Thermally highly conductive coating on base structure accommodating component

A high thermal conductivity, substrate technology, used in circuit thermal components, printed circuit components, semiconductor/solid-state device components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

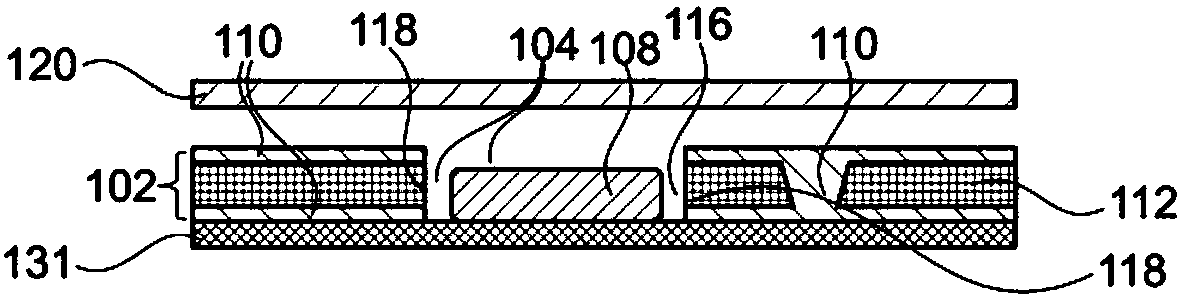

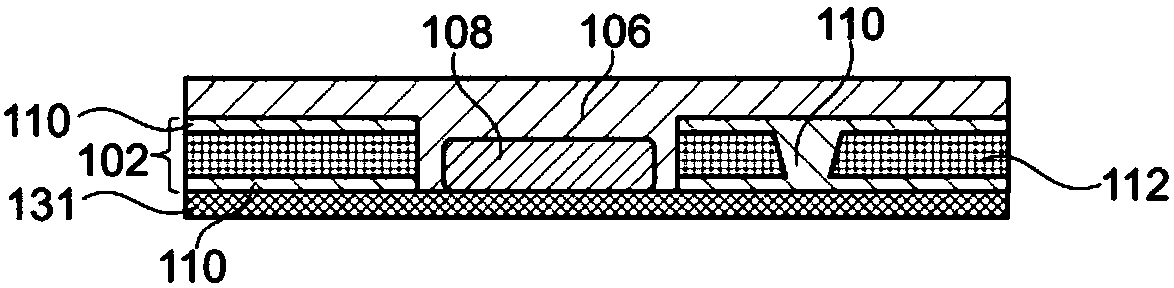

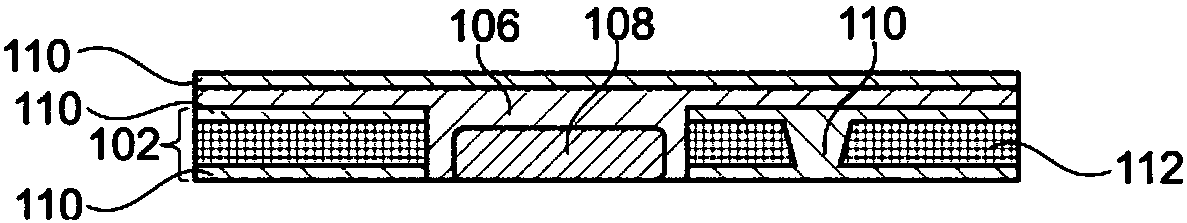

[0053] Before referring to the drawings, exemplary embodiments will be described in further detail and some basic considerations upon which exemplary embodiments of the invention have been formed will be outlined.

[0054] According to an exemplary embodiment of the invention, heat can be dissipated directly in the case of embedding the component in the component carrier. One gist according to an exemplary embodiment is to allow heat to dissipate from the area of the component carrier where the component is placed. By taking this measure, it is possible to reduce the thermal cycle range, or lower the operating temperature in the area around the embedded component and on / on the component itself which is subject to high heat dissipation. According to an exemplary embodiment, the component carrier design is configured to allow for improved heat flow and dissipation from the area in which the component is embedded. Several materials can be advantageously implemented for this pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com