Composite fabricated cement concrete pavement structure and construction method thereof

A technology of cement concrete and pavement structure, which is applied to cohesive pavement paved on site, roads, buildings, etc. It can solve the problems that affect the service life and driving comfort of asphalt pavement, rutting of asphalt pavement, large interlayer shear force, etc. problems, achieve good driving comfort, save construction time, and reduce reflection cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

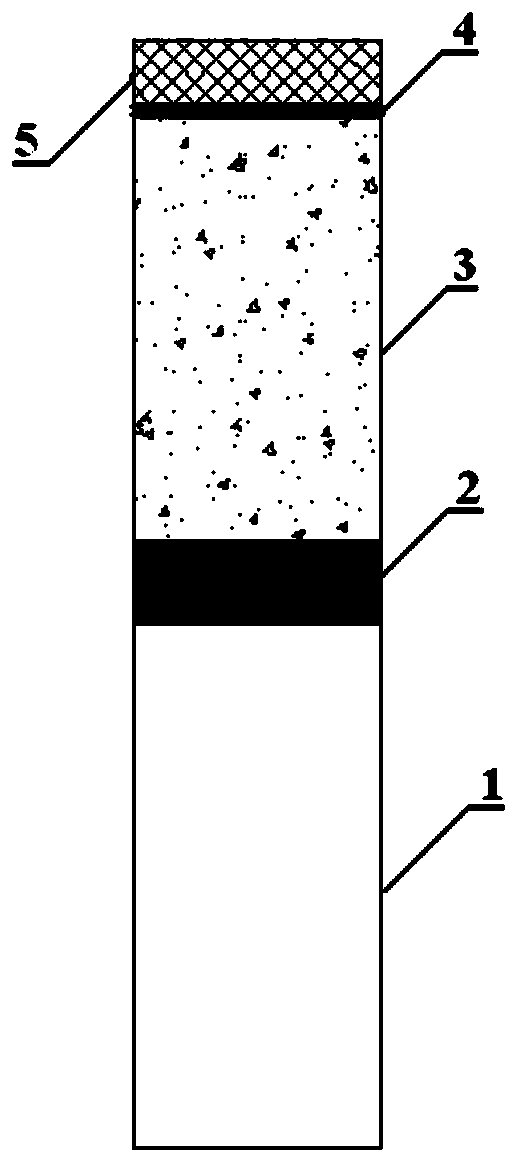

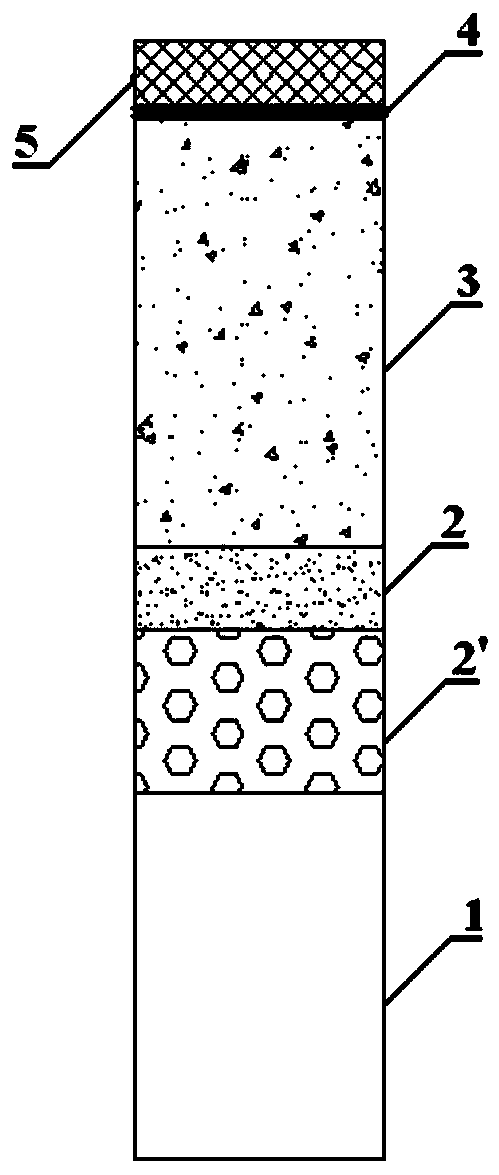

[0062] The schematic diagram of the composite assembled cement concrete pavement structure provided by Embodiment 1 of the present invention can be found in figure 2 Shown; Among them, 1 is the cement stabilized gravel base, the thickness is 36cm, the mixing ratio of the cement stabilized gravel is 5:95; 2 is the rubber modified asphalt synchronous gravel seal layer, the thickness is 1cm; 3 is the assembly Type prefabricated concrete slab, the design bending and tensile strength is 5.0MPa, and the thickness is 26cm; 4 is the rubber modified asphalt synchronous crushed stone seal layer, the thickness is 0.5cm; 5 is the rubber modified asphalt concrete AC-13, the thickness is 4cm.

[0063] The above-mentioned composite prefabricated cement concrete pavement structure is applied to a new secondary road in a certain area in Northeast China, and the construction method is as follows:

[0064] (1) Lay the cement stabilized gravel base, and then detect the surface elevation, compact...

Embodiment 2

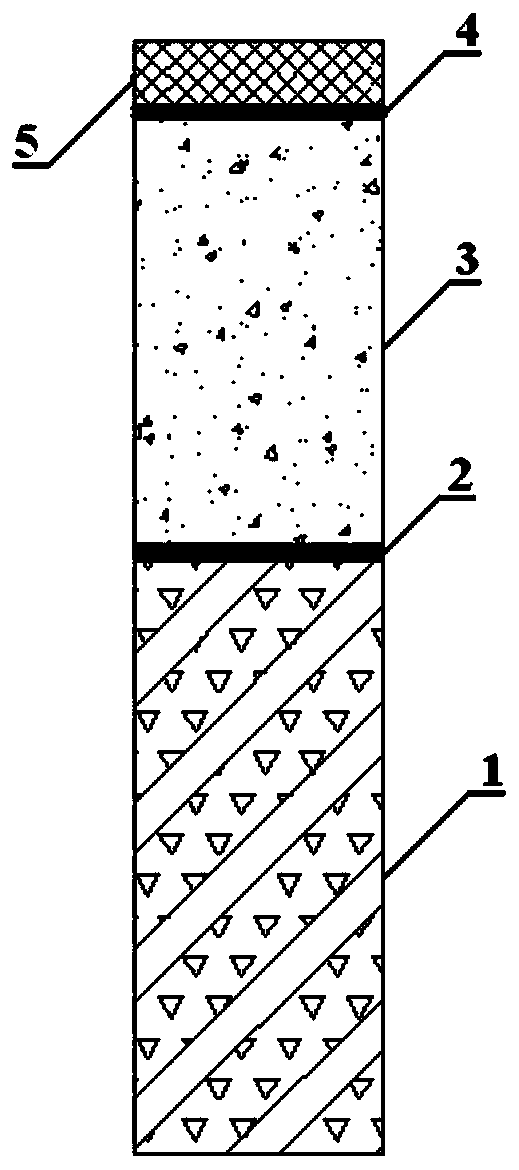

[0074] The schematic diagram of the composite assembled cement concrete pavement structure provided by Embodiment 2 of the present invention can be found in image 3 2' is graded gravel with a thickness of 10cm; 2 is medium-coarse sand with a thickness of 5cm; 3 is an assembled prefabricated concrete slab with a design bending and tensile strength of 5.0MPa and a thickness of 26cm; 4 is the rubber-modified asphalt synchronous gravel seal layer, the thickness is 0.5cm; 5 is the rubber-modified asphalt concrete SMA-13, the thickness is 4cm.

[0075] The above-mentioned composite assembled cement concrete pavement structure is applied to repair the deck pavement of a stone arch bridge of a secondary road in a certain area in Northeast China that has been open to traffic for 20 years. The construction method is as follows:

[0076] (1) On-site inspection of the surface elevation, compaction, flatness, and transverse slope of the road bed (old pavement base), and whether the CBR va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com