Manufacturing method for separation type double-layer turnout shock-absorbing fastener system

The technology of a vibration damping fastener and a manufacturing method, applied in the field of rail transit, can solve the problems of high cost, complex structure, unfavorable on-site installation and maintenance, etc., and achieve the effect of solving the warping problem and improving the overall stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in conjunction with accompanying drawing and specific embodiment:

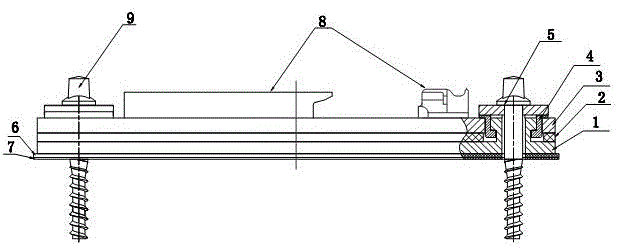

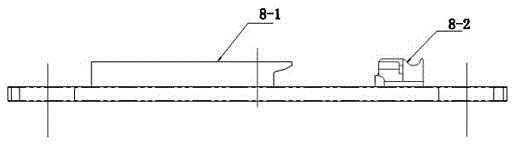

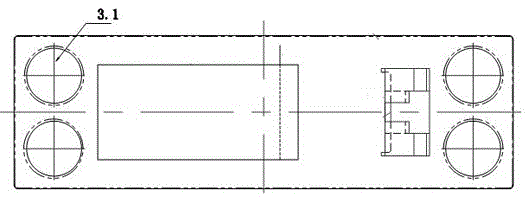

[0037] Such as figure 1 As shown, a processing method of a separate double-layer turnout vibration-damping fastener system, the separated double-layer turnout vibration-damping fastener system includes an upper iron backing plate 3, a middle rubber backing plate 2 and a lower iron backing plate 1. The upper iron backing plate 2 is provided with a connecting piece connected to the rail. In this embodiment, the connecting piece connected to the rail is the spring bar seat 8-2 and the slide bed 8-1; the lower iron backing plate 1 is provided with a raised column 9; the specific steps of the processing method of the separate double-layer turnout vibration-damping fastener system are as follows:

[0038] 1) Obtain the upper iron backing plate 3, the lower iron backing plate 1 and the middle rubber backing plate 2 of the required size by direct cutting;

[0039] 2) combine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com