Multilayer printed board lamination method

A multi-layer printed board and board layer technology, applied in the field of printed board manufacturing, can solve problems such as the inability of multi-layer printed boards to meet the needs of technological development, and achieve the goal of improving flatness and improving the pass rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

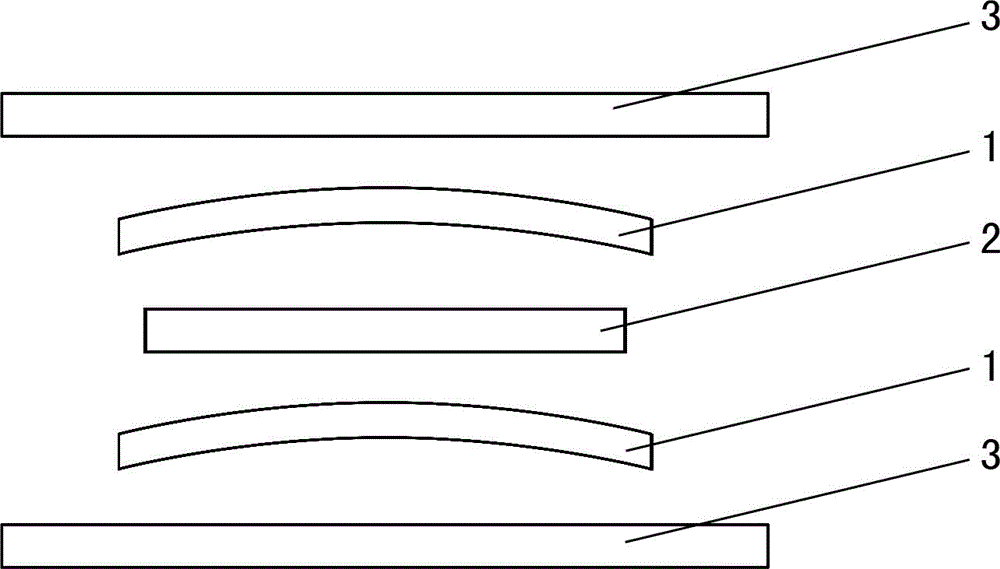

[0028] Such as figure 1 As shown, this multilayer printed board lamination method includes the following steps:

[0029] (1) Calculate the warpage degree of the general warpage produced by the multilayer printed board in the case of straight board lamination, and the warpage degree is calculated as follows: the multilayer printed board using the straight board lamination method For calculating the warpage of the sample, the sample is placed on the platform with the protruding side of the sample facing up, the warpage of the sample = R / L, where R is the maximum vertical distance between the sample and the platform, and L is the opposite angle of the sample contacting the platform line length;

[0030] (2) According to the calculated degree of warpage, set warpage guide plates 1 of various specifications. The warpage guide plate 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com