Adjustable bridge rail support

An adjustable technology for bridge bearings, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as uneven stress, cracking, and non-recoverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

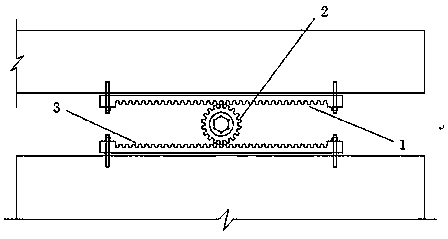

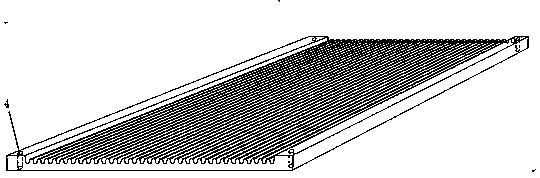

[0015] see Figure 1 to Figure 3 , the steel-concrete composite structure bridge support includes an upper track plate 1, a lower track plate 3 through which the gear shaft 2 and the upper track plate 1 are mechanically transmitted.

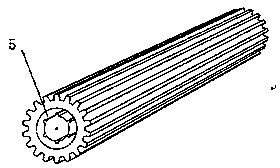

[0016] Preferably, positioning bolt holes 4 are provided around the upper track plate 1 , and the upper track plate 1 is connected to the main beam through studs passing through the positioning bolt holes 4 . Positioning bolt holes 4 are also provided around the lower track plate 3 , and the lower track plate 3 is connected to the supporting structure through studs passing through the positioning bolt holes 4 . The gear shaft 2 is a roller with gears. The two ends of the central shaft of the gear shaft 2 are provided with locking grooves 5 , and the gear shaft 2 is connected with the external power mechanism through the locking grooves 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com