System and method for thermal management of electronic devices

A technology for thermal management systems and electronic devices, which is applied in the direction of electrical components, electrical components, circuit heating devices, etc., and can solve problems such as increased parasitic capacitance, time-consuming, and manual assembly characteristics errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

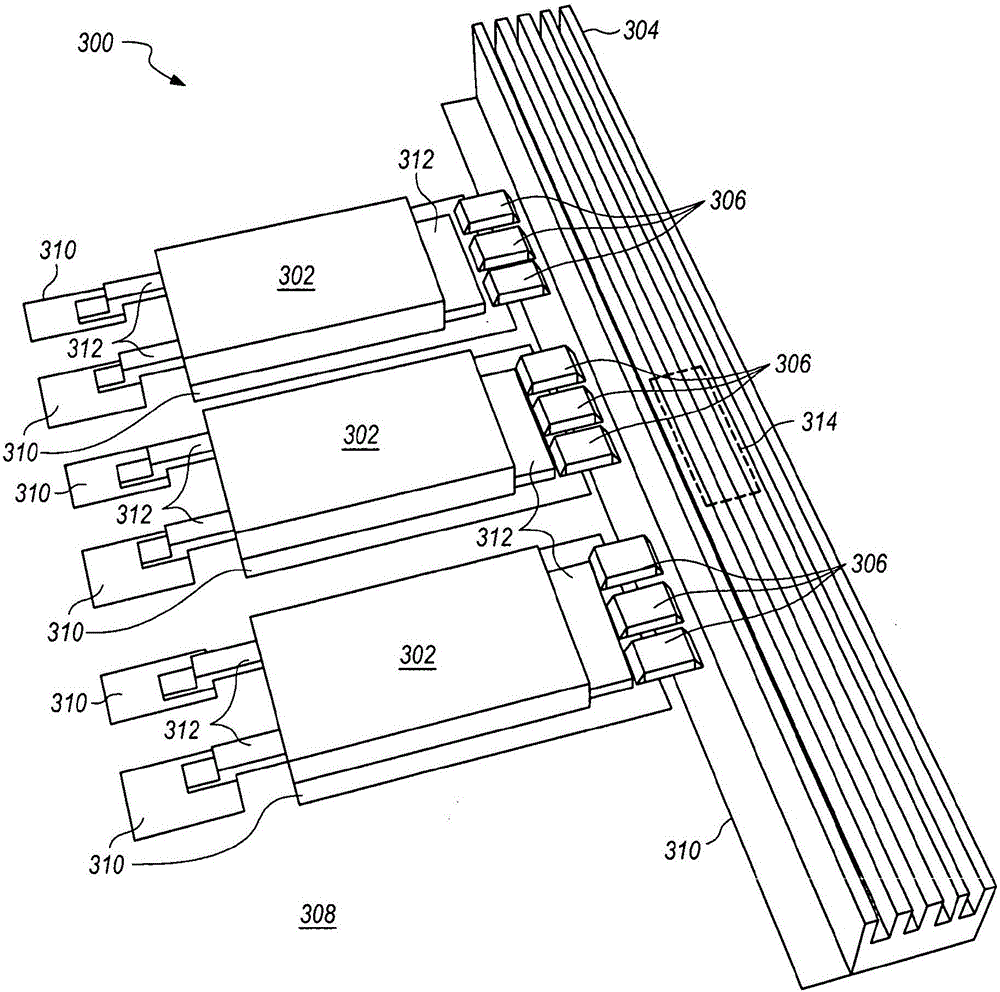

[0035] image 3 A diagram of a thermal management system 300 for an electronic device is shown. System 300 includes one or more electronic components 302 , a heat sink 304 , and one or more thermally conductive and electrically insulating thermal bridges 306 . In one example, semiconductor device 302 is a power field effect transistor (FET) or other device that generates heat during operation that must be conducted away from the device to manage device temperature so that it remains within normal operating limits.

[0036] Each thermal bridge 306 is between the heat sink 304 and a corresponding one of the electronic devices 302, thermally couples a corresponding one of the electronic devices 302 to the heat sink 304, and electrically connects a corresponding one of the electronic devices 302 to the heat sink 304. insulation. In one example, multiple thermal bridges (three thermal bridges in the example system 300 ) are interposed between the heat sink 304 and a respective one o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com