Patents

Literature

231results about "Circuit thermal details" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

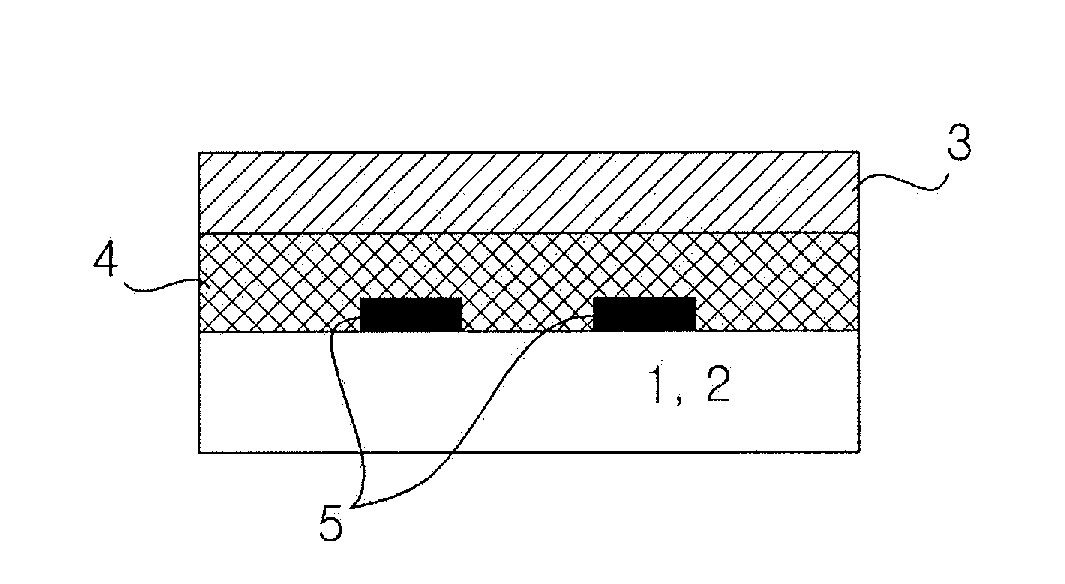

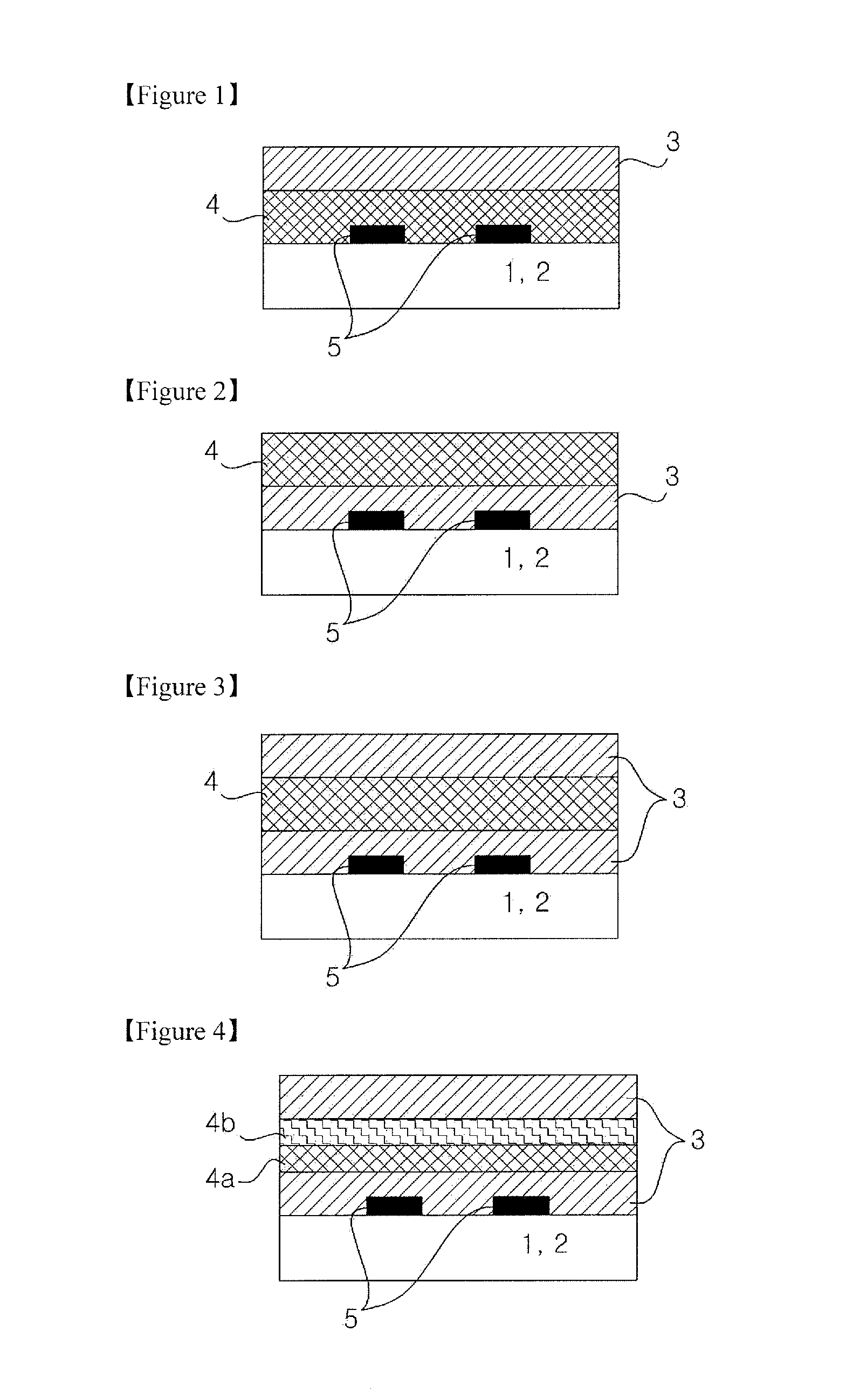

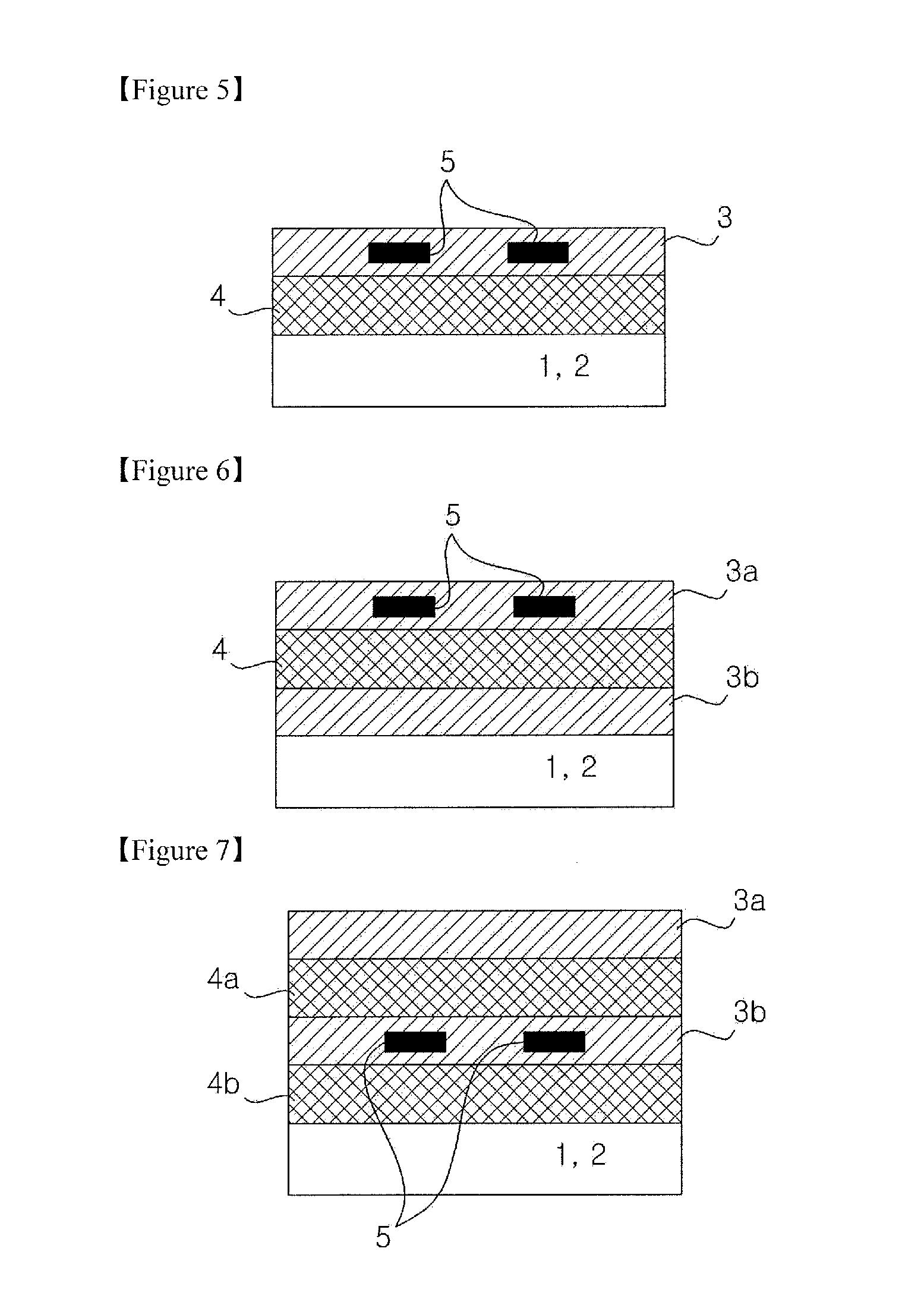

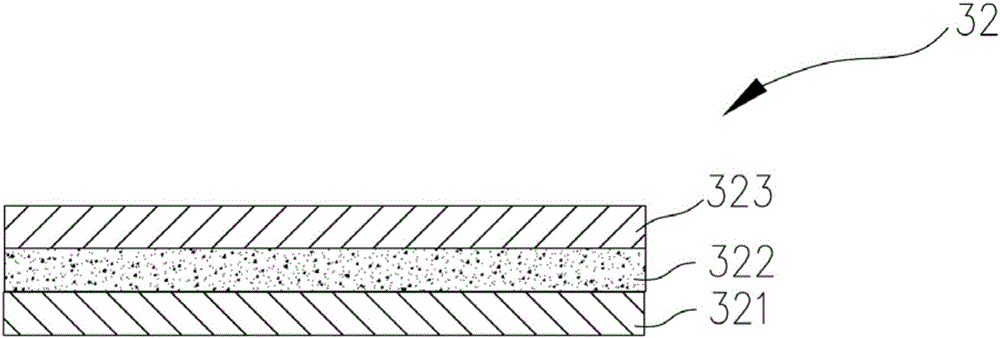

Passive layer for attenuation of near-field electromagnetic waves and heatdissipation including graphene, and electromagnetic device including the same

ActiveUS20140218867A1Reduce distractionsReduce noiseMagnetic/electric field screeningDecorative surface effectsUltrasound attenuationGraphene

The present invention relates to a passive layer including graphene for the attenuation of near-field electromagnetic waves and heat dissipation. The passive layer blocks electromagnetic waves radiated from an external electronic device or prevents electromagnetic waves generated in an electronic device from emitting to the outside. The passive layer is designed to reduce interference between transmission circuits of a device in the near-field region or influence such as malfunction caused by external electromagnetic waves. The present invention also relates to an electromagnetic device and a circuit board, each including the passive layer.

Owner:KOREA INST OF SCI & TECH +1

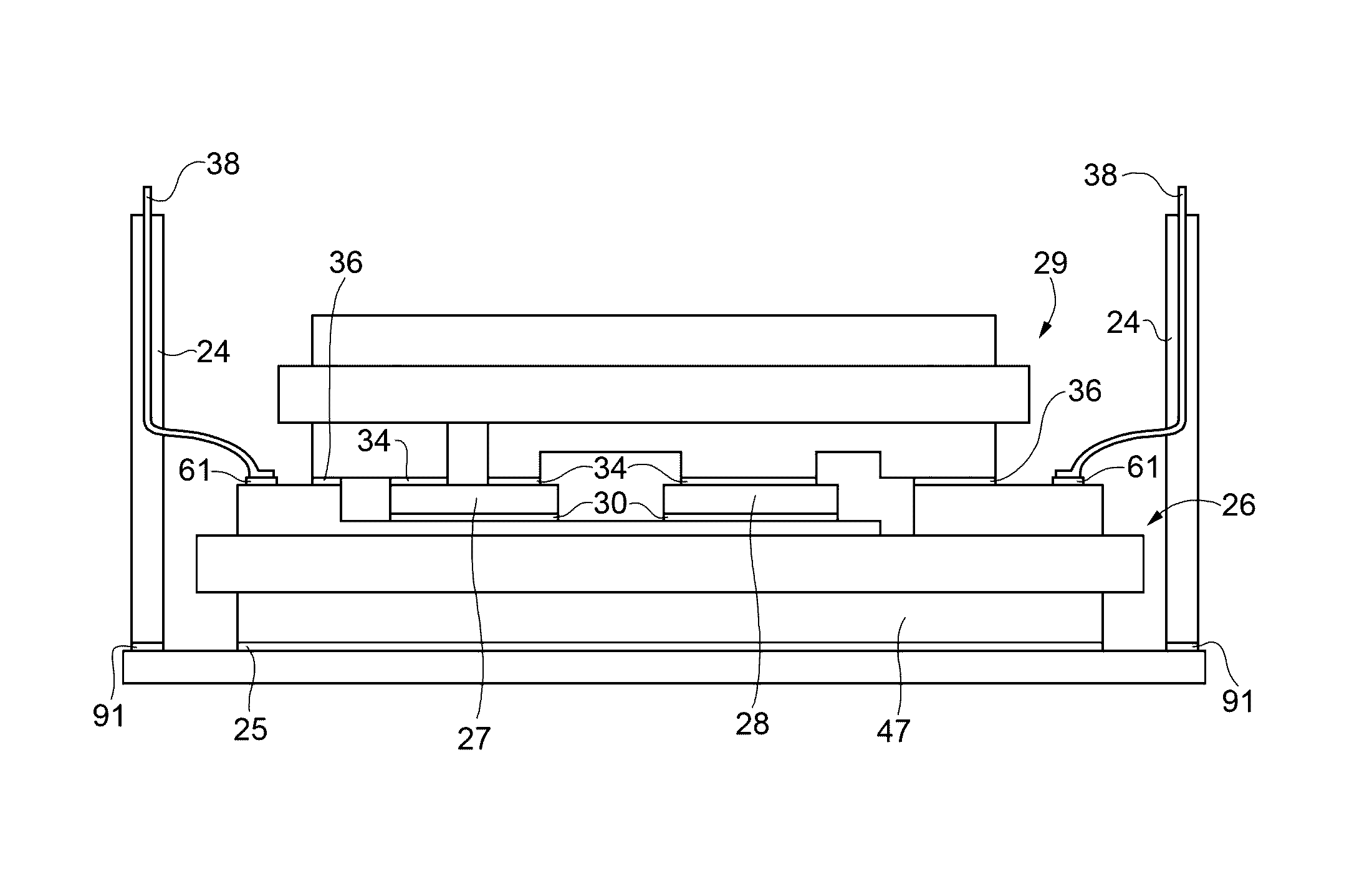

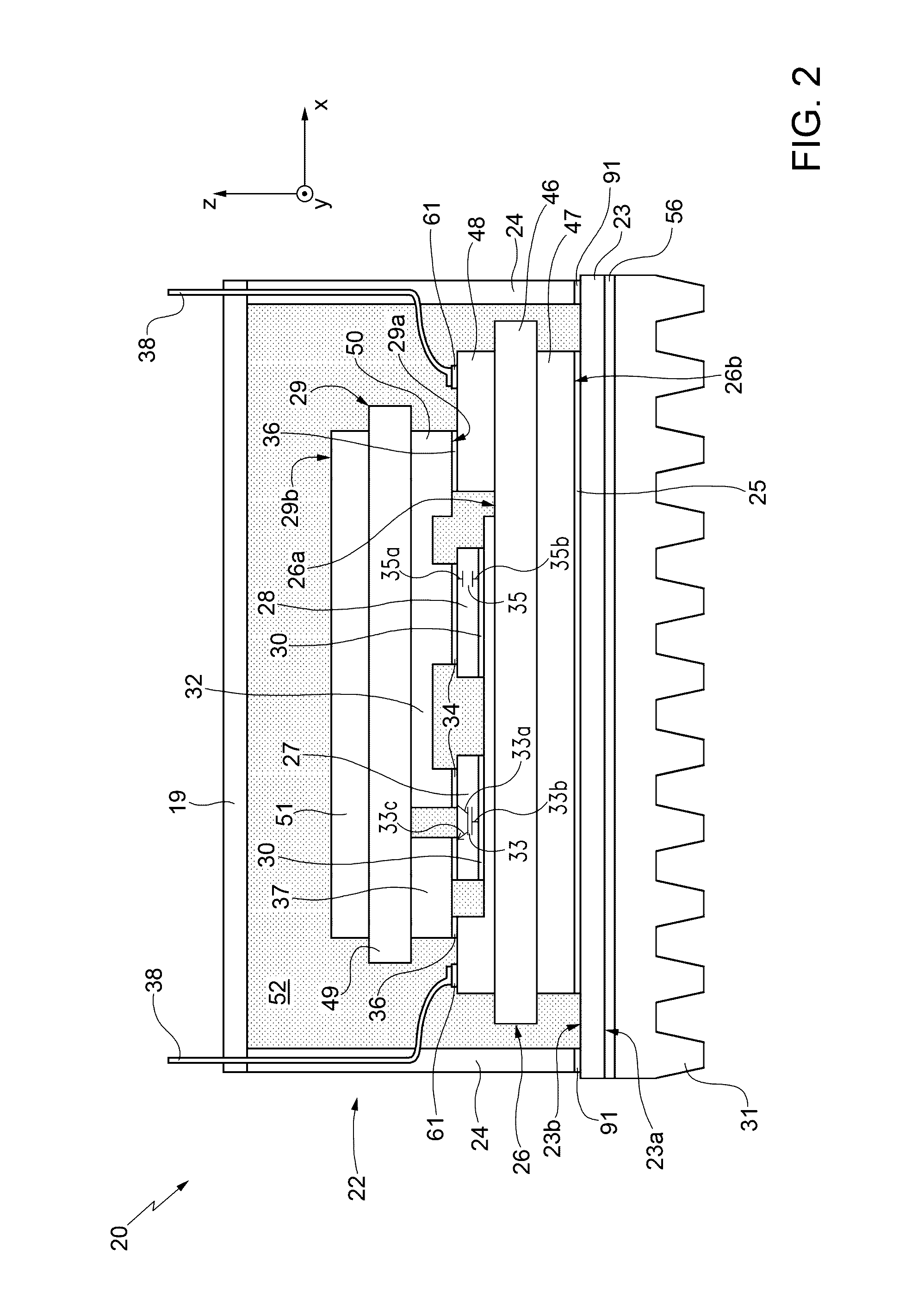

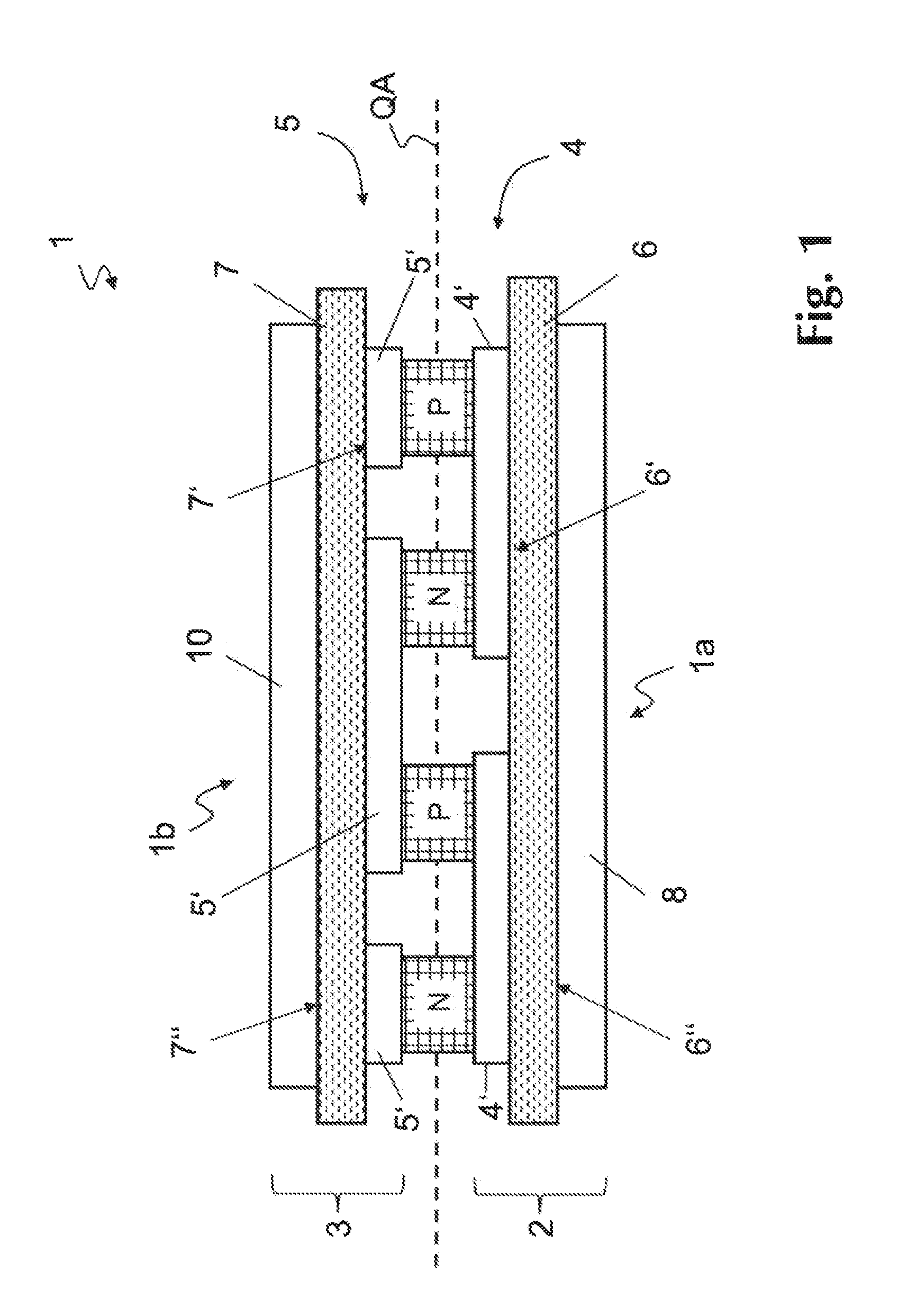

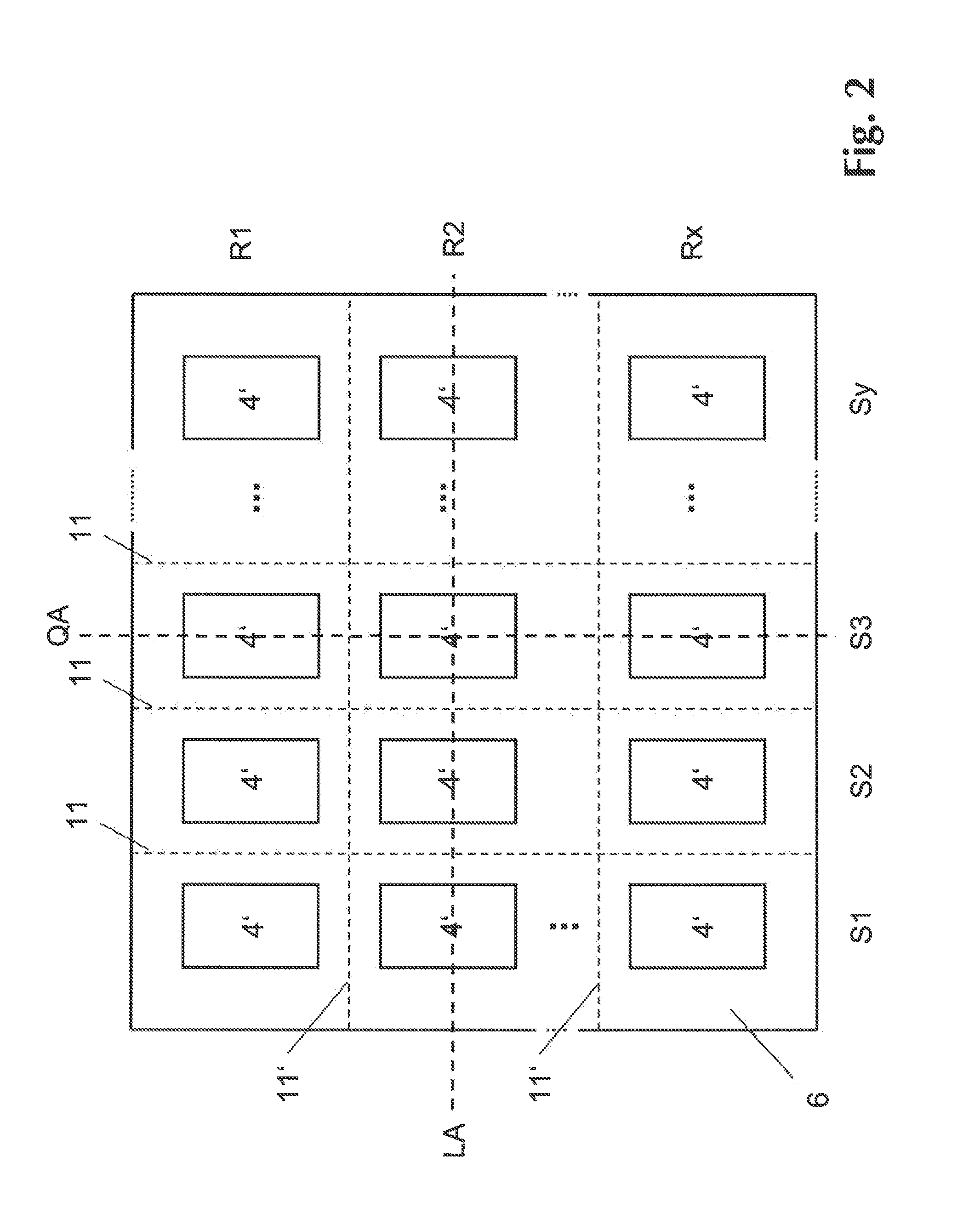

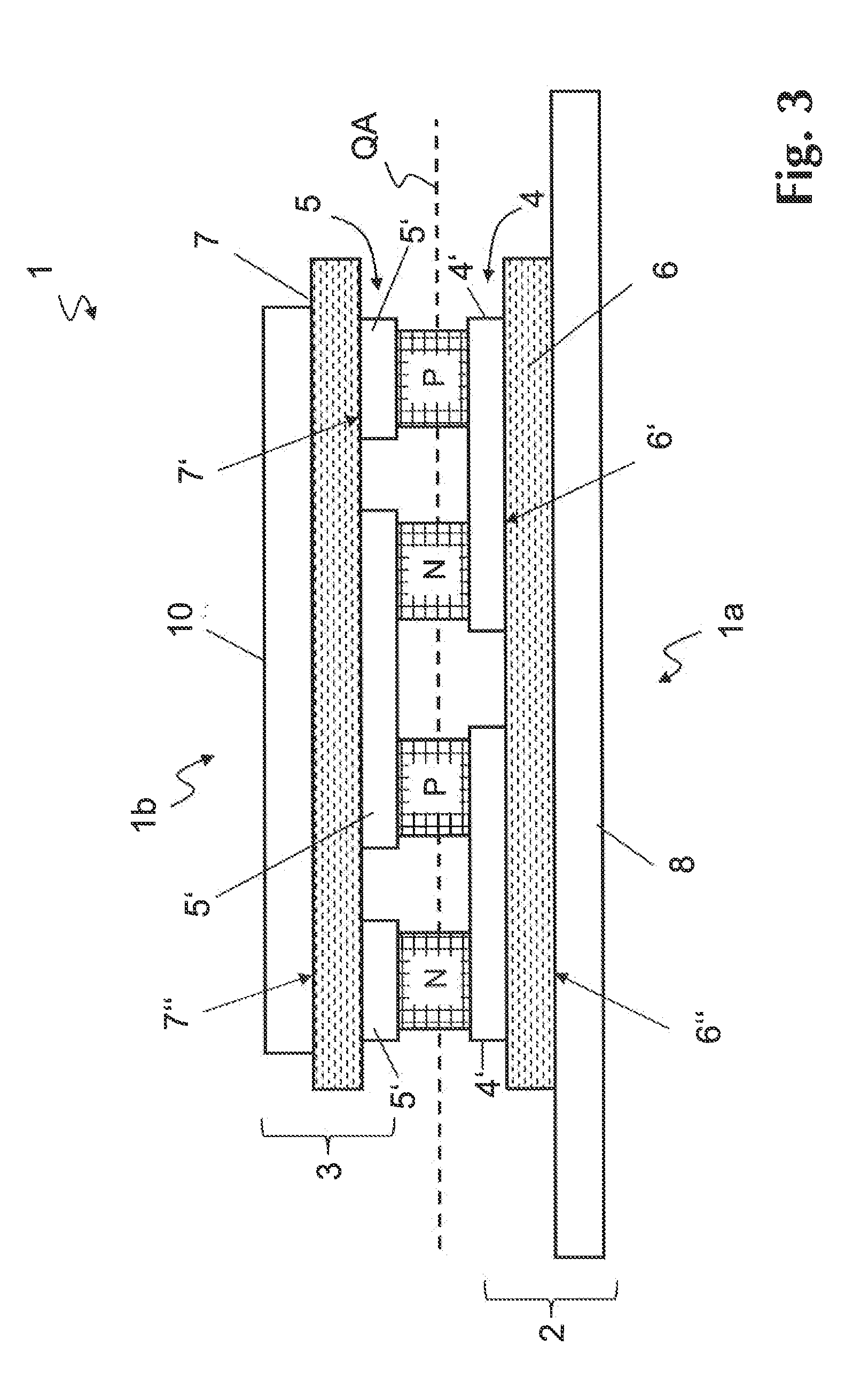

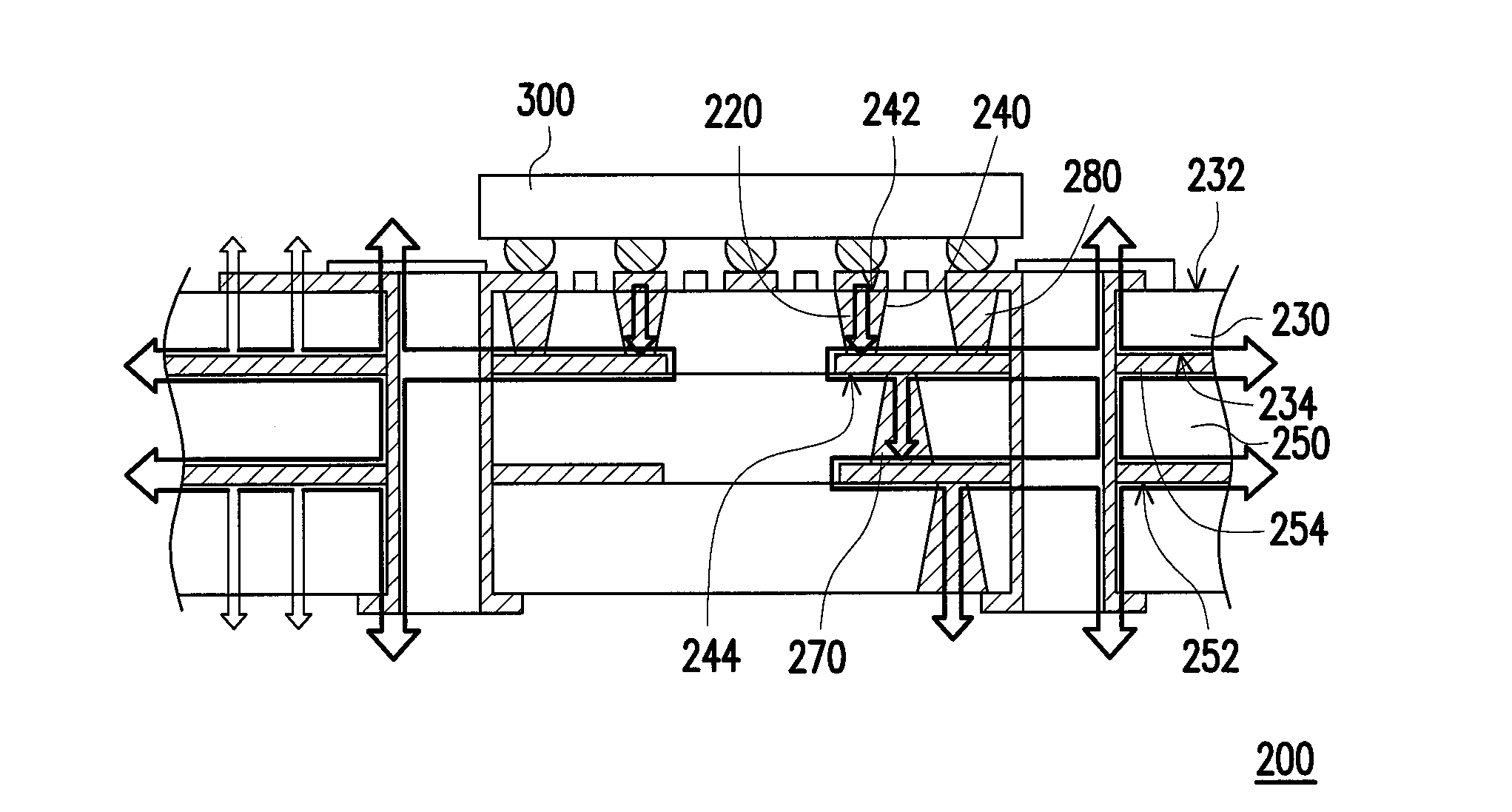

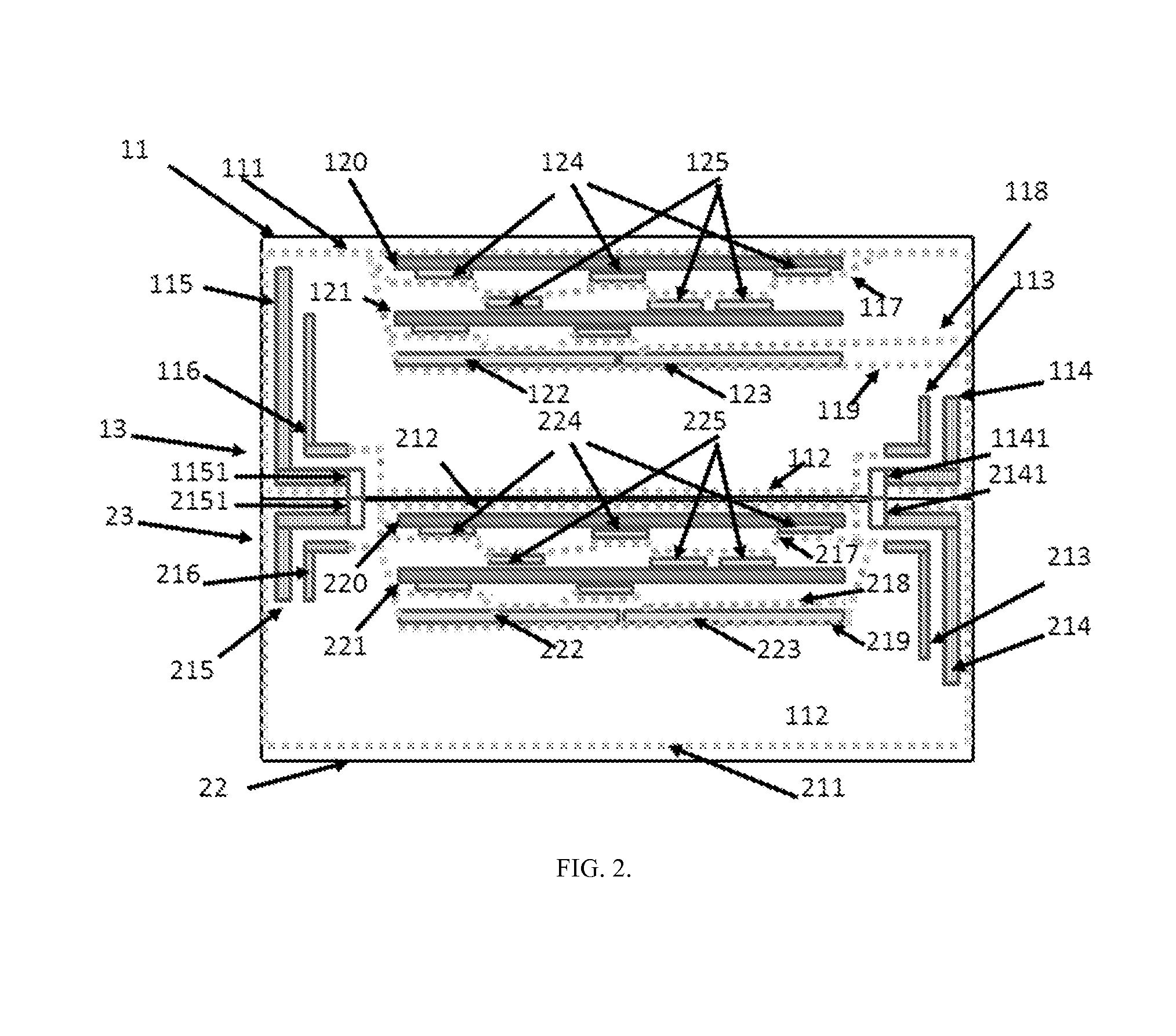

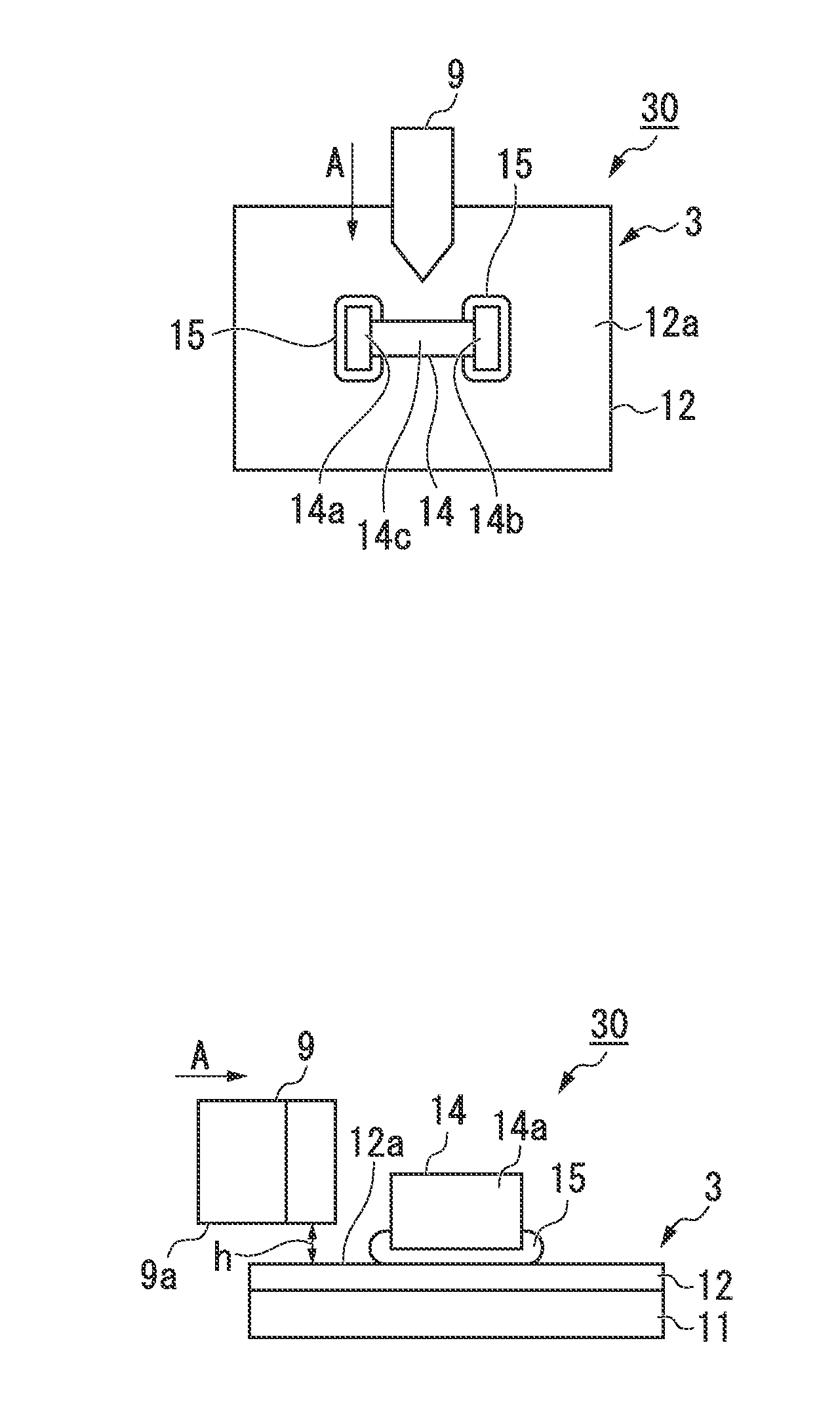

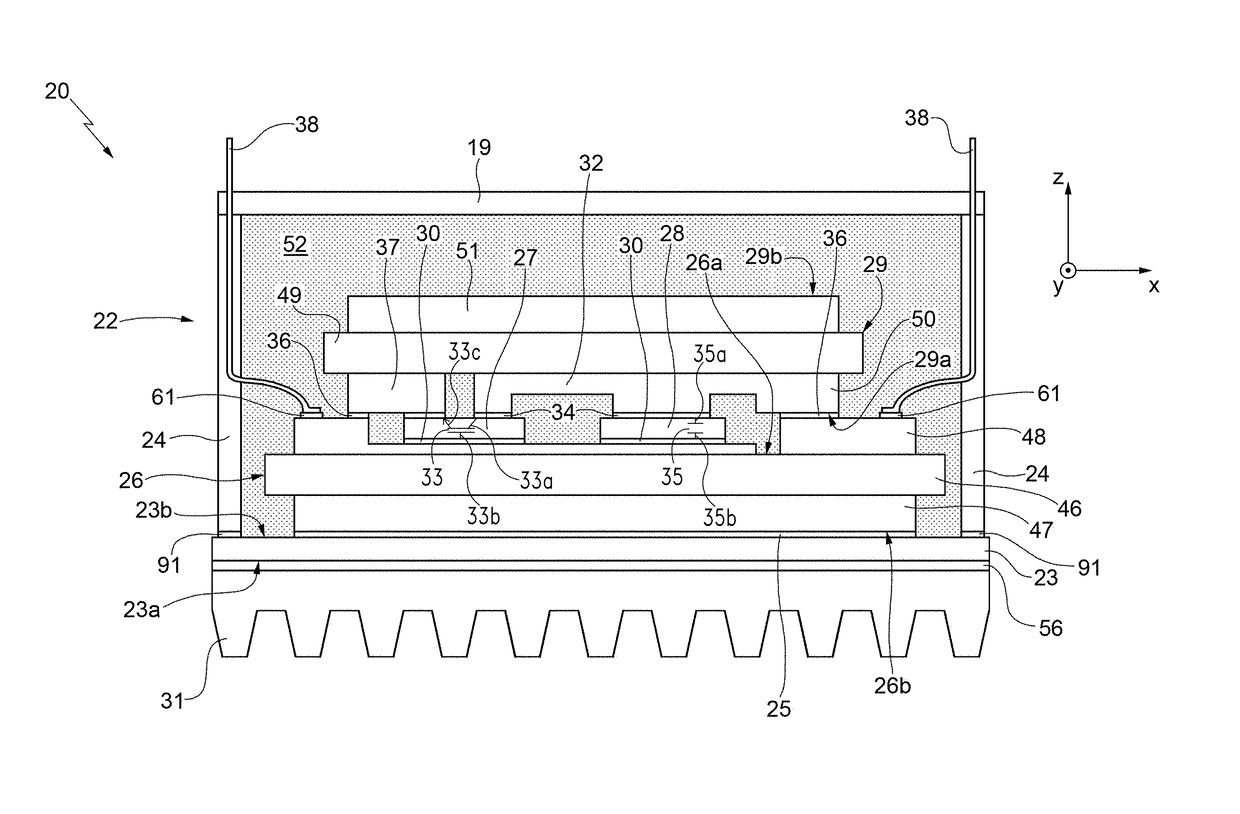

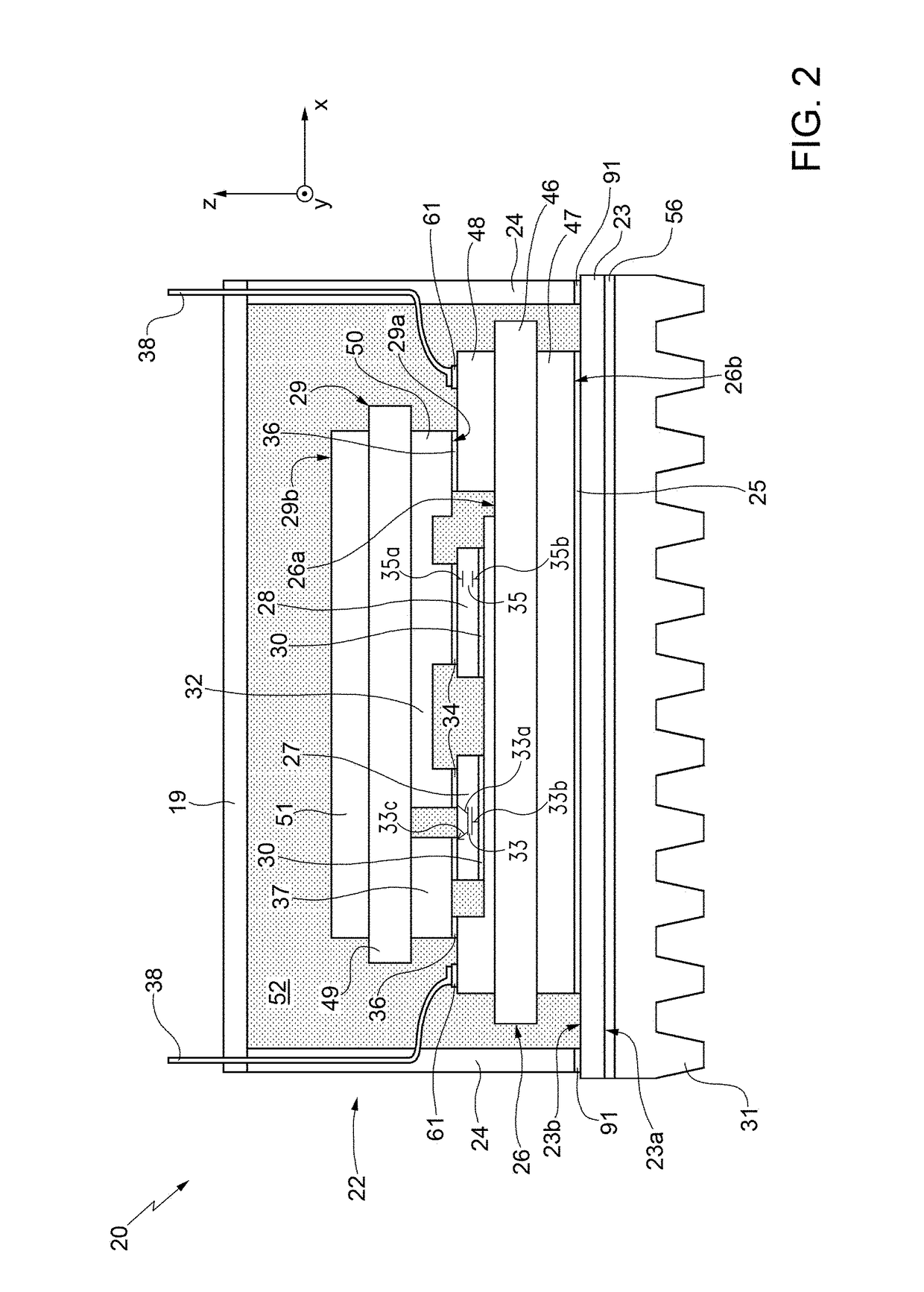

Electronic power module with enhanced thermal dissipation and manufacturing method thereof

ActiveUS20170064808A1Improve cooling effectCircuit thermal detailsSemiconductor/solid-state device detailsDBcCoupling

An electronic power module comprising a case that houses a stack, which includes: a first substrate of a DBC type or the like; a die, integrating an electronic component having one or more electrical-conduction terminals, mechanically and thermally coupled to the first substrate; and a second substrate, of a DBC type or the like, which extends over the first substrate and over the die and presents a conductive path facing the die. The die is mechanically and thermally coupled to the first substrate by a first coupling region of a sintered thermoconductive paste, and the one or more conduction terminals of the electronic component are mechanically, electrically, and thermally coupled to the conductive path of the second substrate by a second coupling region of sintered thermoconductive paste.

Owner:STMICROELECTRONICS SRL

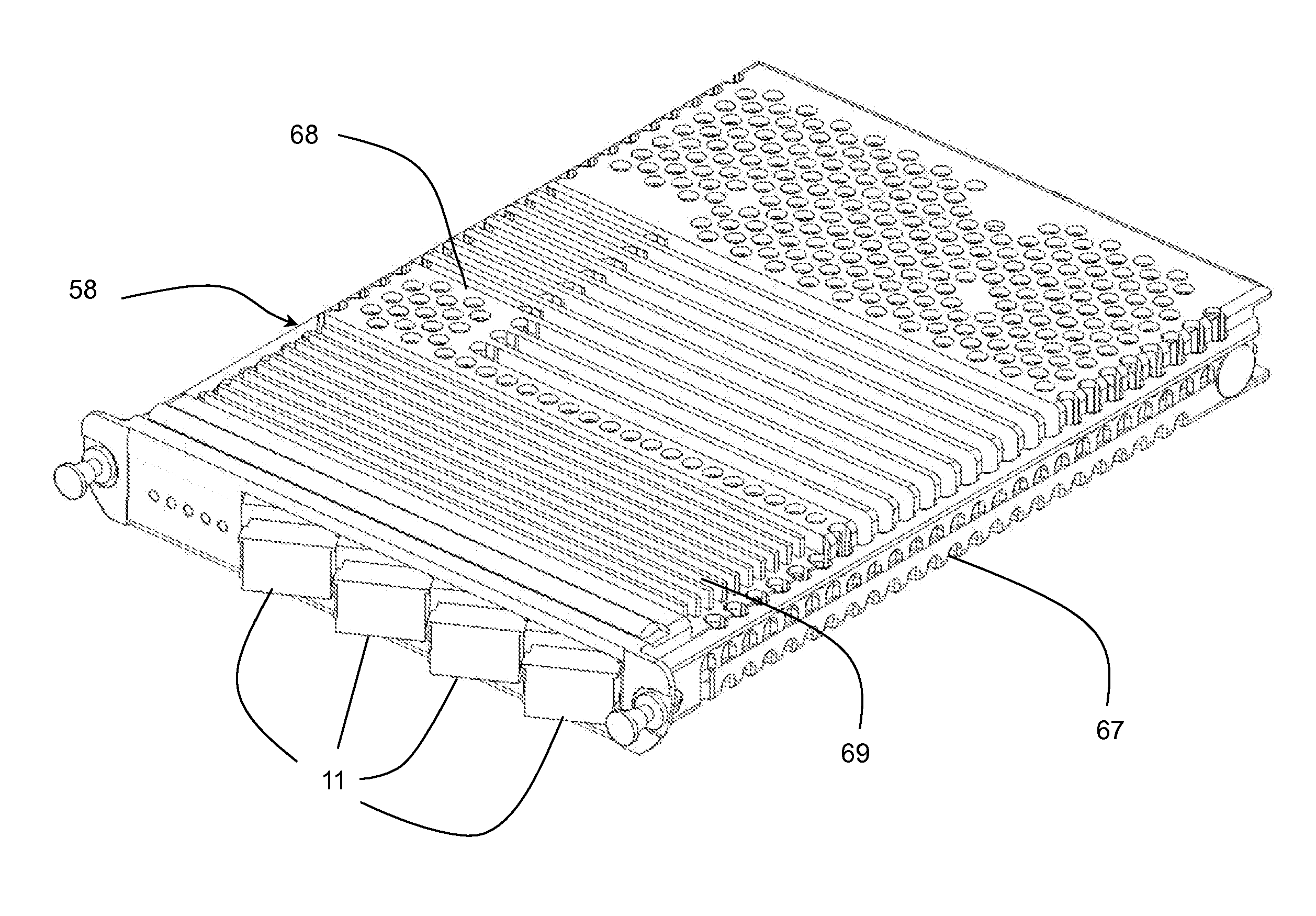

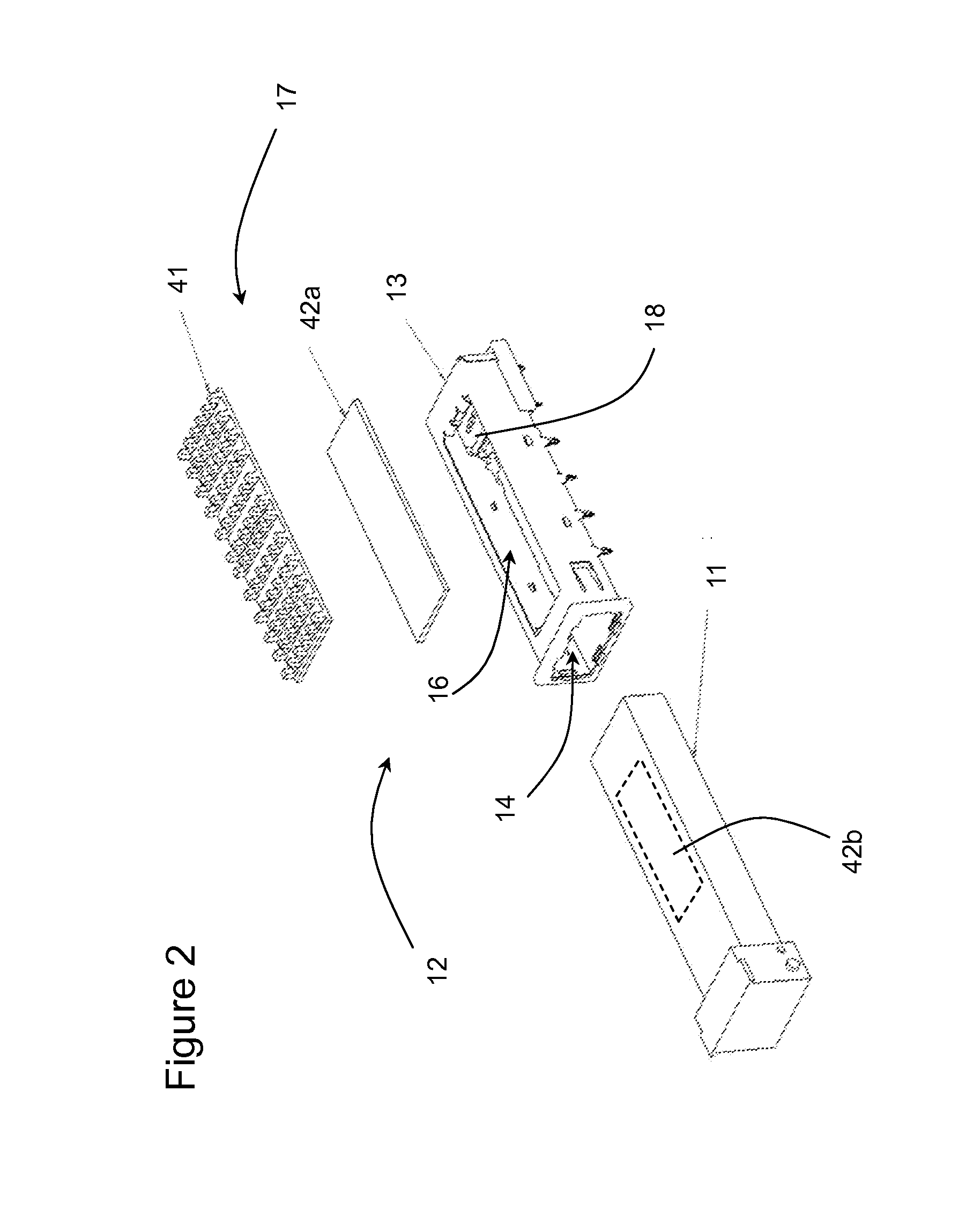

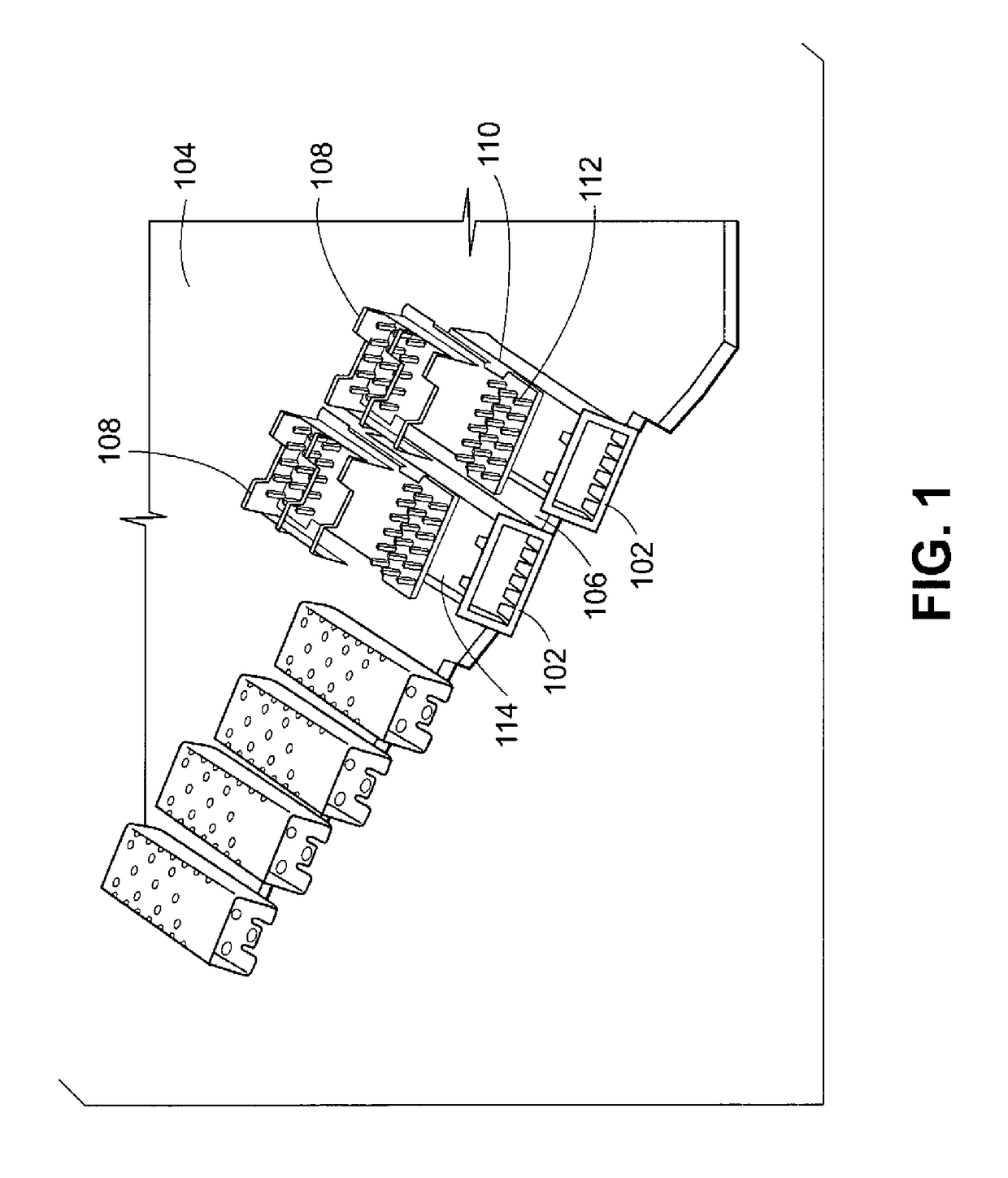

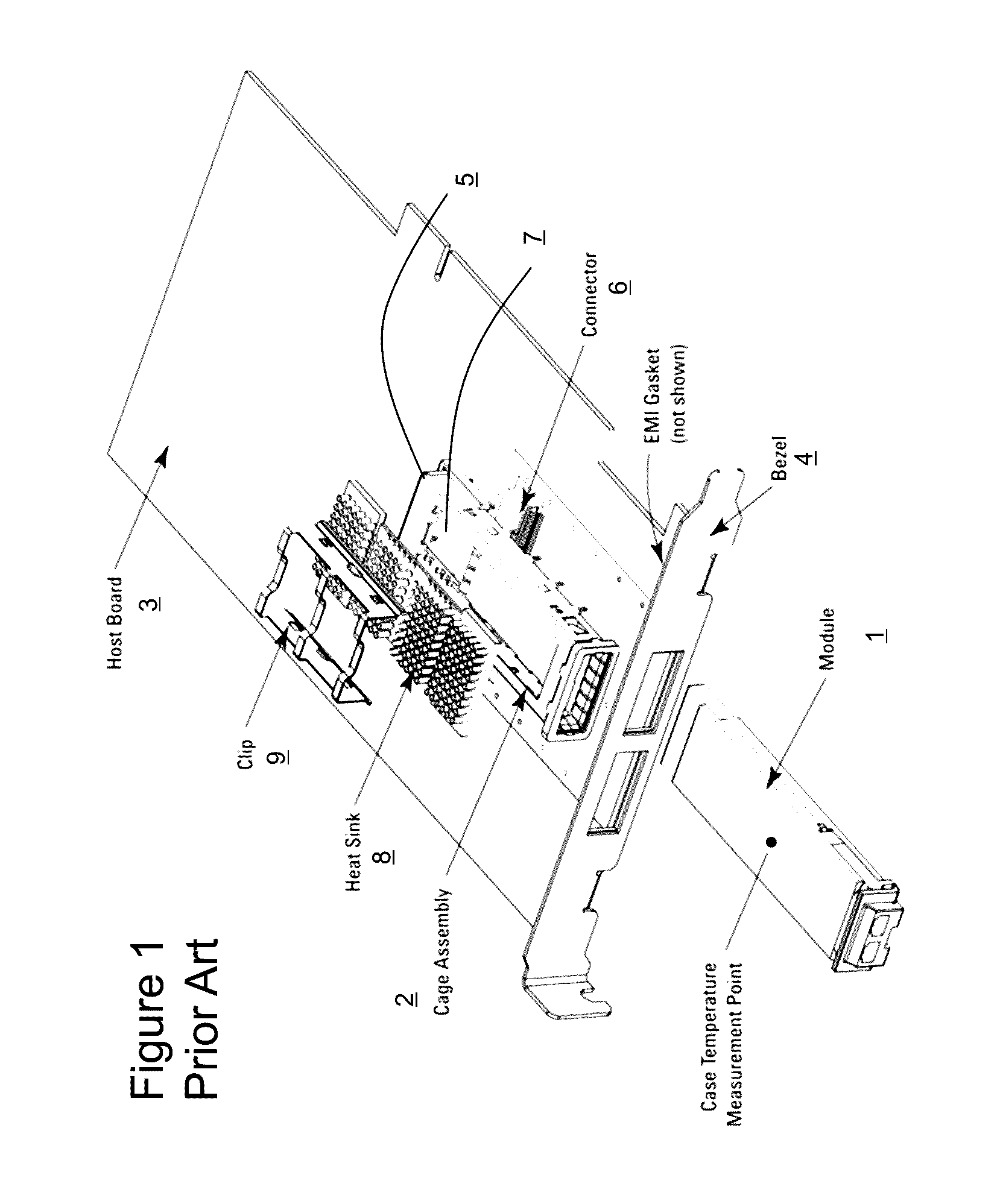

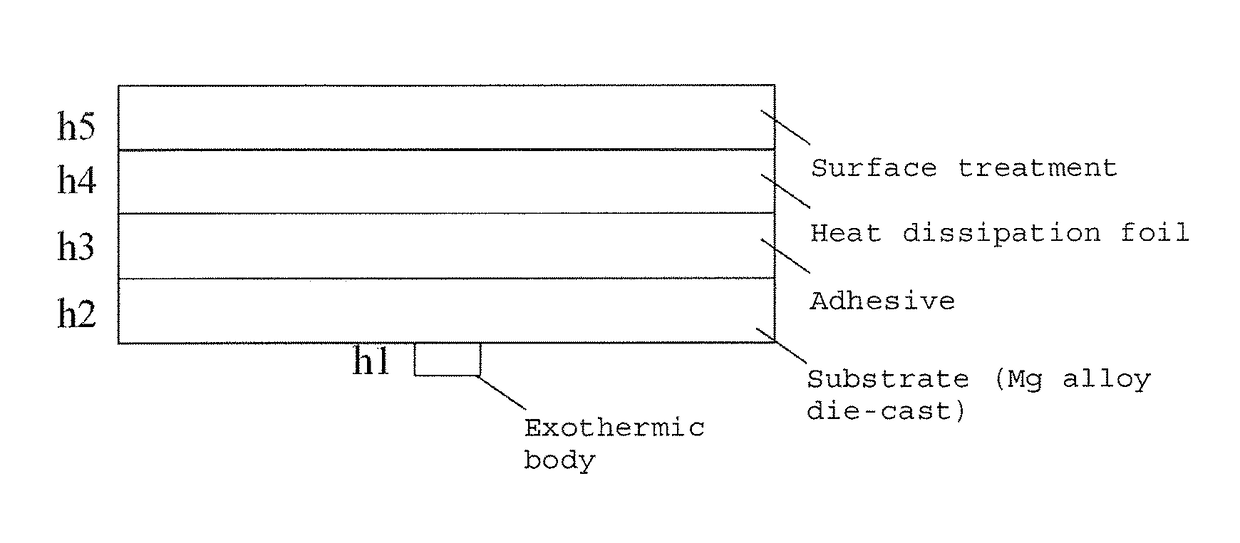

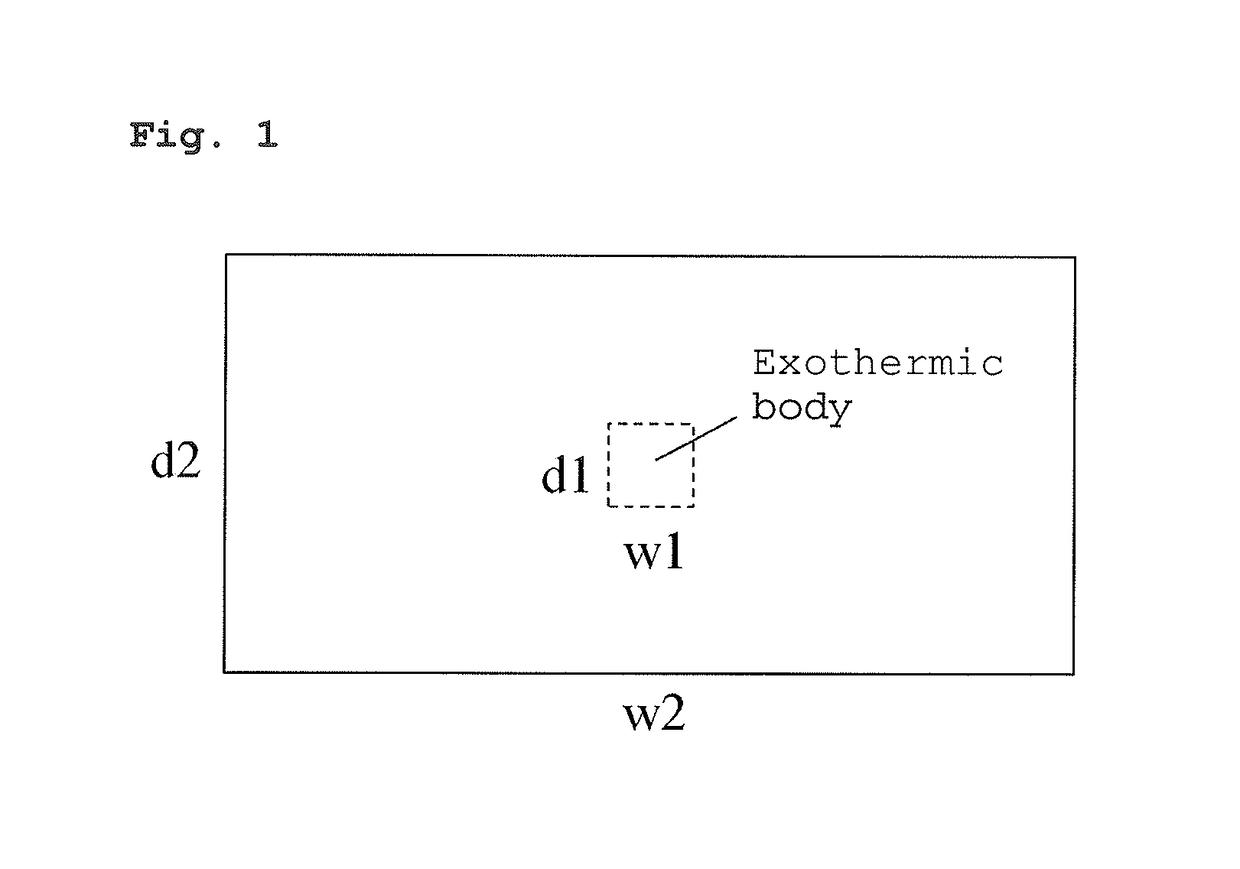

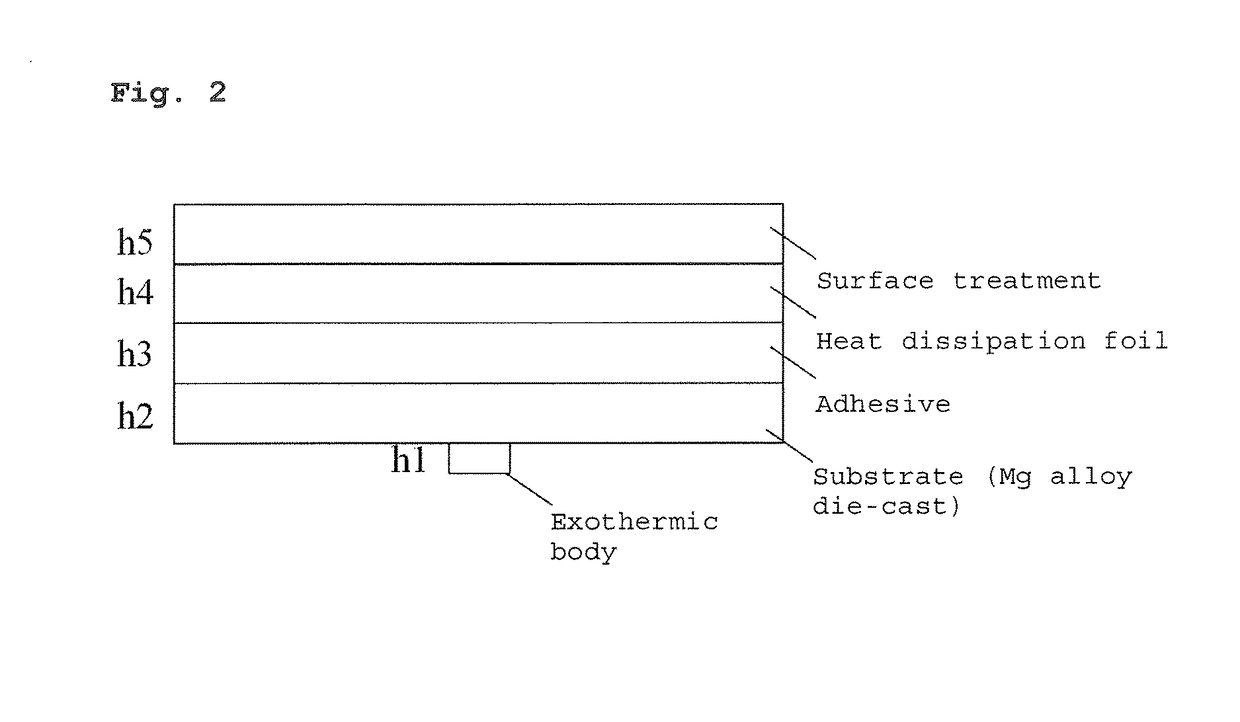

Sliding thermal contact for pluggable optic modules

Present thermal solutions to conduct heat from pluggable optical modules into heat sinks use a metal heat sink attached with a spring clip. The interface between the pluggable module and the heat sink is simple metal-on-metal contact, which is inherently a poor thermal interface and limits heat dissipation from the optical module. Heat dissipation from pluggable optical modules is enhanced by the application of thermally conductive fibers, such as an advanced carbon nanotube velvet. The solution improves heat dissipation while preserving the removable nature of the optical modules.

Owner:LUMENTUM OPERATIONS LLC

Copper Heat Dissipation Material, Carrier-Attached Copper Foil, Connector, Terminal, Laminate, Shield Material, Printed-Wiring Board, Metal Processed Member, Electronic Device and Method for Manufacturing the Printed Wiring Board

ActiveUS20160120017A1Satisfy heat dissipationSatisfactory performanceCoupling device connectionsCell electrodesSurface roughnessAlloy

A copper heat dissipation material having a satisfactory heat dissipation performance is provided. The copper heat dissipation material has an alloy layer containing at least one metal selected from Cu, Co, Ni, W, P, Zn, Cr, Fe, Sn and Mo on one or both surfaces, in which surface roughness Sz of the one or both surfaces, measured by a laser microscope using laser light of 405 nm in wavelength, is 5 μm or more.

Owner:JX NIPPON MINING& METALS CORP

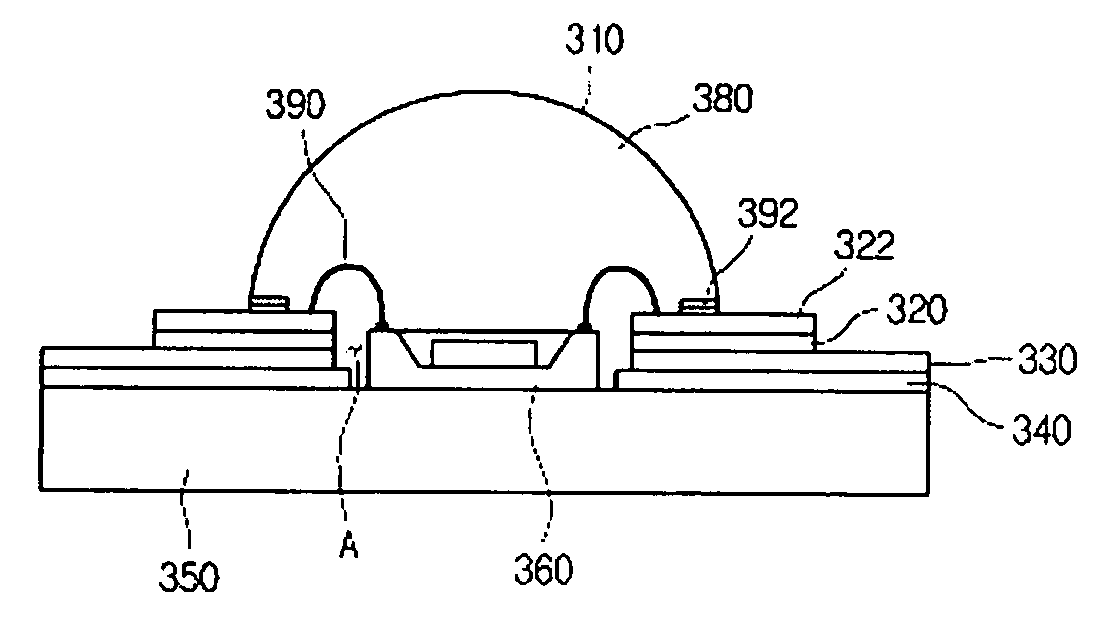

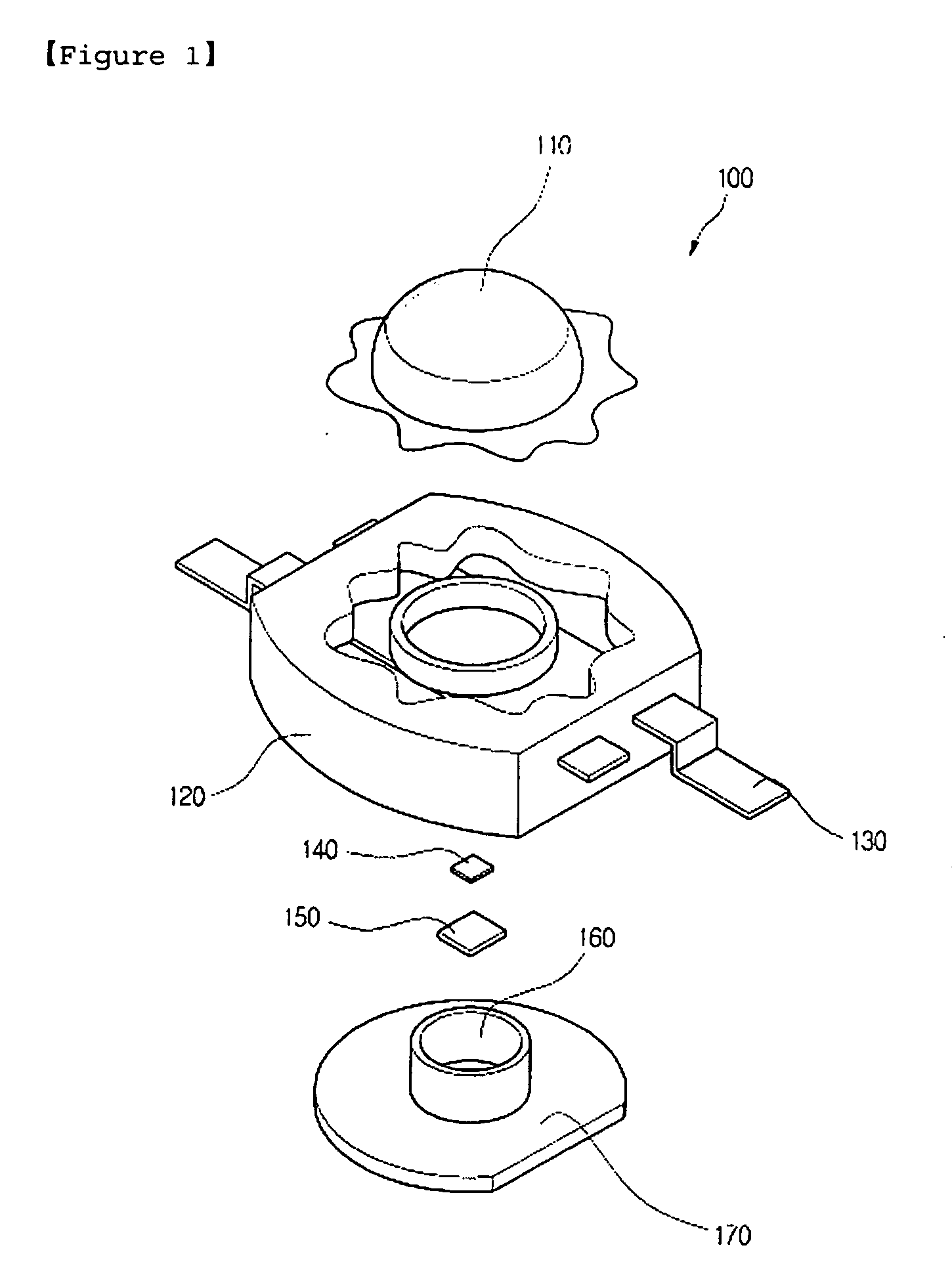

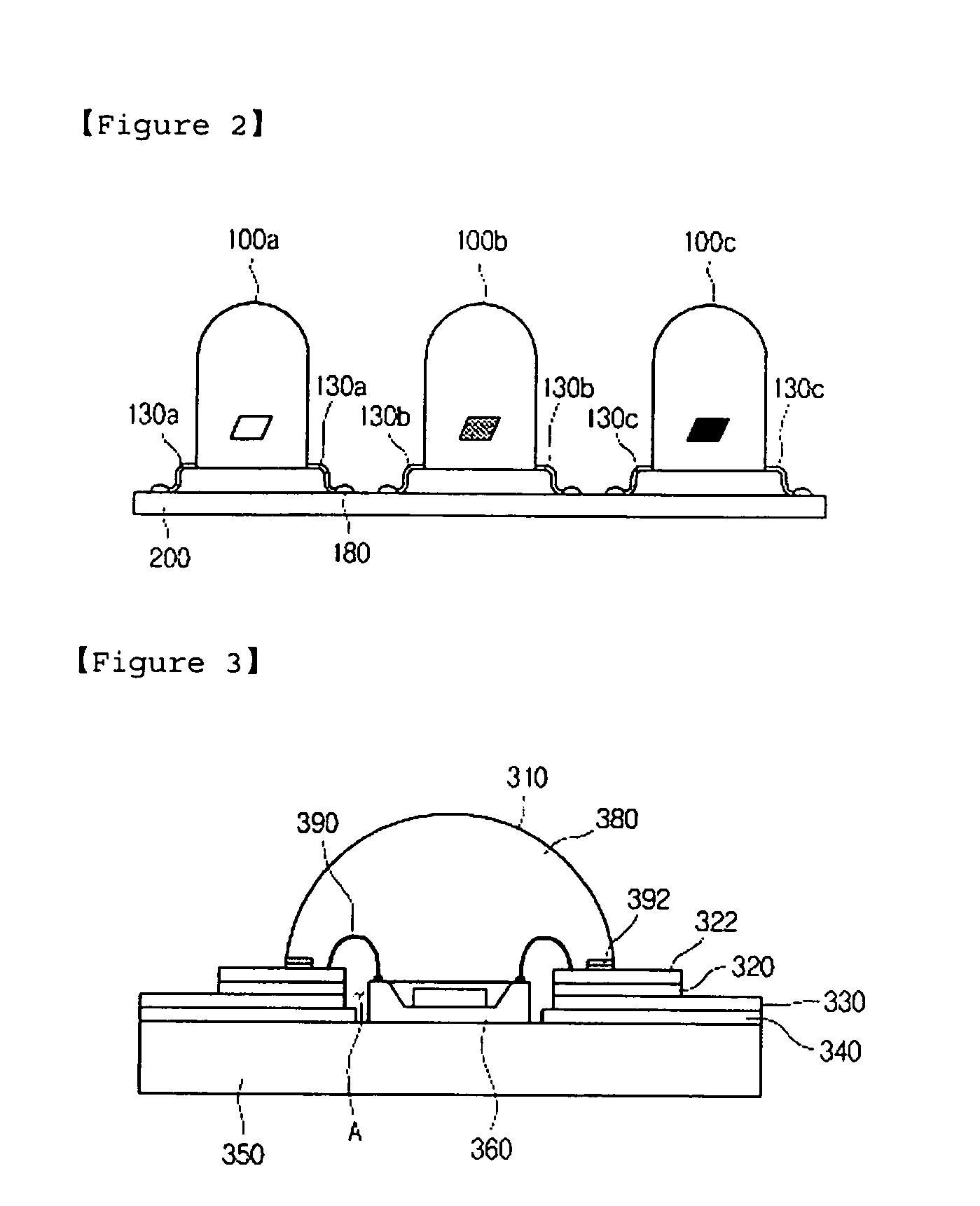

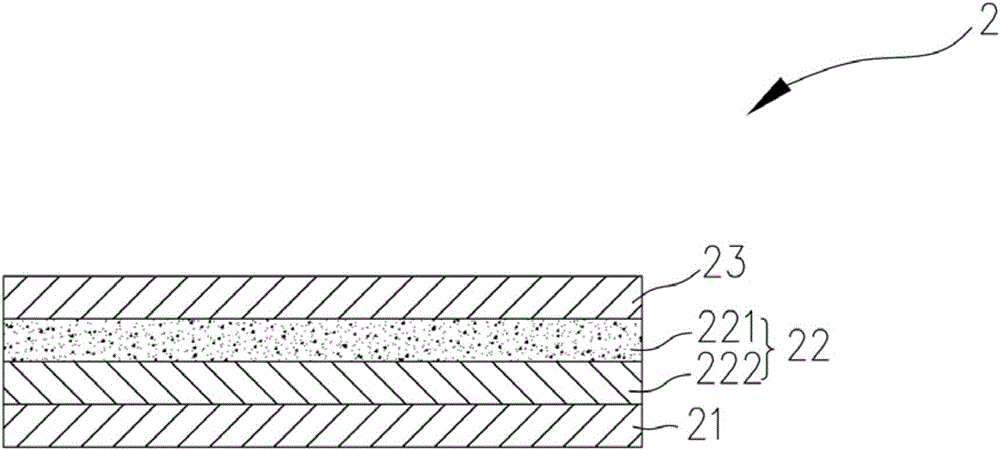

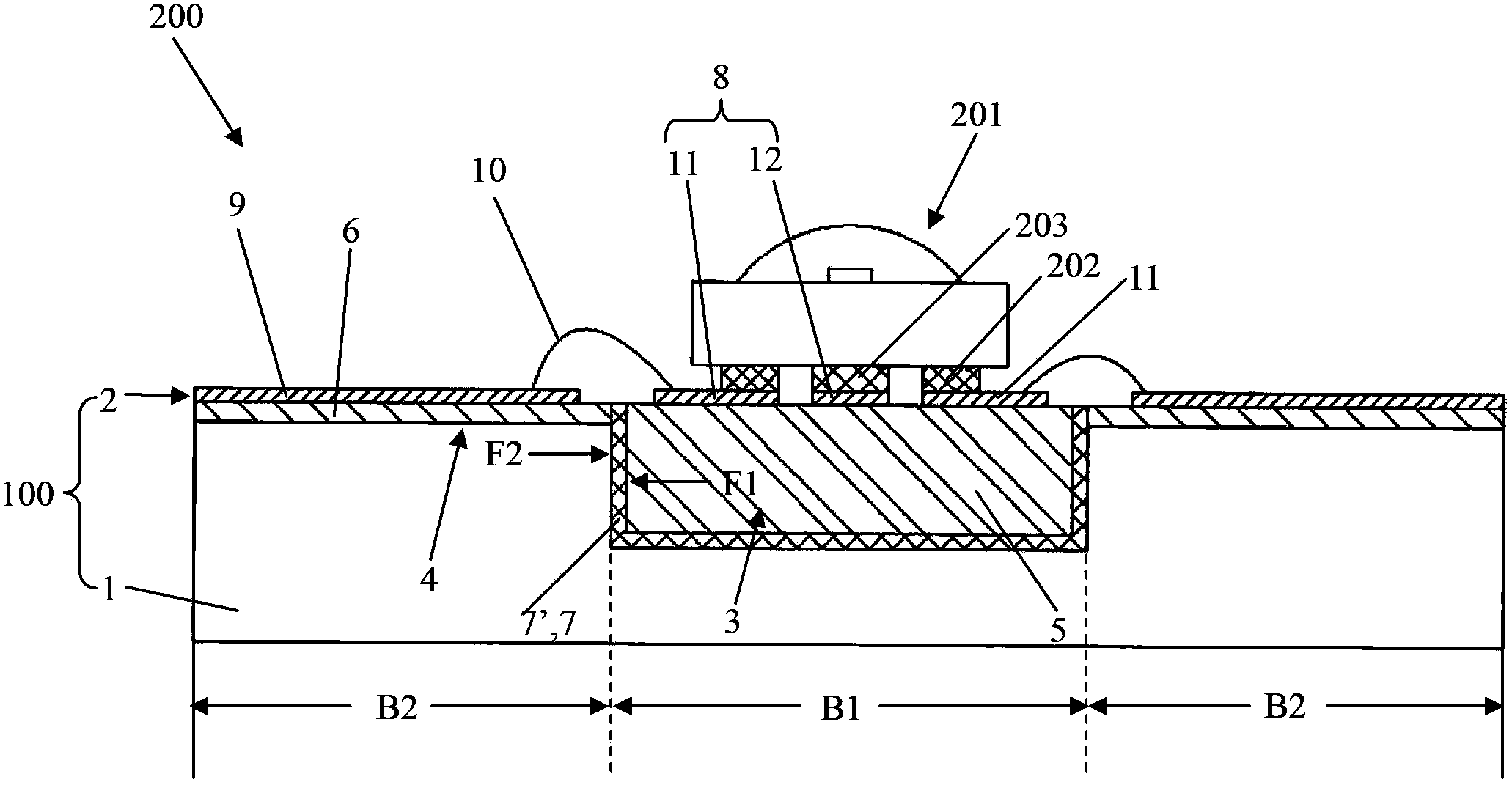

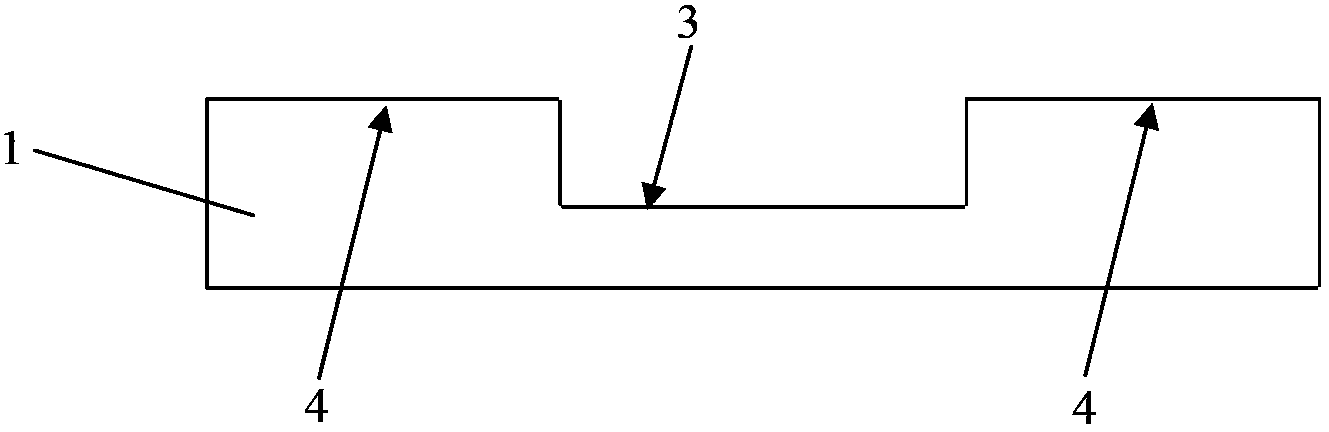

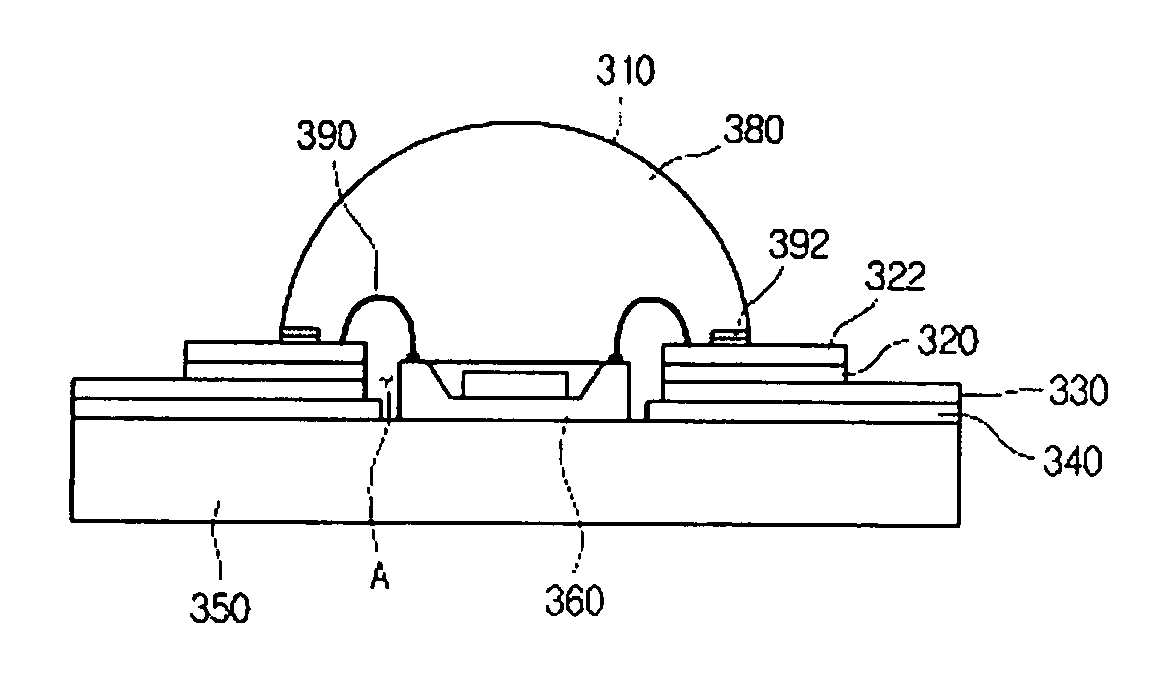

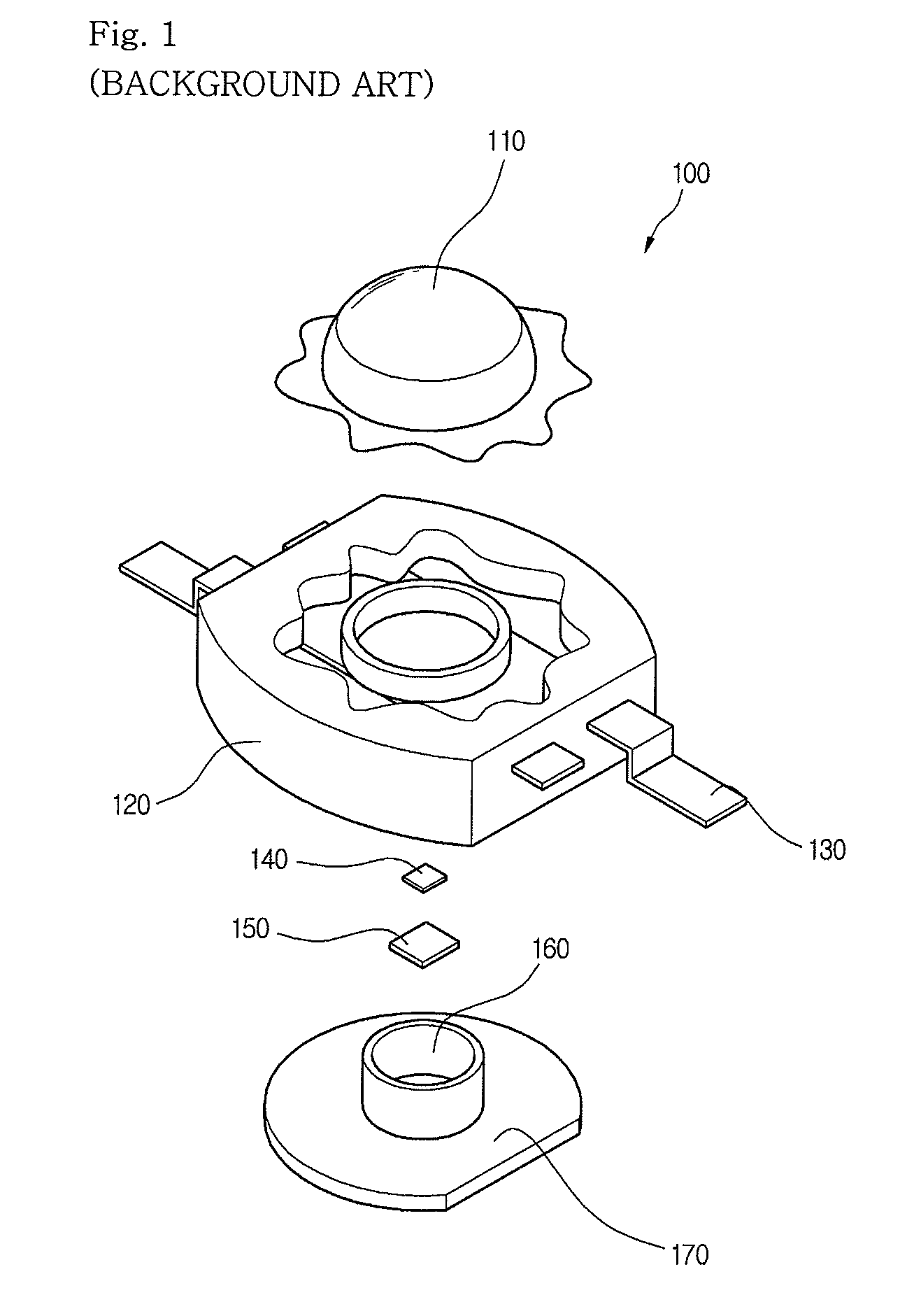

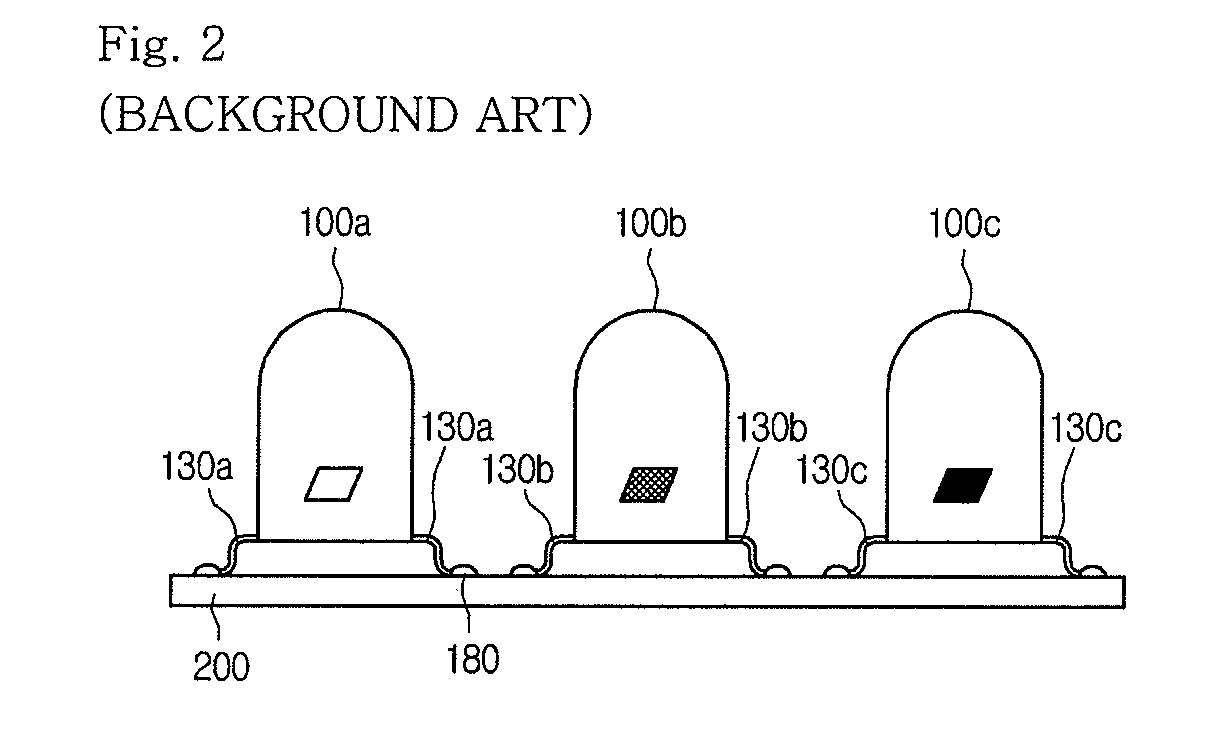

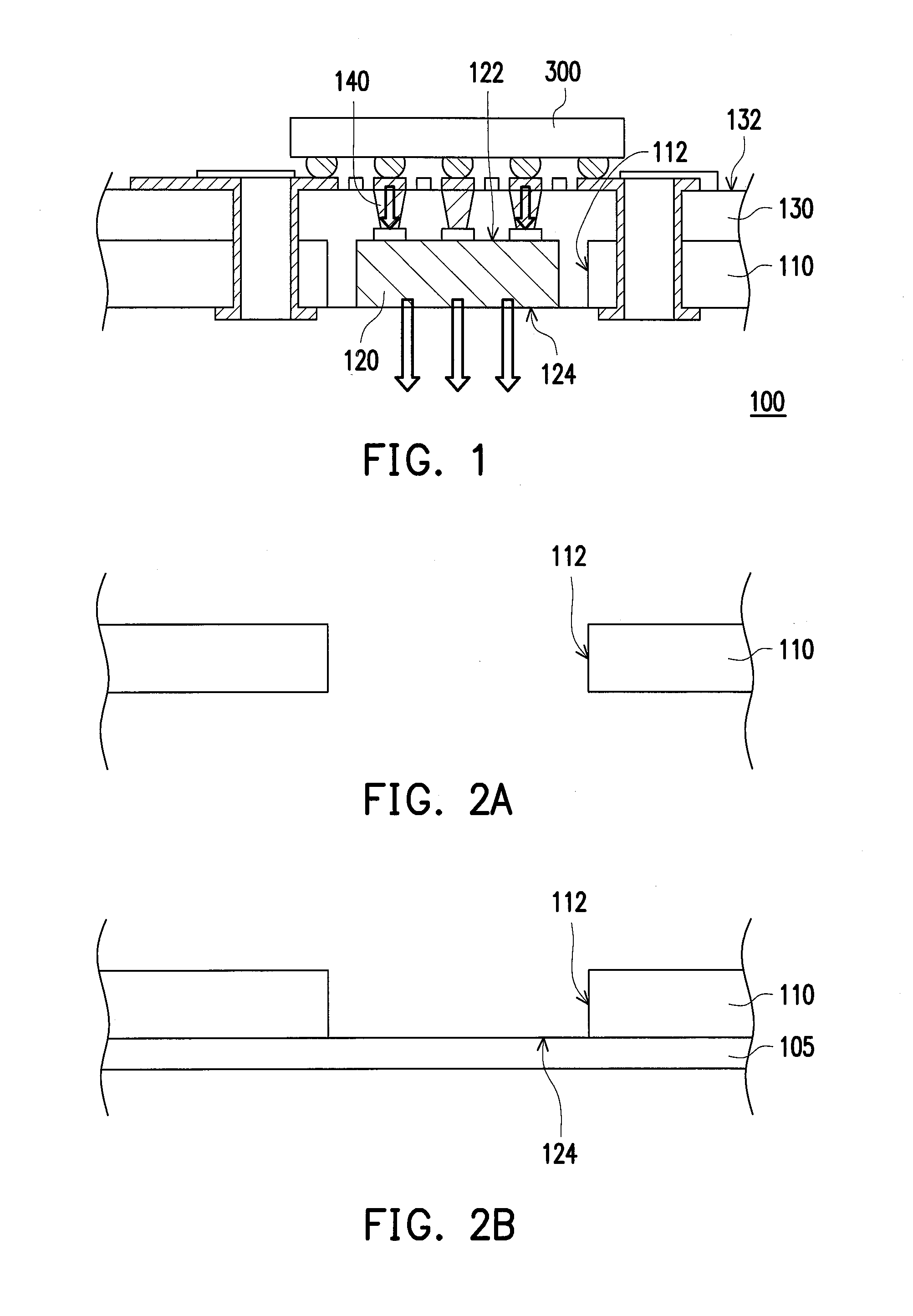

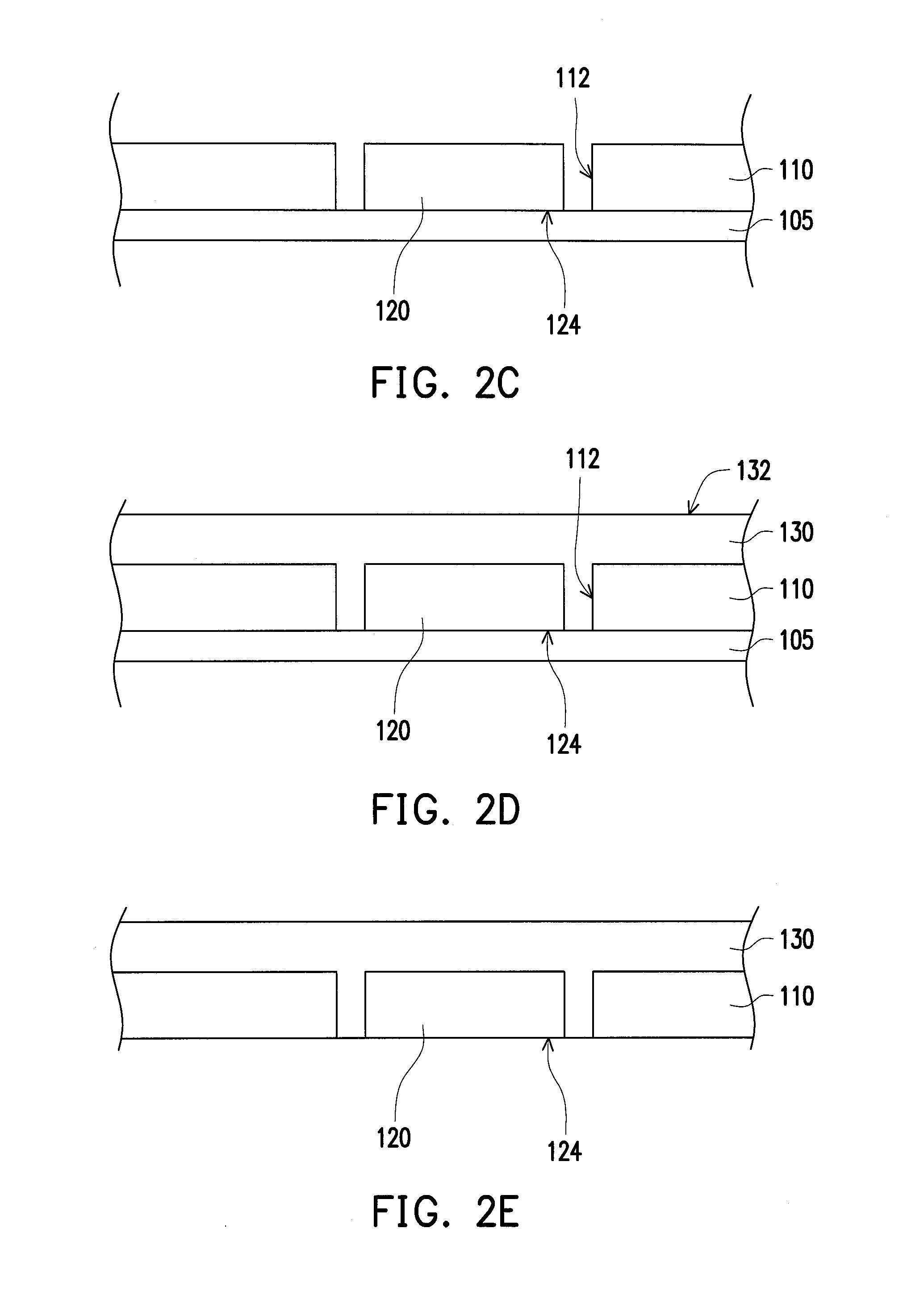

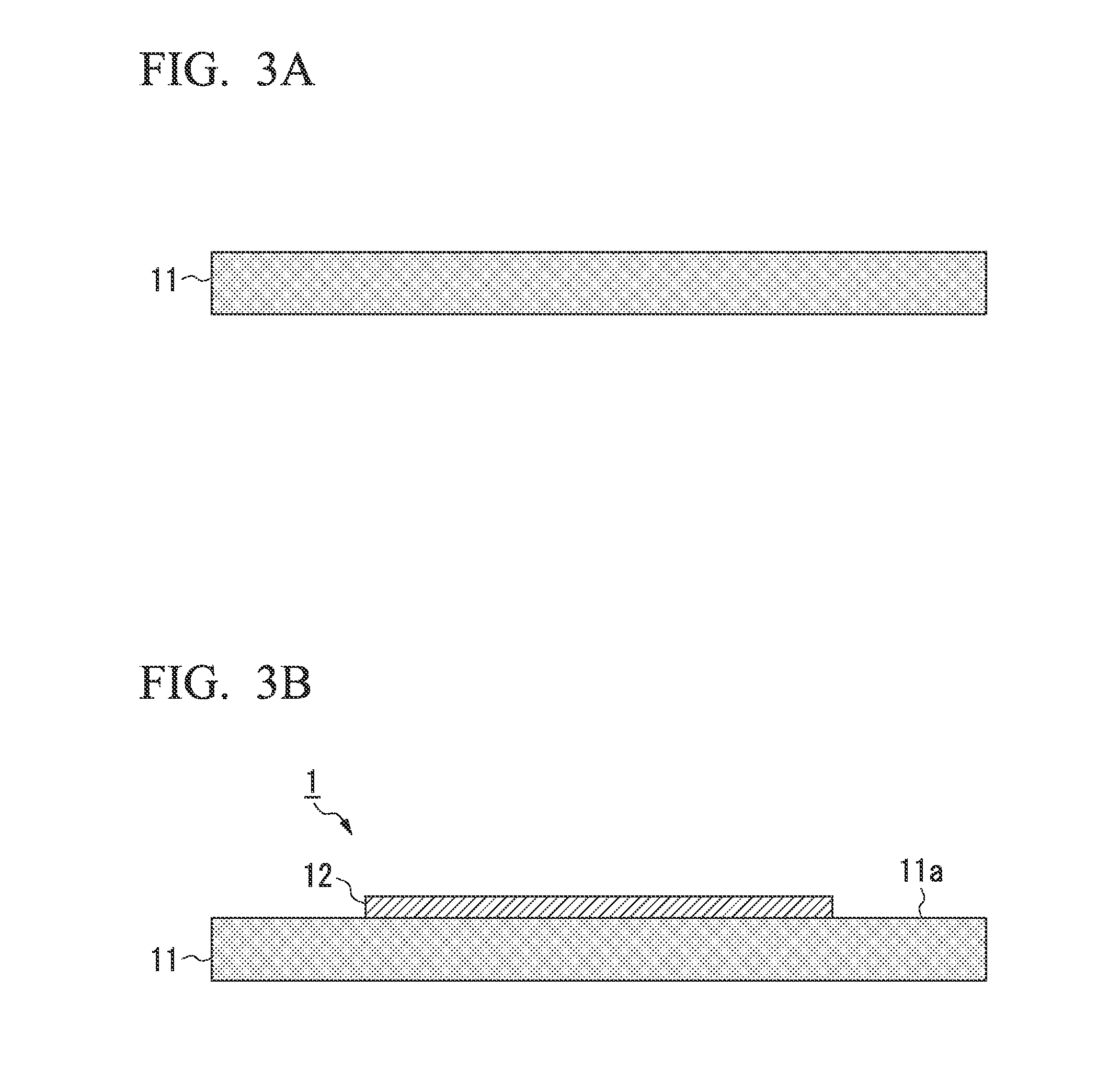

Package for Light Emitting Device

ActiveUS20080290352A1Efficient releaseSmall sizeCircuit thermal detailsSolid-state devicesLight-emitting diodeLight emitting device

The present invention discloses a light emitting device package, comprising: a metal base; an electrical circuit layer provided at an upper side of the metal base for providing a conductive path; a light emitting device mounted in a second region having a smaller thickness than a first region on the metal base; an insulating layer sandwiched between the meta base and the electrical circuit layer; an electrode layer provided at an upper side of the electrical circuit layer; and a wire for electrically connecting the electrode layer and the light emitting device. Further, there is provided a light emitting device package which is improved in light emission efficiency since the light emitting device is placed on a small thickness portion of the metal base.

Owner:SUZHOU LEKIN SEMICON CO LTD

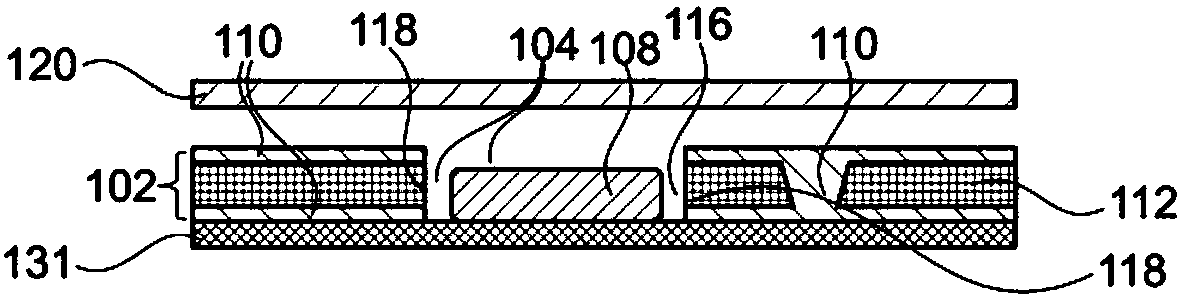

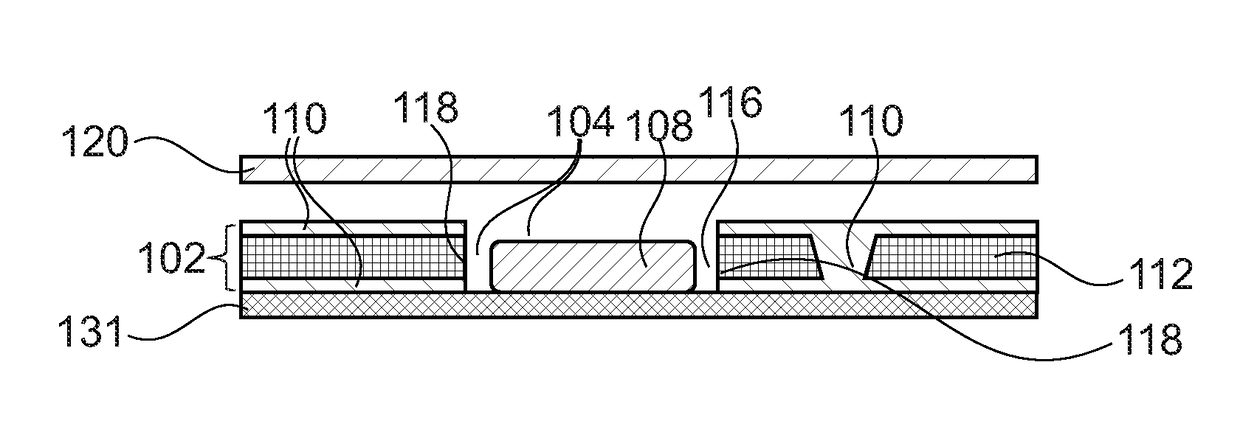

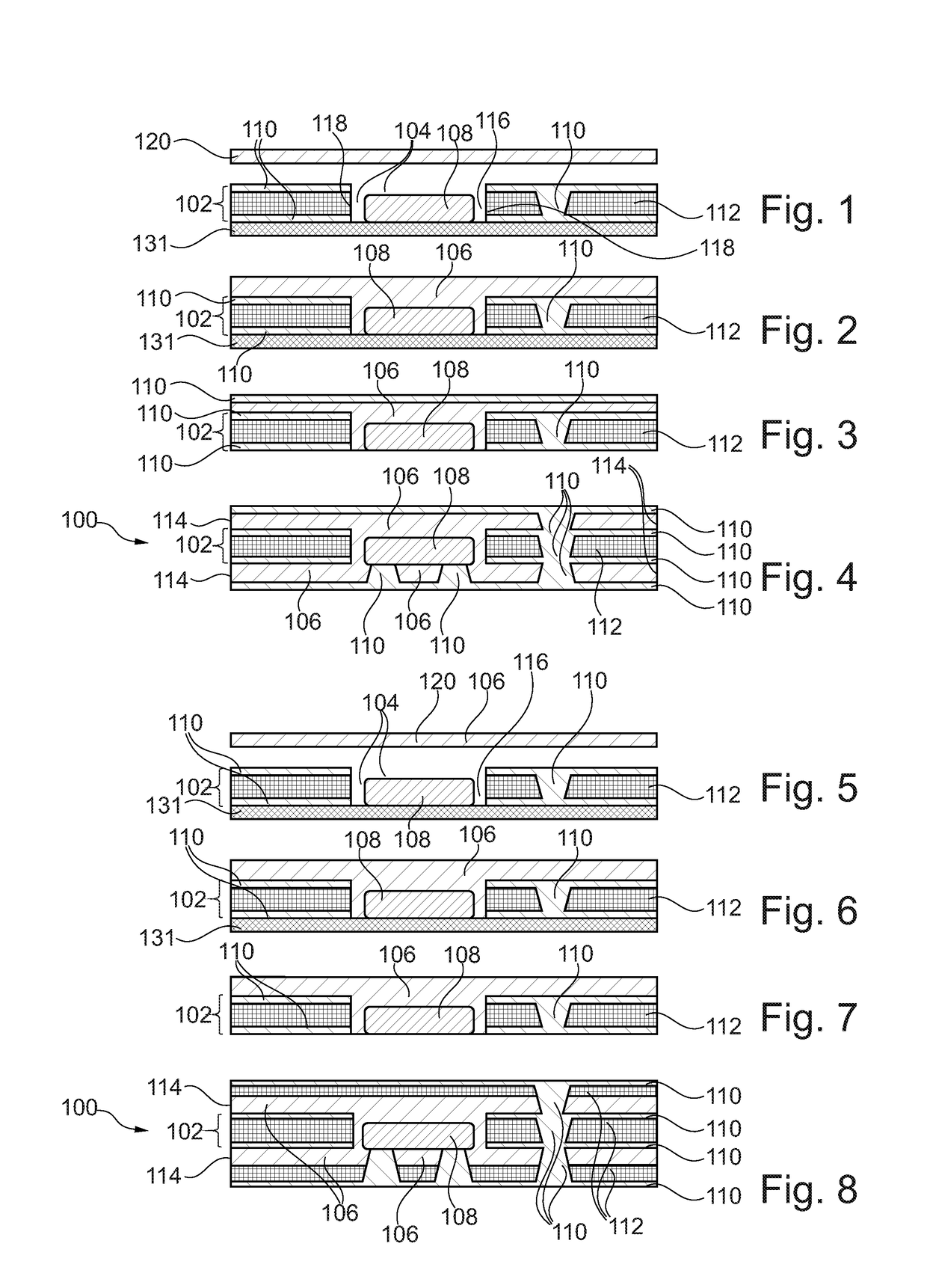

Thermally highly conductive coating on base structure accommodating component

ActiveCN108347820APrinted circuit assemblingCircuit thermal detailsConductive coatingMaterials science

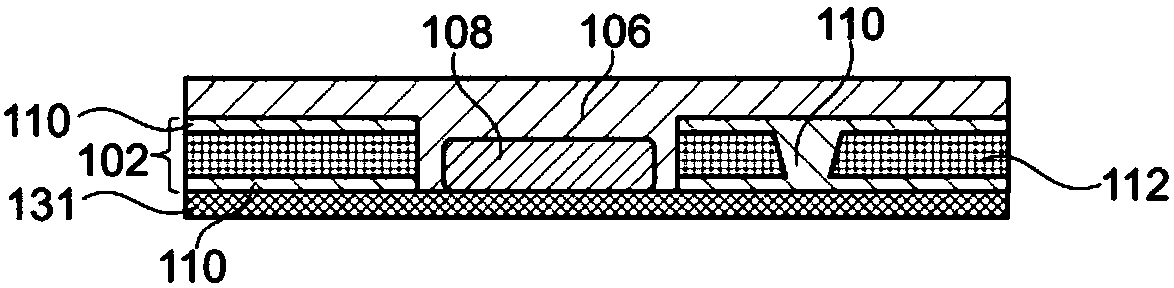

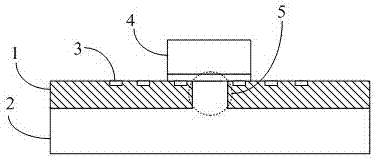

A component carrier (100) comprises a base structure (102) with a recess (104), a thermally highly conductive coating (106) covering at least a part of a surface of the base structure (102) and a component (108) in the recess (104).

Owner:AT & S CHINA

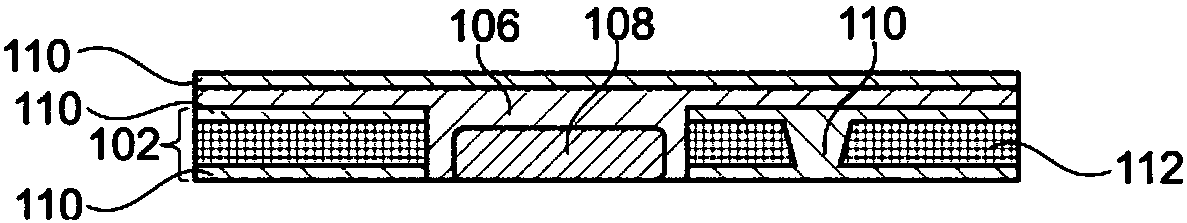

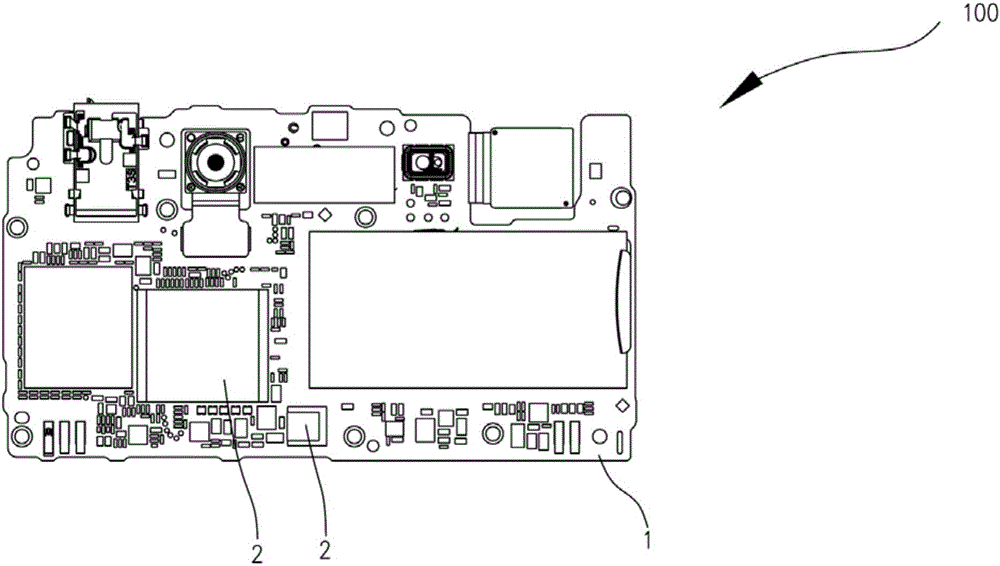

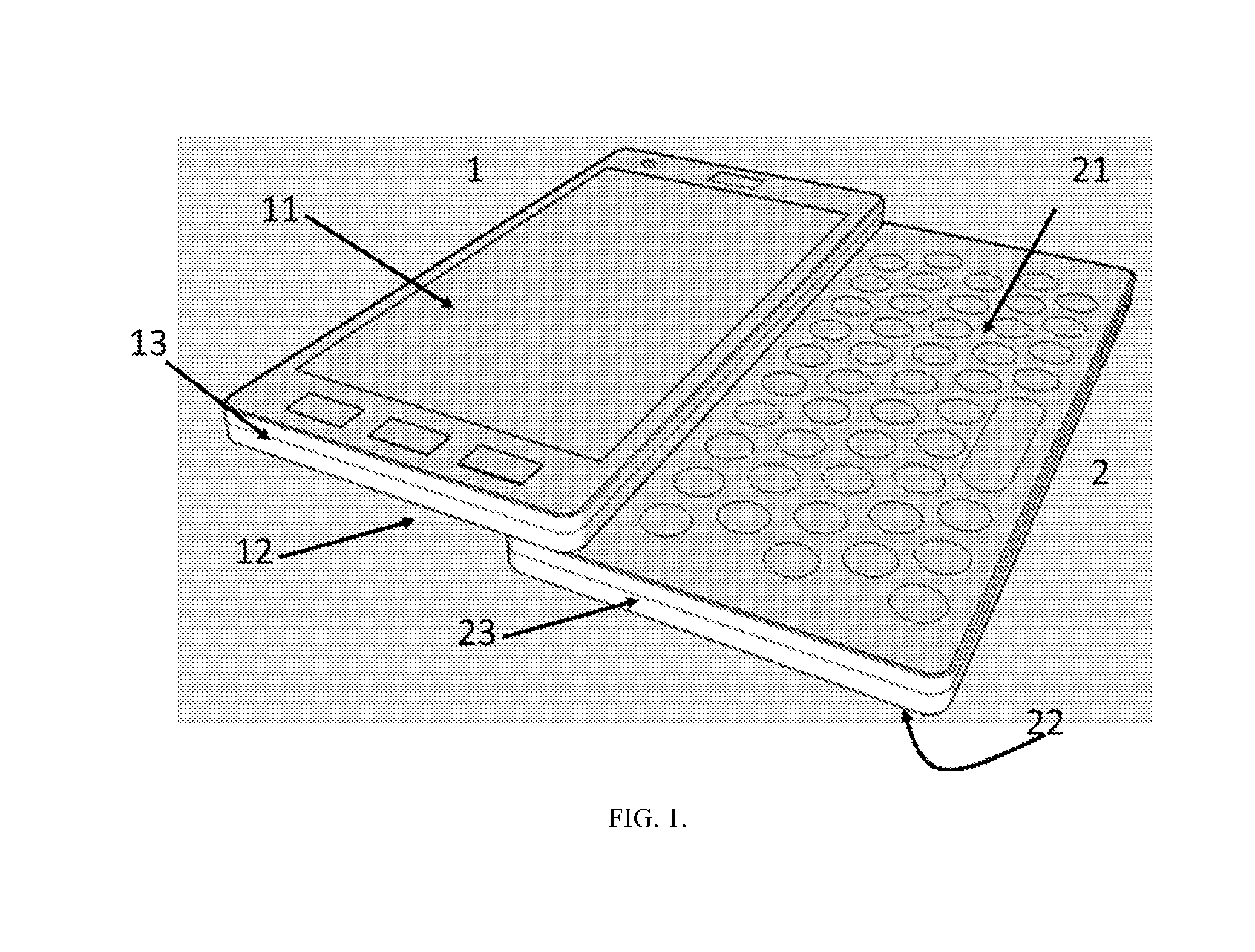

Chip, circuit board and mobile terminal

ActiveCN105792620AReduce the temperatureIncrease temperatureCircuit thermal detailsSemiconductor/solid-state device detailsHeat conductingHybrid material

The invention discloses a chip comprising a body and a heat absorbing and heat radiating member. The body is provided with multiple pins which are used for being plugged on a circuit board. The heat absorbing and heat radiating member is arranged on the body. The heat absorbing and heat radiating member comprises hybrid material having the material property of heat absorbing, heat storing and heat radiating functions. The hybrid material is formed by mixing of heat absorbing and heat storing material and heat conducting and heat radiating material. The heat conducting and heat radiating material is used for transferring heat on the body to the heat absorbing and heat storing material. The heat absorbing and heat storing material is used for absorbing and storing heat on the body and storing heat conducted by the heat conducting and heat radiating material. According to the chip, the heat absorbing and heat radiating member is arranged on the body, the heat absorbing and heat radiating member comprises the hybrid material having the heat absorbing, heat storing and heat radiating functions, and heat on the body is absorbed, stored and radiated by utilizing the hybrid material so that temperature of the body of the chip can be reduced, and normal operation of the circuit board and a mobile terminal having the chip can be guaranteed. The invention also provides the circuit board and the mobile terminal.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

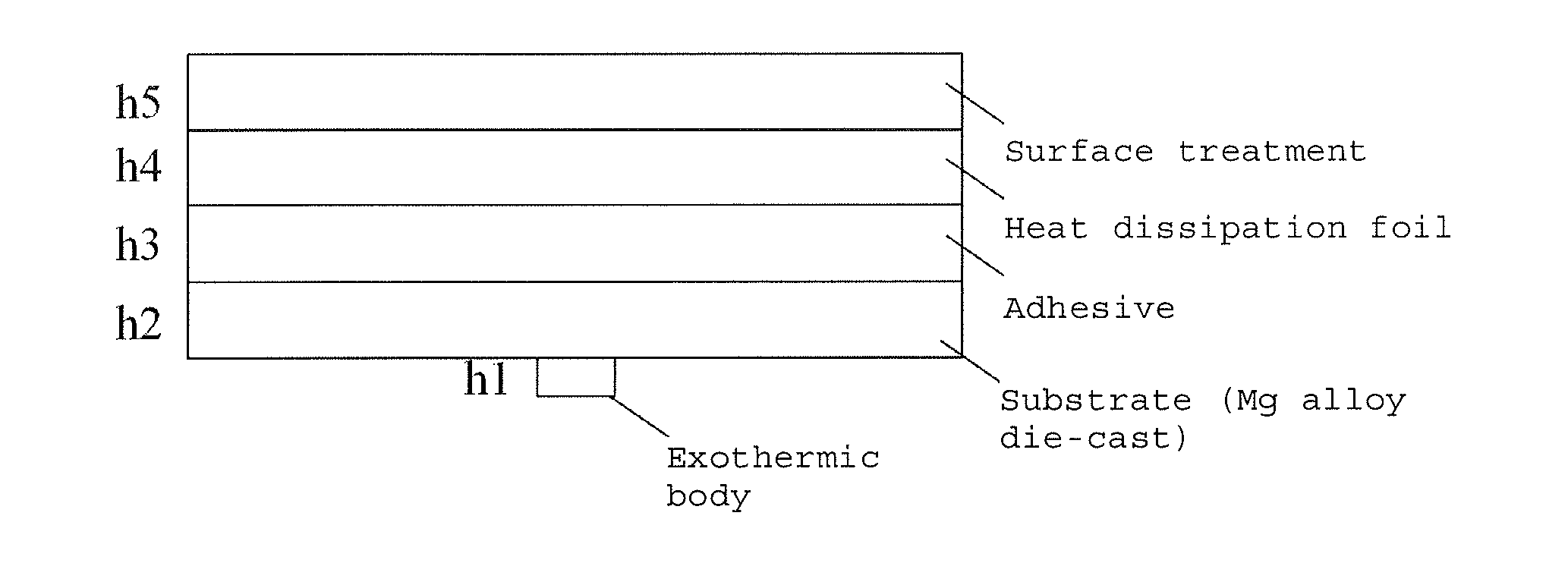

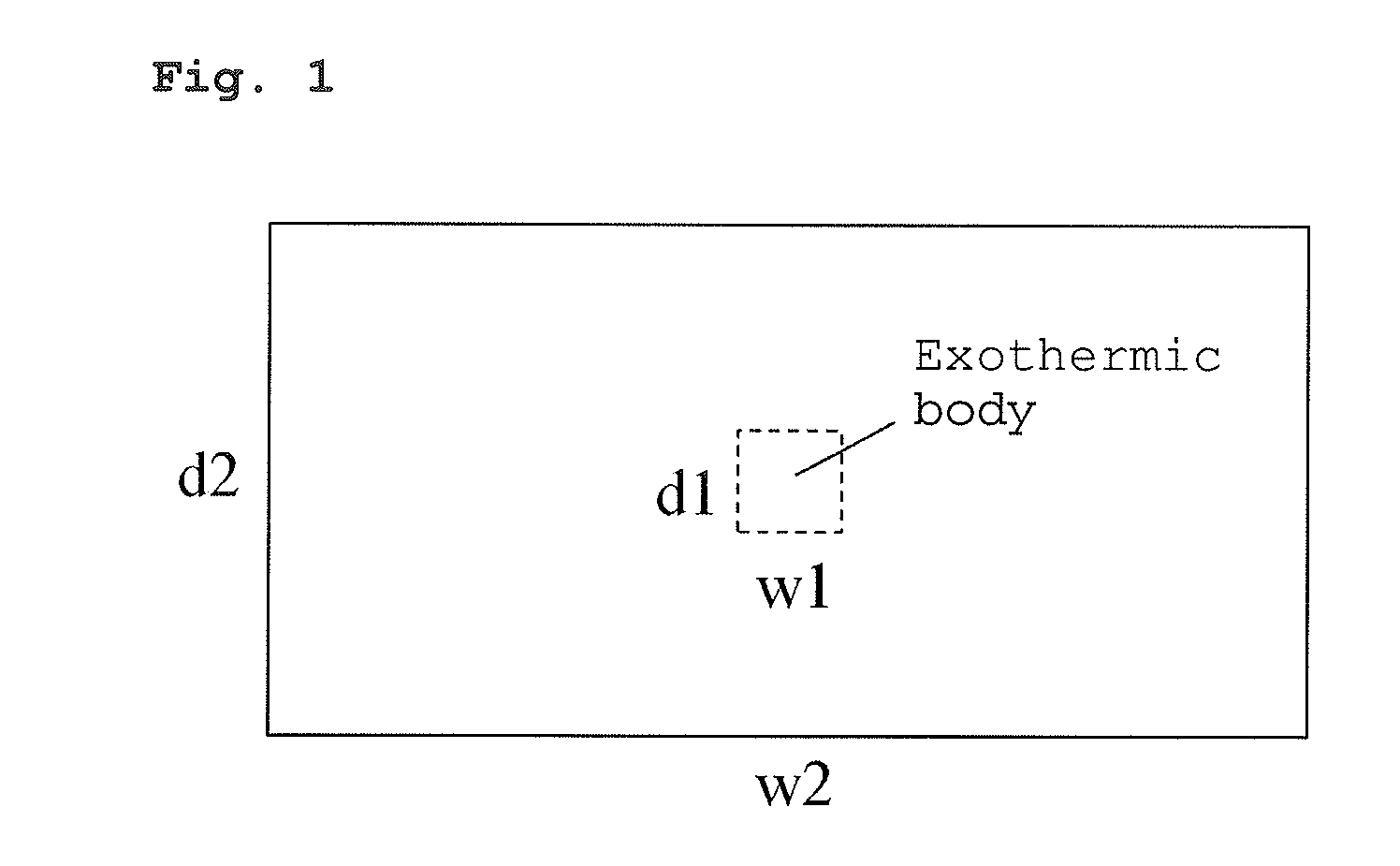

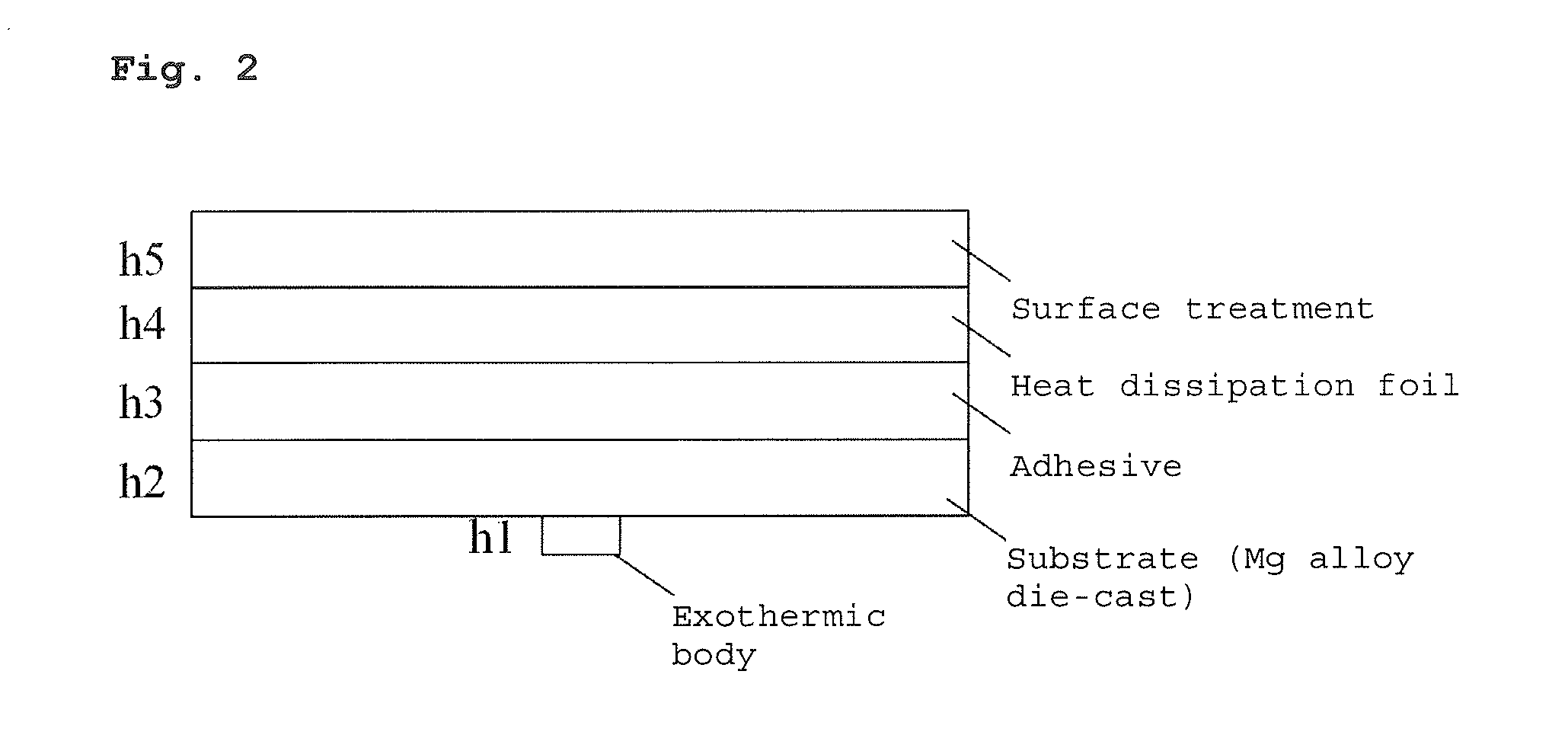

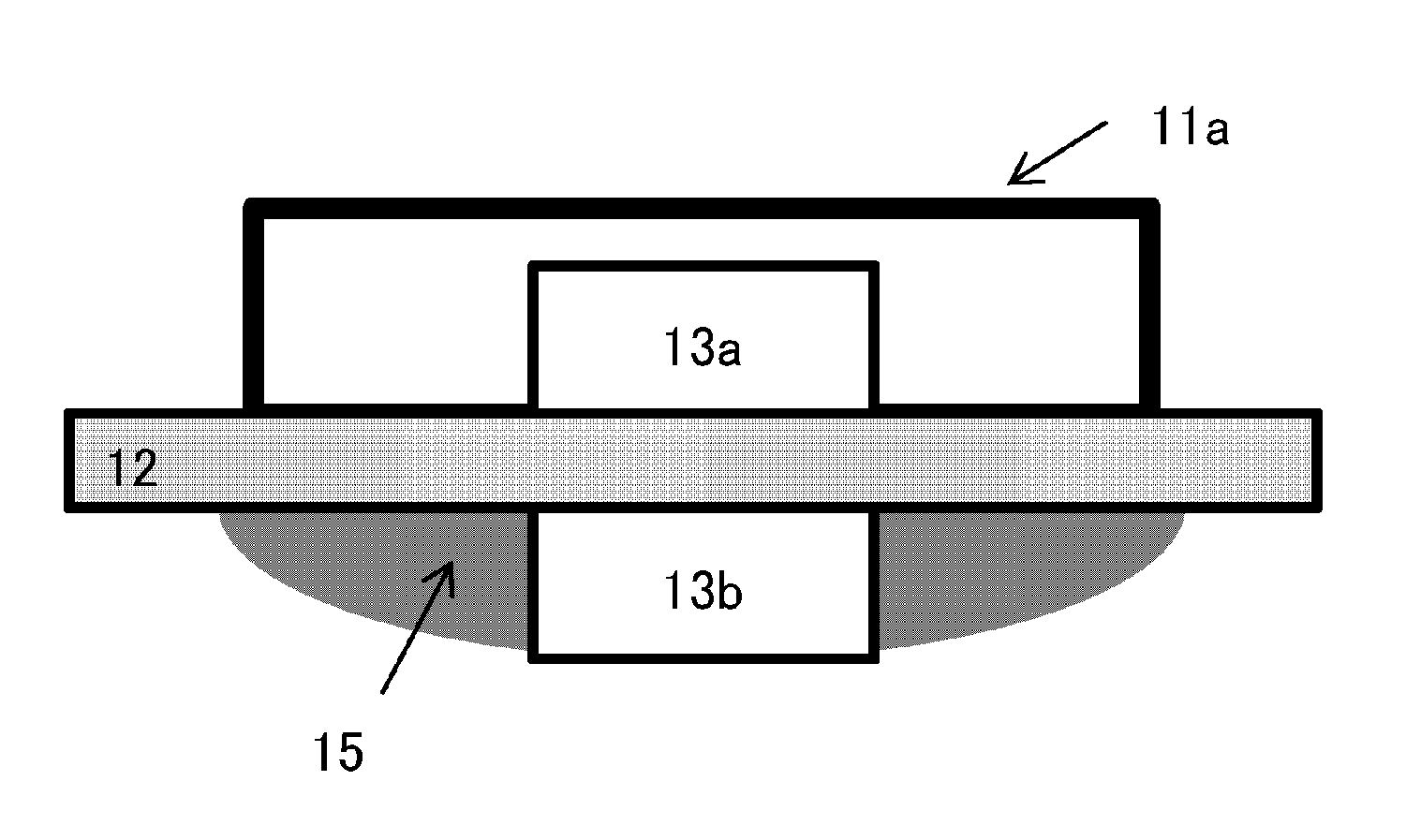

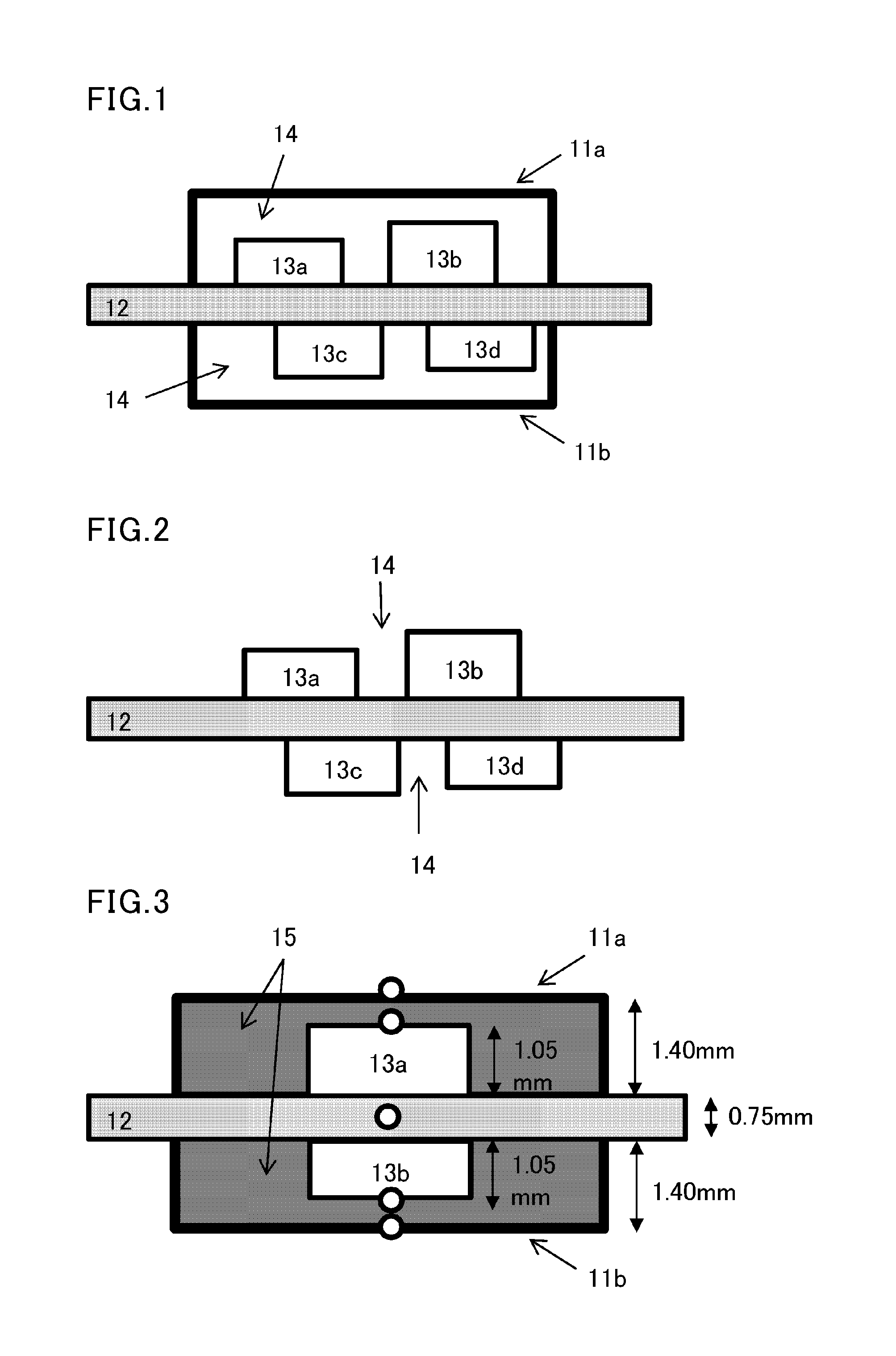

Heat dissipating structure

ActiveUS20160157334A1Avoid overall overheatingAvoid performance degradationCircuit thermal detailsSemiconductor/solid-state device detailsPrinted circuit boardLiquid resin

A heat dissipation structure including: a printed circuit board; a first heat-generating element; a second heat-generating element; and a cured product of a thermally conductive curable liquid resin composition, the printed circuit board having a first surface and a second surface that is opposite to the first surface, the first heat-generating element being placed on the first surface, the second heat-generating element being placed on the second surface, the first heat-generating element generating an equal or greater amount of heat than the second heat-generating element, the second heat-generating element being surrounded by the cured product, the first heat-generating element being surrounded by a layer that has a lower thermal conductivity than the cured product.

Owner:KANEKA CORP

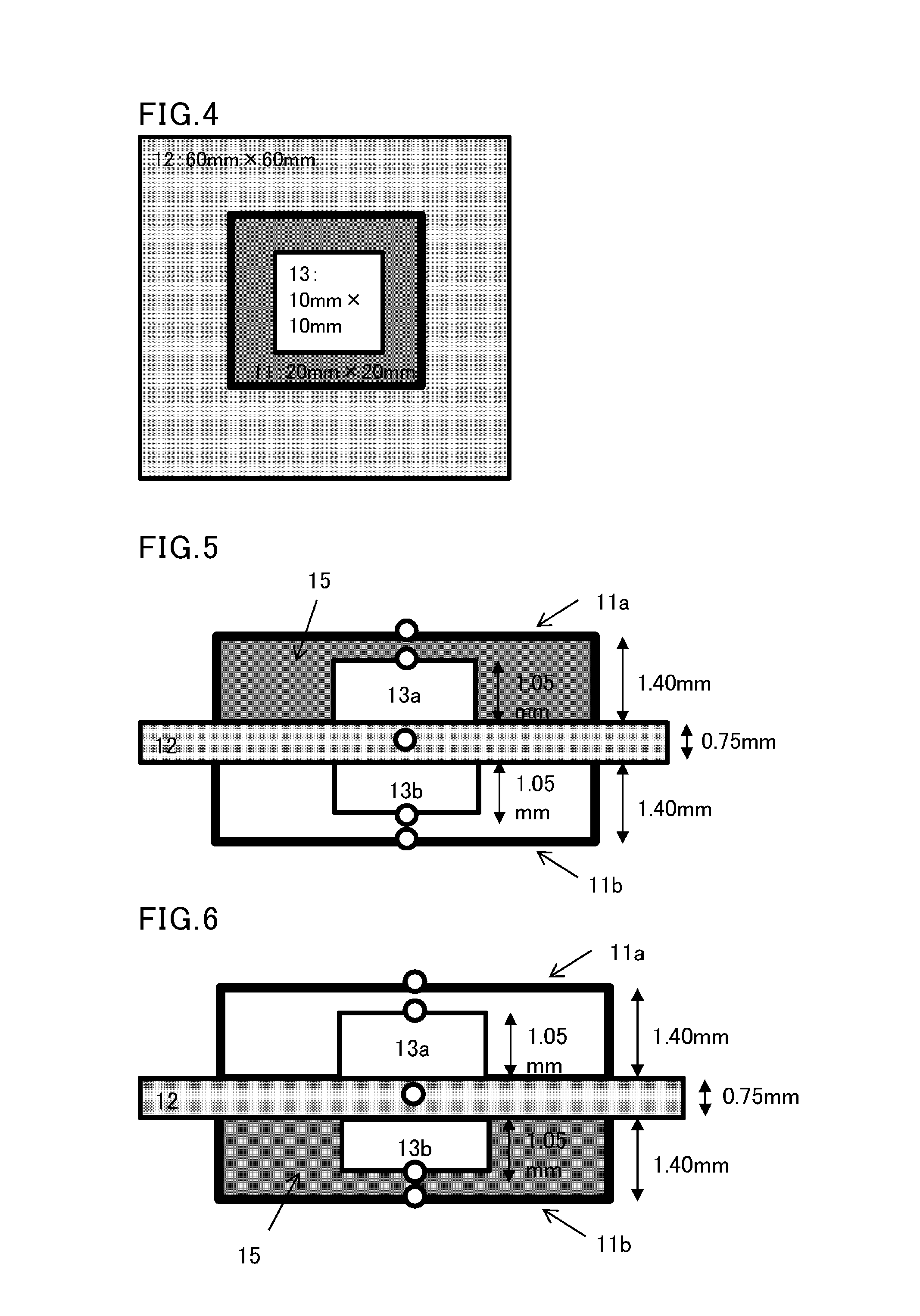

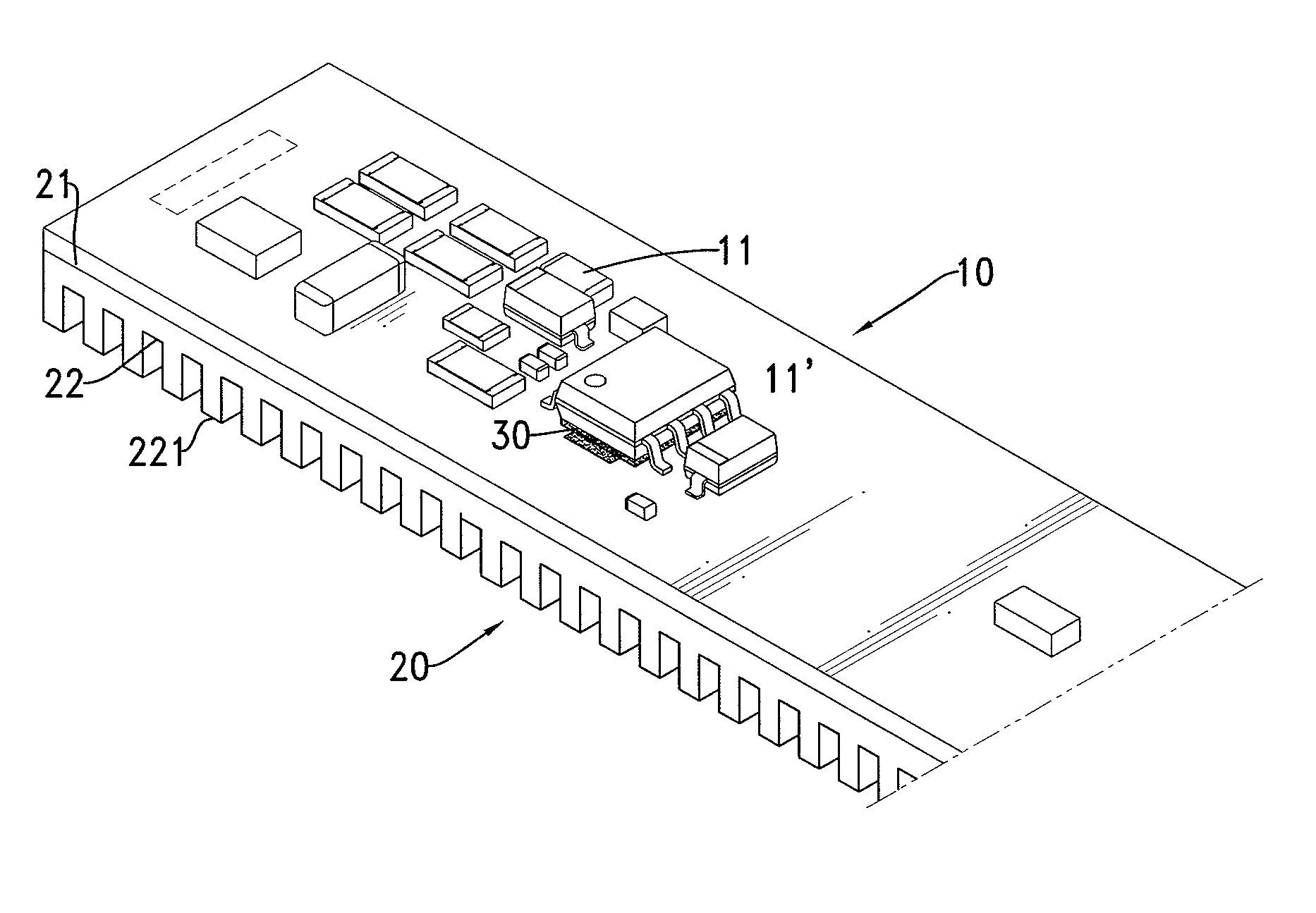

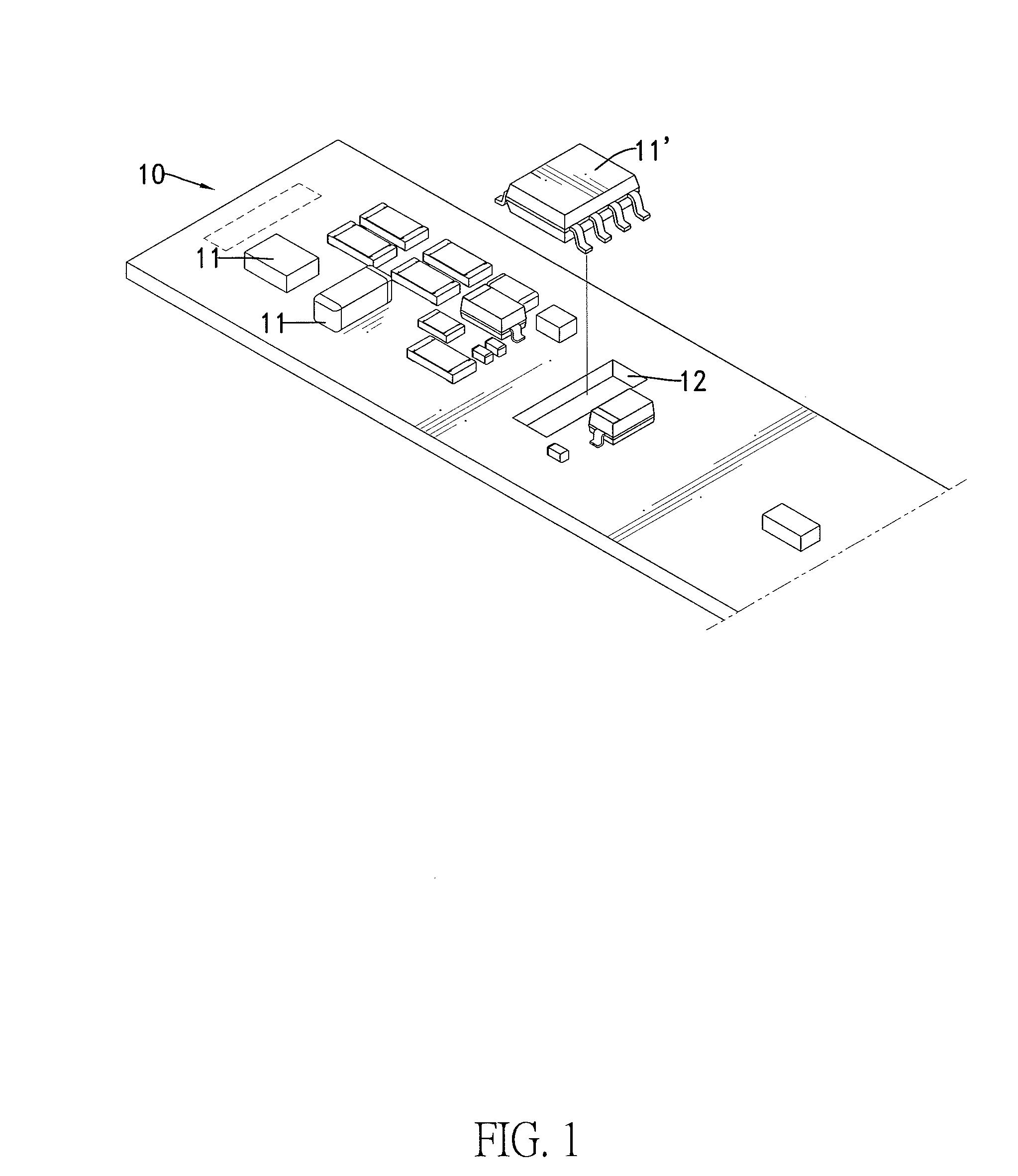

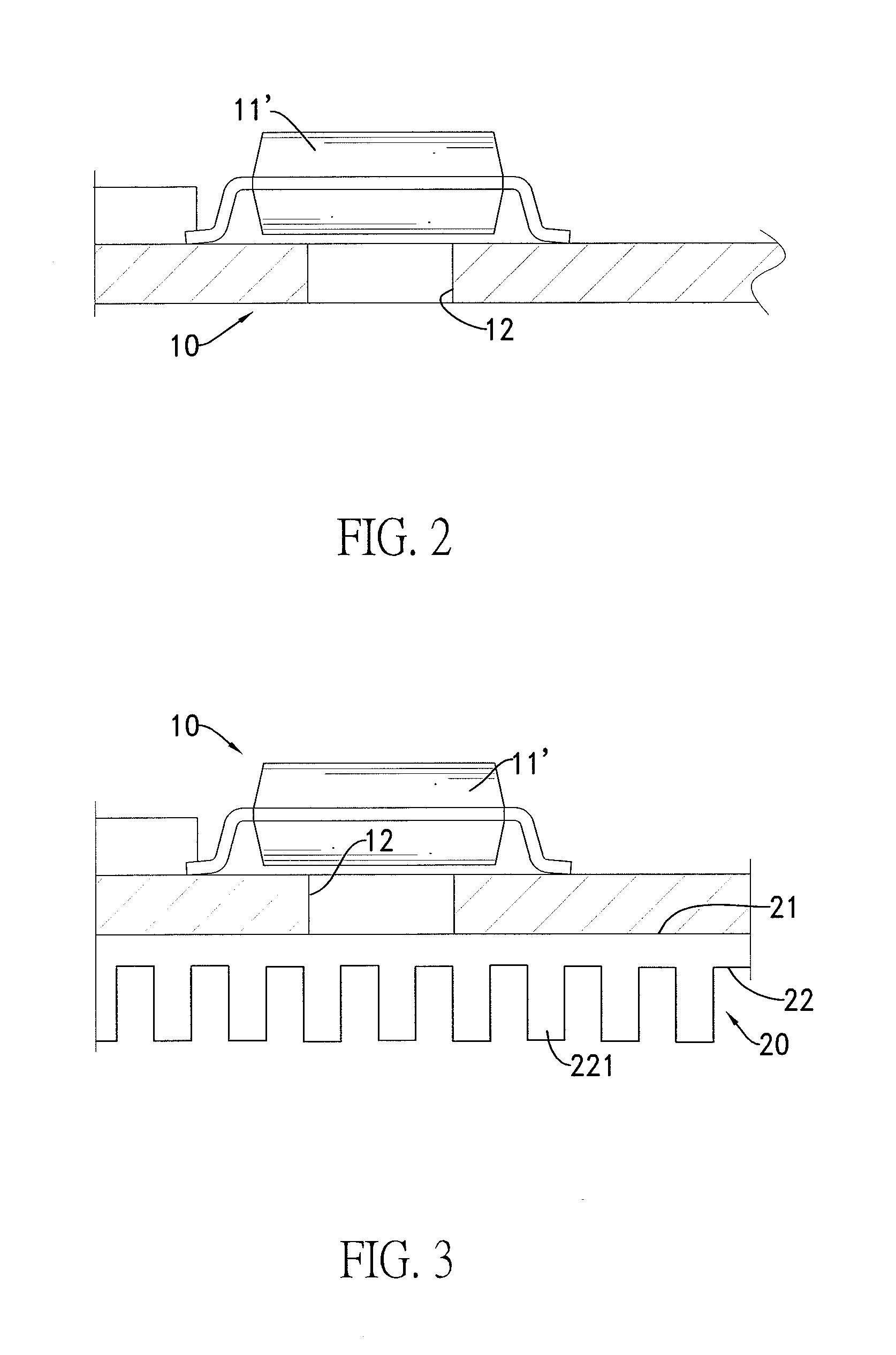

Printed circuit board set having high-efficiency heat dissipation

InactiveUS20150029674A1Improve thermal conductivityLow thermal conductivityCircuit thermal detailsPrinted circuit manufactureConductive materialsPrinted circuit board

A printed circuit board set having high-efficiency heat dissipation includes a printed circuit board (PCB) and a heat dissipating device. The PCB has multiple electronic elements, at least one heat dissipating hole, and at least one thermally conductive material. The electronic elements are disposed on the top surface of the PCB. Each of the at least one heat dissipating hole is formed through the top and bottom surfaces of the PCB and aligns with one of the electronic elements. Each of the at least one thermally conductive material is disposed in the corresponding heat dissipating hole and in contact with the corresponding electronic element. The heat dissipating device is attached to the bottom surface of the PCB and in contact with the at least one thermally conductive material. With a high thermal conductivity, the at least one thermally conductive material rapidly transfers the waste heat produced by the PCB in operation to the heat dissipating device for heat dissipation.

Owner:JITBOUNDARY UNITED PRODION

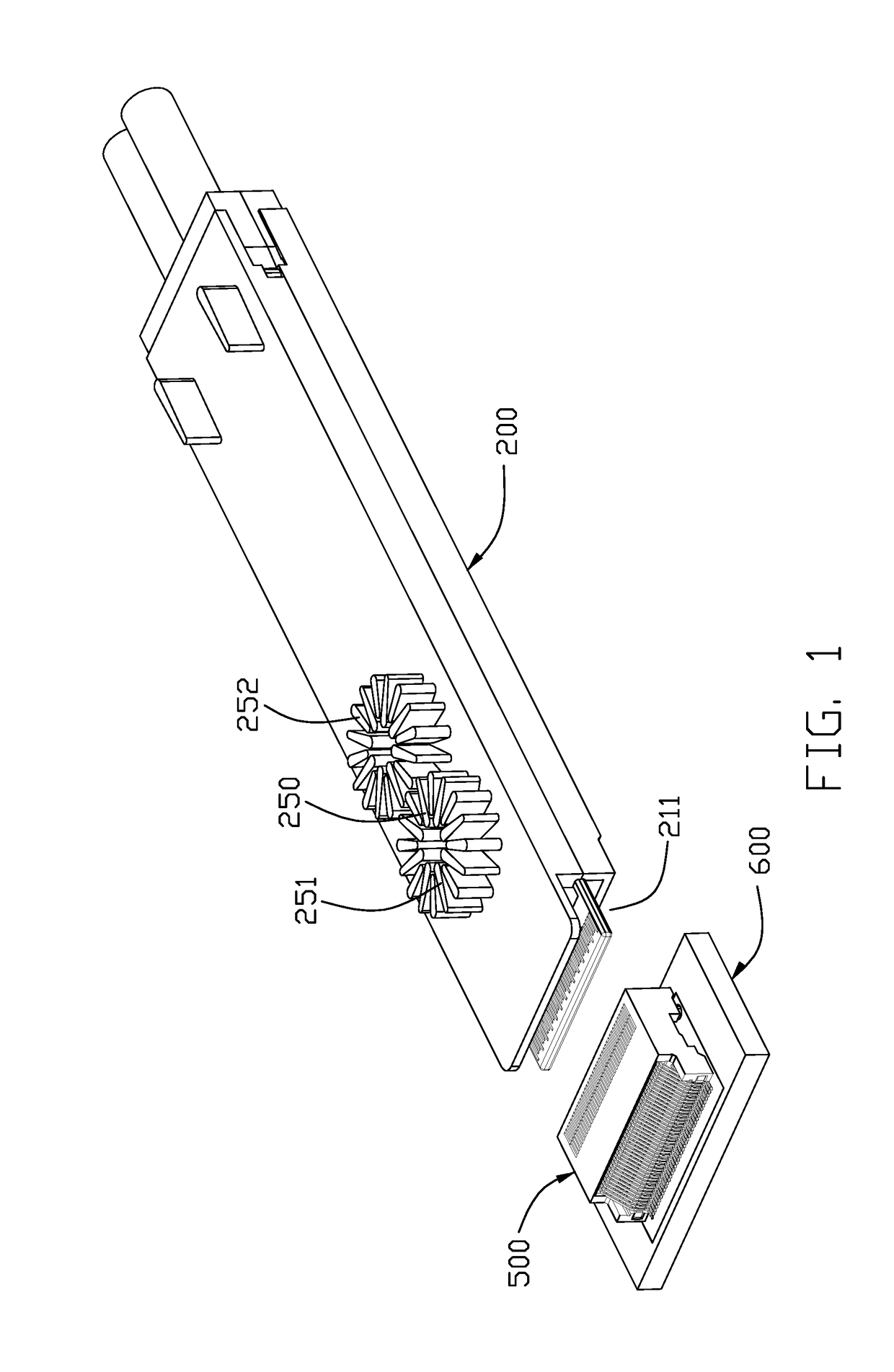

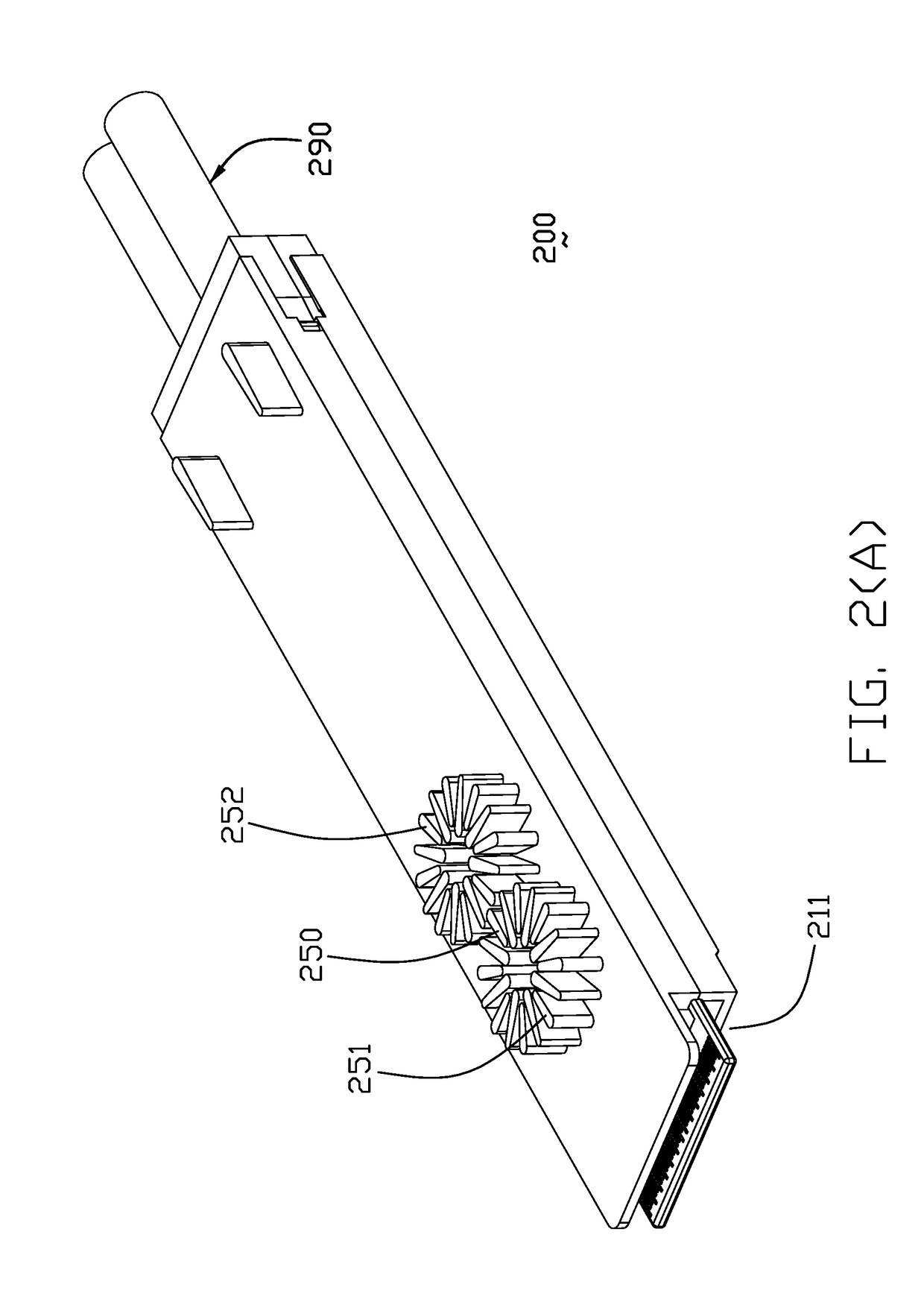

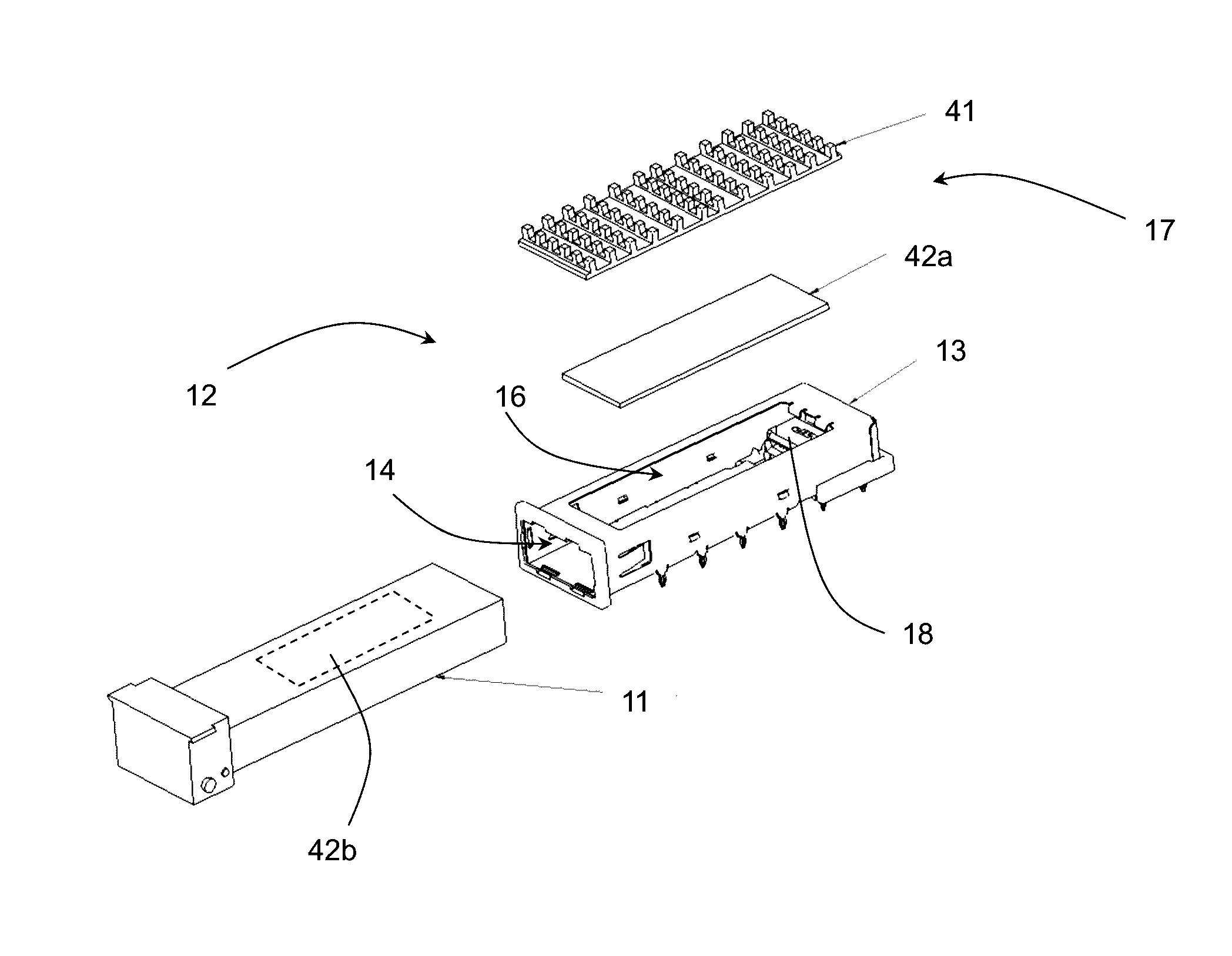

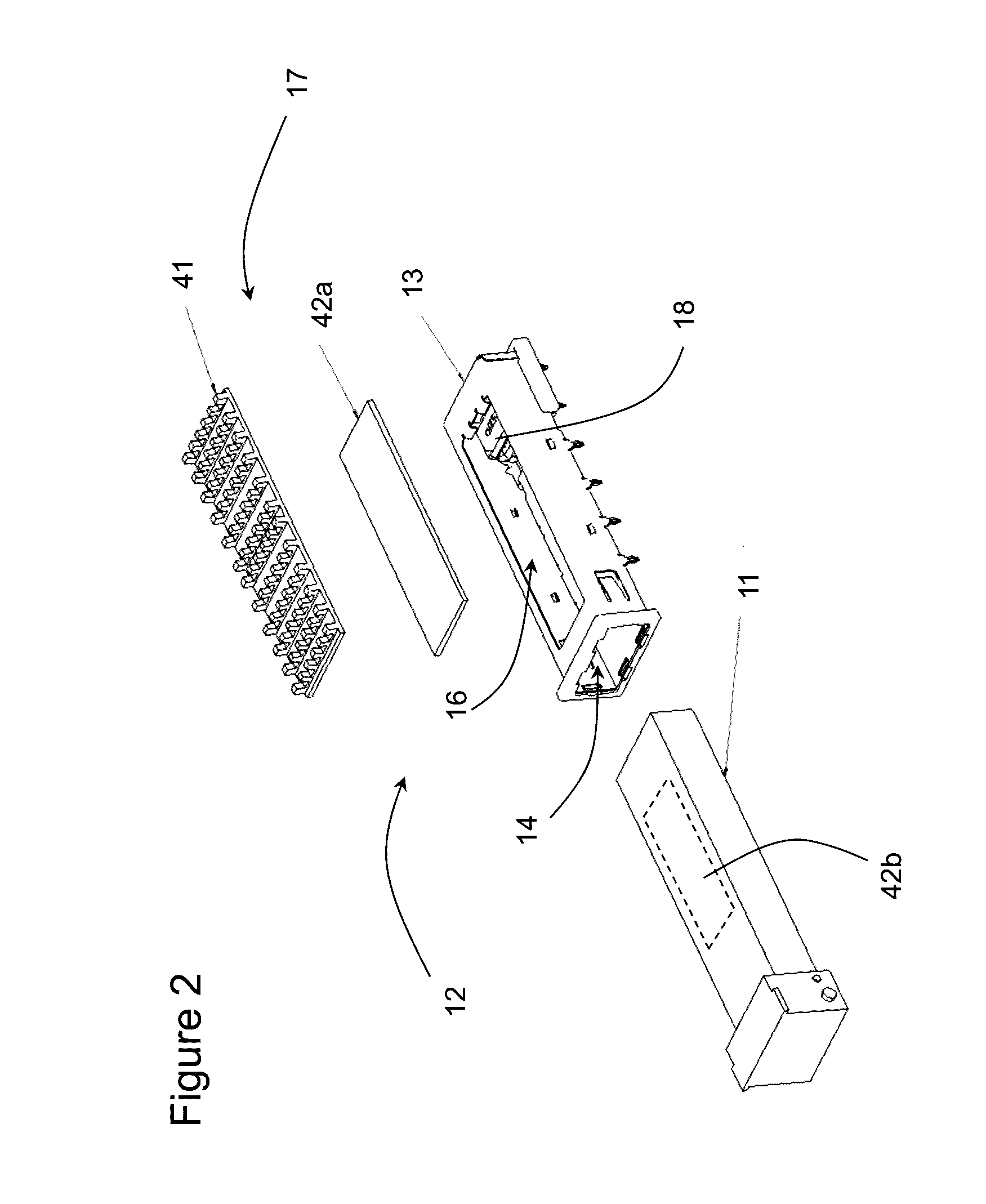

Plug connecetor with a metallic enclosure having heat sink member thereon

ActiveUS20170194751A1Improve cooling effectHeat dissipationCircuit thermal detailsContact member cases/bases manufactureMetallic enclosureEngineering

A plug connector includes a metallic enclosure with a heat sink member exposed on an exterior surface to enclose a printed circuit board; a set of electronic components assembled upon the printed circuit board; a thermal pad sandwiched between the set of electronic components and the metallic enclosure to dissipate heat from the electronic component to the metallic enclosure and eventually to the air via the heat sink member; wherein a center of said heat sink member is essentially aligned with a center of said set of electronic components or a center of the thermal pad for efficient dissipation of heat.

Owner:FOXCONN INTERCONNECT TECHNOLOGY LIMITED

Circuit board, electronic module comprising the same, lighting device, and circuit board manufacturing method

InactiveCN103517542AImprove thermal conductivityHigh hardnessCircuit thermal details3D rigid printed circuitsComputer moduleEngineering

Owner:OSRAM GMBH

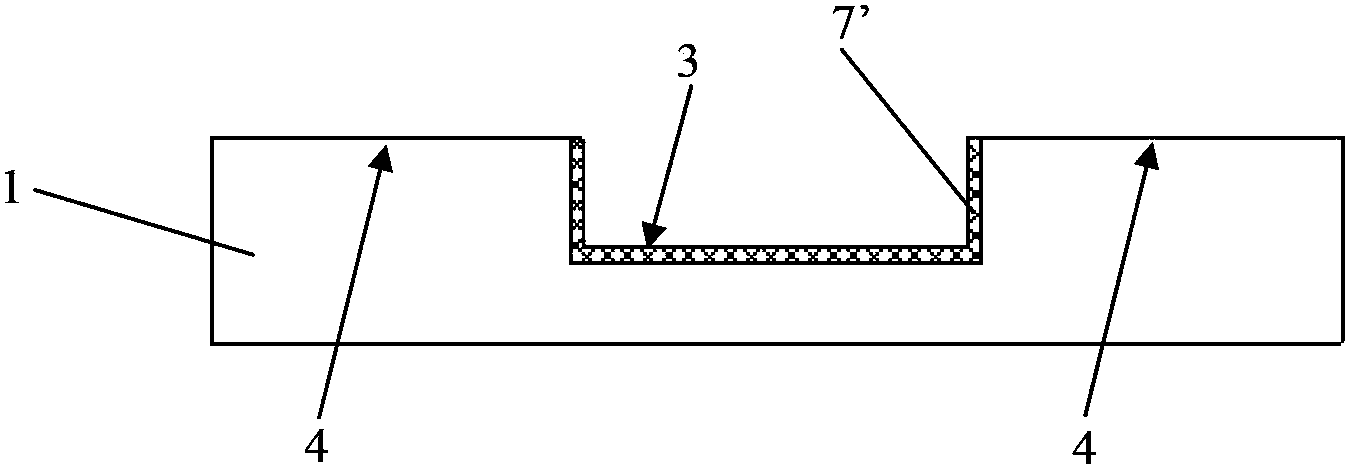

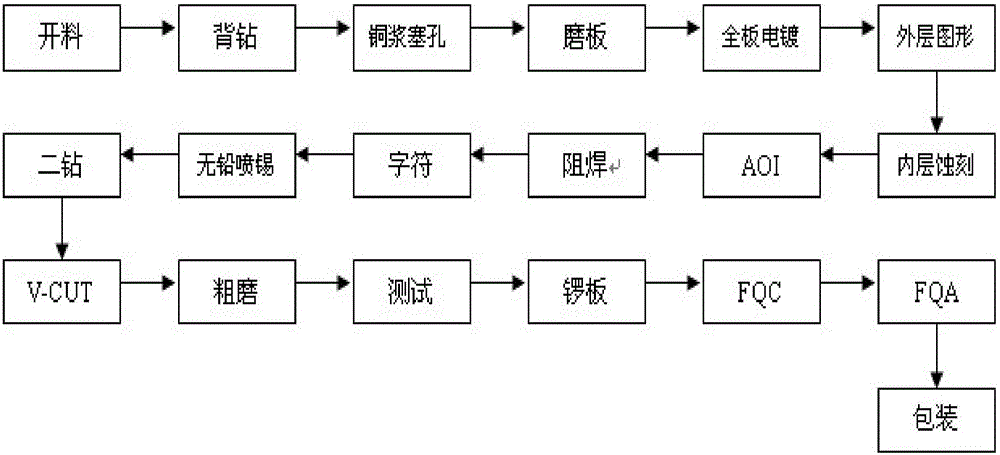

Manufacture method for manufacturing high-thermal-conductivity and single-sided aluminum substrate

InactiveCN106572609AImprove thermal conductivityAchieve direct connectionCircuit thermal detailsConductive material chemical/electrolytical removalHeat conductingCopper foil

The invention provides a manufacture method for manufacturing a high-thermal-conductivity and single-sided aluminum substrate. The method comprises the steps of preparing a high-thermal-conductivity and single-sided aluminum substrate by using a conventional single-sided aluminum substrate; forming patterns on the outer layer of the high-thermal-conductivity and single-sided aluminum substrate; etching the high-thermal-conductivity and single-sided aluminum substrate after the patterns on the outer layer of the high-thermal-conductivity and single-sided aluminum substrate are well formed; and forming a circuit on the copper foil layer of the high-thermal-conductivity and single-sided aluminum substrate. According to the technical scheme of the manufacture method for manufacturing the high-thermal-conductivity and single-sided aluminum substrate, the depth-controlled hole drilling process is conducted and then holes are prepared as copper paste plugholes. In this way, an aluminum substrate is directly connected with the patterns of a circuit, so that the heat dissipation function is realized through a heat-conducting and insulating layer during the operation of elements welded on the patterns of the circuit. Meanwhile, the rapid heat dissipation function is realized through the connection of the copper paste plugholes with the aluminum substrate. Therefore, the thermal conductivity of the single-sided aluminum substrate is greatly improved, and the heat dissipation effect is effectively ensured.

Owner:SHENZHEN SUN & LYNN CIRCUITS

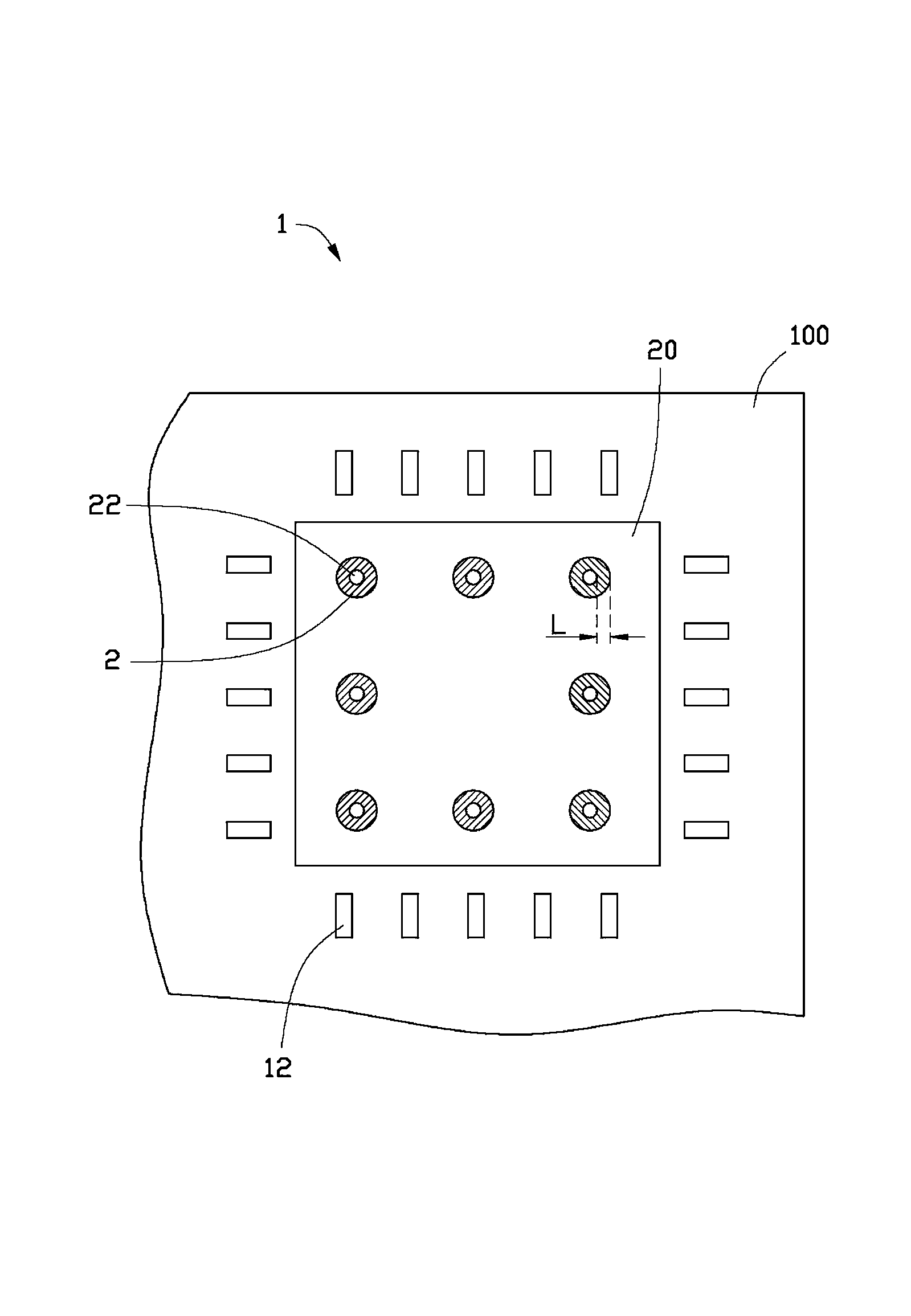

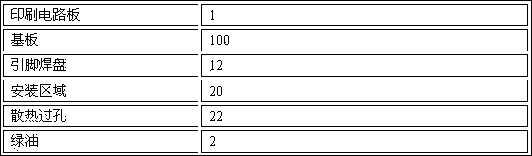

Printed circuit board

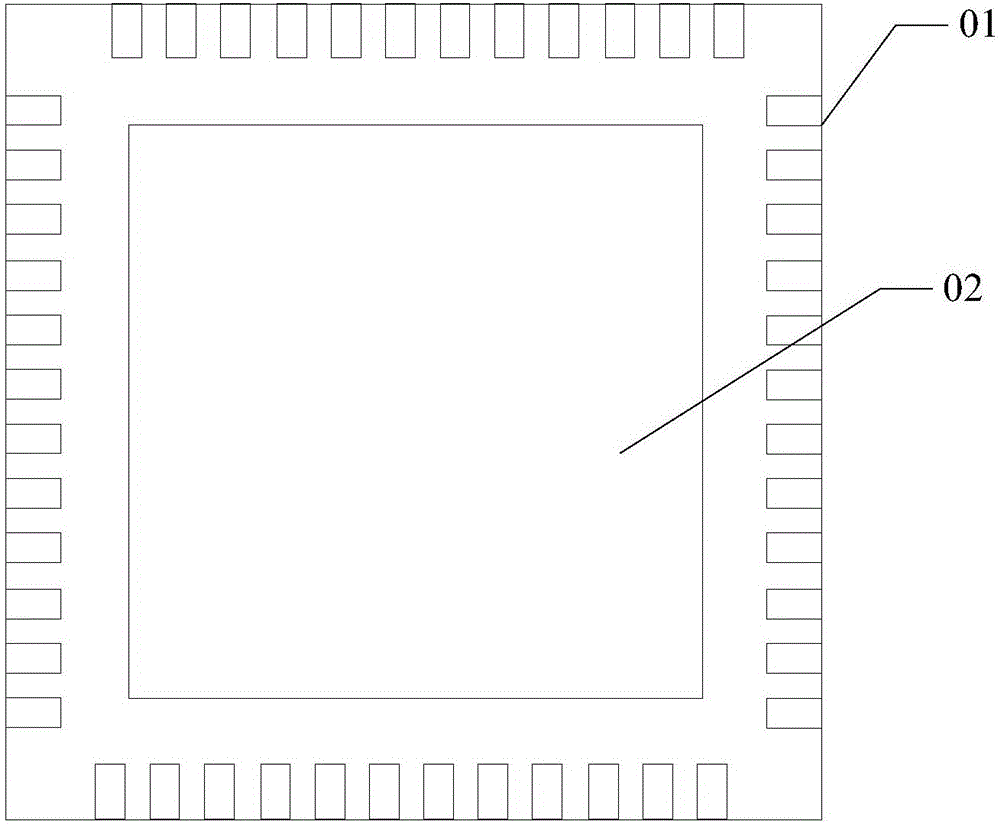

InactiveCN104135814APrevent via hole tin leakageCircuit thermal detailsOrganic non-polymeric coatingCopper foilSolder mask

A printed circuit board (PCB) comprising a base board, the base board defines a thermal pad and a plurality of pin pads for solder an integrated circuit (IC) with a Quad Flat No-lead (QFN) package, wherein a plurality of thermal vias are defined on the thermal pad through the base board, a solder mask is defined around each of the thermal vias.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Thermoelectric generator module, metal-ceramic substrate and method of producing such a metal-ceramic substrate

InactiveUS20140345664A1Simple and reliable attachmentCircuit thermal detailsThermoelectric device with peltier/seeback effectHot zoneCeramic substrate

Owner:ROGERS GERMANY

Package for light emitting device with metal base to conduct heat

ActiveUS7821020B2Efficient releaseIncrease productionCircuit thermal detailsSolid-state devicesLight emitting deviceLight-emitting diode

A light emitting device includes a metal base, an electrical circuit layer provided at an upper side of the metal base for providing a conductive path, a light emitting device mounted in a second region having a smaller thickness than a first region on the metal base, an insulating layer sandwiched between the metal base and the electrical circuit layer, an electrode layer provided at an upper side of the electrical circuit layer, and a wire for electrically connecting the electrode layer and the light emitting device. The light emitting device package has improved light emission efficiency since the light emitting device is placed on a small thickness portion of the metal base.

Owner:SUZHOU LEKIN SEMICON CO LTD

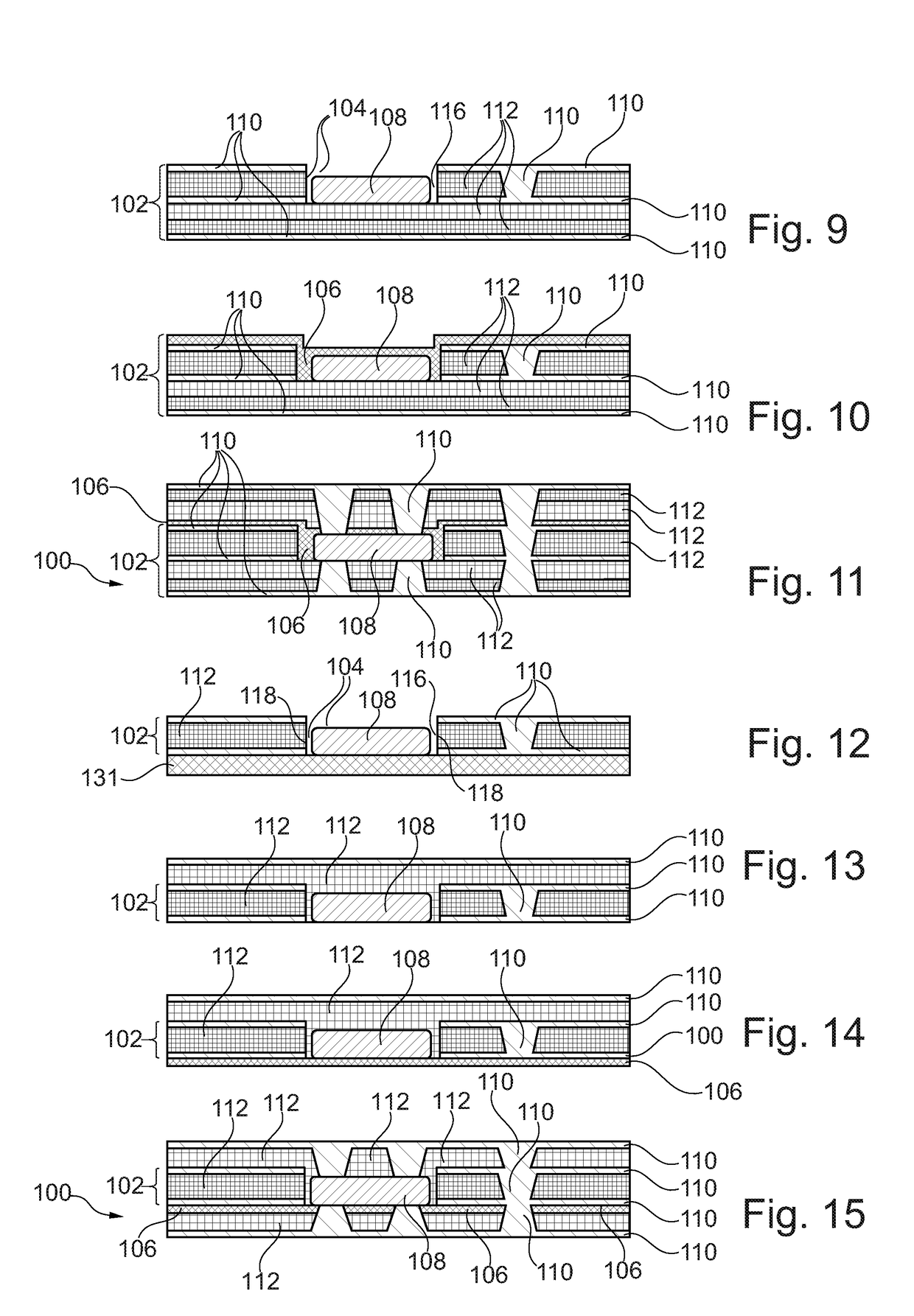

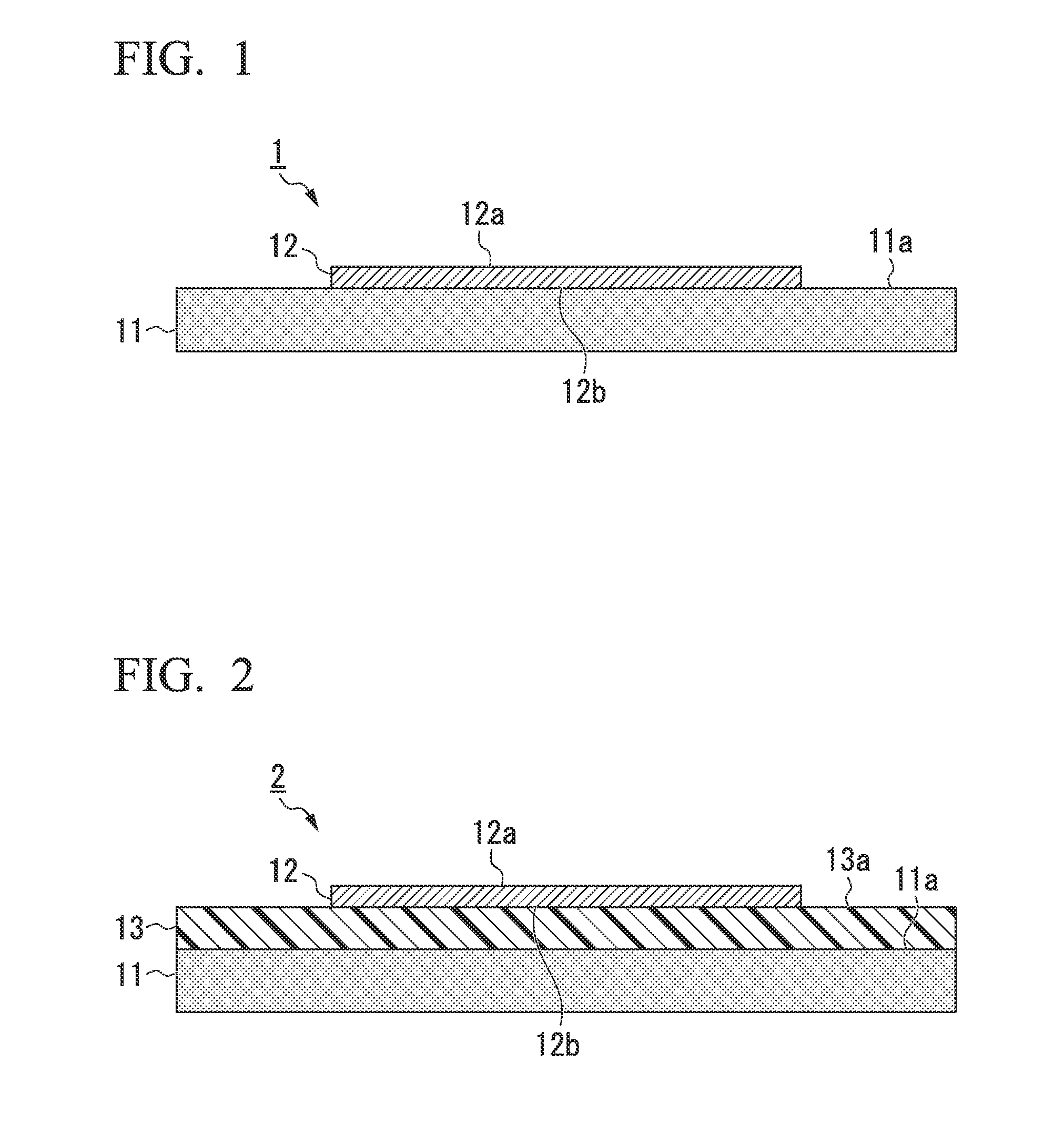

Thermally Highly Conductive Coating on Base Structure Accommodating a Component

ActiveUS20180213634A1Printed circuit assemblingCircuit thermal detailsConductive coatingMaterials science

A component carrier has a base structure with a recess, a thermally highly conductive coating covering at least a part of a surface of the base structure, and a component in the recess.

Owner:AT & S CHINA

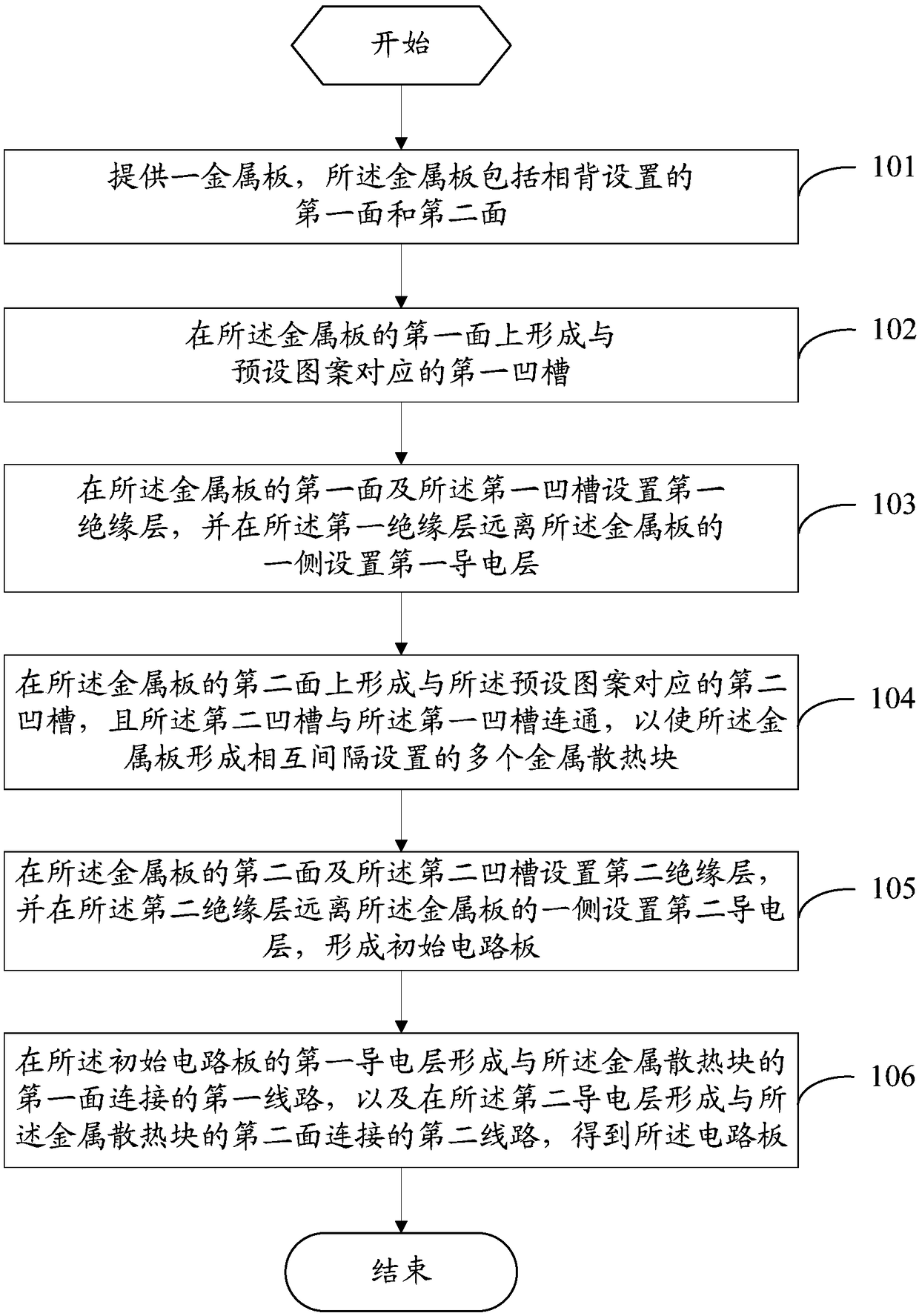

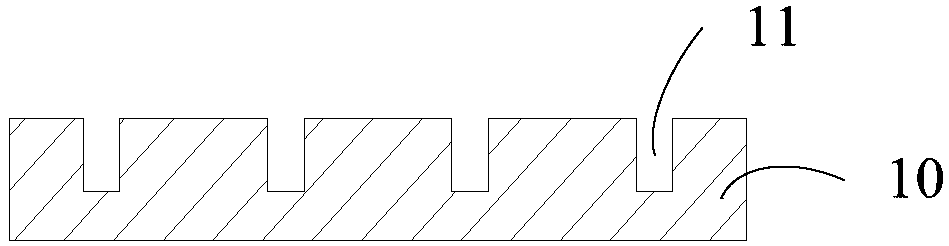

Circuit board manufacturing method, circuit board, and mobile terminal

ActiveCN108347838ARegular and uniform shapeSolve warpingCircuit thermal detailsPrinted circuits stress/warp reductionComputer terminalPrinted circuit board

The invention provides a circuit board manufacturing method, a circuit board, and a mobile terminal. The method comprises the steps: providing a metal plate; forming a first groove, corresponding to apreset pattern, on the first surface of the metal plate; Setting first insulating layers on the first surface of the metal plate and the first groove, and setting a first conductive layer at one side, far from the metal plate, of each first insulating layer; forming a second groove, corresponding to the preset pattern, on the second surface of the metal plate, wherein the second groove is communicated with the first groove; forming a plurality of metal heat dissipation blocks; setting second insulating layers on the second surface of the metal plate and the second groove, setting a second conductive layer at one side, far from the metal plate, of each second insulating layer, and forming an initial circuit board; forming a first circuit connected with the metal heat dissipation blocks onthe first conductive layer of the initial circuit board, forming a second circuit connected with the metal heat dissipation blocks on the second conductive layer, and obtaining a circuit board. Therefore, the method can solve a problem that a conventional circuit board is warped because of the non-uniform stress.

Owner:VIVO MOBILE COMM CO LTD

Method for manufacturing pyroelectric separation LED plate

InactiveCN107278030AImprove machining accuracyPrevent affecting processing qualityCircuit thermal detailsMetal core circuit manufactureEtchingBiochemical engineering

The invention provides a method for manufacturing a pyroelectric separation LED plate. For the structural characteristics of the pyroelectric separation LED plate, the method employs steps different from the steps of a manufacturing method for a common LED plate, and comprises a step of optimizing a thermal conduction part at steps of copper plate etching and insulating layer manufacturing: pasting a film before the etching of a copper plate, carrying out the exposing and development, enabling other parts, expect the thermal conduction part, of the copper plate to be exposed, and carrying out the half-etching of the copper plate, thereby improving the half-etching precision. The method also comprises a step of carrying out the groove milling of a PP piece corresponding to the thermal conduction part of the copper plate during the manufacturing of the insulating layer, wherein the slot size of the groove milling is 0.2mm greater than the length of the single side of the thermal conduction part of the copper plate, thereby guaranteeing that the PP piece can be sleeved by the copper piece after groove milling, preventing slight deviation from affecting the machining quality during stitching, and effectively improving the product quality through the above means.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

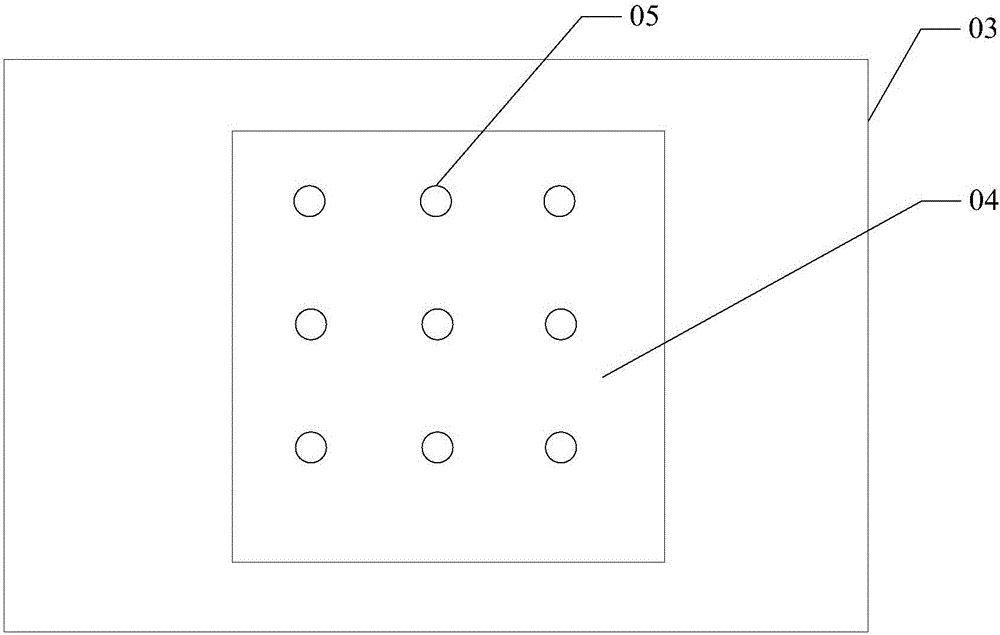

Heat-radiation pad, design method thereof and printed circuit board (PCB)

InactiveCN106604526APrevent tin leakageImprove product qualityCircuit thermal detailsElectrical connection printed elementsPrinted circuit boardDesign methods

The invention provides a heat-radiation pad, a design method thereof and a PCB, and aims at preventing the heat-radiation pad from tin leakage and improving the product quality. The heat-radiation pad is divided into solder feeding areas independent from each other and a non solder feeding area surrounding all the solder feeding areas; only the non solder feeding area is provided with through holes and through hole pads corresponding to the through holes respectively; and the minimal distance between the edge of each through hole pad and the edge of the adjacent solder feeding area is greater than or equivalent to a preset value.

Owner:ZHEJIANG DAHUA TECH CO LTD

Wiring board structure

InactiveUS20150053462A1Improve cooling efficiencyDissipate quicklyCircuit thermal detailsPrinted electric component incorporationActive coolingDielectric layer

A wiring board structure adapted to carry a heat generating component is provided. The wiring board structure includes a core layer, an active cooler, a dielectric layer and a plurality of conductive vias. The core layer has a cavity penetrating through the core layer. The active cooler includes a cold surface and a hot surface. The active cooler is disposed in the cavity. The dielectric layer covers the core layer and fills a gap between the active cooler and the cavity. The heat-generating component is disposed on an outer surface of the dielectric layer. The conductive vias are disposed in the dielectric layer and connecting the cold surface and the outer surface to connect the heat-generating component and the active cooler. A wiring board structure having an active cooling via is also provided.

Owner:UNIMICRON TECH CORP

Configurable heat conducting path for portable electronic device

ActiveUS20150029660A1Avoid overall overheatingEfficient heatingCircuit thermal detailsDigital data processing detailsThermoelectric materialsThermodynamics

A portable electronic device includes at least one energy module which further included thermoelectric materials which may convert heat to electric power. A plurality of heat removers selectively thermal contact to at least one wall of an enclosure of the portable electronic device depended on the configuration of the portable electronic device.

Owner:AZTRONG

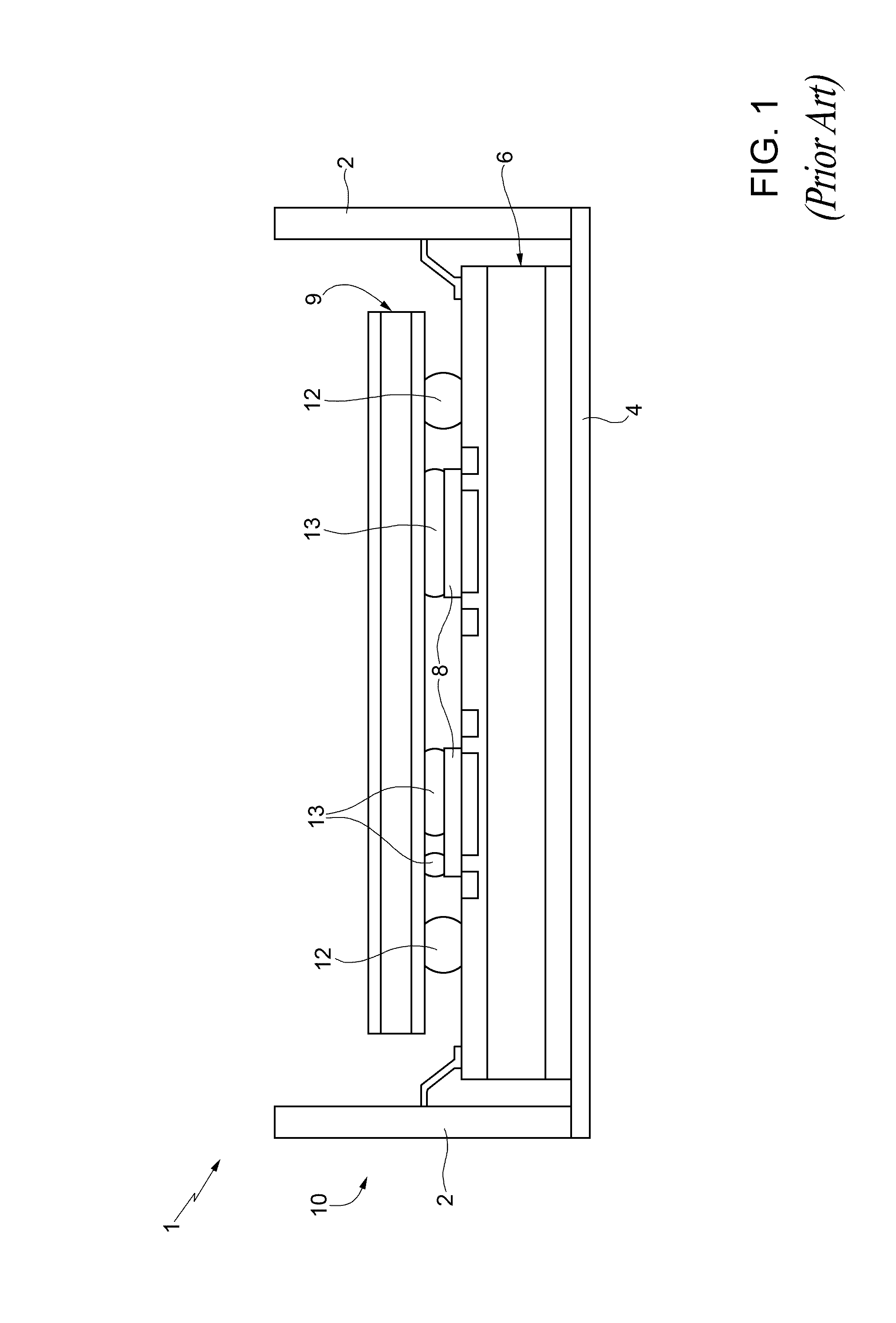

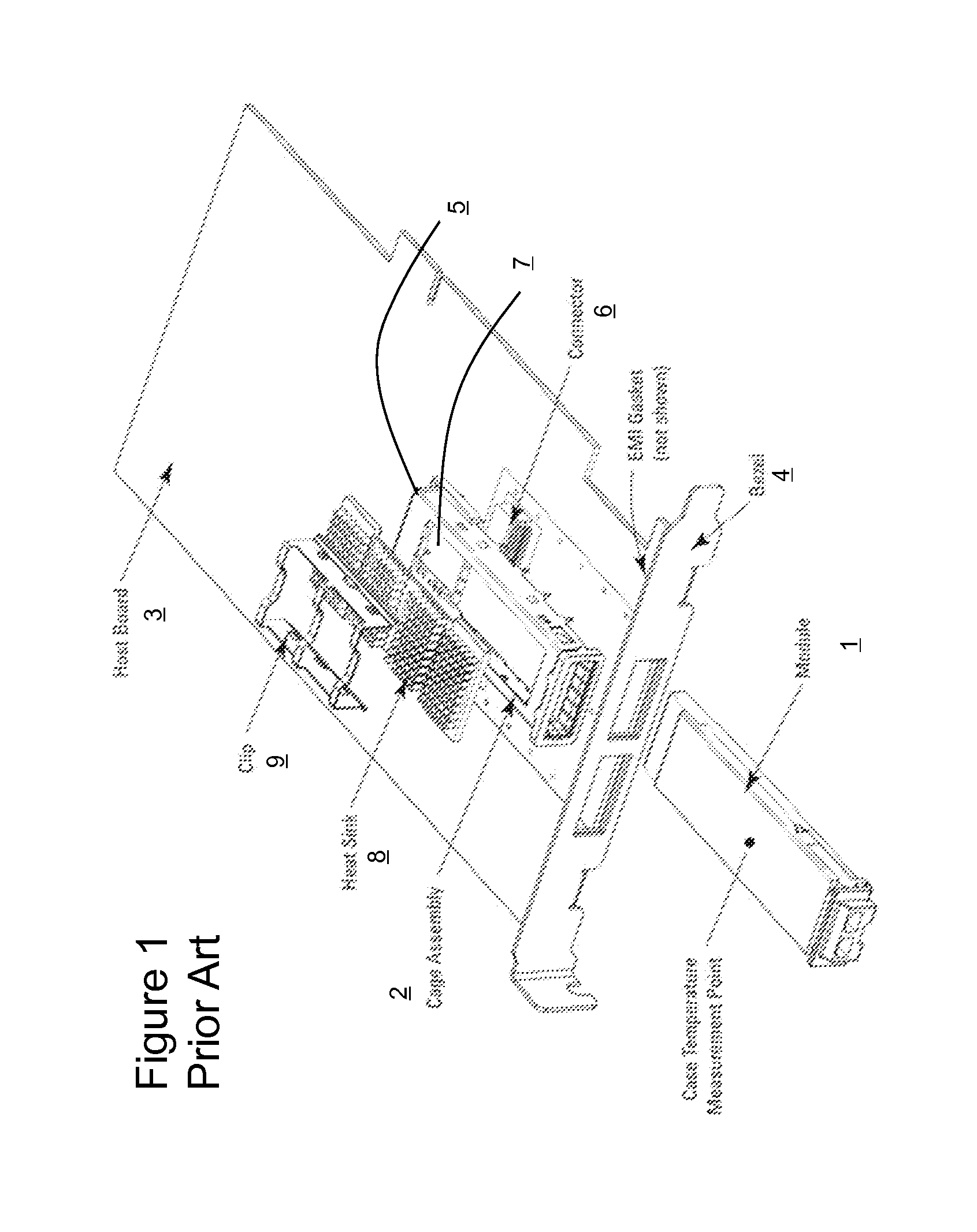

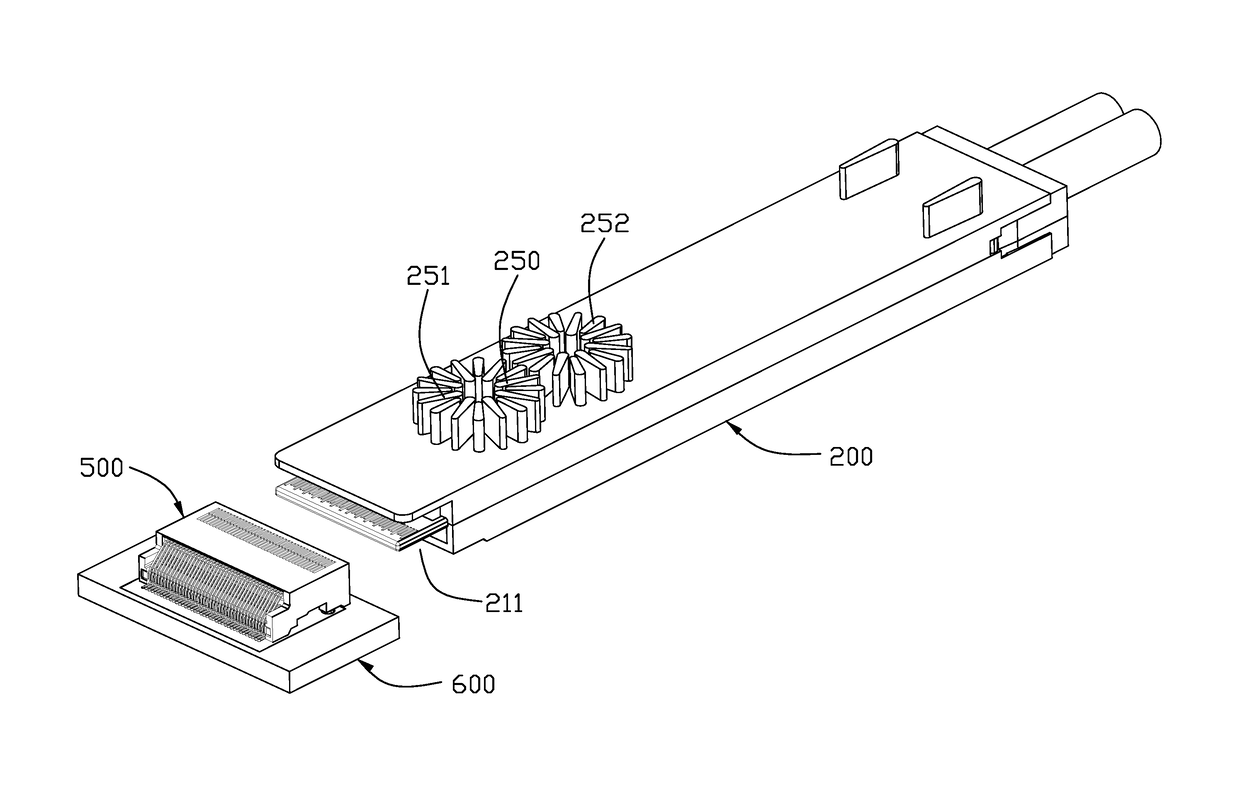

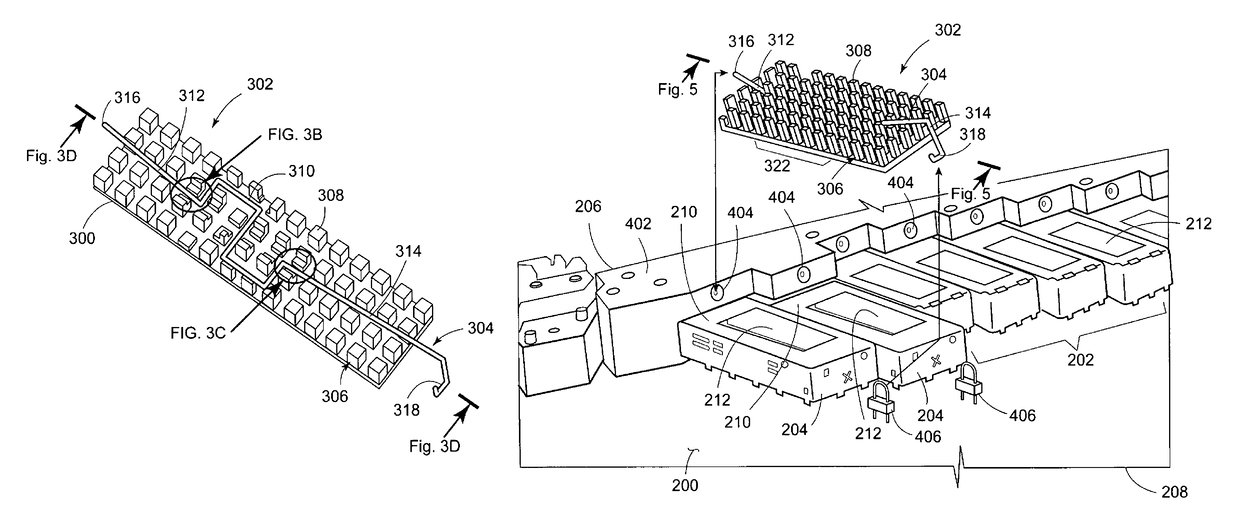

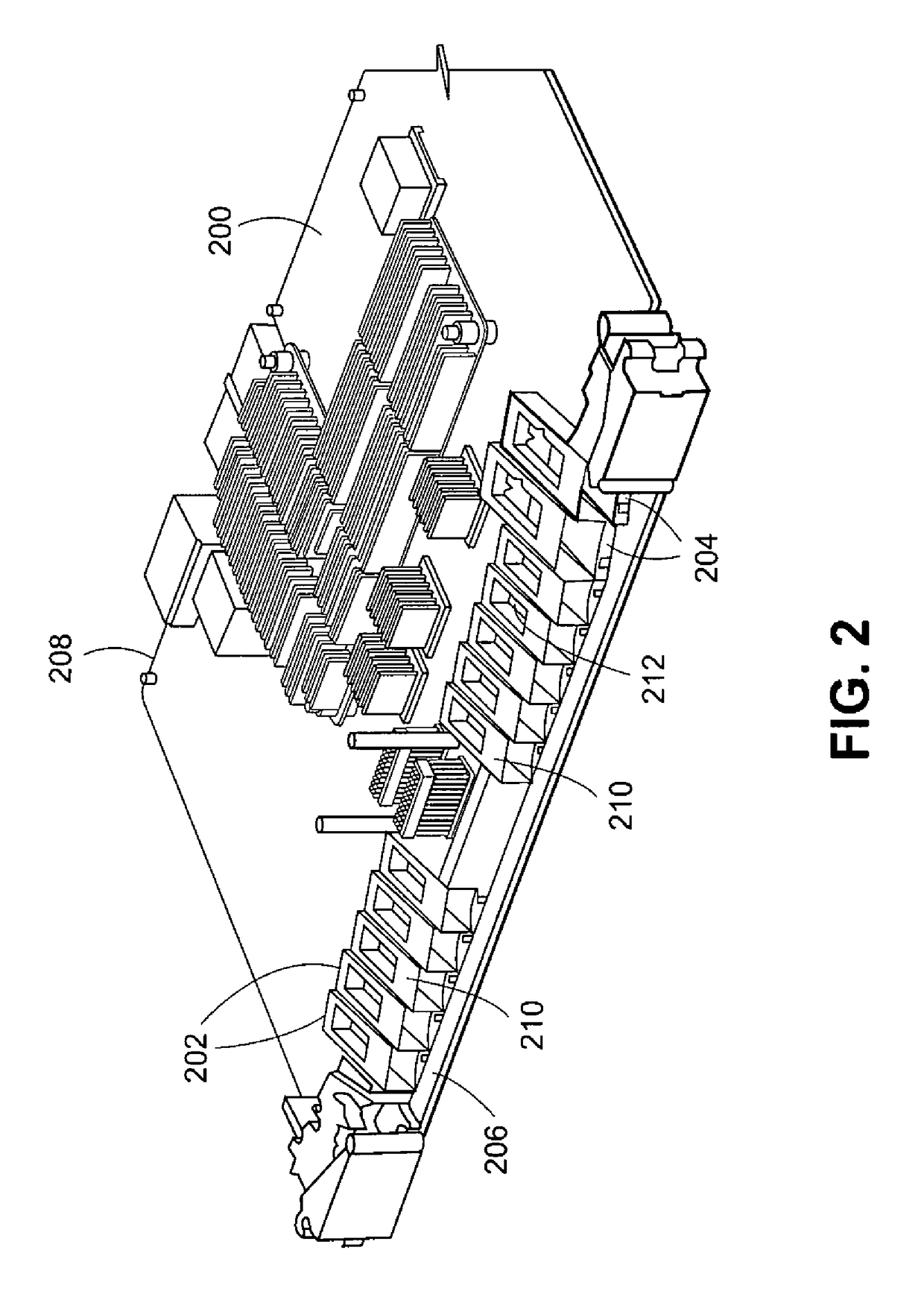

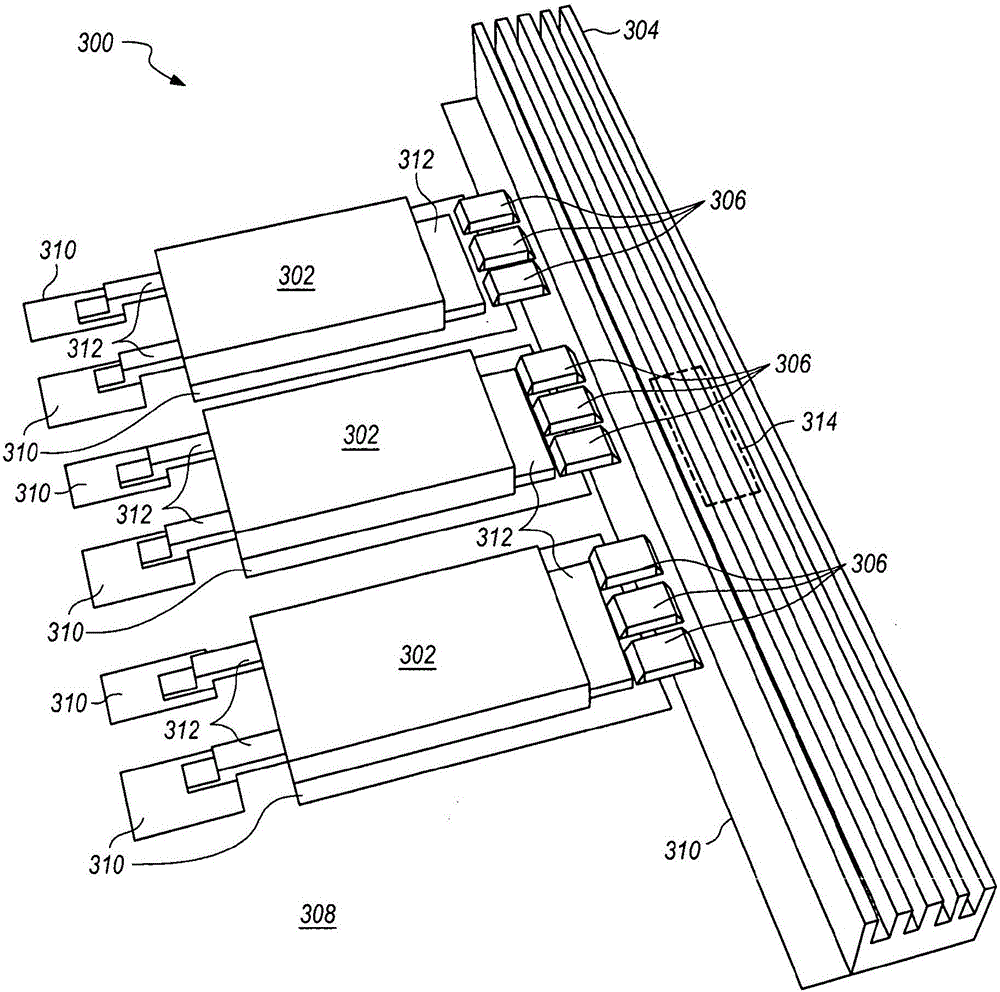

Fixation of heat sink on SFP/XFP cage

ActiveUS9681583B2Circuit thermal detailsSemiconductor/solid-state device detailsHigh densityEngineering

An apparatus and system for a heat sink assembly, and a procedure for forming a heat sink assembly. The heat sink assembly includes a heat sink having a base and fins extending from the base, and a spring clip disposed on the heat sink between the fins. The spring clip includes a first tab that forms a first angle with respect to the base of the heat sink and including a second tab that forms a second angle with respect to the base of the heat sink. The first and second tabs are attached to the circuit board. By virtue thereof, a heat sink attachment to cage is provided that is space-efficient and permits a higher density of cages on a circuit board than do conventional arrangements.

Owner:CORIANT OPERATIONS

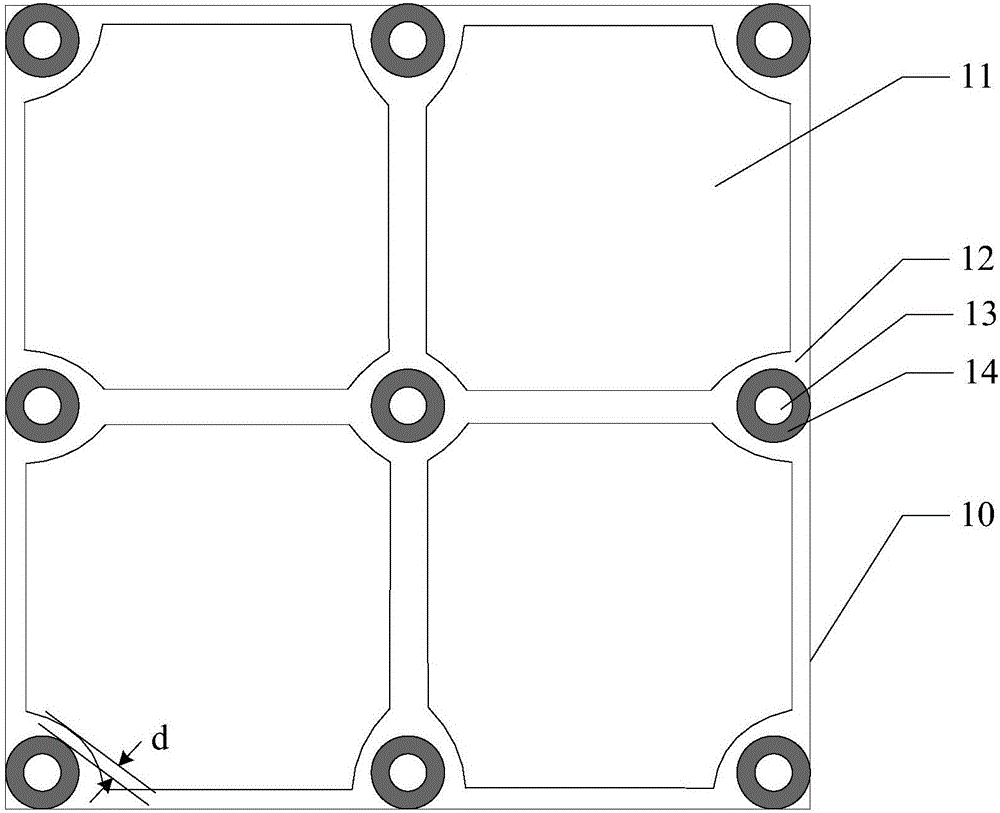

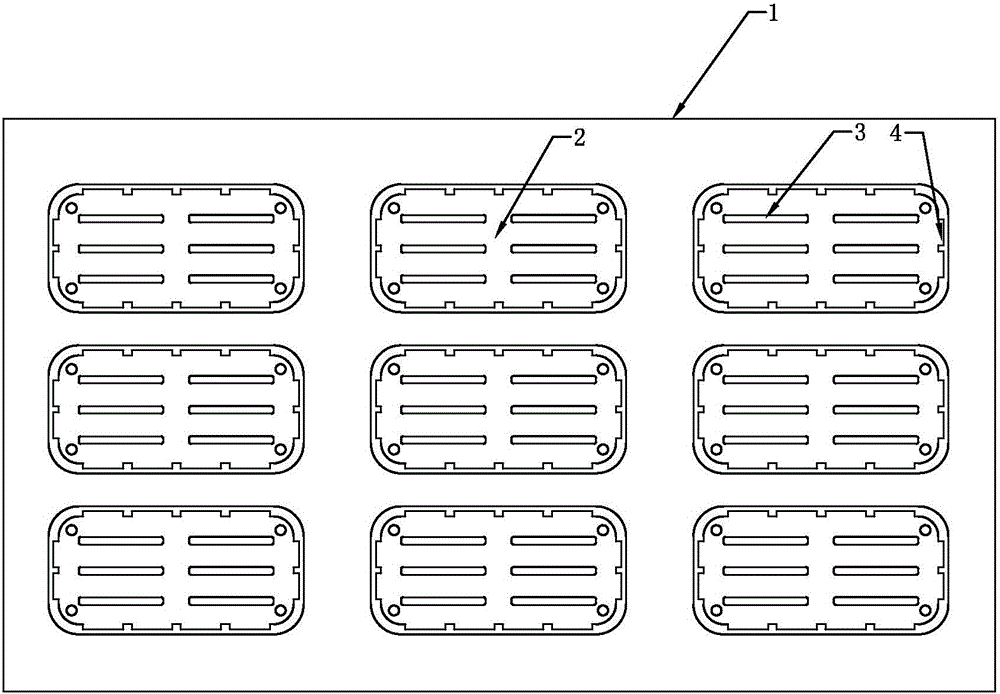

Circuit board processing tool for copper block brown oxidation

InactiveCN106211630AMeet browning needsSimple structureCircuit thermal detailsInsulating substrate metal adhesion improvementEngineeringCopper

The invention discloses a circuit board processing tool for copper block brown oxidation. The circuit board processing tool comprises a support plate, a plurality of accommodating cavities used for accommodating copper blocks are arranged on the support plate at an interval, bottom parts of the accommodating cavities are respectively provided with a plurality of via holes, and side walls of the accommodating cavities are provided with grooves. In the circuit board processing tool for copper block brown oxidation, the accommodating cavities of different specifications can be designed based on sizes of the copper blocks to be brown oxidized, requirements for brown oxidation of the copper blocks of different sizes can therefore be met, a horizontal brown oxidation line can be crossed via a normal PCB board brown oxidation mode, brown oxidation of other PCB boards cannot be affected, the circuit board processing tool is simple in structure and low in cost, the circuit board processing tool can be reused for many times, and the circuit board processing tool is convenient to operate and good in wearing property.

Owner:开平依利安达电子第三有限公司

Sliding thermal contact for pluggable optic modules

Present thermal solutions to conduct heat from pluggable optical modules into heat sinks use a metal heat sink attached with a spring clip. The interface between the pluggable module and the heat sink is simple metal-on-metal contact, which is inherently a poor thermal interface and limits heat dissipation from the optical module. Heat dissipation from pluggable optical modules is enhanced by the application of thermally conductive fibers, such as an advanced carbon nanotube velvet. The solution improves heat dissipation while preserving the removable nature of the optical modules.

Owner:LUMENTUM OPERATIONS LLC

Copper heat dissipation material, carrier-attached copper foil, connector, terminal, laminate, shield material, printed-wiring board, metal processed member, electronic device and method for manufacturing the printed wiring board

ActiveUS9724896B2Satisfactory performanceCell electrodesSemiconductor/solid-state device detailsSurface roughnessAlloy

A copper heat dissipation material having a satisfactory heat dissipation performance is provided. The copper heat dissipation material has an alloy layer containing at least one metal selected from Cu, Co, Ni, W, P, Zn, Cr, Fe, Sn and Mo on one or both surfaces, in which surface roughness Sz of the one or both surfaces, measured by a laser microscope using laser light of 405 nm in wavelength, is 5 μm or more.

Owner:JX NIPPON MINING & METALS CORP

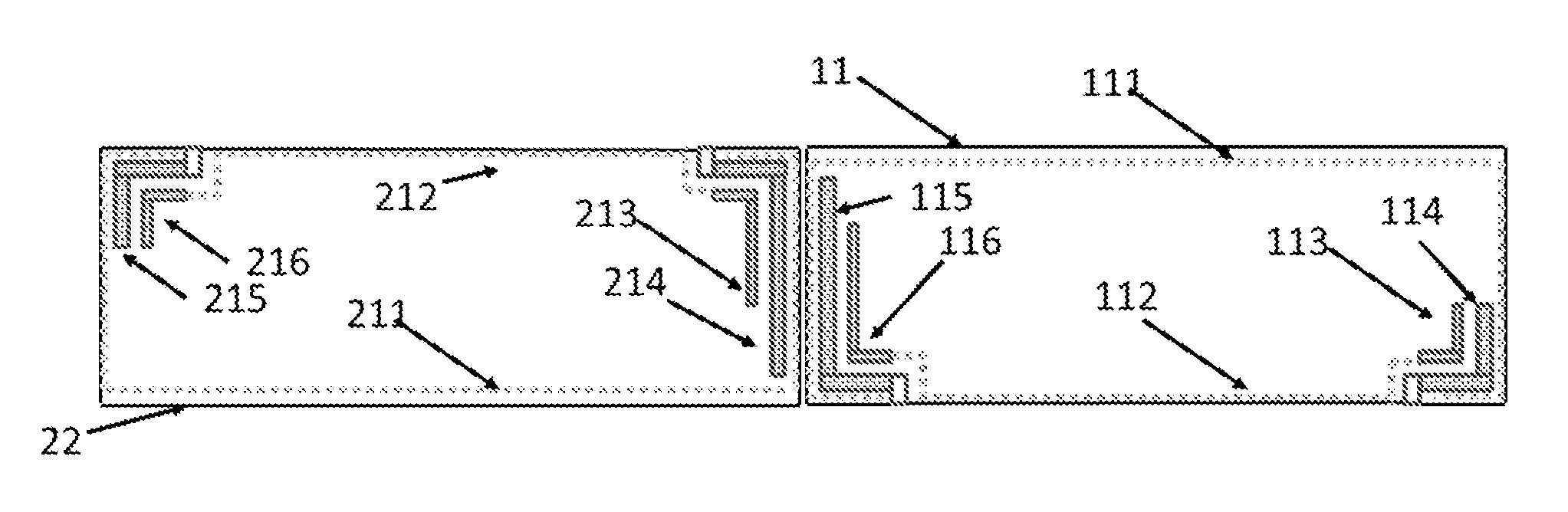

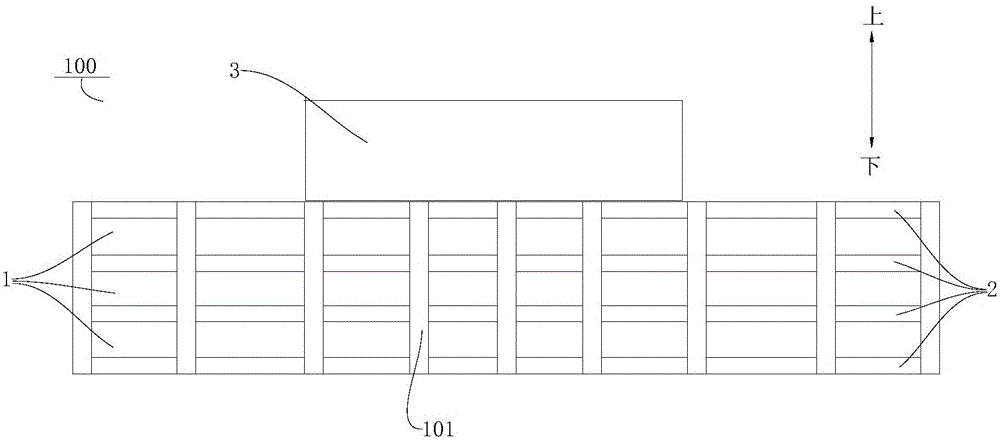

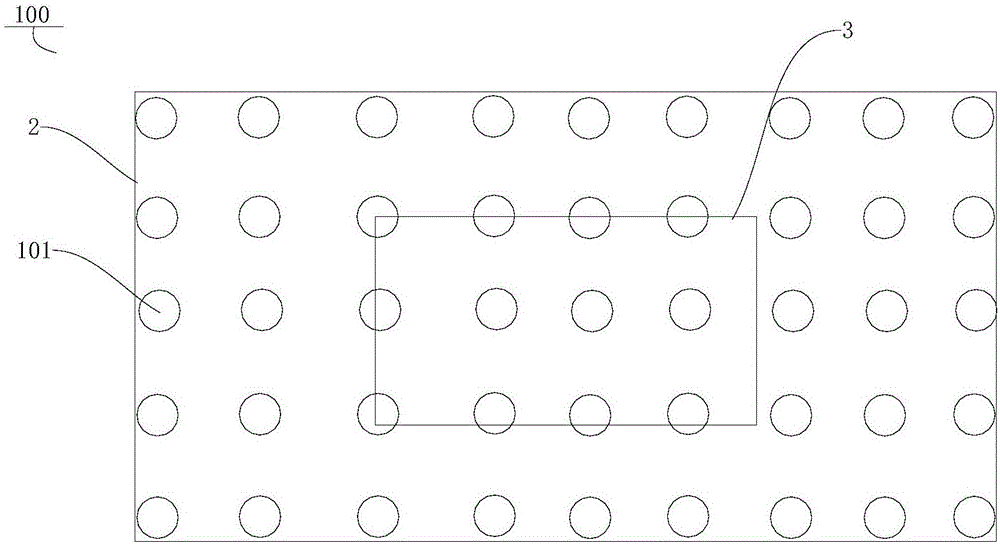

A PCB and a mobile terminal with the same

InactiveCN106231780AImprove cooling effectImprove cooling efficiencyCircuit thermal detailsCircuit thermal arrangementsInsulation layerElectronic component

The invention provides a PCB and a mobile terminal with the same. The PCB comprises a plurality of printed circuit layers, insulation layers, and a plurality of heat dissipation layers. Each printed circuit layer is formed from printed circuits. The printed circuit layers are stacked successively from top to bottom. The top-layer printed circuit layer of the multiple printed circuit layers is connected with an electronic component. Each insulation layer is arranged between every two adjacent printed circuit layers. The multiple heat dissipation layers and the multiple printed circuit layers are arranged on the corresponding insulation layers in one-to-one correspondence. Each heat dissipation layer is located right below the electronic component. The multiple heat dissipation layers are arranged right below the electronic component in the PCB, so that rapid and effective heat dissipation of the electronic component is achieved and the operation reliability of the electronic component and a mobile terminal is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Laminate and circuit board

ActiveUS20160286653A1Improve joint forcePrinted circuit assemblingCircuit thermal detailsElectronic componentRelative humidity

Provided are a laminate including a silver layer on a substrate, in which the silver layer includes a surface in which Kurtosis of a roughness curve satisfies at least one of Condition (i) the change rate of Kurtosis is greater than or equal to 50% under conditions of a temperature of 85° C. and a relative humidity of 85% after 240 hours have elapsed and Condition (ii) the change rate of Kurtosis is greater than or equal to 200% under conditions of a temperature of 85° C. and a relative humidity of 85% after 480 hours have elapsed, and a circuit board in which an electronic component is mounted on the surface of the laminate through a conductive joint portion.

Owner:TOPPAN EDGE INC

Electronic power module with enhanced thermal dissipation and manufacturing method thereof

ActiveUS9986631B2Improve cooling effectCircuit thermal detailsSemiconductor/solid-state device detailsDBcCoupling

An electronic power module comprising a case that houses a stack, which includes: a first substrate of a DBC type or the like; a die, integrating an electronic component having one or more electrical-conduction terminals, mechanically and thermally coupled to the first substrate; and a second substrate, of a DBC type or the like, which extends over the first substrate and over the die and presents a conductive path facing the die. The die is mechanically and thermally coupled to the first substrate by a first coupling region of a sintered thermoconductive paste, and the one or more conduction terminals of the electronic component are mechanically, electrically, and thermally coupled to the conductive path of the second substrate by a second coupling region of sintered thermoconductive paste.

Owner:STMICROELECTRONICS SRL

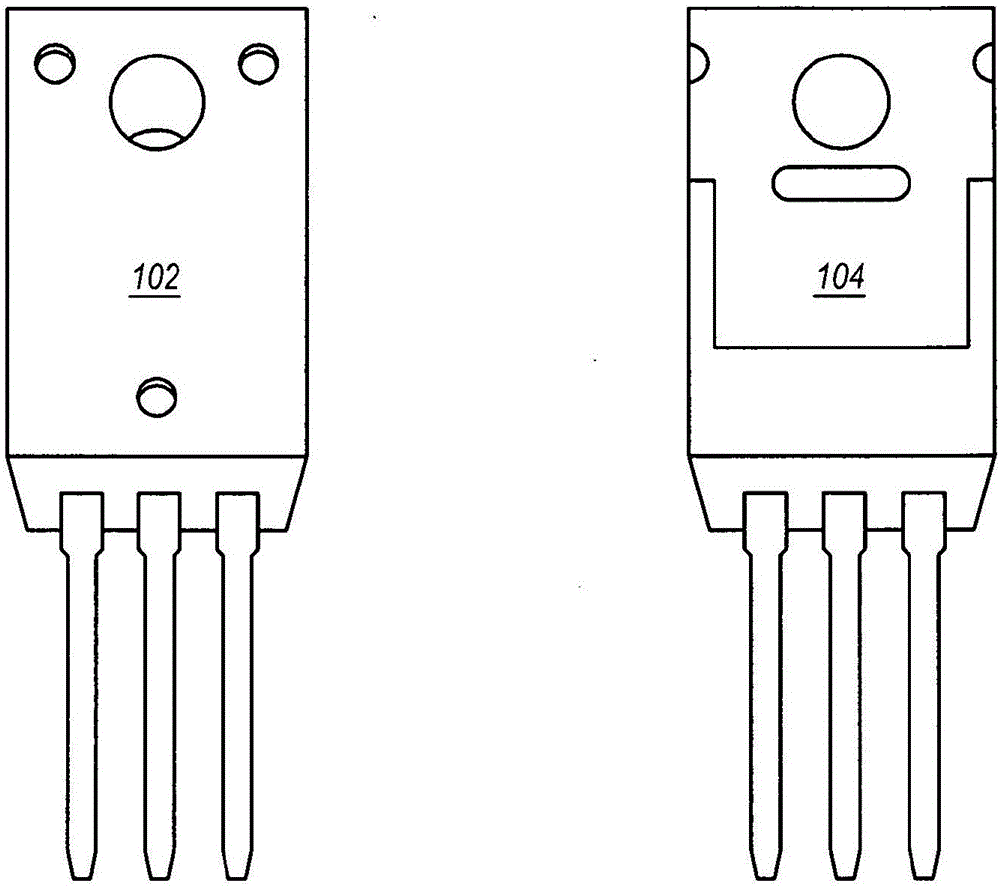

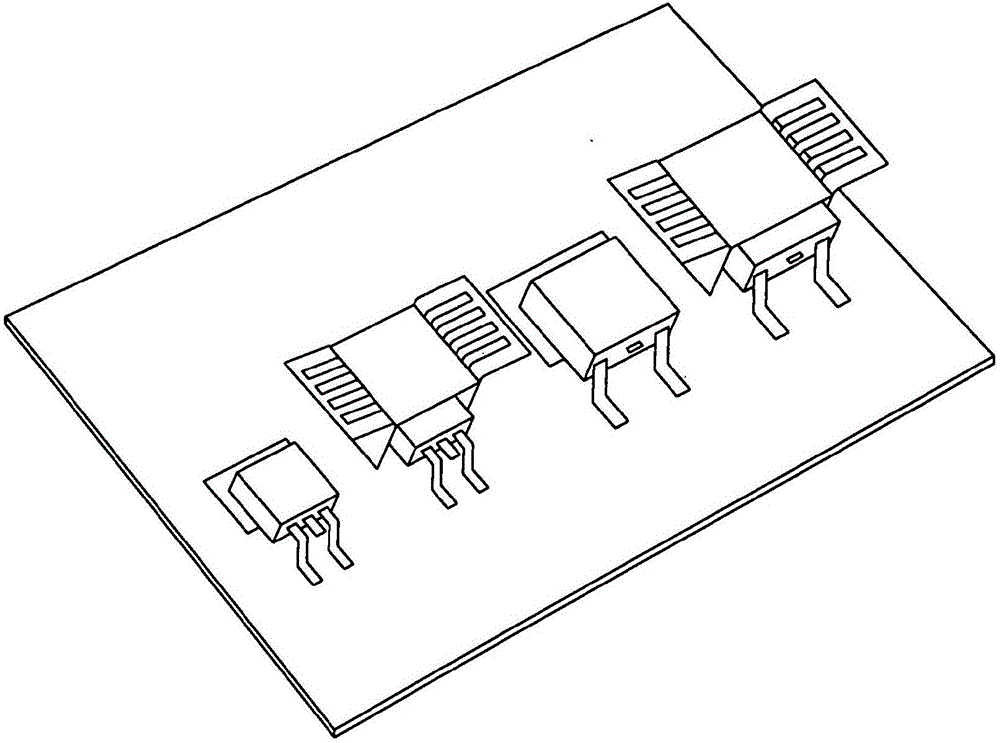

System and method for thermal management of electronic devices

InactiveCN106714510ACircuit thermal detailsSemiconductor/solid-state device detailsElectricityThermal bridge

A thermal management system and method for electronic devices is provided. The system includes an electronic device, a heat sink, and a thermally conducting and electrically insulating thermal bridge that is interposed between the electronic device and the heat sink. The thermal bridge thermally couples the electronic device to the heat sink and electrically isolates the electronic device from the heat sink. The electronic device, the heat sink, and the thermal bridge are mounted on a same planar surface of a printed circuit board.

Owner:TYCO HEALTHCARE GRP LP

Radiating flexible circuit board and surface coating thereof

InactiveCN106658948AImprove cooling effectExtended service lifeCircuit thermal detailsFlexible printed circuitsEpoxyCoated surface

The invention discloses a radiating flexible circuit board. The radiating flexible circuit board comprises a flexible insulating base layer, a conductive circuit layer and a radiating coating; the conductive circuit layer is located between the flexible insulating base layer and the radiating coating, and the flexible insulating base layer and the conductive circuit layer are bonded in a pressing manner after an adhesive is coated; the radiating coating is formed by curing the coated surface coating; and the surface coating is formed by mixing acrylic resin, epoxy resin, glass fibers, a heat-conducting filling, sodium dodecyl benzene sulfonate, a curing agent and a solvent at a high temperature of 88-105 DEG C. The radiating flexible circuit board provided by the invention solves the problem of local overheating caused by small used space of the existing flexible circuit board as the radiating coating is added on the surface of the conductive circuit layer, improves the heat radiation performance of the circuit board while the circuit board is efficiently protected against external impact damage, and is steady in performance, long in service life and wide in application foreground.

Owner:安徽鹏展电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com