Asphalt pavement structure for urban tunnel deformation seam and paving method thereof

An asphalt pavement and deformation joint technology, which is applied in the field of transportation engineering, can solve the problems affecting the service performance and driving comfort of the asphalt pavement, reduce reflection cracks and water seepage, improve flexibility, good fatigue resistance and water tightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

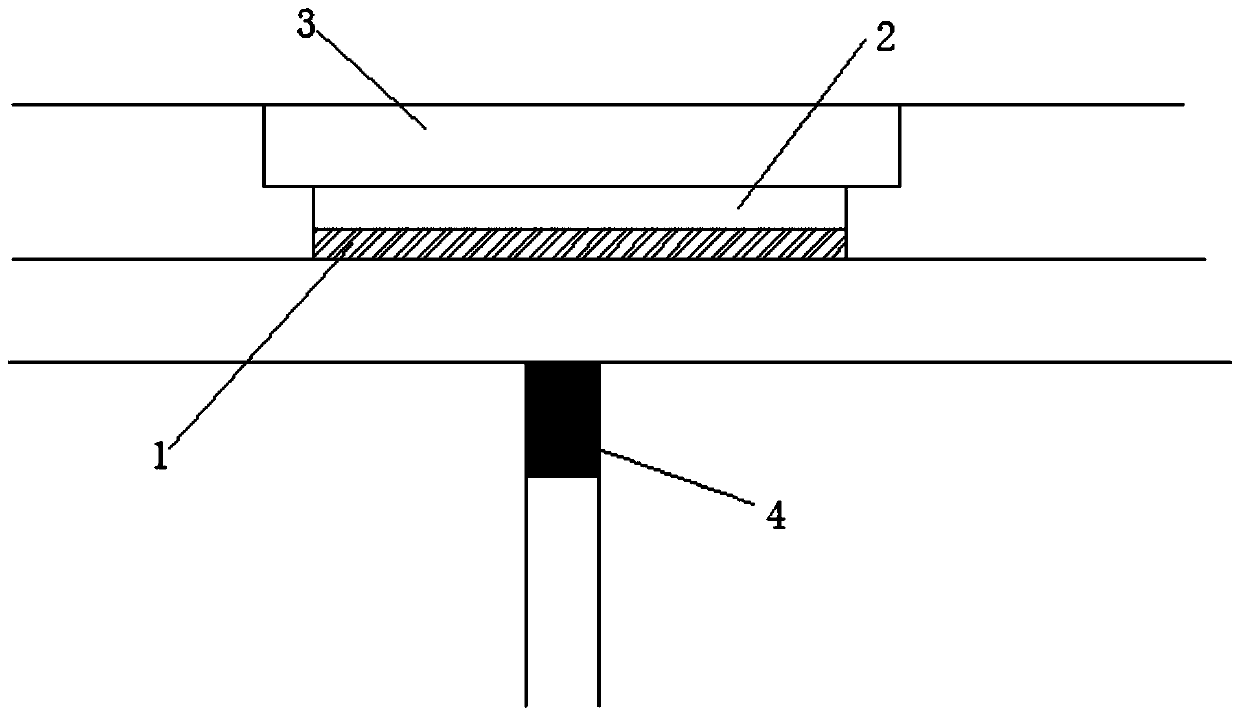

[0035] like figure 1 as shown,

[0036] A kind of asphalt pavement structure that is used for the deformation joint of urban tunnel, described asphalt pavement structure comprises the stress absorbing layer 1 of laying from bottom to top, asphalt concrete lower layer 2 and asphalt concrete upper layer 3; Wherein, described stress absorbing layer is The normal temperature thermosetting modified asphalt binder 4 is composed of gravel; the asphalt concrete upper layer 3 and the asphalt concrete lower layer 2 are respectively paved with normal temperature thermosetting modified asphalt mixture.

[0037] Further, the total pavement thickness of the asphalt pavement structure is 7-10cm.

[0038] Further, the stress absorbing layer 1 is made by the following method: put the prepared normal temperature thermosetting modified asphalt binder 4 into the asphalt spreader, and spray it on the top of the base layer through the nozzle of the asphalt spreader On the surface, then sprinkle 5...

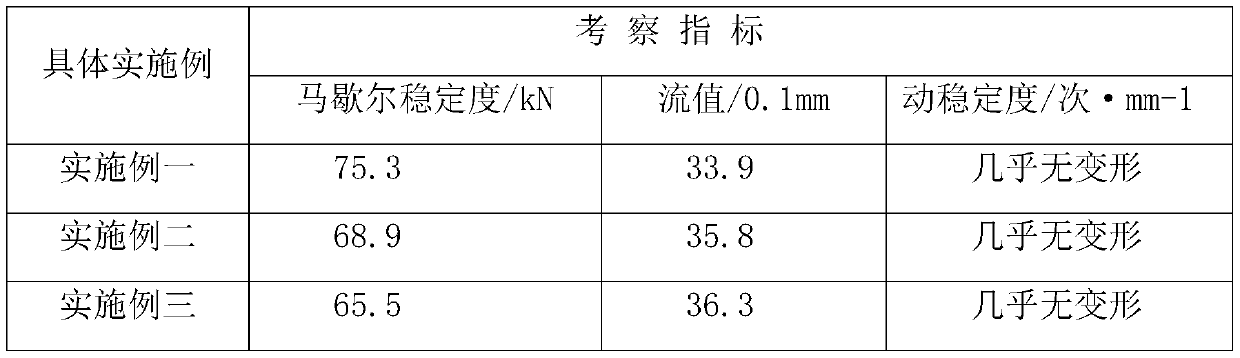

Embodiment 1

[0056] (1) Old road surface treatment

[0057] Taking the deformation joint as the center, use a milling machine to first mill out a 3cm-thick upper layer with a width of 120cm; then, mill out a 3cm-thick lower layer with a width of 90cm; then, Vacuum cleaners and hot air blowers are used to clean the dust and residual old asphalt mixture on the newly exposed road surface and dry the surface of the old road surface to ensure the cleanliness and dryness of the top surface of the old road surface.

[0058] (2) Implementation of stress absorbing layer

[0059] Mix the components D and G of the normal temperature thermosetting asphalt binder at a mass ratio of 1:1.8 at 30°C, and then use a small emulsified asphalt spreader to spray the mixed normal temperature thermosetting modified asphalt on the road surface Then, sprinkle single-size aggregates with a particle size of 5-10 mm at a coverage rate of 65% to form a stress-absorbing layer with a width of 90 cm and a thickness of 1 ...

Embodiment example 2

[0067] (1) Old road surface treatment

[0068] With the deformation joint as the center, use a milling machine to mill out a 3cm-thick upper layer with a width of 120cm; then, mill out a 4cm-thick lower layer with a width of 100cm; then, Vacuum cleaners and hot air blowers are used to clean the dust and residual old asphalt mixture on the newly exposed road surface and dry the surface of the old road surface to ensure the cleanliness and dryness of the top surface of the old road surface.

[0069] (2) Implementation of stress absorbing layer

[0070] Mix the components D and G of the normal temperature thermosetting asphalt binder at a mass ratio of 1:1.8 at 23°C, and then use a small emulsified asphalt spreader to spray the mixed normal temperature thermosetting modified asphalt on the road surface Then, sprinkle single-size aggregates with a particle size of 5-10 mm at a coverage rate of 80% to form a stress-absorbing layer with a width of 100 cm and a thickness of 1 cm.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com