Low-cost warping-free high-flame-retardant polypropylene furniture material and preparation method thereof

A flame-retardant polypropylene, no warping technology, applied in the field of organic polymer nanocomposite materials, can solve the problem of affecting the mechanical properties and appearance of polypropylene systems, difficult to meet high-end polypropylene furniture materials, unable to meet the performance of household materials, etc. problems, to achieve excellent mechanical properties and flame retardant properties, smooth surface without warping, and reduce product costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

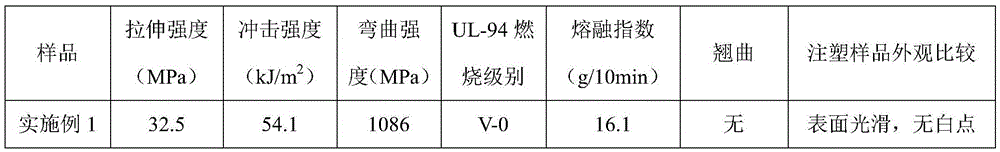

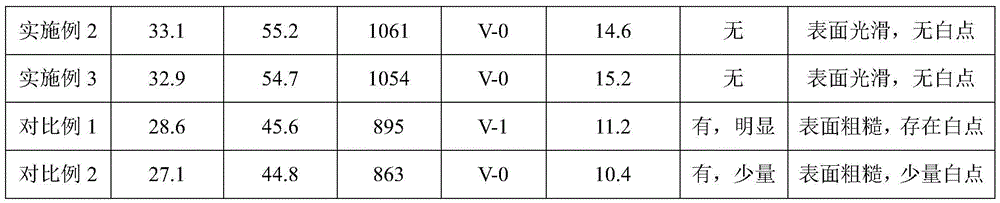

Examples

Embodiment 1

[0029] A kind of low-cost non-warp polypropylene furniture material of the present invention is made up of the raw material of following weight portion: polypropylene is 50%, short glass fiber organic masterbatch is 15%, toughening agent POE-g-MAH ( Grafting ratio (2.5%) is 9%, nanometer calcium carbonate is 25%, lubricant heat-resistant type aliphatic hyperbranched polyester mixture (average relative molecular weight is 5200) 1%.

[0030] First, prepare short glass fiber organic masterbatch according to the following steps:

[0031] Step 1: Liquid paraffin and monoalkoxy pyrophosphate coupling agent are diluted and mixed according to the volume ratio of 1:1;

[0032] Step 2: Put the pentaerythritol diphosphate melamine salt in a high-speed mixer, drop into the mixed solution of step 1 with a mass ratio of 2:1 to the pentaerythritol diphosphate melamine salt while stirring, and continue stirring for 10-15 minutes;

[0033] Step 3: Add short glass fibers with a mass ratio of 5...

Embodiment 2

[0037] A kind of low-cost non-warping polypropylene furniture material of the present invention is made up of the raw material of following weight portion: polypropylene is 24%, short glass fiber organic masterbatch is 35%, toughening agent POE-g-MAH ( Graft rate (2.5%) is 5.4%, nanometer calcium carbonate is 35%, lubricant heat-resistant type aliphatic hyperbranched polyester mixture (average relative molecular weight is 11500) 0.6%.

[0038] The preparation method of the short glass fiber organic masterbatch and the polypropylene furniture material of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0040]A kind of low-cost non-warp polypropylene furniture material of the present invention is made up of the raw material of following weight portion: polypropylene is 35%, short glass fiber organic masterbatch is 25%, toughening agent POE-g-MAH ( Grafting ratio (2.5%) is 8.5%, nano calcium carbonate is 31%, lubricant heat-resistant type aliphatic hyperbranched polyester mixture (average relative molecular weight is 10000) 0.5%.

[0041] The preparation method of short glass fiber organic masterbatch and polypropylene furniture material of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com