Method for regenerating positive active material from waste lithium iron phosphate batteries

A technology for lithium iron phosphate batteries and positive active materials, which is applied in battery electrodes, secondary batteries, battery recycling, etc., and can solve the problems of complex recycling process, poor phase uniformity, and low recovery rate of target products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

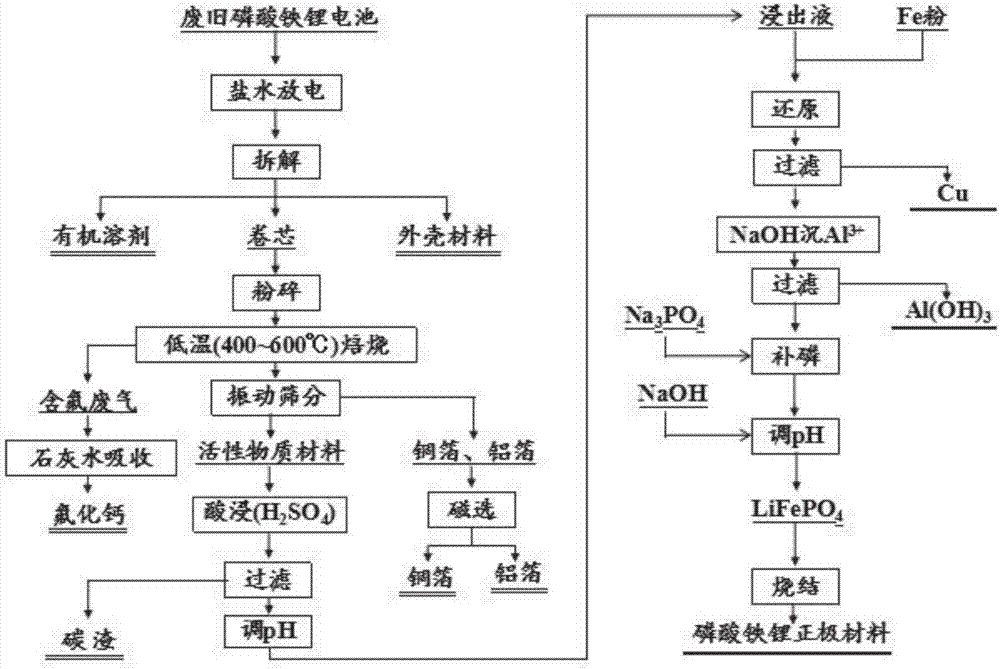

Method used

Image

Examples

Embodiment 1

[0079] Soak the waste lithium iron phosphate battery in 20g / L sodium chloride solution until the end-of-discharge voltage is 0.5V, and manually disassemble and separate the organic solvent, winding core and shell. The winding core is mechanically crushed, and the crushed particle size is 5mm. It is roasted in the air at 500°C for 5 hours, and then the active material and copper and aluminum foil are screened out by vibration. The roasting waste gas is absorbed by 40mg / L lime aqueous solution, and the copper foil is obtained by magnetic separation. and aluminum foil, the active material is leached with 2mol / L sulfuric acid, the pH value is controlled to 0.5, and the carbon residue and leachate are obtained by filtration and separation. Then add copper and Fe to the leachate 3+ 1.1 times the theoretical amount of iron powder, the Fe 3+ and Cu 2+ reduced to Fe 2+ and copper simple substance, remove the filter residue after filtering, then add appropriate amount of sodium hydro...

example 1

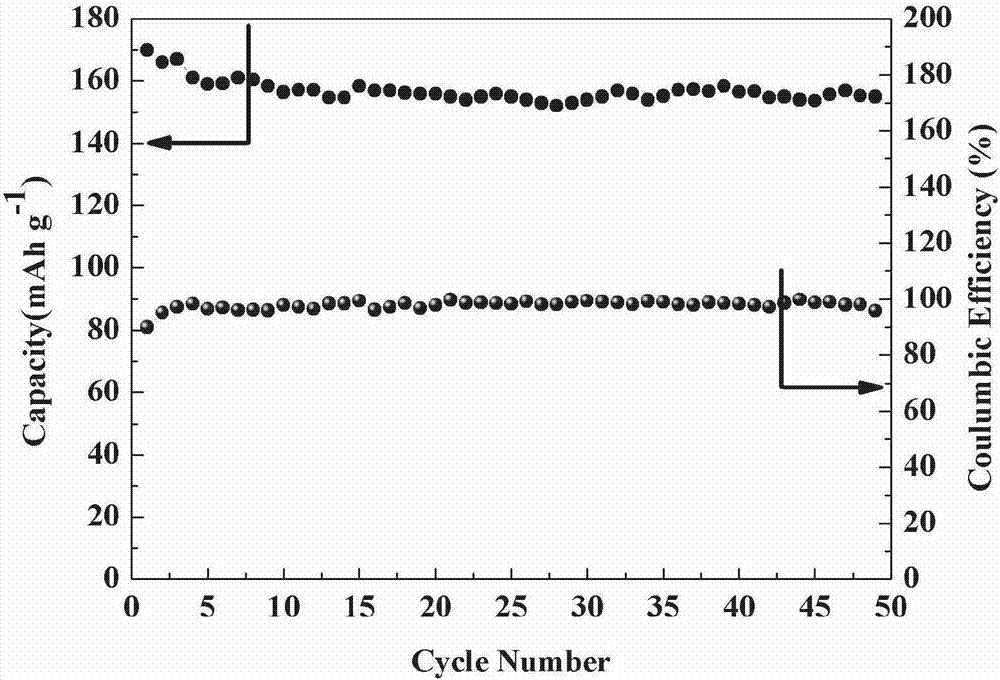

[0083] The electrochemical performance of the lithium iron phosphate that example 1 reclaims is as image 3 shown.

Embodiment 2

[0085]Soak the waste lithium iron phosphate battery in 30g / L sodium chloride solution until the end-of-discharge voltage is 0.1V, disassemble and separate the organic solvent, winding core and shell. The winding core is mechanically crushed, and the crushed particle size is 6mm. It is roasted in the air at 400°C for 10 hours, and then the active material and copper and aluminum foil are screened out by vibration. The roasting waste gas is absorbed by 40mg / L lime aqueous solution, and the copper foil is obtained by magnetic separation. and aluminum foil, the active material is leached with 5mol / L sulfuric acid, the pH value is controlled to be equal to 1, and the carbon residue and leachate are obtained by filtration and separation. Then the theoretical amount of copper removal and Fe in the leaching solution 3+ 1 times iron powder, remove the copper-containing filter residue after filtering, then add an appropriate amount of potassium hydroxide to the filtrate to adjust the pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com