Printed circuit board

A technology for printed circuit boards and substrates, which is applied in the fields of printed circuits, printed circuits, and printed circuit manufacturing. It can solve problems such as tin leakage, short circuit, and aesthetic impact, and achieve the effect of preventing tin leakage through holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and preferred embodiment the present invention is described in further detail:

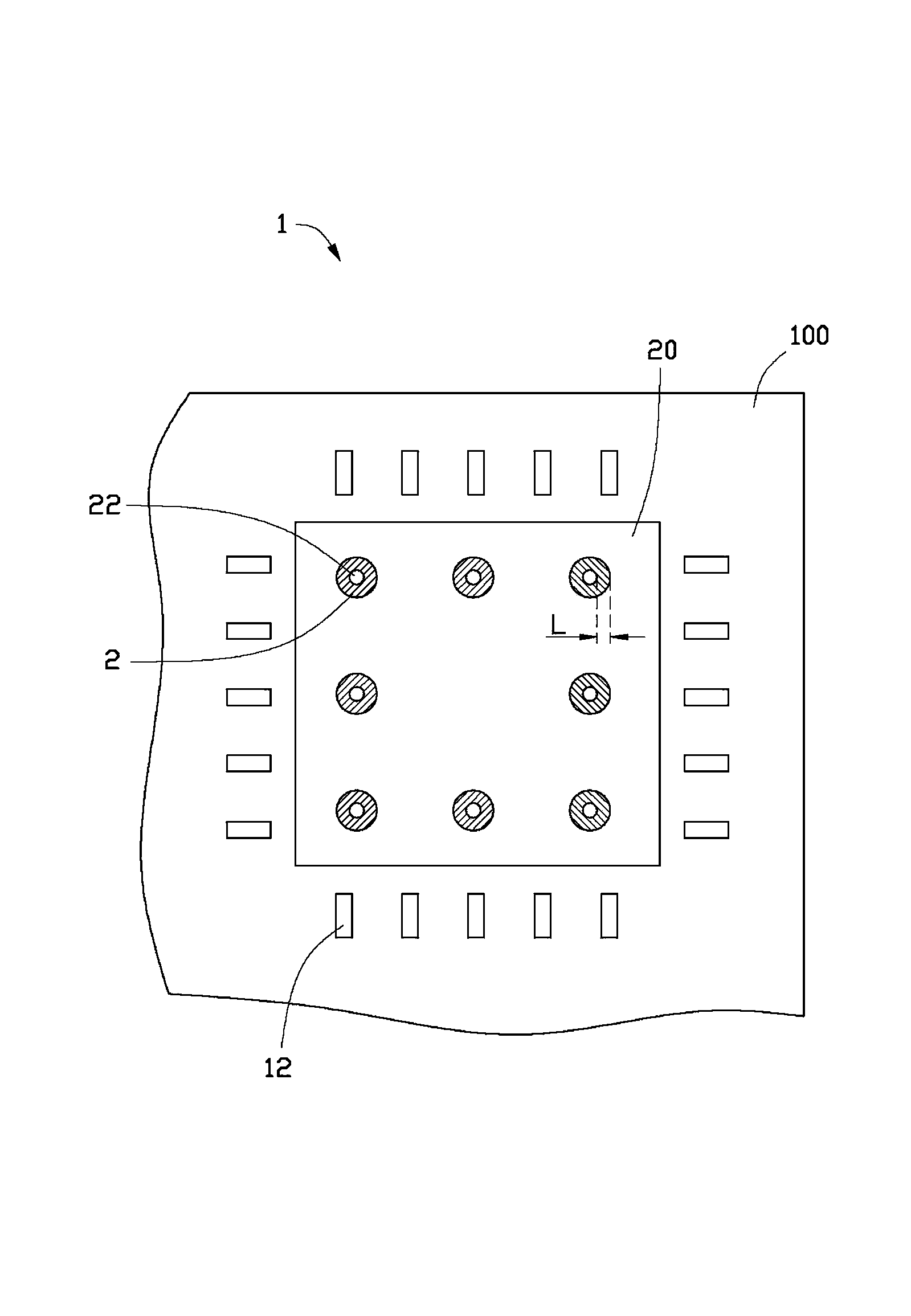

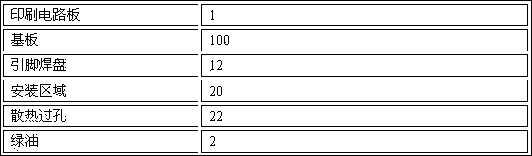

[0012] Please refer to figure 1 , the printed circuit board 1 of the present invention includes a substrate 100 . A mounting area 20 is provided on the substrate 100 for mounting a QFN packaged chip. A plurality of lead pads 12 are arranged around the installation area 20 , and a plurality of heat dissipation vias 22 are arranged on the installation area 20 , and a ring-shaped green oil 2 is arranged around each heat dissipation via 22 . The annular green oil 2 and the corresponding heat dissipation via hole 22 form concentric circles with a radius difference of L. The green oil 2 is solder resist. The rest of the installation area 20 is provided with copper foil. The shape of the green oil 2 is not limited to the ring shape in this embodiment, any shape of green oil can be arranged around the heat dissipation via hole 22 as required, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com