Super-thick bamboo-wood composite board and producing method thereof

A bamboo-wood composite and board technology, which is applied in the manufacturing field of ultra-thick bamboo-wood composite boards and ultra-thick bamboo-wood composite boards, can solve the problems of increased cost, large amount of glue, and difficulty of thick boards, and achieves the realization of manufacturing, The effect of reducing the amount of glue and solving the warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

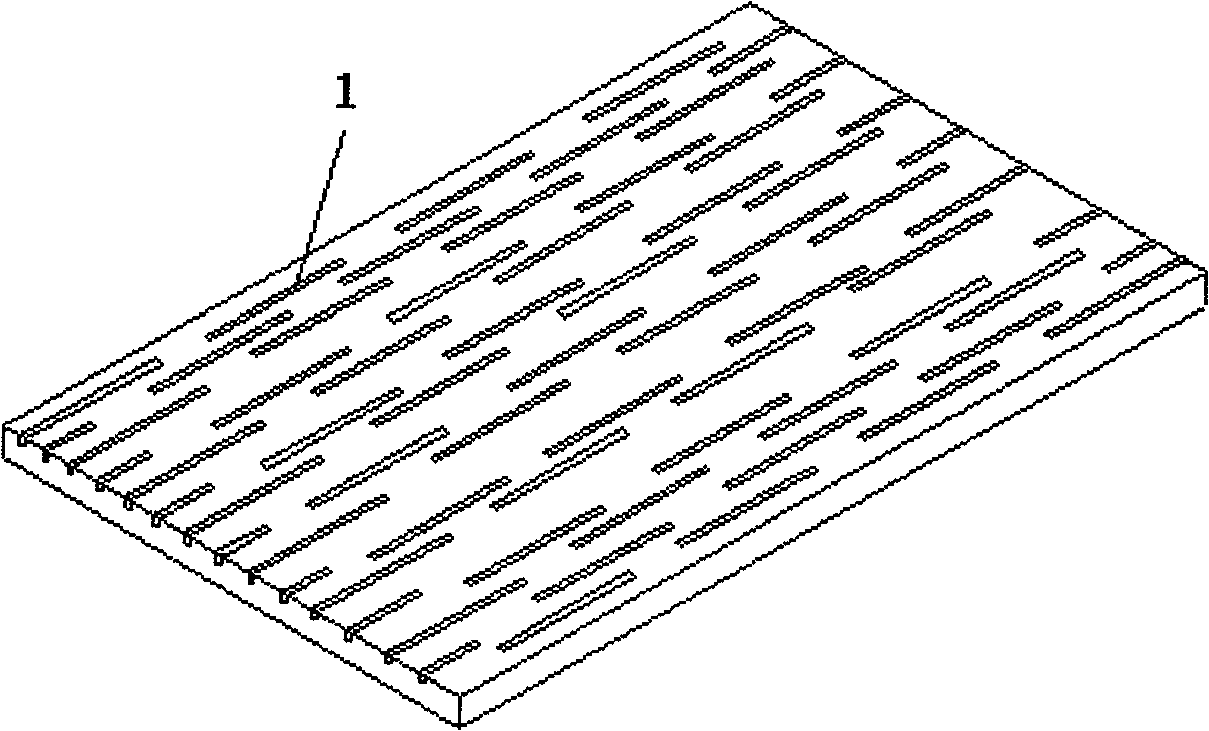

[0088] The manufacturing technology of laminated bamboo timber belongs to the well-known technology (Zhao Renjie, Yu Yunshui, Bamboo-based Panel Technology, China Forestry Publishing House, 2002). The bamboo is cut into 2500mm long bamboo sections by a cutting machine; Cut into bamboo slices with a width of 20mm; use a rough planer to remove part of the bamboo green and bamboo yellow on the surface; steam and cook the above rough planed bamboo strips, and carry out anti-mildew and anti-corrosion treatments; dry them to a moisture content of 7 %-9%; The dried bamboo strips are finely planed with a precision planer to keep the thickness accuracy at ±0.2mm, and the water-based polymer isocyanate adhesive is coated on the side and surface of the bamboo strips according to the predetermined width and After the thickness has passed through the horizontal stitching and the parallel grain assembly, using a press with a positive pressure of 2.0 MPa and a lateral pressure of 0.2 MPa, it is ...

Embodiment 2

[0108] The manufacturing technology of reorganized bamboo belongs to well-known technology (Zhao Renjie, Yu Yunshui, Bamboo-based wood-based panel technology, China Forestry Publishing House, 2002). It is divided into cold-pressing drying method and hot-pressing method. The cold-pressing drying method is to process bamboo into bamboo filaments or bamboo bundles, then dipping, drying, molding, cold pressing, high temperature drying and gluing to make the board; The pressing method is to process bamboo into bamboo filaments or bamboo bundles, and then dipping, drying, paving, and hot pressing. The above-mentioned reconstituted bamboo is sawed, cross-spliced, and finger-joined to form a thickness of 5, 6, Reconstituted bamboo veneers of 7.5, 10, 15 and 20mm, width 50mm and length 4000mm.

[0109] The peeling, degradation and gluing process of the Chinese fir veneer is the same as in Example 1.

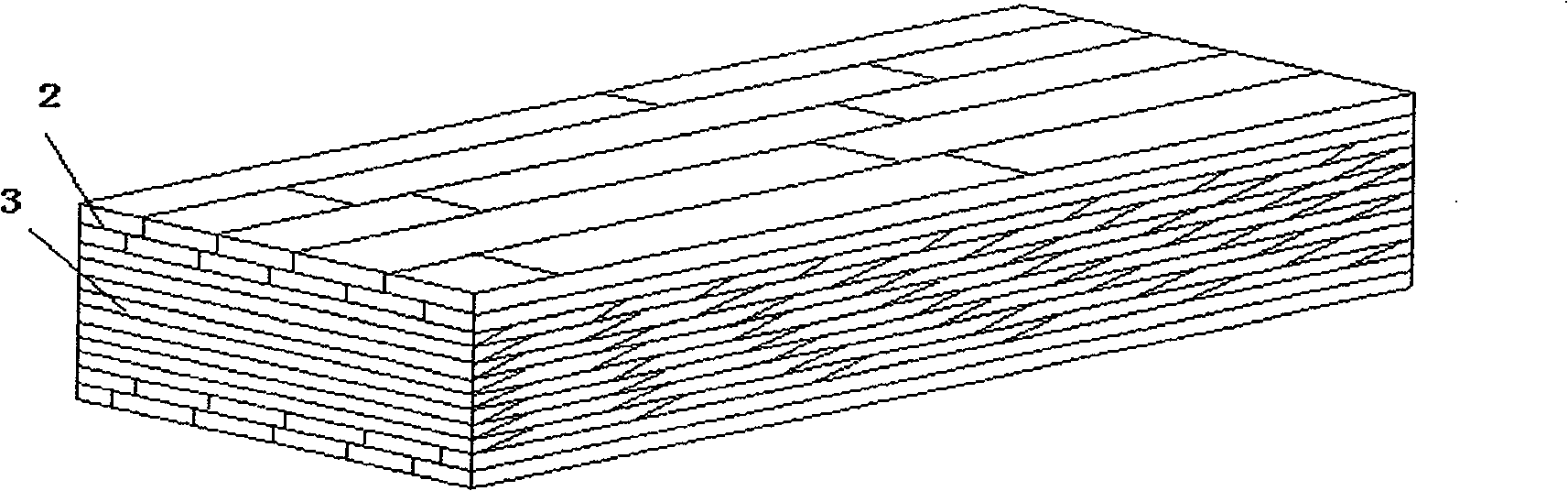

[0110] Lay the glued recombined bamboo veneer and Chinese fir super-thick veneer on the u...

Embodiment 3

[0116]The manufacturing process of the laminated bamboo and the reconstituted bamboo is the same as in Example 1 and Example 2, and it is sawed into a board with a thickness of 8 mm.

[0117] The peeling and stress degradation of the eucalyptus veneer is the same as in Example 1, and the thickness of the veneer is 8 mm.

[0118] The resorcinol adhesive is composed of a main agent and a curing agent, and the amount of the curing agent is (8-15)% of the main agent. After stirring, the resorcinol adhesive is formed.

[0119] The main agent is a linear resorcinol resin liquid containing alcohol, the curing agent is polyoxymethylene, and the dosage of polyoxymethylene is (8-15)% of the main agent. After being evenly stirred, a resorcinol adhesive is formed.

[0120] Coat the resorcinol adhesive evenly on the surface of the stress-degraded wood veneer and the surface of the reconstituted bamboo or bamboo glulam. The amount of glue for each layer is 150g / m 2 ~300g / m 2 between.

[0121] P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com