseases, preventing water ingress, and delaying reflective cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

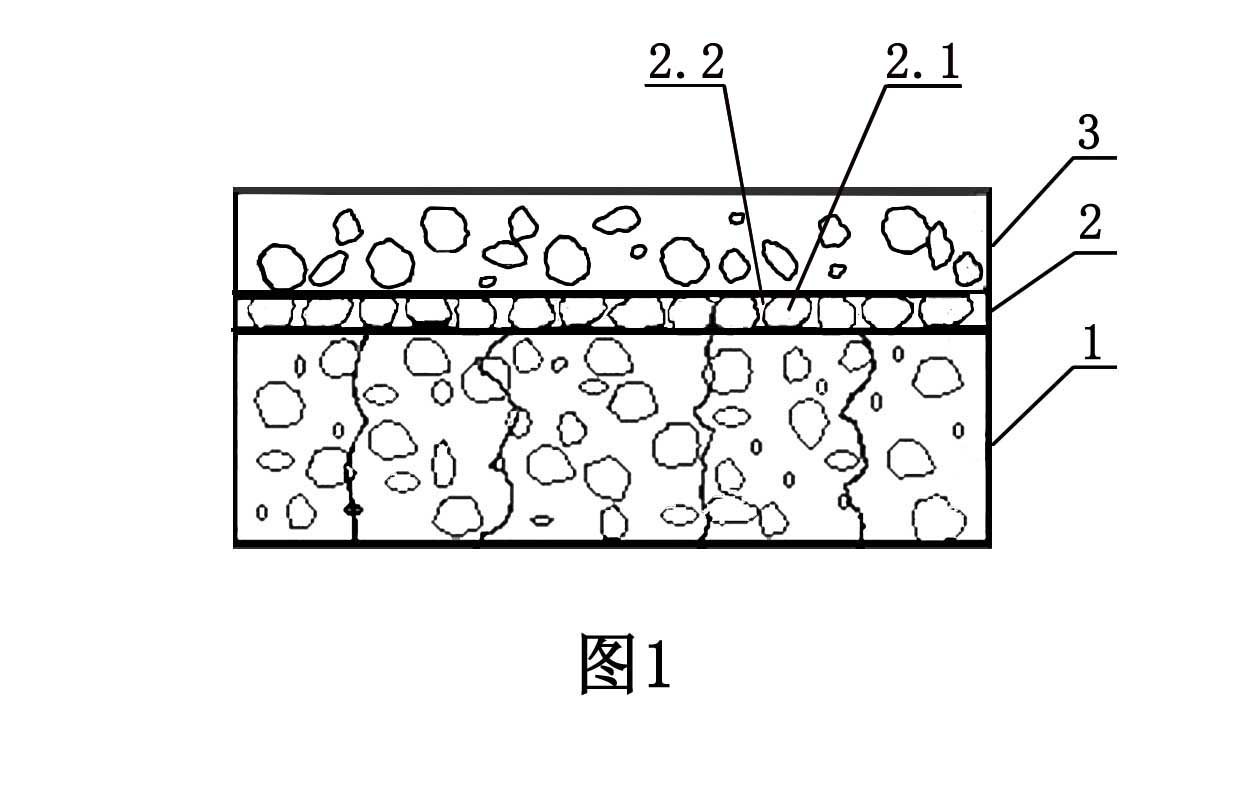

[0042] Embodiment one sees figure 1 As shown, this hot-sprinkling rubber asphalt pavement is laid from bottom to top by a lower bearing layer 1, a rubber asphalt waterproof adhesive layer 2 and a surface layer 3, and is characterized in that: the rubber asphalt waterproof adhesive layer 2 is formed by rolling the rubber asphalt 2.1 sprayed on the lower bearing layer and the gravel 2.2 uniformly sprayed on the rubber asphalt layer simultaneously, and the spraying amount of the rubber asphalt is 2.2-2.6 kg / m 2 ; The sprinkling amount of the gravel is 60-70% of the sprinkling area of the rubber asphalt.

Embodiment 2

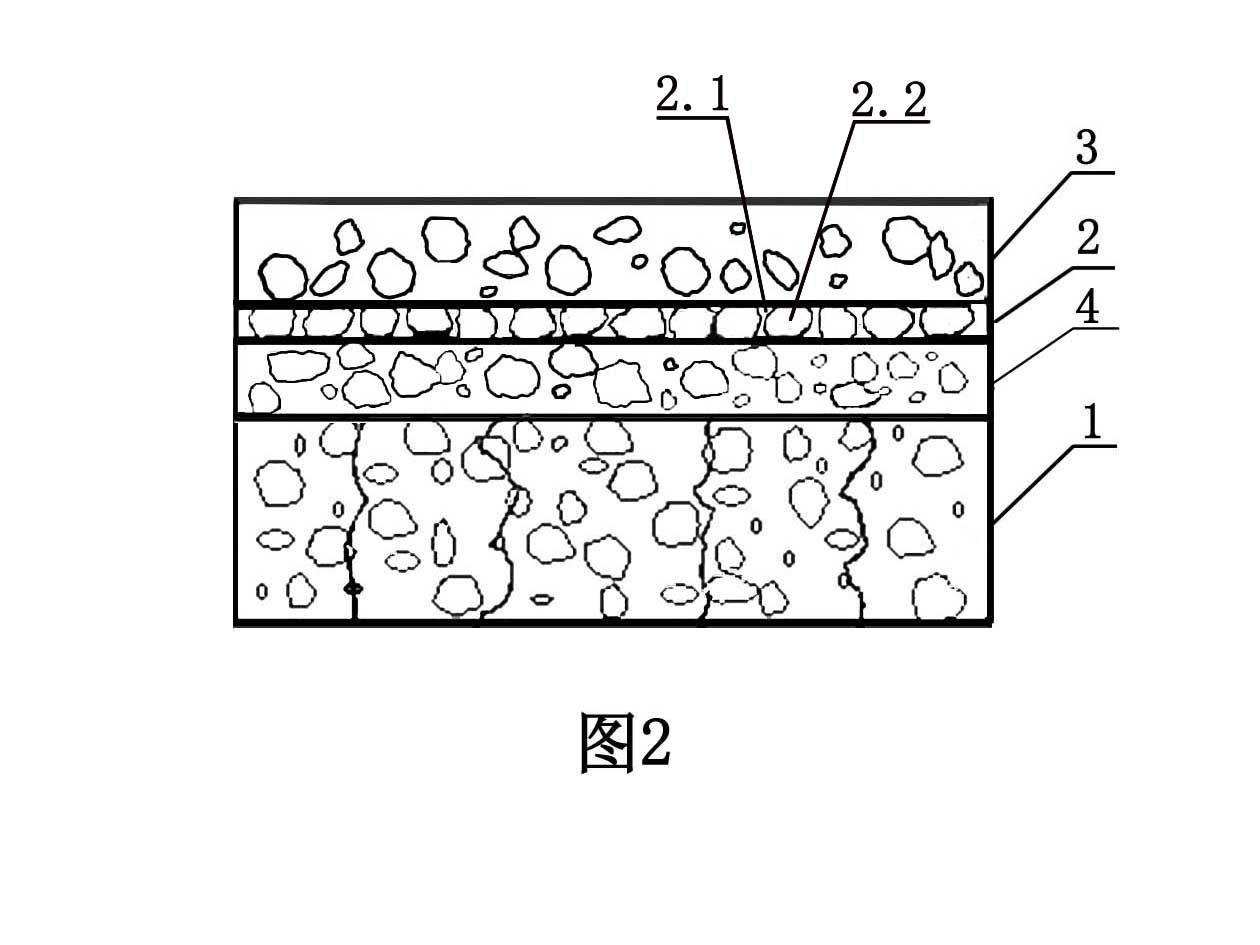

[0043] Embodiment two see figure 2 As shown in the figure, a leveling layer is laid on the under-bearing layer of the hot-sprinkled rubber asphalt pavement, and the leveling layer is located between the under-bearing layer and the rubber asphalt waterproof bonding layer.

[0044] The underlying layer 1 is an old road surface, or a cement concrete bridge deck or road surface, or an asphalt concrete bridge deck or road surface, or a semi-rigid base.

[0045] The particle size of the crushed stone is 16-19 mm when the rubber asphalt waterproof bonding layer 2 is laid on the surface of the semi-rigid base, and the particle size of the crushed stone is 16-19 mm when the rubber asphalt waterproof bonding layer 2 is laid under the surface layer It is 1 / 3~1 / 2 of the thickness of the surface layer, and the crushed stone is a limestone material with a single particle size, and the crushed stone content beyond the particle size range is less than 10%.

[0046] When the asphalt rubber w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com