Patents

Literature

85results about How to "Prevent affecting processing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

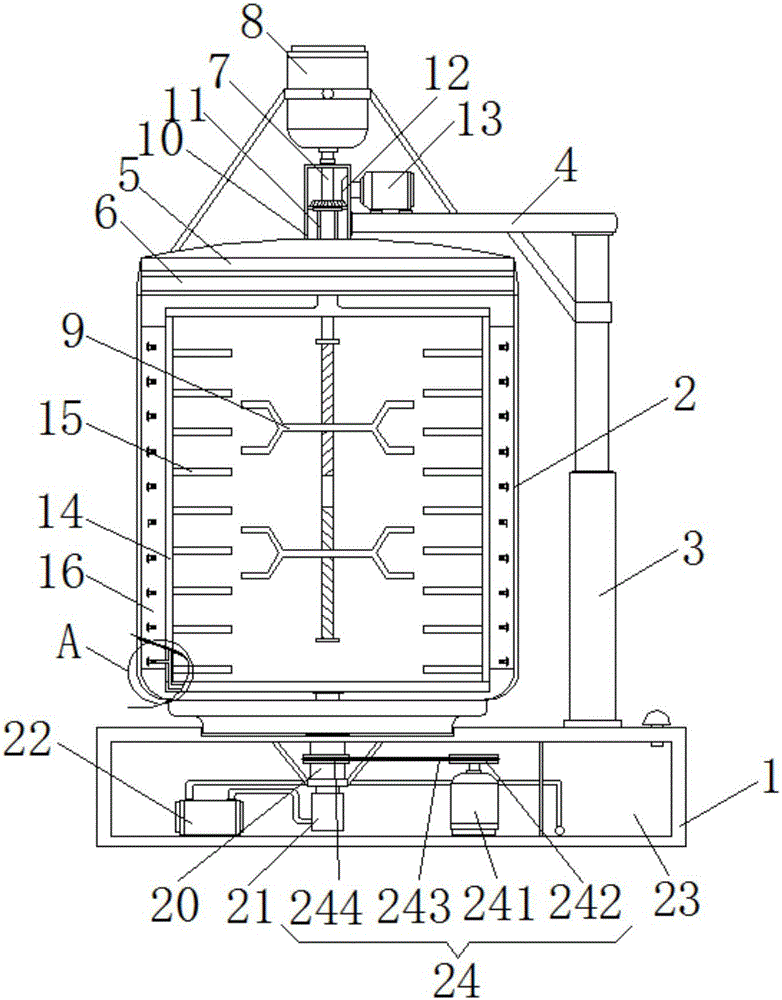

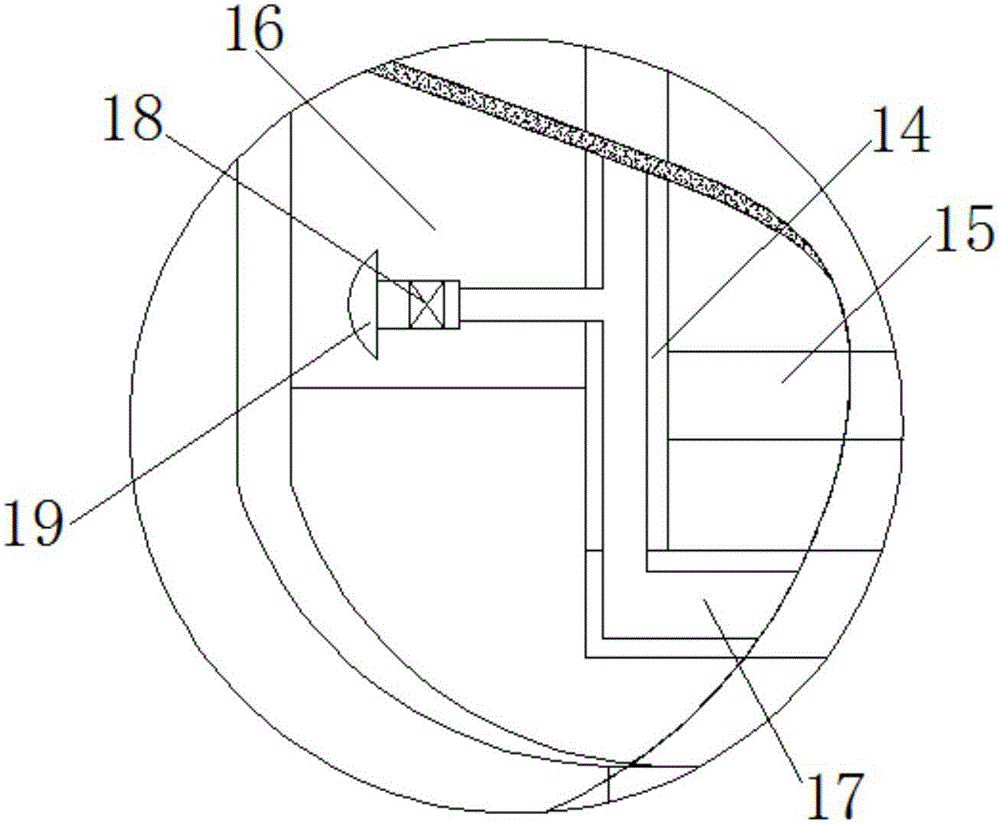

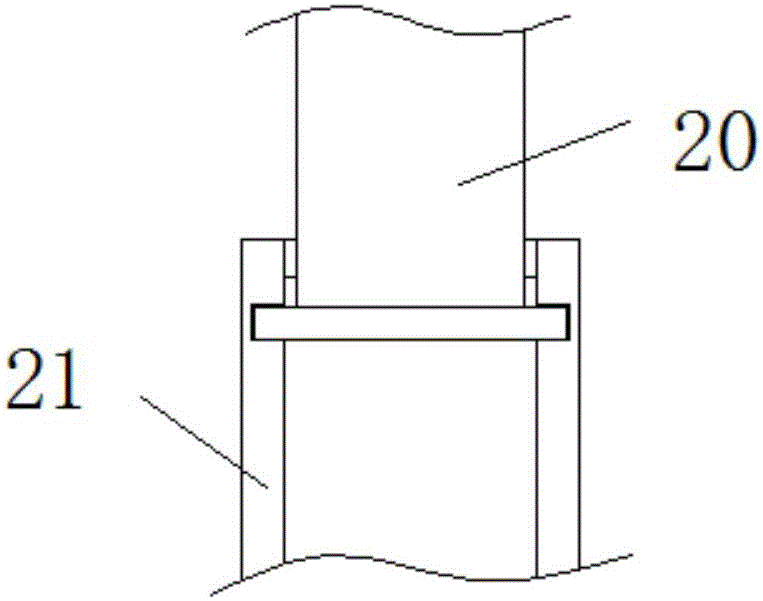

Uniform-mixing efficient vacuum stirring machine

InactiveCN107175029AImprove processing efficiencyWell mixedRotary stirring mixersTransportation and packagingPulp and paper industryVacuum pump

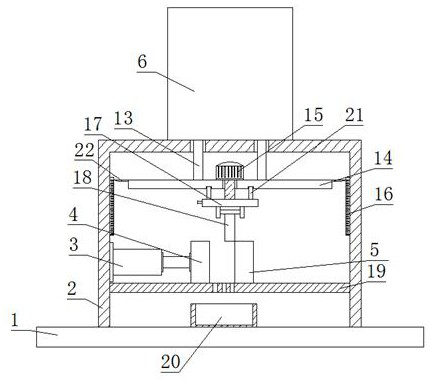

The invention relates to the technical field of vacuum stirring machines, and discloses a uniform-mixing efficient vacuum stirring machine. The uniform-mixing efficient vacuum stirring machine comprises a hollow base, wherein a stirring barrel and a hydraulic retractable rod are movably mounted on the upper surface of the base successively from left to right; a supporting plate is fixedly mounted at the top end of the hydraulic retractable rod; a sealing cover covers an opening of the stirring barrel; a vacuum pump which communicates with the stirring barrel is arranged in the sealing cover; a lead screw which penetrates in and extends into the stirring barrel is inserted in the middle of the sealing cover; stirring paddles sleeve the lead screw; and the top end of the lead screw is fixedly connected with an output shaft of a first servo motor fixedly mounted on the sealing cover. According to the uniform-mixing efficient vacuum stirring machine, by the lead screw with forward screws and reverse threads and the stirring paddles, up-down stirring movement can be carried out in stirring, and meanwhile, by stirring fins, mixing uniformity can be greatly improved.

Owner:宁波智正伟盈信息科技有限公司

Plate processing and cutting equipment convenient to clean

InactiveCN107738319AReduce driftProtect healthProfiling/shaping machinesBark-zones/chip/dust/waste removalAgricultural engineeringHuman health

The invention relates to the technical field of processing equipment, and discloses a plate processing and cutting equipment that is convenient for cleaning, including a workbench, one side of the top of the workbench is fixedly connected with a fixed seat, and the top of the fixed seat is fixedly connected with a hydraulic cylinder , the top of the hydraulic cylinder is fixedly connected with a hydraulic telescopic rod, one side of the hydraulic telescopic rod is fixedly connected with a beam, the bottom of the beam is fixedly connected with a slide rail, and the inside of the slide rail is movably connected with a cutting device, The cutting device includes a slider. This easy-to-clean plate processing and cutting equipment, through the cooperation of the telescopic column and the spring, the limit plate clamps the wood body to prevent the wood body from shifting during cutting, which affects the processing quality. The exhaust fan drains the air to reduce the flying of sawdust and protect the health of the staff. Through the drawer on the side of the workbench, the sawdust in the collection tank falls into the drawer, which is convenient for the staff to clean up in a centralized manner.

Owner:江门市尚林板饰厂有限公司

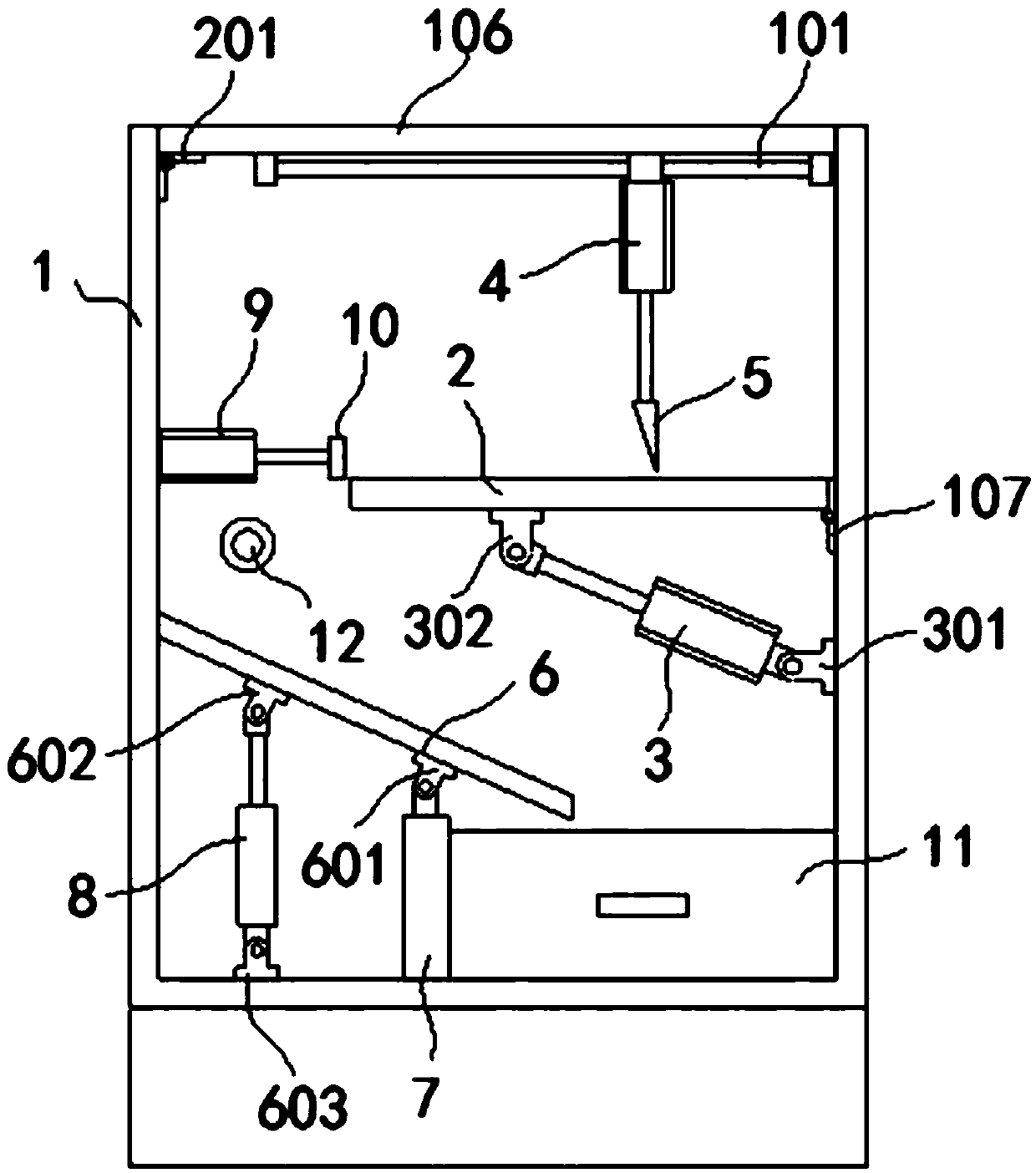

Thermal cutting device for chemical fabric

InactiveCN107604629APrevent affecting processing qualityAvoid wrinklesSevering textilesWrinkle skinEngineering

The invention relates to a thermal cutting device for chemical fabric. The device comprises a tank body, a first motor is fixedly connected to the portion, close to a first supporting column, of the bottom of an inner cavity of the tank body, and a first belt wheel is connected with the outer surface of a second belt wheel through a first belt in a sliding mode; a first gear is meshed with the outer surface of a second gear through a gear belt in a transmission mode, a pressing device is fixedly connected with the side, away from the tank body, of the bottom of a supporting plate, and a lifting device is fixedly connected with the middle of one side of the top, away from the inner cavity of the tank body, of a connection block; a horizontal mobile device is fixedly connected to the side, away from the connection block, of the lifting device, and a thermal cutting device body is fixedly connected to the side, away from the lifting device, of the horizontal mobile device. The invention relates to the technical field of chemical fabric processing. The device can process chemical fabric products of various specifications, replacement and further cutting processing are avoided, the timeis saved, the cost is lowered, wrinkles are prevented, and the situation is avoided that the phenomenon of easy silk falling-off of cutting edges of the chemical fabric happens and accordingly the processing quality is influenced.

Owner:HUZHOU WUTENG NEW MATERIAL

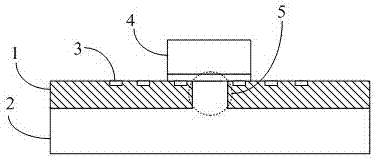

Method for manufacturing pyroelectric separation LED plate

InactiveCN107278030AImprove machining accuracyPrevent affecting processing qualityCircuit thermal detailsMetal core circuit manufactureEtchingBiochemical engineering

The invention provides a method for manufacturing a pyroelectric separation LED plate. For the structural characteristics of the pyroelectric separation LED plate, the method employs steps different from the steps of a manufacturing method for a common LED plate, and comprises a step of optimizing a thermal conduction part at steps of copper plate etching and insulating layer manufacturing: pasting a film before the etching of a copper plate, carrying out the exposing and development, enabling other parts, expect the thermal conduction part, of the copper plate to be exposed, and carrying out the half-etching of the copper plate, thereby improving the half-etching precision. The method also comprises a step of carrying out the groove milling of a PP piece corresponding to the thermal conduction part of the copper plate during the manufacturing of the insulating layer, wherein the slot size of the groove milling is 0.2mm greater than the length of the single side of the thermal conduction part of the copper plate, thereby guaranteeing that the PP piece can be sleeved by the copper piece after groove milling, preventing slight deviation from affecting the machining quality during stitching, and effectively improving the product quality through the above means.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

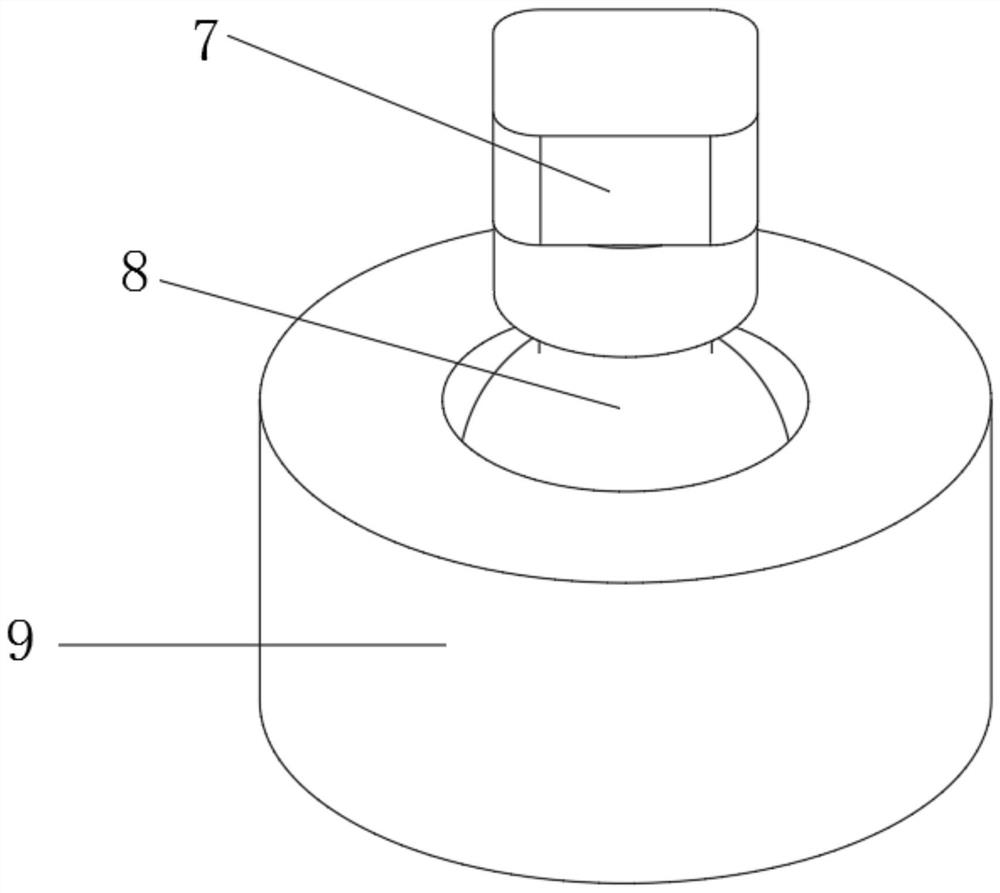

Grinding device for bearing machining

InactiveCN107263239ASmooth rotationEasy to adjustEdge grinding machinesGrinding work supportsArchitectural engineering

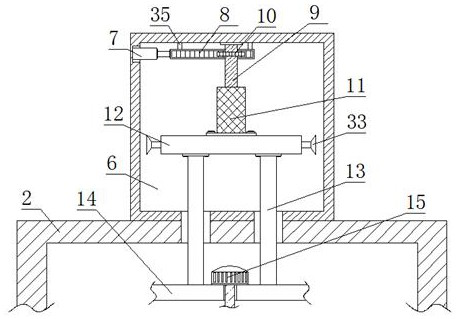

The invention discloses a grinding device for bearing processing, comprising a base, the left side and the right side of the top of the base are respectively fixedly connected with a first support column and a second support column, and the first support column and the second support column The top of the support plate is fixedly connected with a support plate, the top of the support plate is fixedly connected with a motor box, the inside of the motor box is provided with a motor, the output shaft of the motor is fixedly connected with a threaded rod, and the end of the threaded rod is far away from the output shaft of the motor A threaded sleeve is sheathed on the outside of the motor box and the support plate and extends to the support plate in turn. The invention facilitates the rotation of the rotating rod in the movable groove through the setting of the fixed block and the movable groove, and facilitates the adjustment of the screw rod through the setting of the handle. Through the setting of the screw rod, the operation table is driven to move through the cooperation with the fixed shaft, and the bearing The grinding angle is adjusted, and at the same time, it solves the problems that the grinding angle cannot be adjusted, the use is inconvenient, and the production efficiency is reduced.

Owner:LEIYANG XINDAWEI TECH

Portable steel wire rust removal device

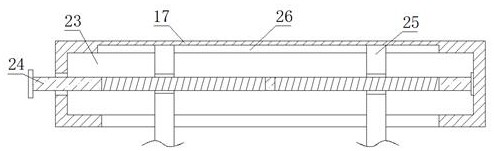

The invention relates to the field of steel wire rust removal, in particular to a portable steel wire rust removal device. The portable steel wire rust removal device comprises a shell, a first rotating shaft, a handle, buckles, rust removal device bodies and a control device; the shell is formed in a manner that two same semi-toroidal structures are hinged at one end through the first rotating shaft, the handle is arranged on t he shell, the buckles are arranged on the two open ends of the shell, the handle can facilitate taking of the device, the number of the rust removal device bodies is two, each rust removal device body comprises a motor, a gear, a second rotating shaft, a rust removal ring and a third rotating shaft, one end of each second rotating shaft is fixedly connected with the corresponding motor, the other end of each second rotating shaft is fixedly connected with the corresponding gear, the dust removal rings are arranged in round grooves in the inner wall of the shell, the control device is arranged on the side wall of the shell. A steel wire on a machine can be directly subject to rust removal, the steel wire does not need to be dismounted, manpower and materialresources are saved, a closed-ring steel wire can be subject to rust removal, the practical range is wide, the device can carry out local derusting on the steel wire, the phenomenon that in the traditional process, the whole steel wire is put into a dust remover is avoided, and resources are saved.

Owner:姚森

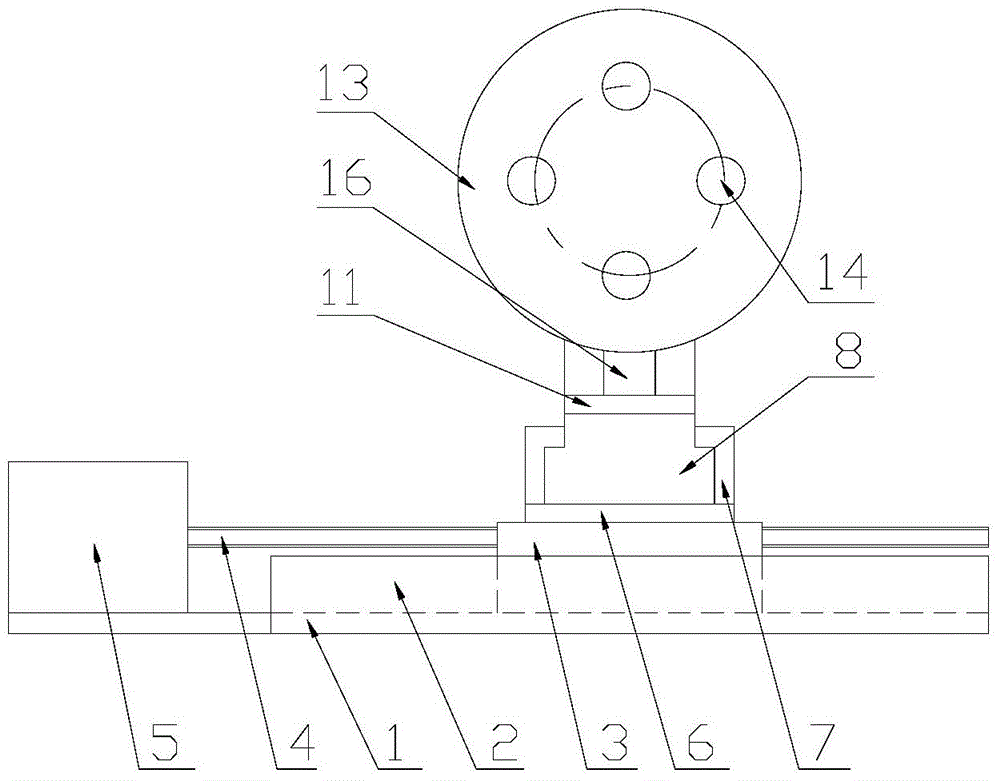

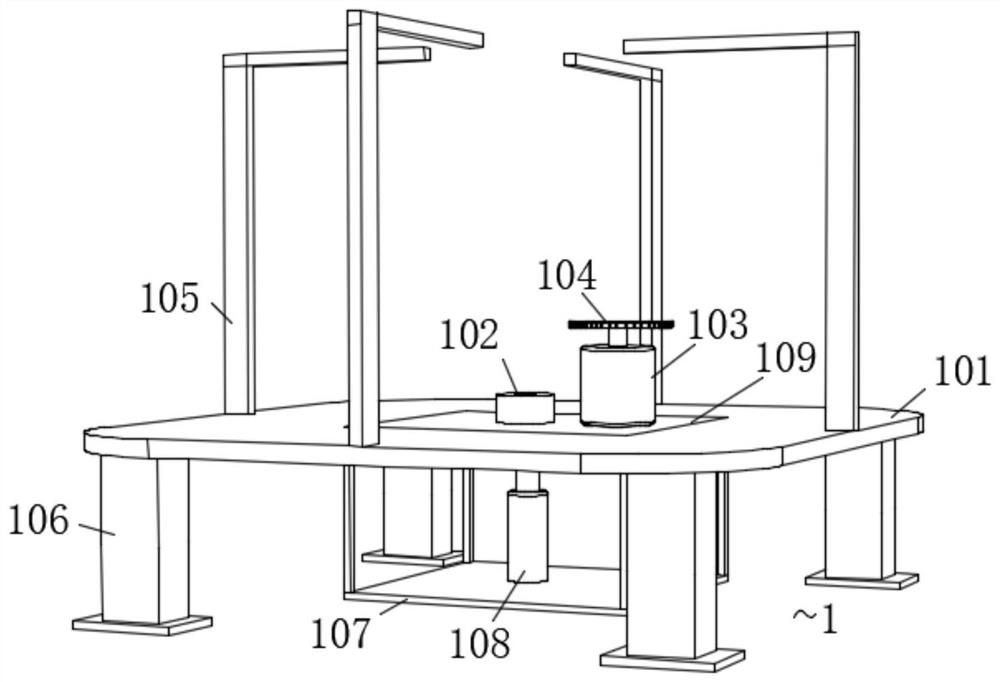

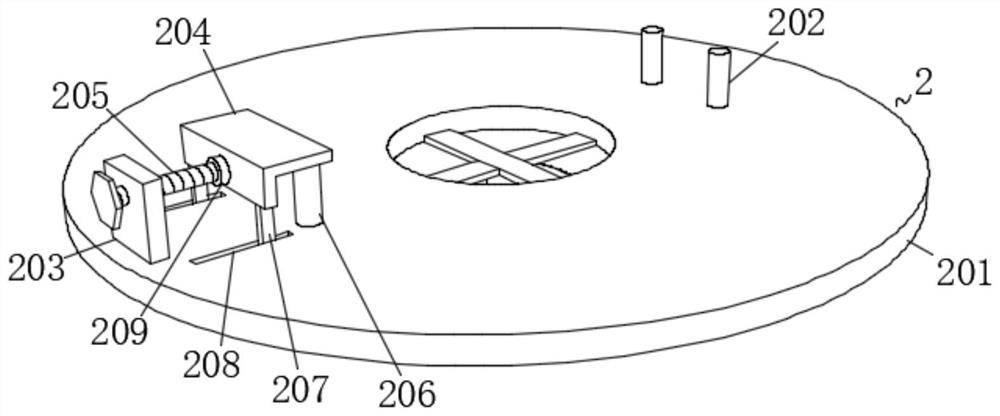

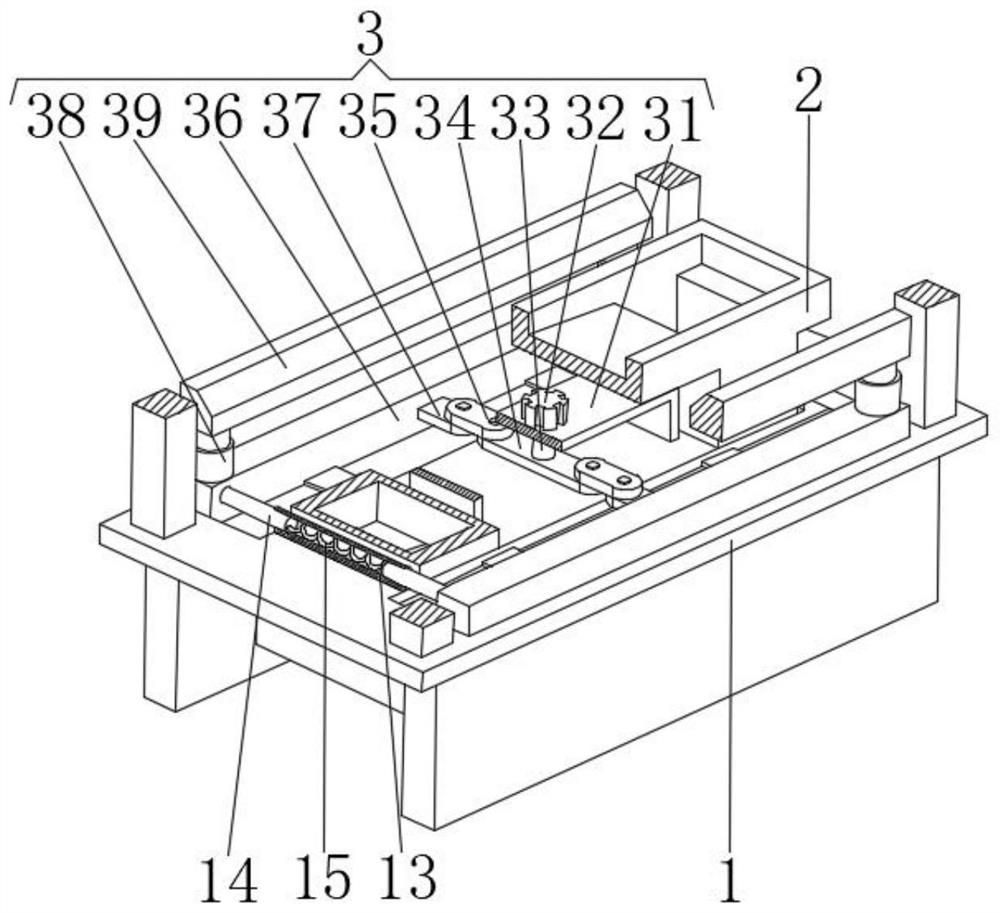

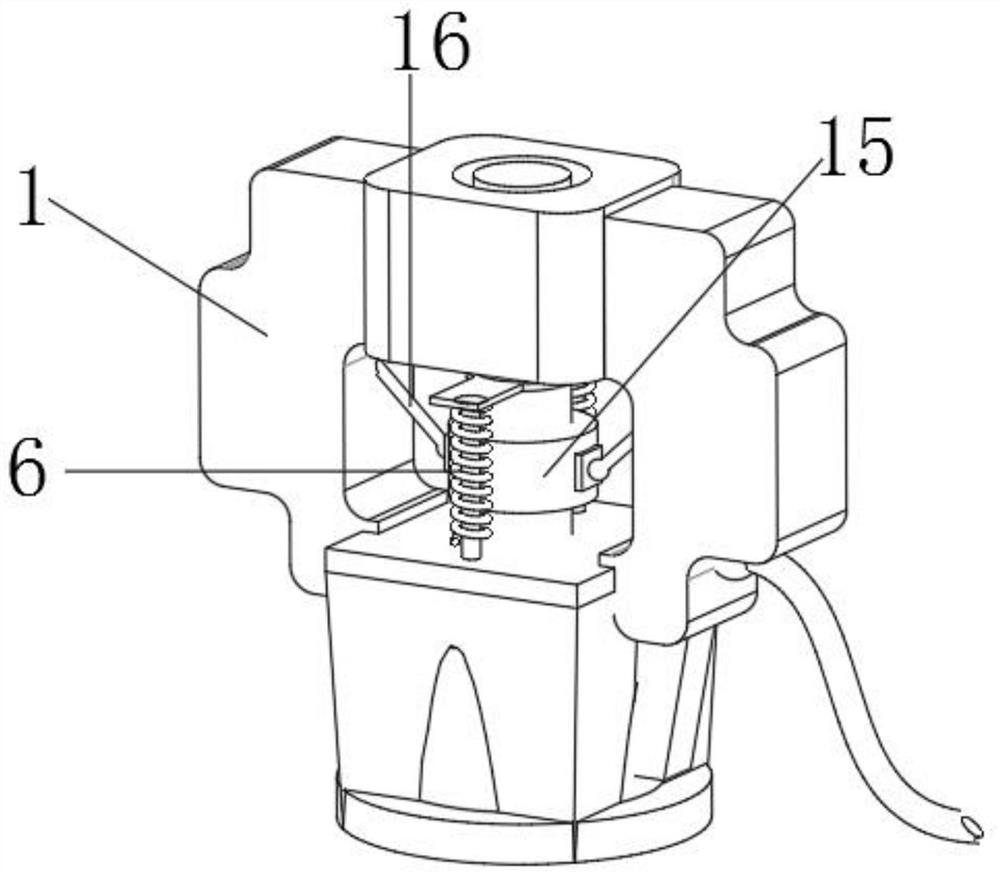

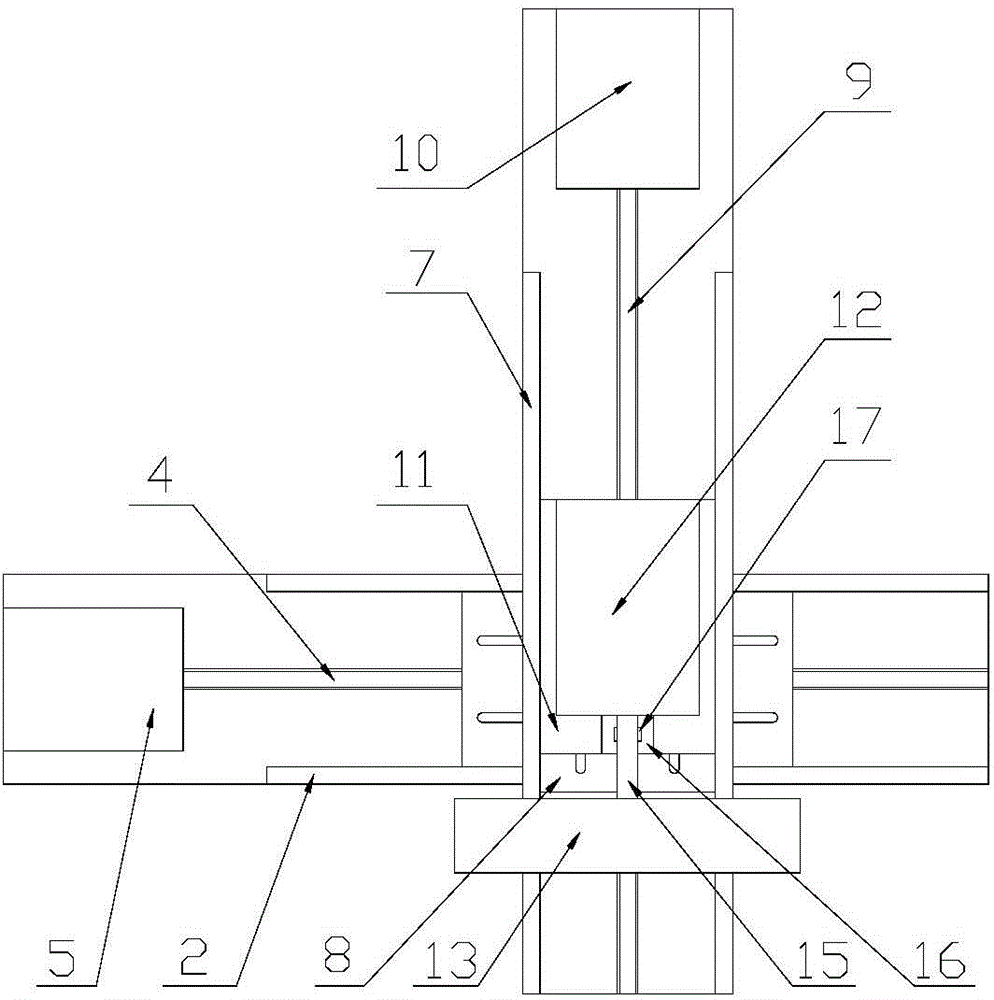

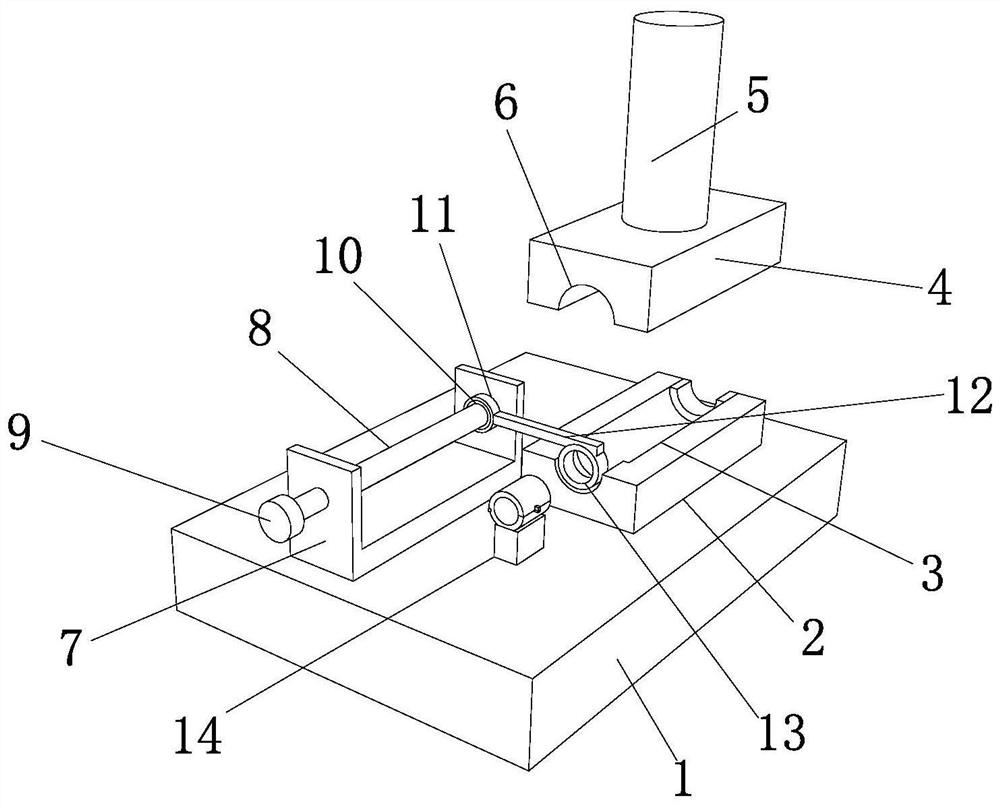

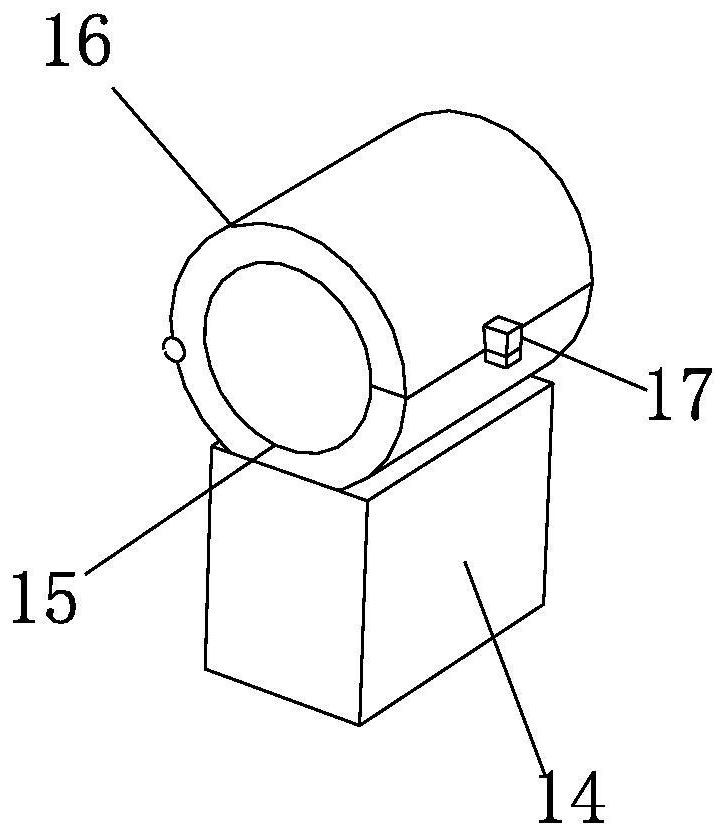

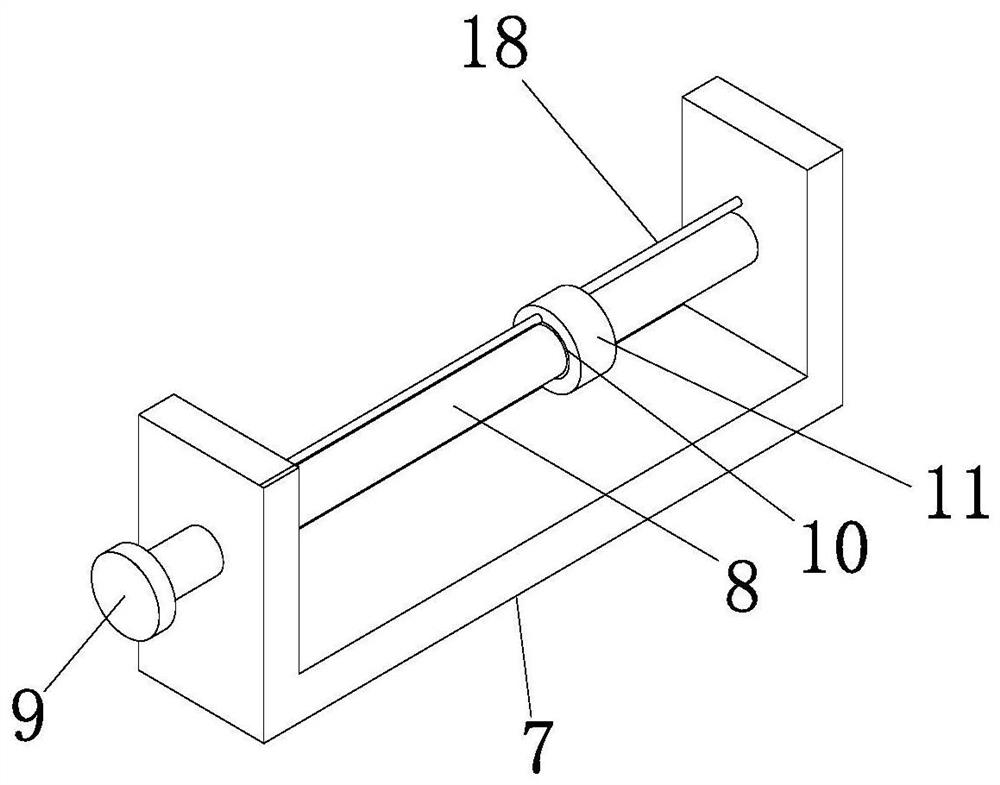

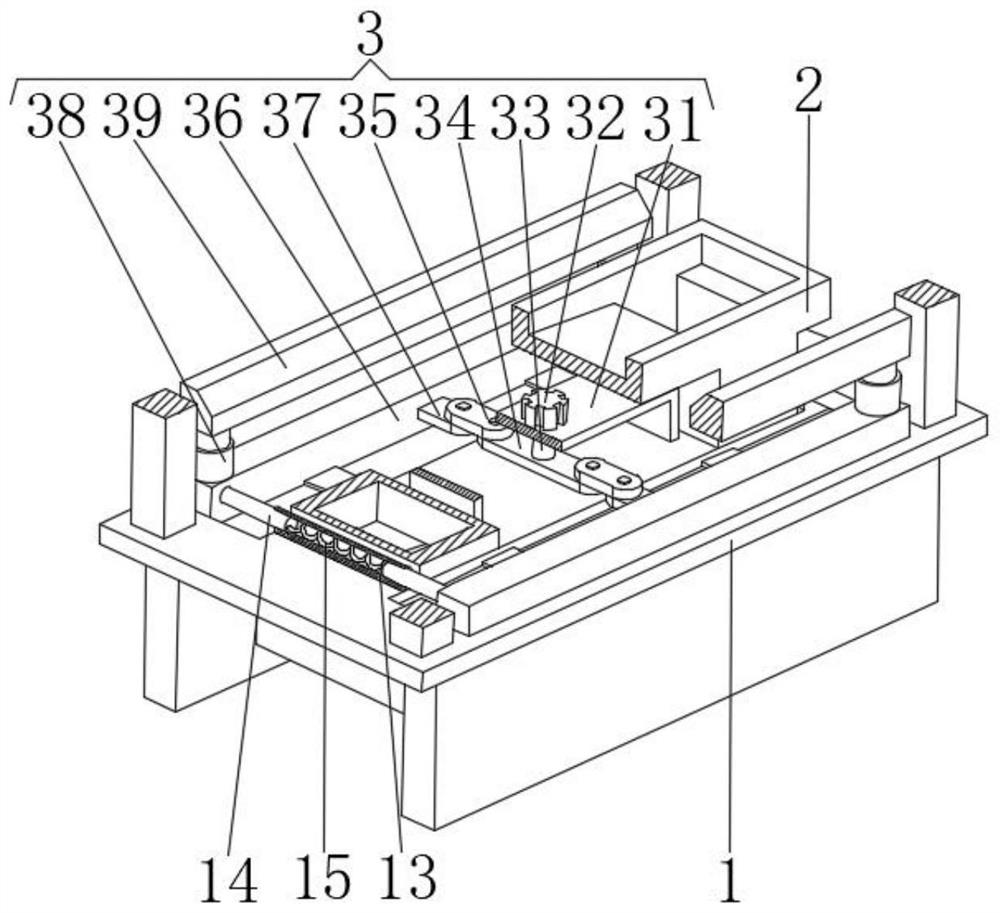

Clamping device of numerical control machine tool

InactiveCN105773211APrevent affecting processing qualityImprove clamping effectPrecision positioning equipmentExpansion mandrelsNumerical controlElectric machinery

The invention discloses a clamping device of a numerical control machine tool. The clamping device is wider in moving range, capable of clamping a plurality of workpieces at a time and conducting machining in turn and higher in working efficiency. The clamping device comprises a first base, wherein the first base is in sliding fit with a first moving plate, and a first screw rod is in internal thread fit with the first moving plate and is connected with a first driving motor arranged on the first base; the first moving plate is fixedly provided with a second base which is in sliding fit with a second moving plate, and a second screw rod is in internal thread fit the second moving plate and is connected with a second driving motor arranged on the second base; the second moving plate is provided with a mounting base, and the longitudinal direction of the mounting base is parallel to a second guide rail; the mounting base is provided with a third driving motor; a rotating shaft of the third driving motor is fixedly provided with a turntable on which four fixtures are arranged; the four fixtures form a square; and the intersection point of diagonals of the square is located on the axis of the first driving motor.

Owner:重庆丰德数控机床有限公司

Leather high-efficiency cutting apparatus for processing sofa

PendingCN108866251AHeight adjustableAffect cutting efficiencyLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusHydraulic pumpSlide plate

The invention discloses a leather high-efficiency cutting apparatus for processing a sofa, which relates to the technical field of sofa production and processing. The leather high-efficiency cutting apparatus comprises a processing table and an installation frame, wherein the middle part of the processing table is provided with a cutting groove, two sides of the top end of the processing table arerespectively provided with first sliding grooves, a first sliding plate is arranged in each first sliding groove, the top end of each first sliding plate is fixedly connected with a fixing apparatus,the middle part of the installation frame is fixedly connected with a hydraulic pump, the bottom of the hydraulic pump is fixedly connected with a first fixed block, a first groove is formed inside the first fixed block, a second motor and a rotating shaft are arranged in the first groove, and the bottom end of the rotating shaft penetrates through the first fixed block and is fixedly connected with a cutting apparatus. According to the leather high-efficiency cutting apparatus for processing the sofa, by arranging the first sliding grooves and the first sliding plates, the leather on the fixing apparatus can be driven to move, and a rapid cutting purpose can be realized; and by arranging a spring, a buffering effect can be realized, and the vibration when in cutting can be prevented frominfluencing the cutting efficiency of the cutting apparatus.

Owner:安吉菲菲椅业有限公司

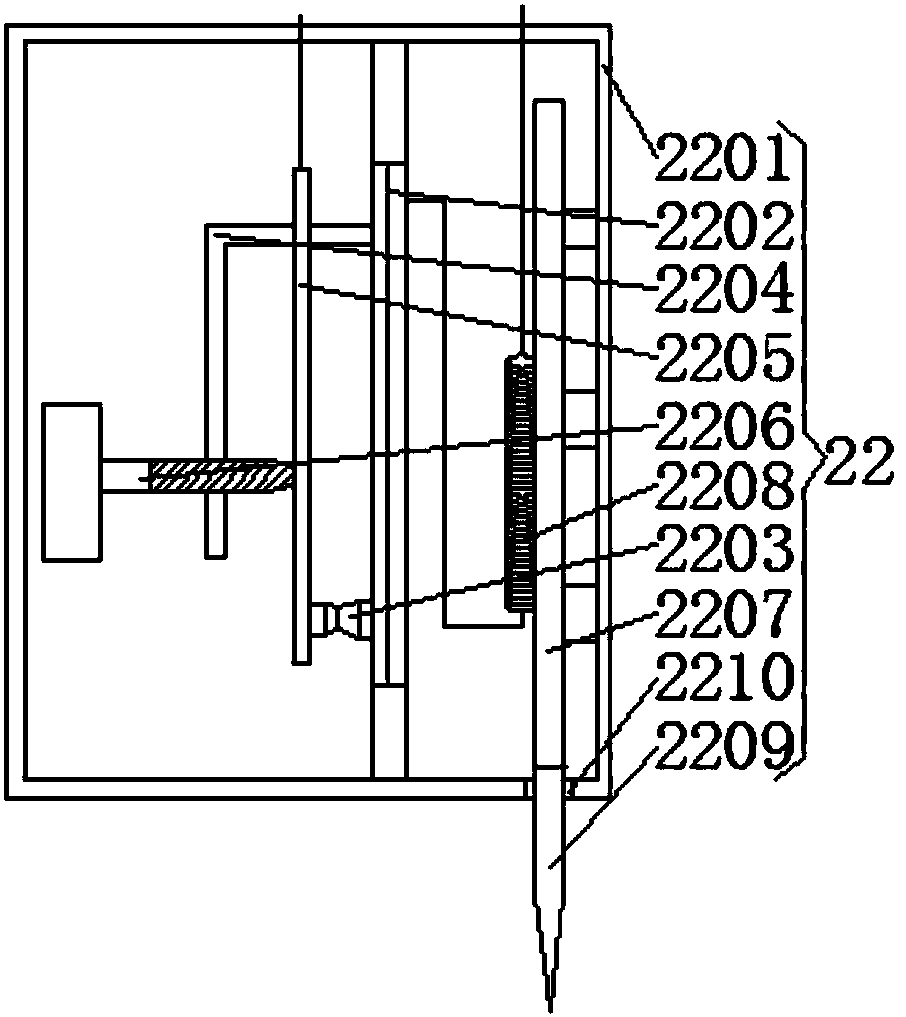

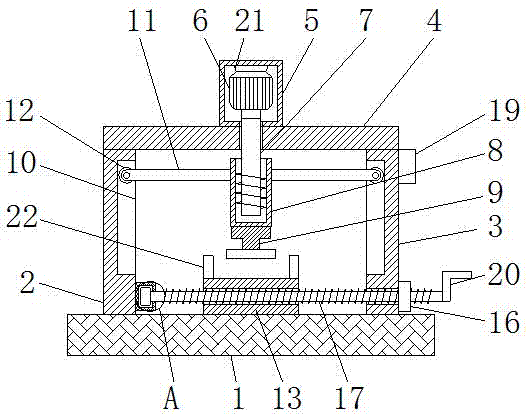

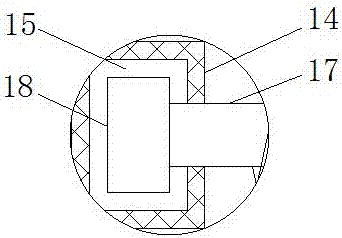

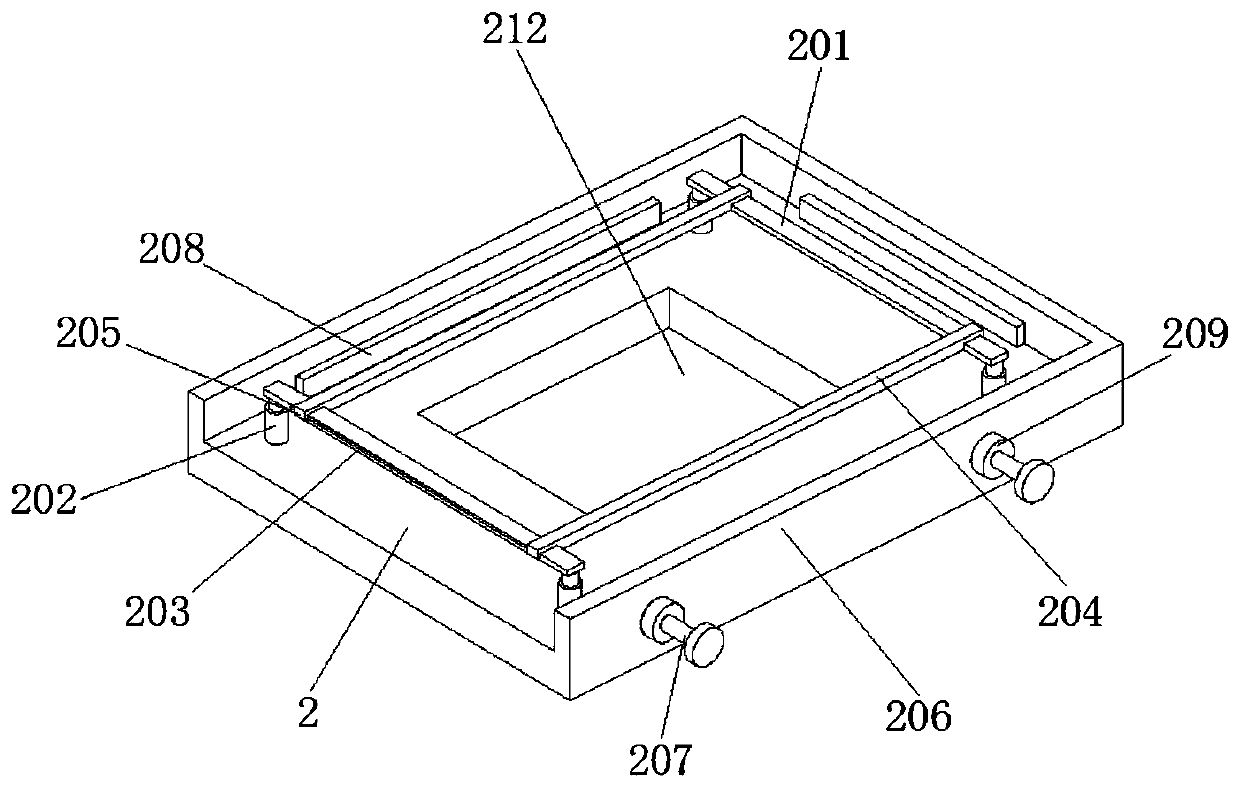

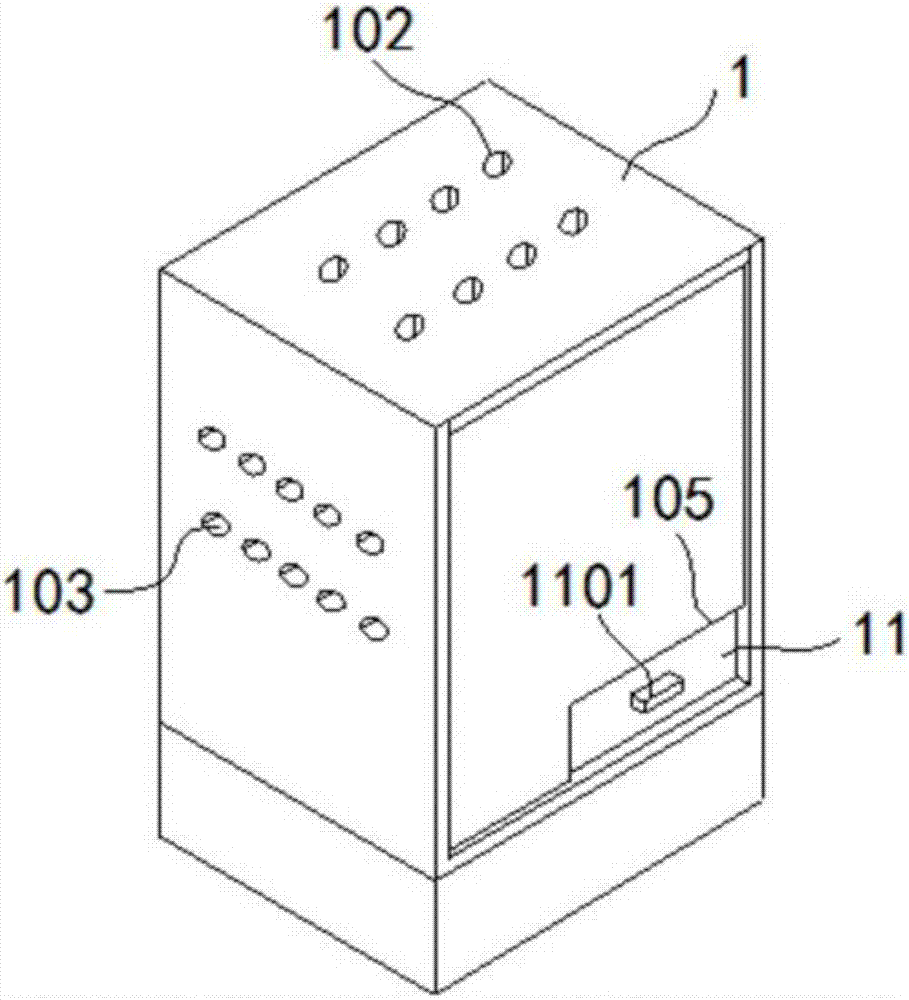

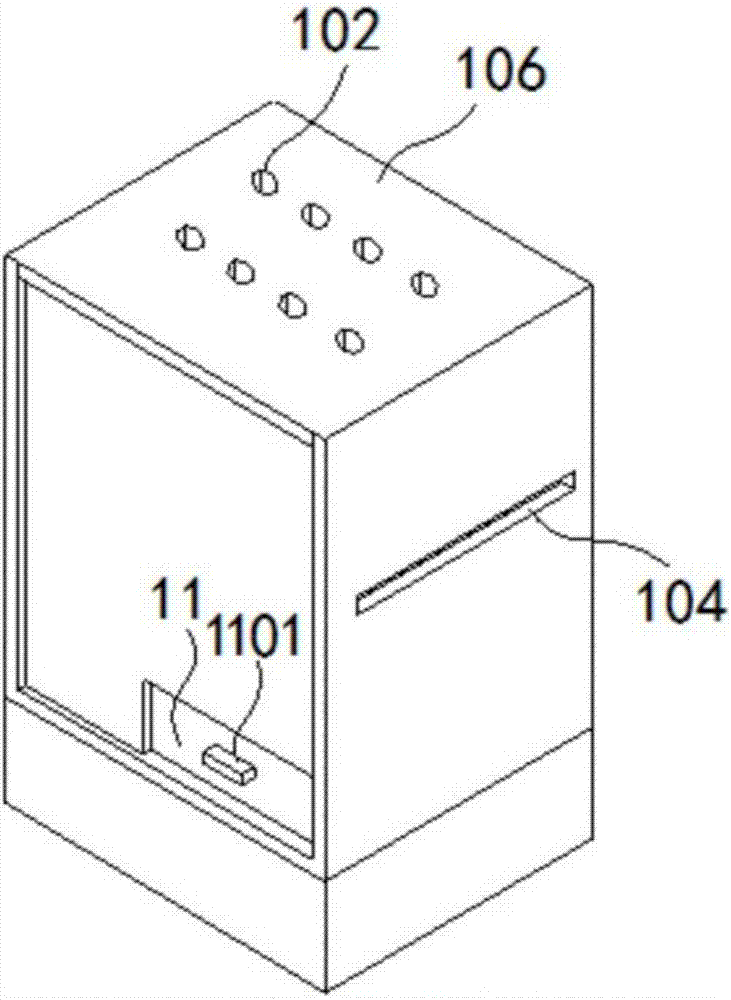

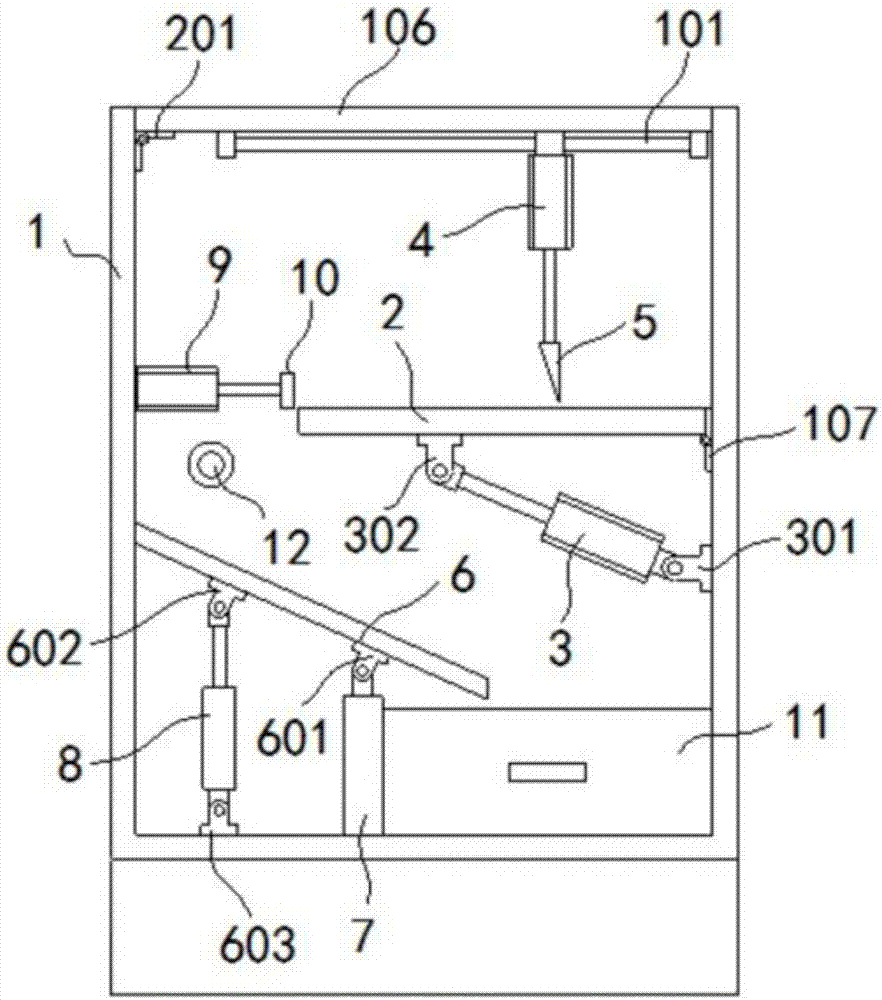

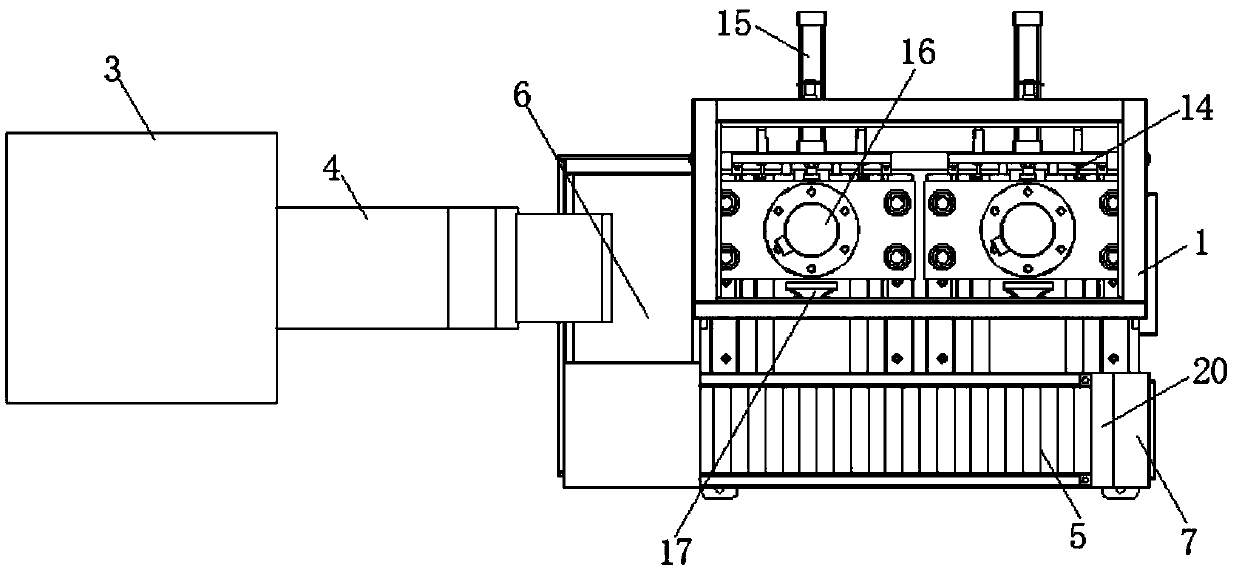

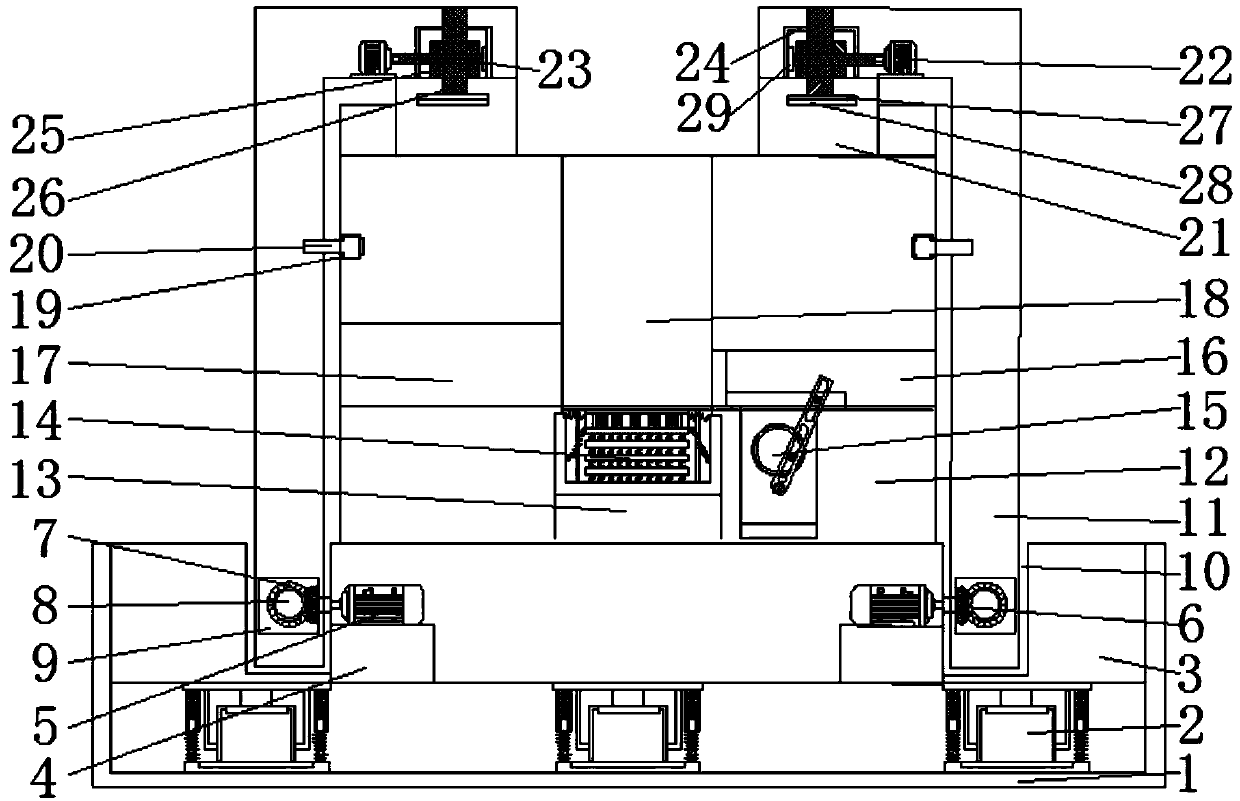

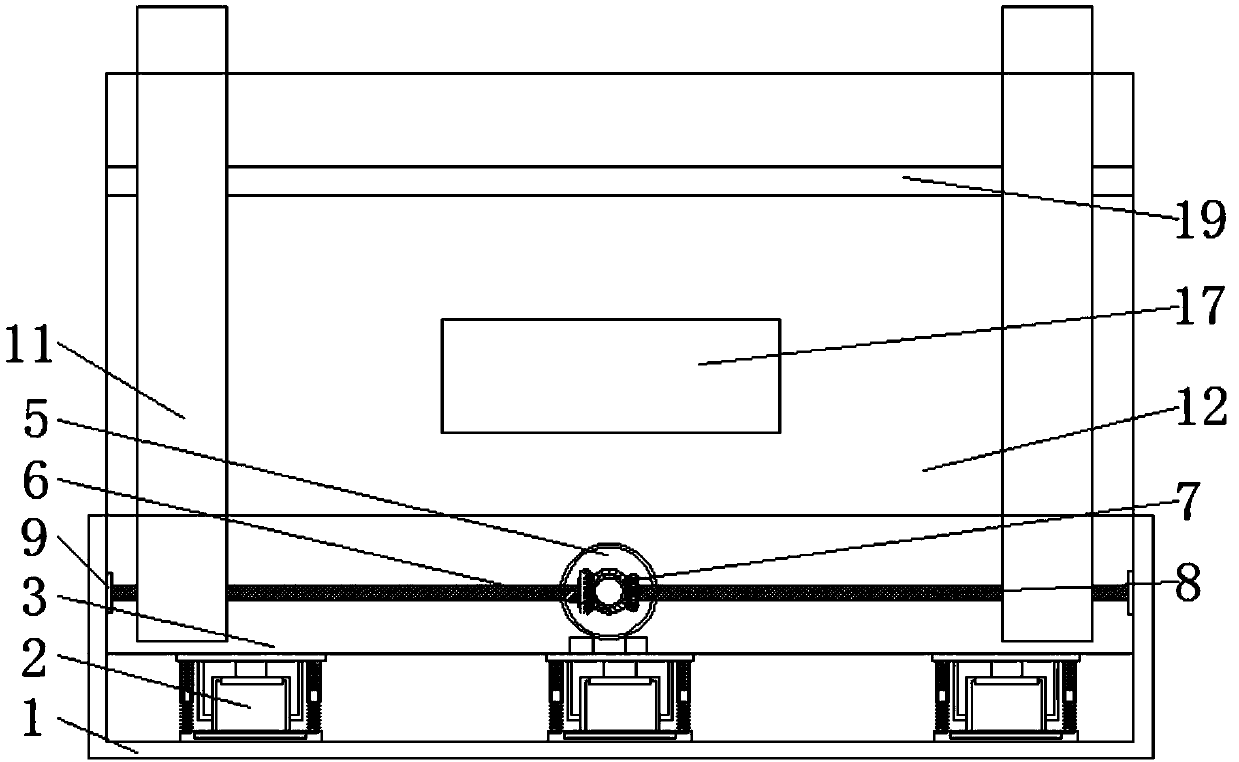

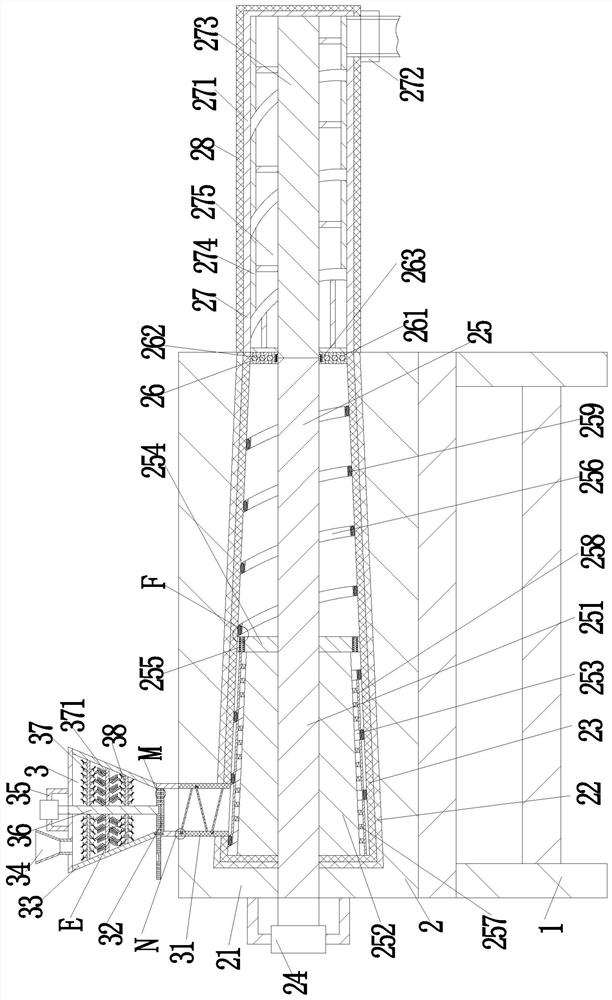

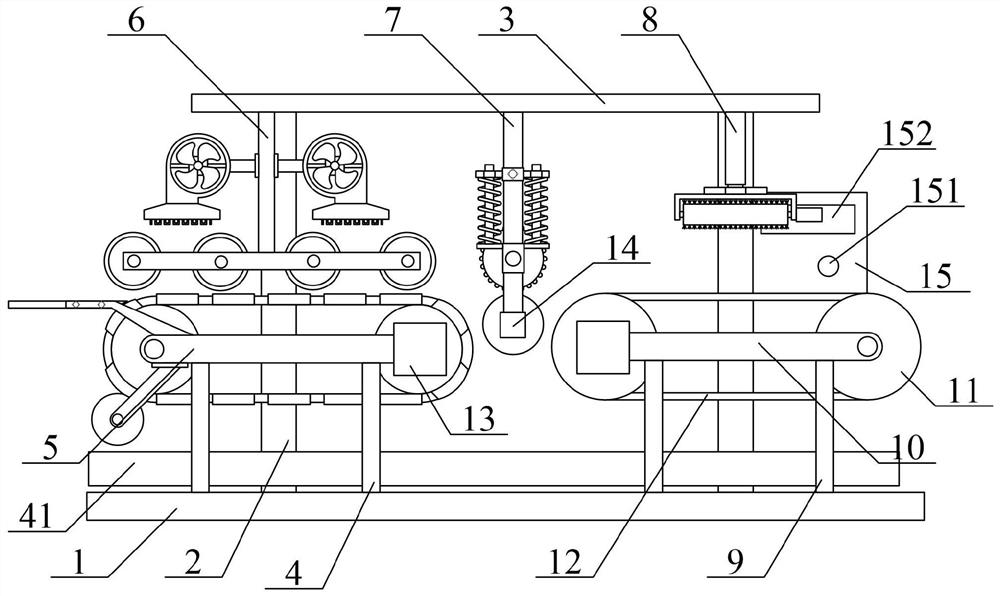

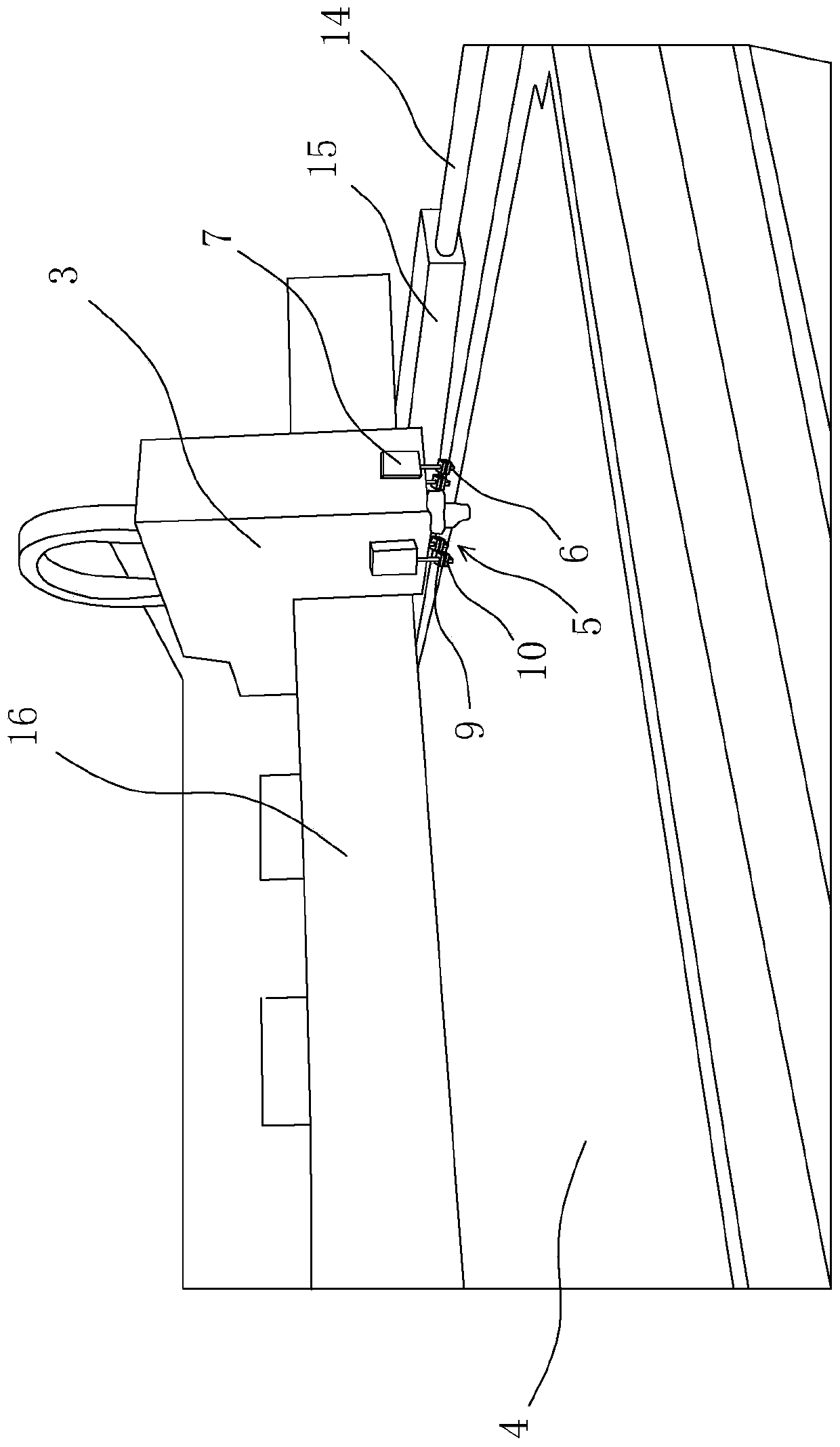

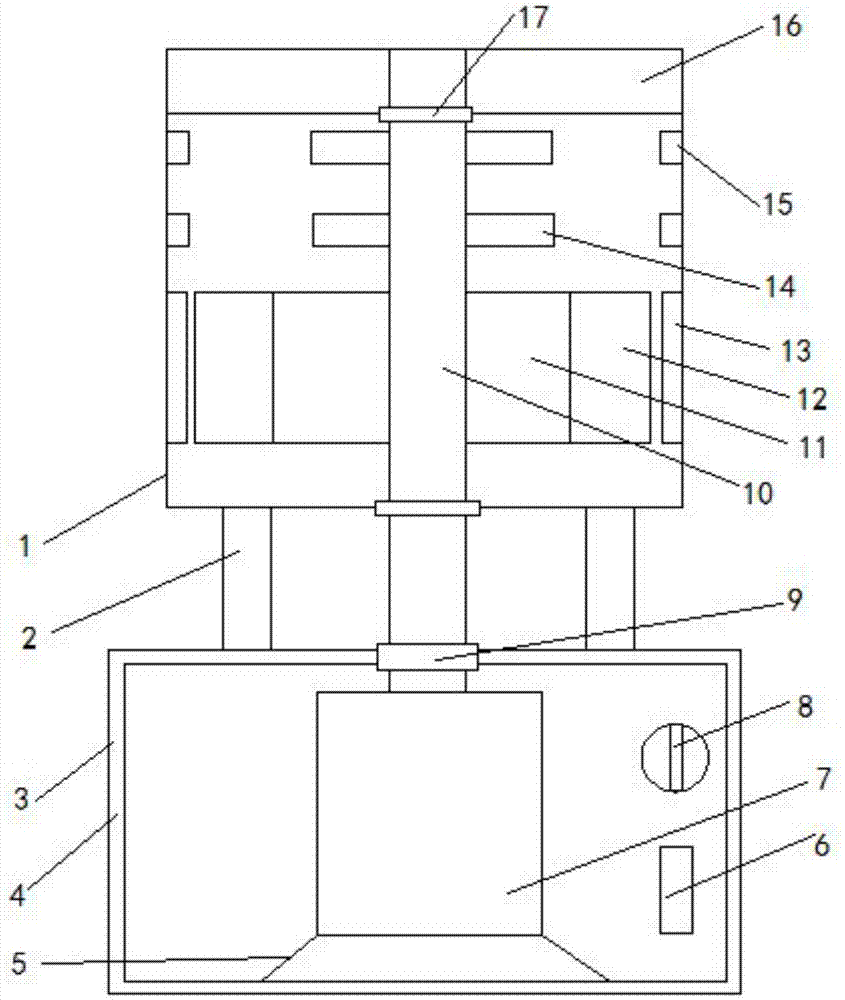

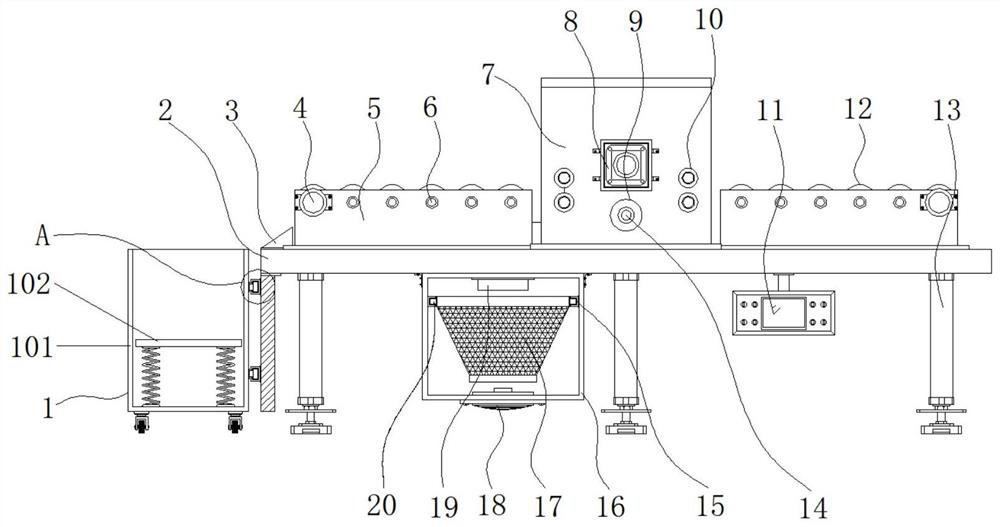

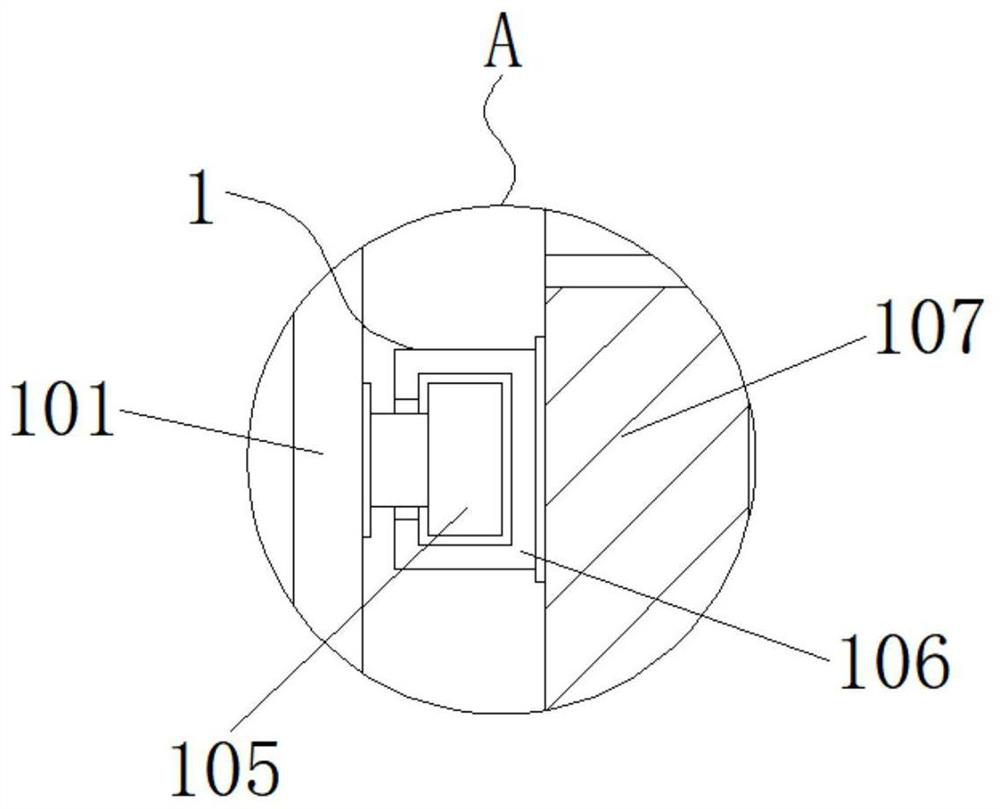

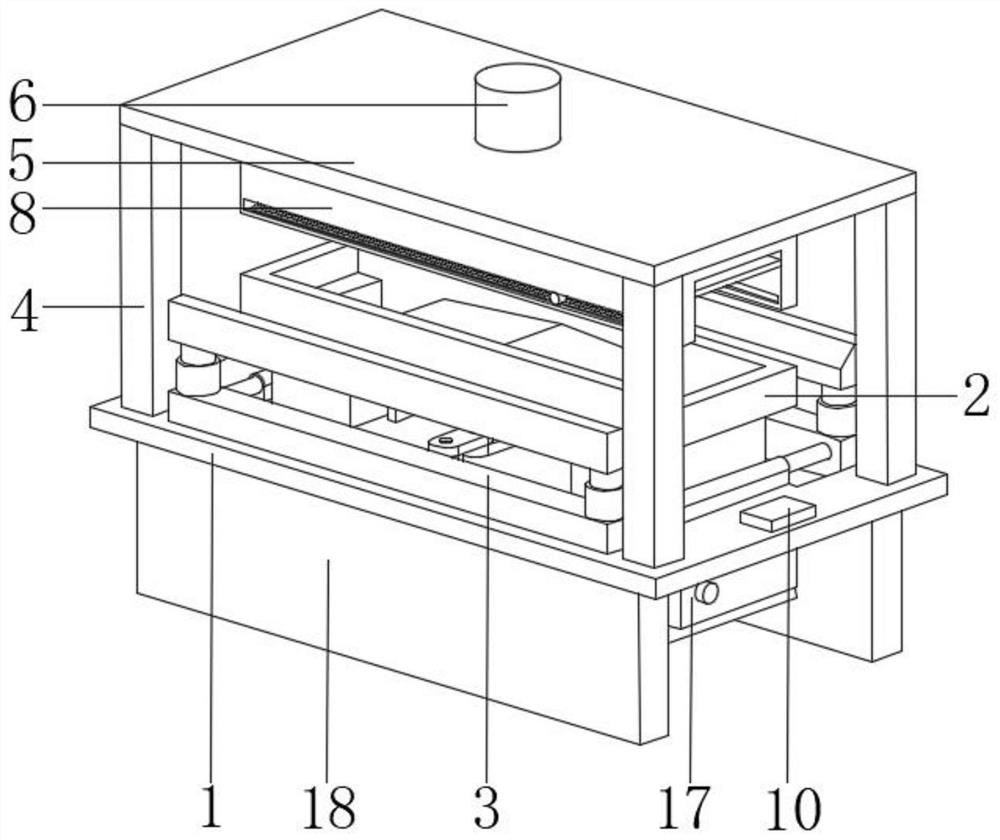

Stainless steel band production device with wide-range adjusting function and production method

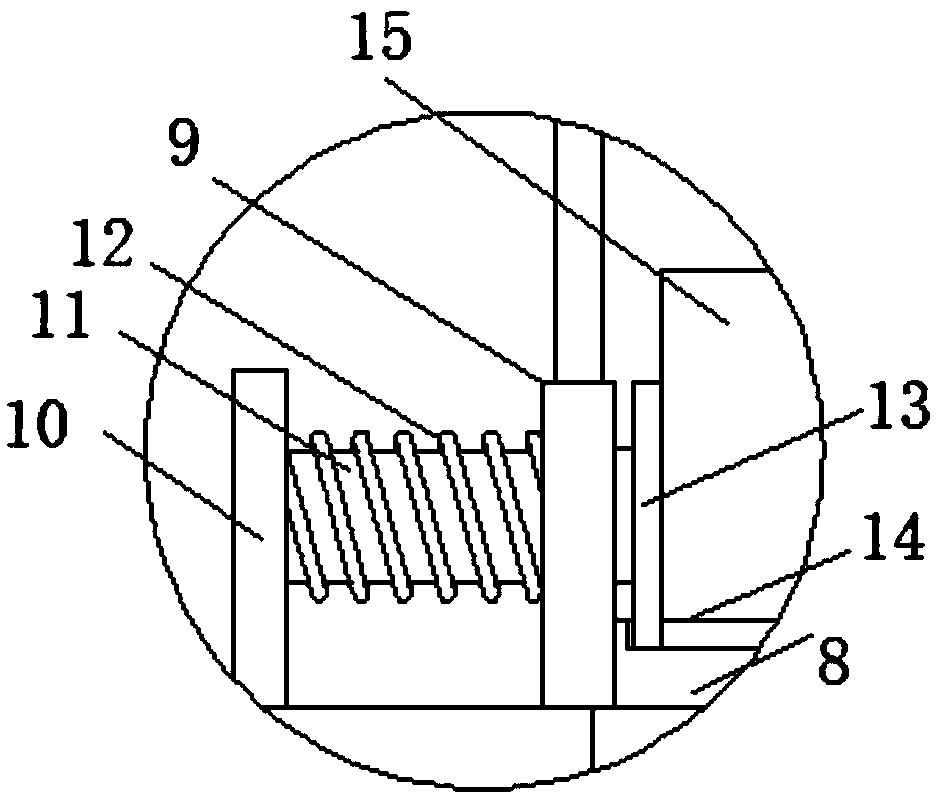

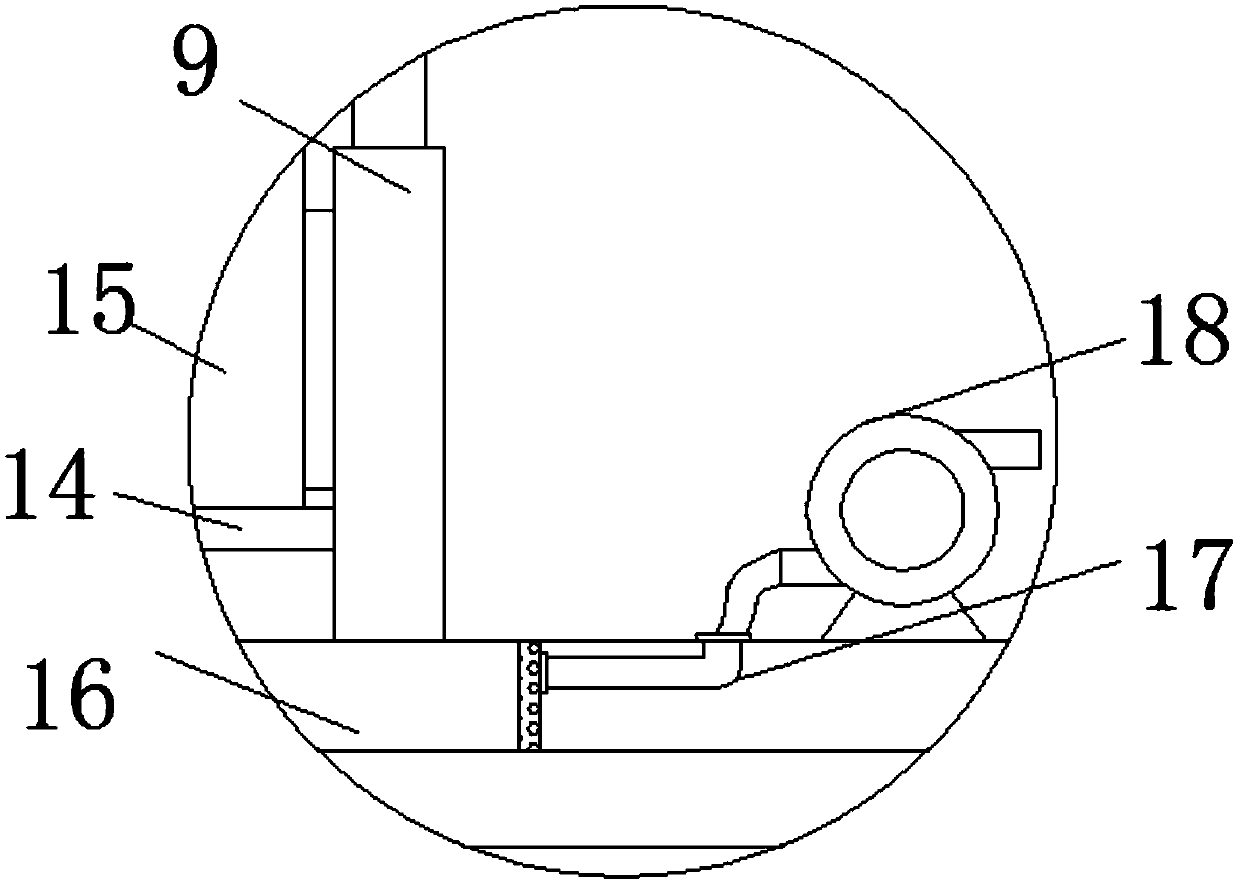

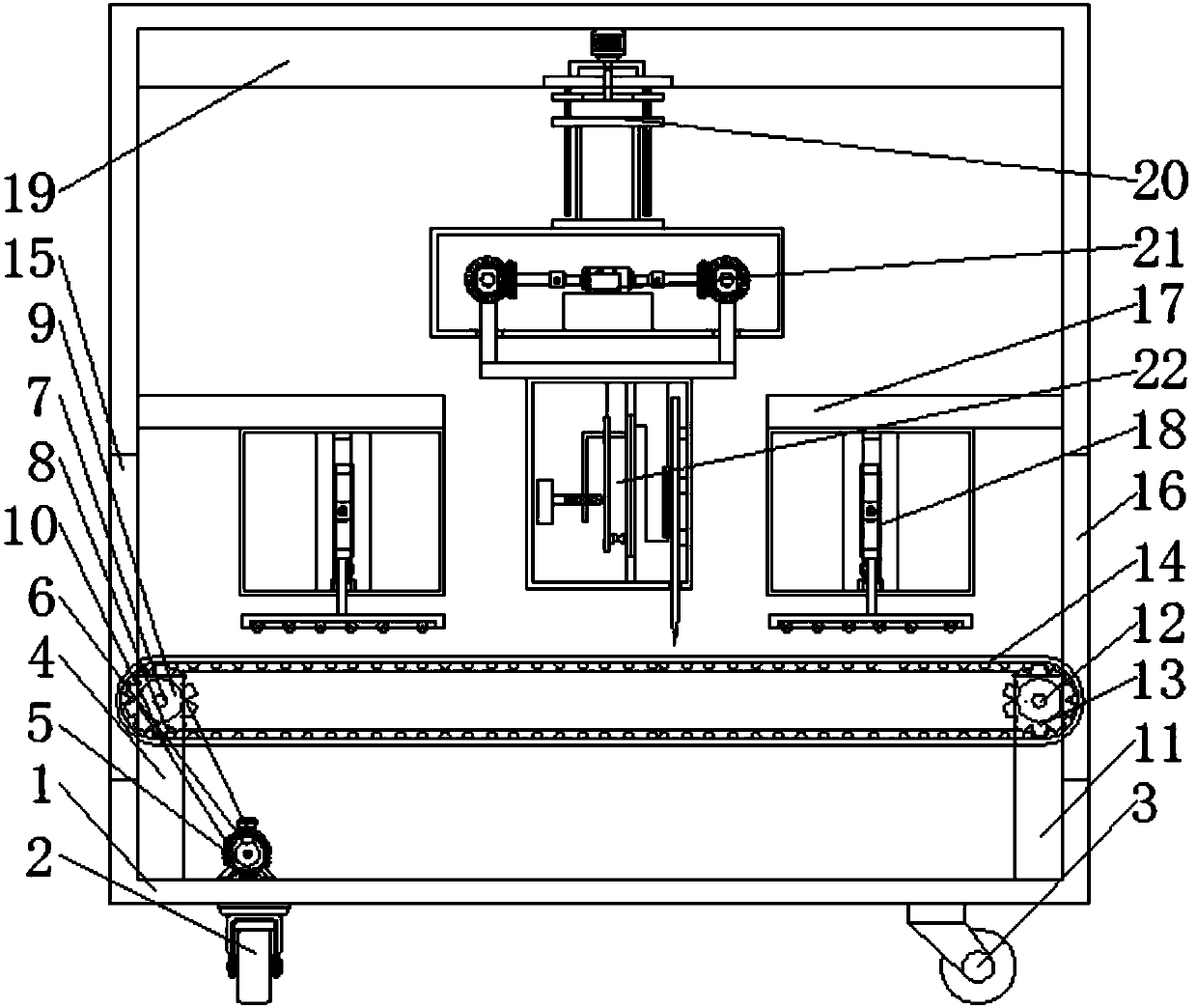

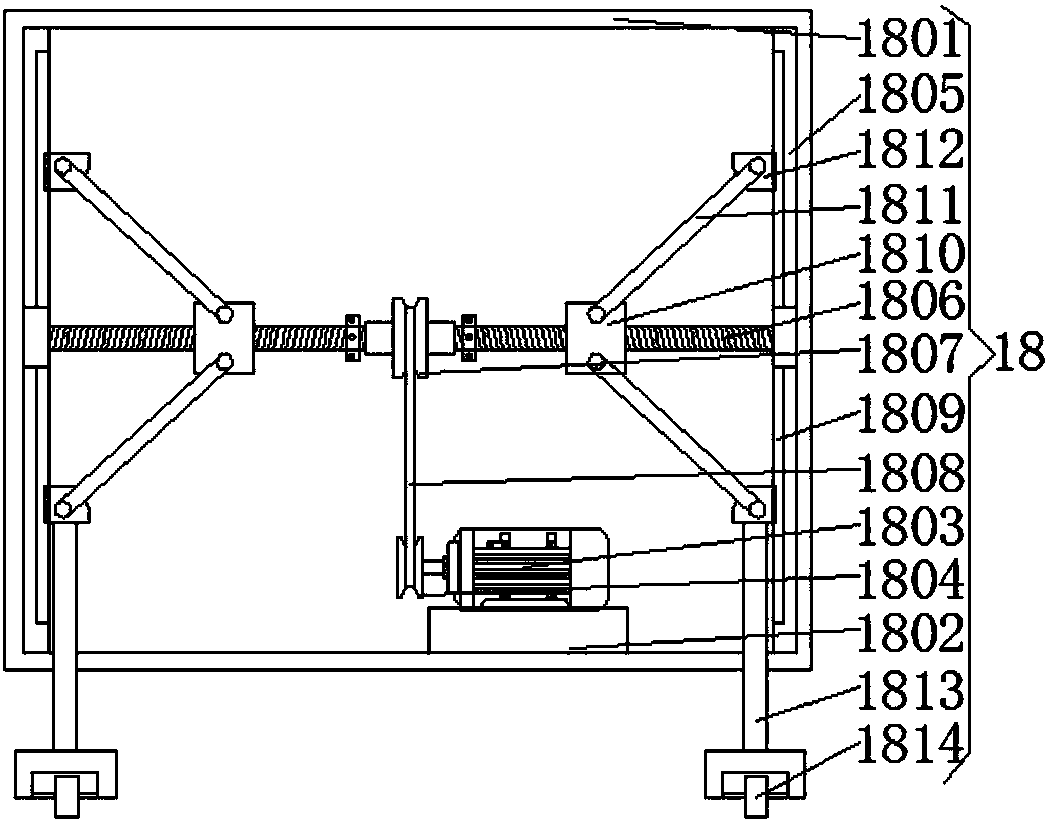

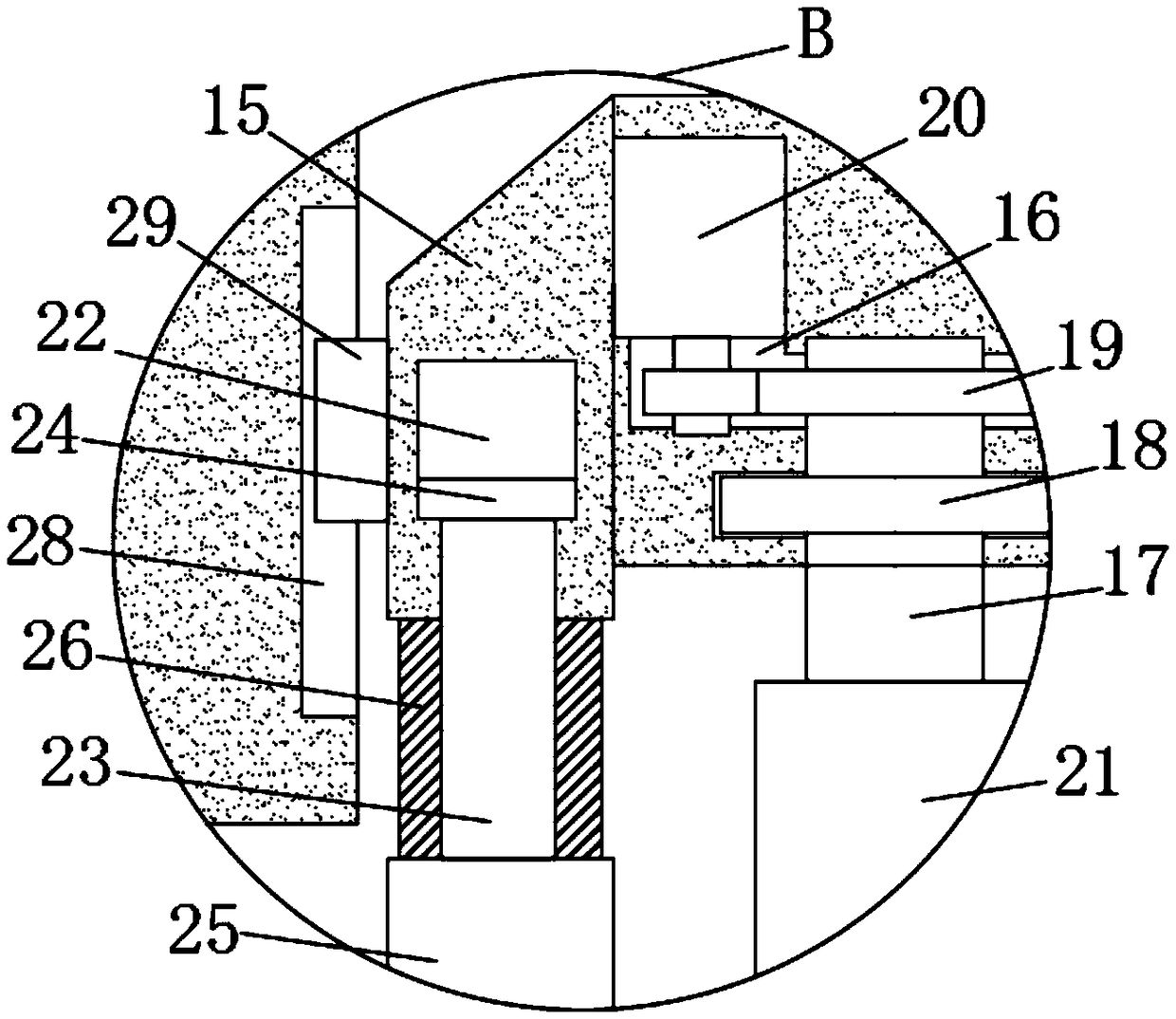

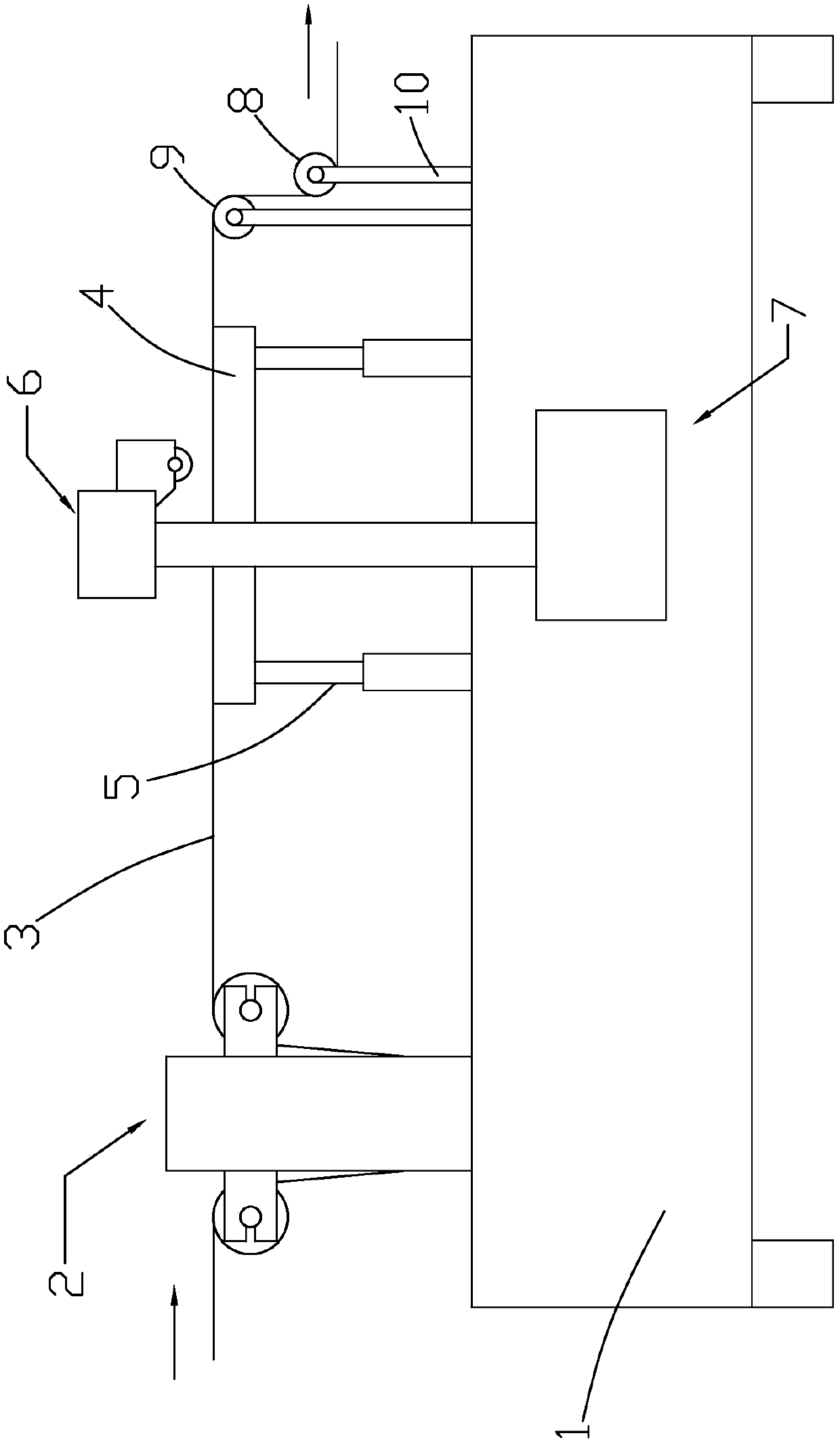

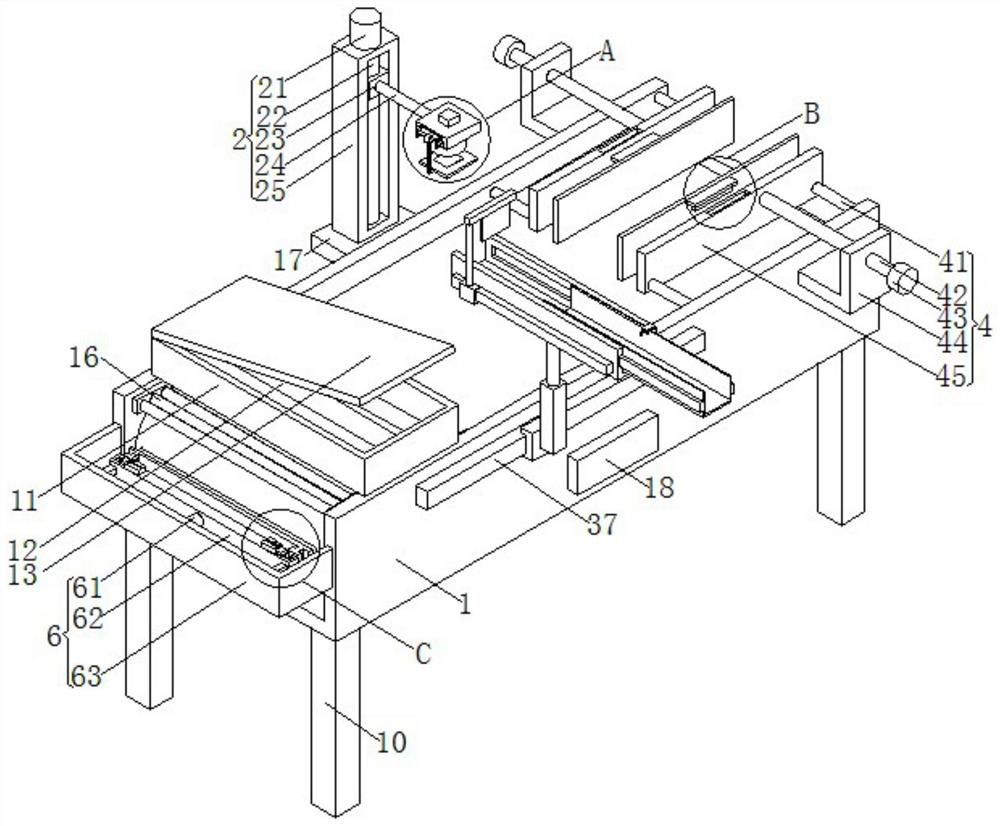

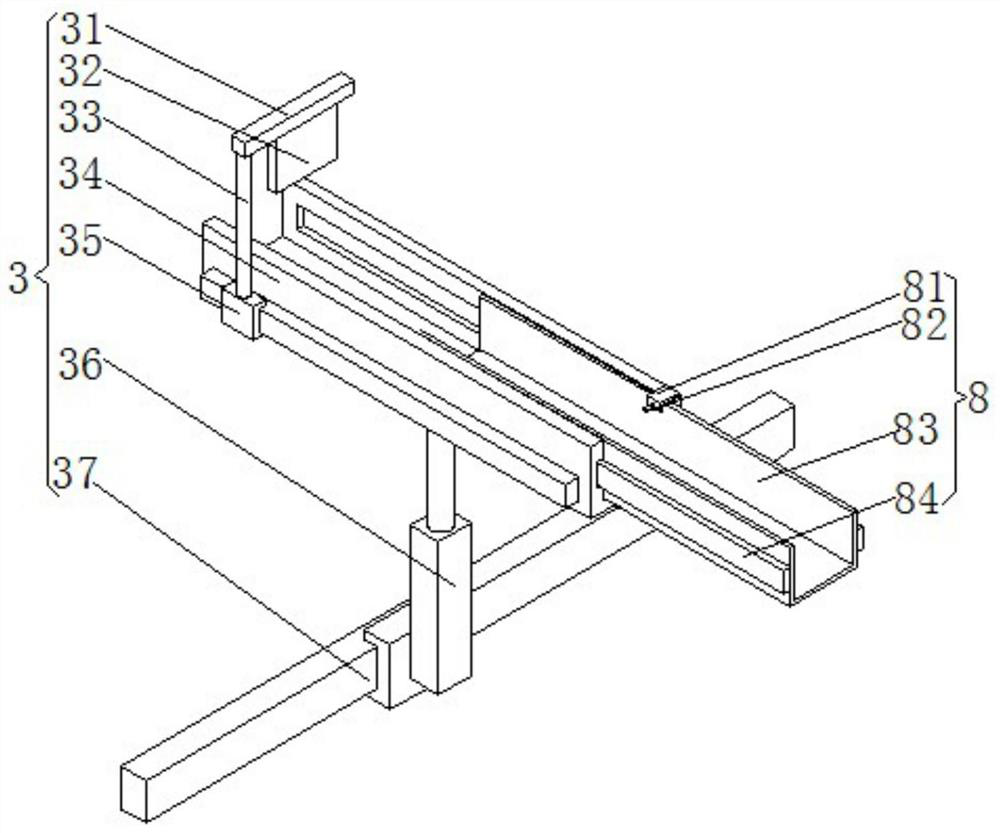

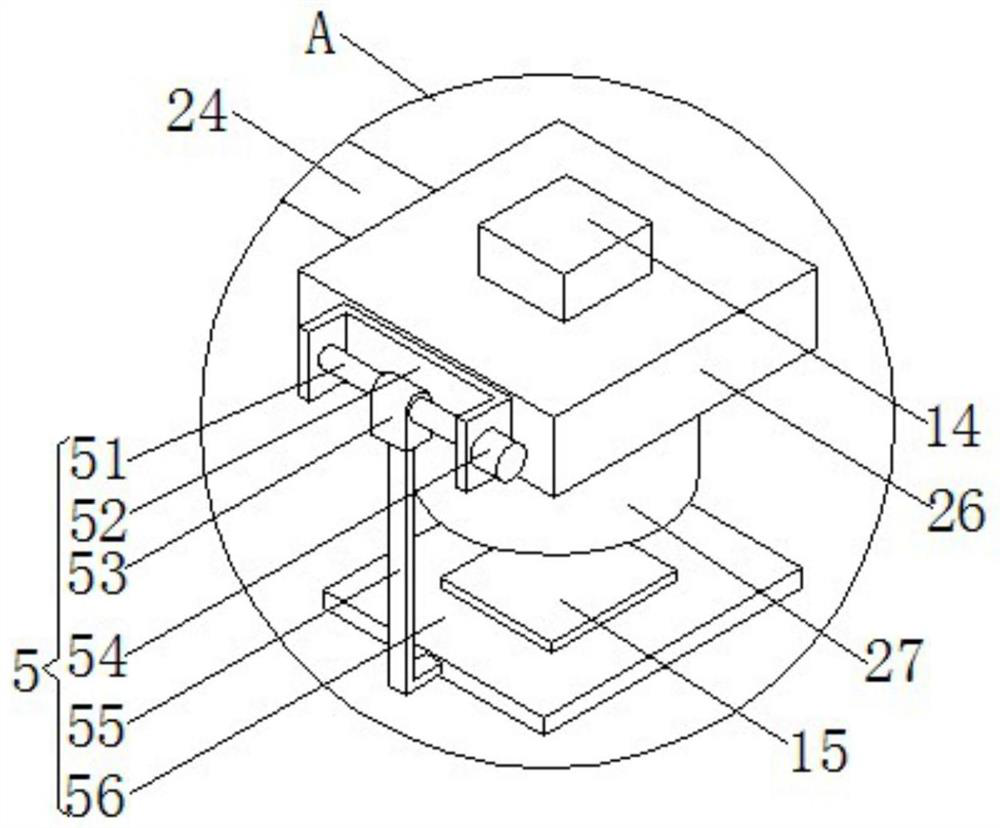

ActiveCN107671347AHigh precisionHigh movement accuracyShearing machinesShearing machine accessoriesAssembly lineRejection rate

The invention discloses a stainless steel band production device with the wide-range adjusting function. The stainless steel band production device comprises a box body, a tensioning mechanism, a machining platform, a cutting mechanism and a height adjusting mechanism. The tensioning mechanism and the machining platform are both located above the box body. The tensioning mechanism is located at the left side of the machining platform. The machining platform is connected with the box body through a hydraulic lifting rod. The cutting mechanism is located above the machining platform and is further connected with the box body through the height adjusting mechanism. A driving roller and a driven roller are further arranged on the top face of the box body and are both located at the right sideof the machining platform. The driving roller and the driven roller are both connected with the box body through a supporting rod. Stainless steel bands penetrate in from the tensioning mechanism andfurther wind across the driven roller and the driving roller to be output after passing through the machining platform. By means of the stainless steel band production device with the wide-range adjusting function, the cutting machining requirements of the stainless steel bands of different widths can be met; and moreover, machining precision of the stainless steel bands is improved, and the rejection rate is lowered. The machining method is simple in technological step, the production demand of an assembly line can be met, manufacturing cost is reduced and the machining period is shortened.

Owner:ZHEJIANG JIANHENG IND

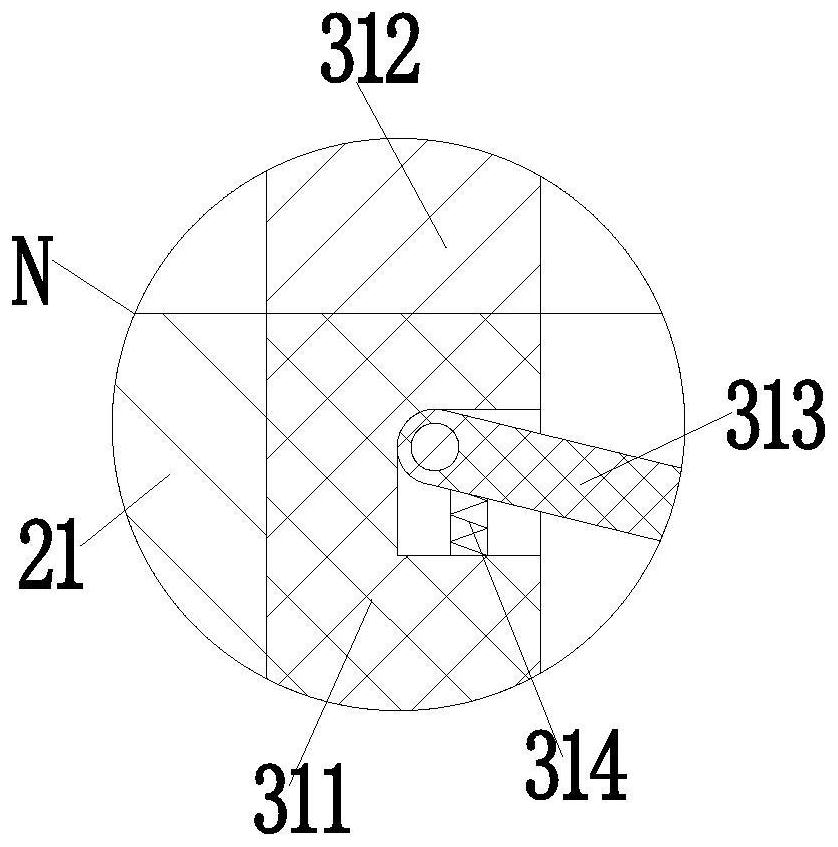

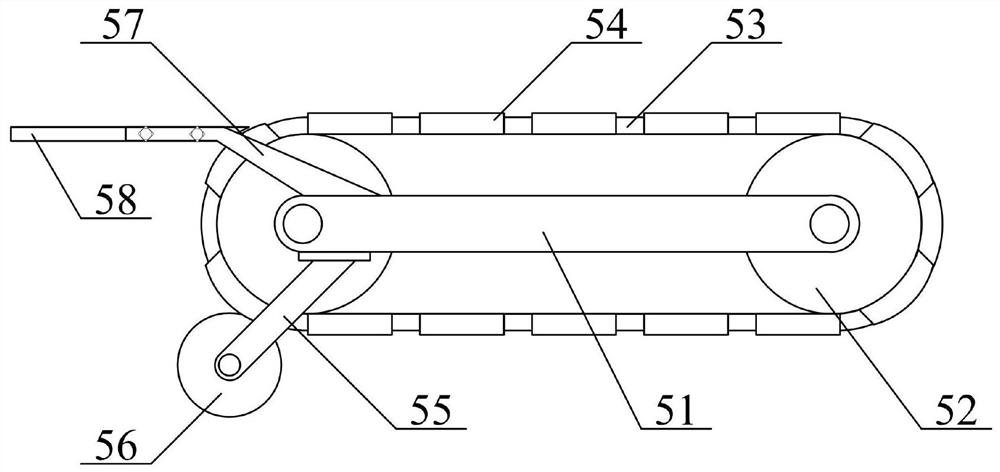

Lead frame plate placing and pushing-out equipment for semiconductor cutting

InactiveCN112838036AEasy to transportImprove stabilitySemiconductor/solid-state device manufacturingCleaning using toolsEquipment useStructural engineering

The invention discloses lead frame plate placing and pushing-out equipment for semiconductor cutting. The lead frame plate placing and pushing-out equipment comprises a conveyor, a taking unit, a placing unit and a fixing plate. In the conveyor, supporting legs are arranged at the four corners of the bottom end of the conveyor, a fixing plate is arranged in the middle of the rear side face of the conveyor, a limiting unit is arranged at the right end of the conveyor, and a cleaning unit is arranged at the left end of the conveyor; the taking unit comprises a motor, a lead screw, a movable block, an electric telescopic rod, a fixing seat, a connecting plate and an electromagnet, the fixing seat is arranged at the top end of the fixing plate, the lead screw is rotationally connected into a groove in the front side face of the fixing seat, the motor is arranged at the top end of the fixing seat, and an output shaft of the motor is connected with the top end of the lead screw; and the movable block is in sliding connection with a groove in the front side face of the fixed seat, a screw hole in the side face of the movable block is in threaded connection with the lead screw, and the lead frame plate placing and pushing-out equipment for the semiconductor tailoring is easy to use, convenient to adjust, low in working intensity and high in production efficiency.

Owner:温州斐锋生态农业科技发展有限公司

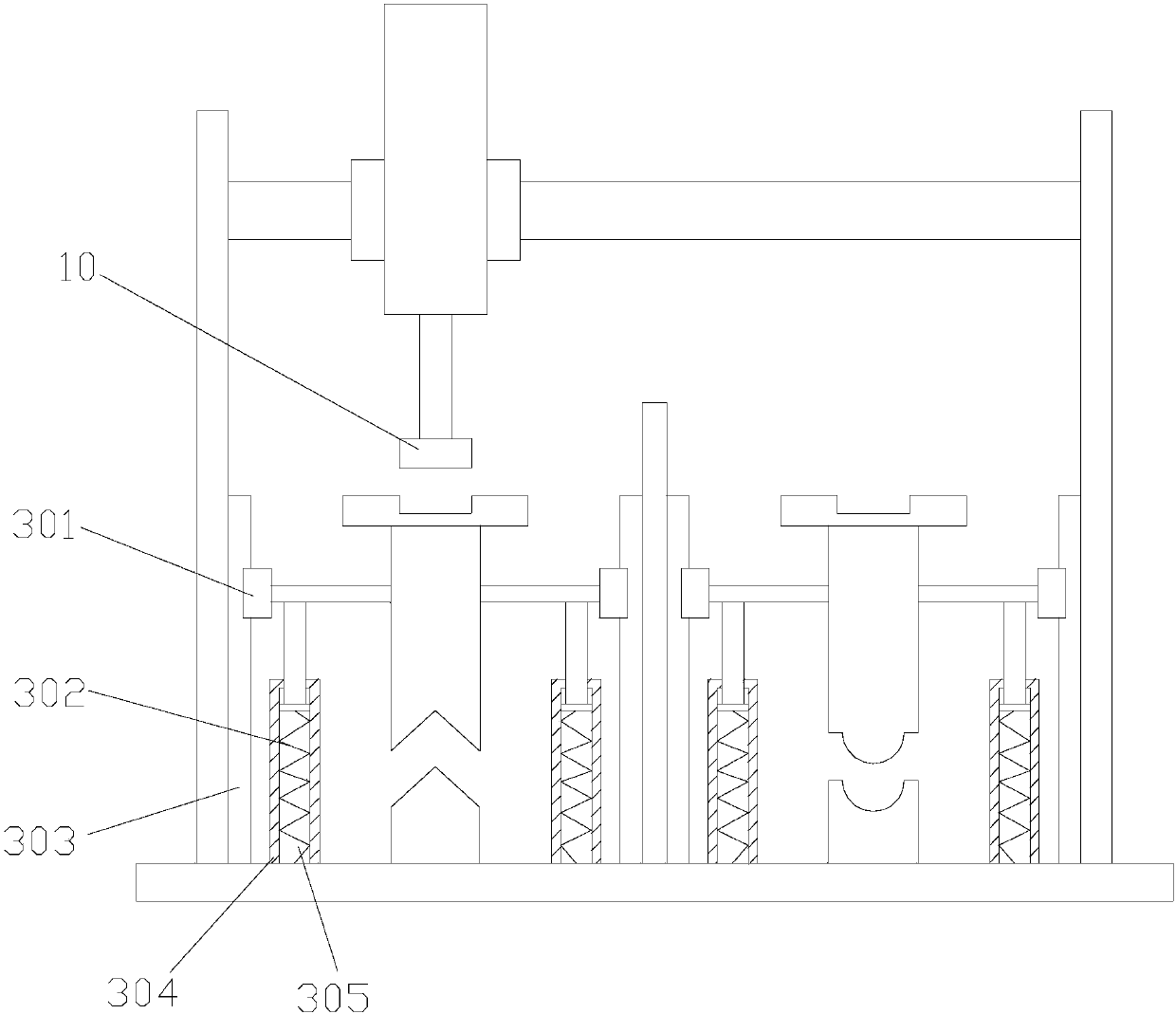

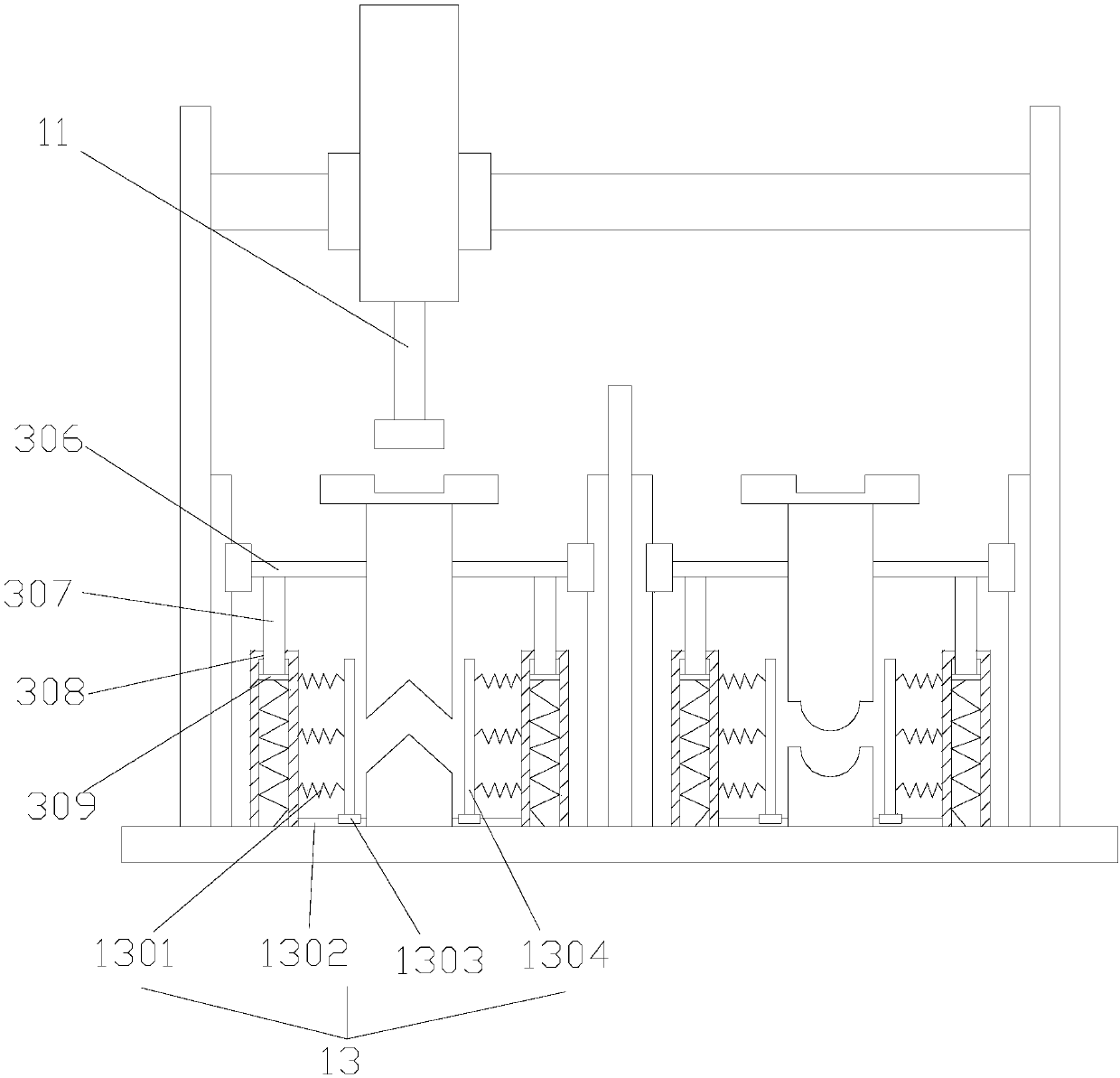

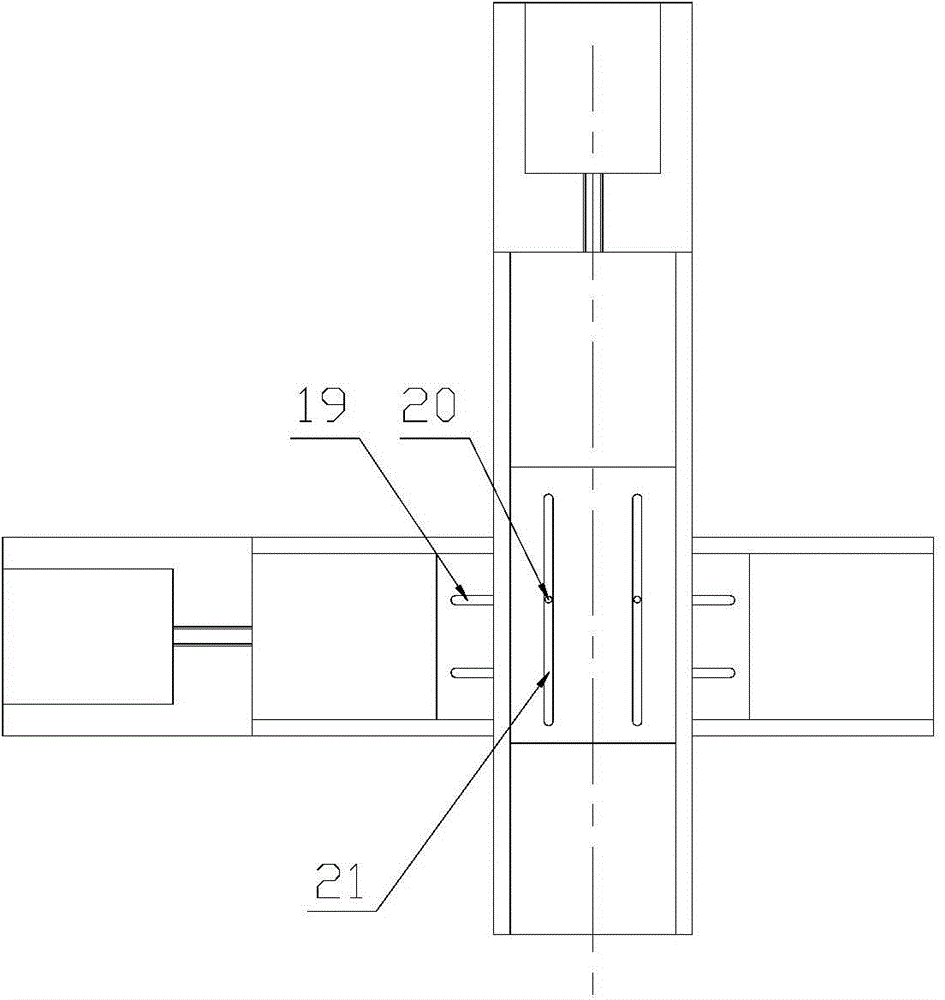

Flat iron bending device for electric power construction

InactiveCN107900159APrevent affecting processing qualityPlay the role of orientationHydraulic cylinderArchitectural engineering

The invention discloses a flat iron bending device for electric power construction. The flat iron bending device for the electric power construction structurally comprises a bottom plate, a left sideplate, a first bending device, a first sliding rail, a first sliding block, a hydraulic cylinder, a right side plate, a second bending device, a partition plate, an ejection block and a lifting rod, wherein the top of the bottom plate is sequentially provided with the left side plate, the first bending device, the partition plate, the second bending device and the right side plate from left to right. According to the flat iron bending device for the electric power construction, the double-station bending devices are arranged on the bottom plate, the double-station bending devices can provide two different bending shapes, when one of the bending shapes is needed, the hydraulic cylinder on the first sliding rail can be moved, and flat iron to be bent on one bending device can be machined through up-and-down extension and retraction of a piston rod of the hydraulic cylinder; and positioning and pressing devices are arranged on the left side and the right side of each bending device so that the influence on the machining quality caused by the fact that the flat iron deviates in the machine process can be prevented, and the positioning and pressing devices play a role in positioning andguiding.

Owner:泉州速创时代工业设计有限公司

Plastic foam packaging material machining system and method

ActiveCN110919735ASolve the inconvenience of processingImprove efficiencyMetal working apparatusStructural engineeringMachining system

The invention relates to the production and machining field, in particular to a plastic foam packaging material machining system and method. The plastic foam packaging material machining system comprises a moving platform and a fixing base. First sliding grooves are symmetrically formed in the moving platform. First sliding rods are fixedly connected into the first sliding grooves. The first sliding rods are both sleeved with first sliders. The tops of the first sliders are both provided with fastening bolts. The fastening bolts are connected to the tops of the first sliders in a threaded manner. The bottoms of the first sliders are both provided with first through holes. The bottoms of the first sliders are both fixedly connected with cutting tool bits. Second through holes are both formed in the cutting tool bits. The second through holes communicate with the first through holes. A steel wire is arranged between the two cutting tool bits. The two ends of the steel wire are both inserted into the second through holes and the first through holes. The two ends of the moving platform are both rotationally connected with adjusting wheels. The two ends of the steel wire are both fixedly connected to the adjusting wheels. The plastic foam packaging material machining system has the advantages of being good in machining effect, rapid in machining speed, high in flexibility and the like and is suitable for popularization.

Owner:佛山市新鸣亿包装材料有限公司

Working method of waste material clearing device

InactiveCN107999956AAchieve dumpingClean up in timeWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingWaste material

The invention discloses a working method of a waste material clearing device. The waste material clearing device comprises a protecting box body, a machining platform, a discharging air cylinder, a first lifting air cylinder, a scraper, a flow guide plate, a supporting rod, a second lifting air cylinder, a material pushing air cylinder, a pushing plate and a water material box. The discharging aircylinder is arranged below the machining platform, pouring of waste materials can be achieved, the waste materials are guided into the waste material box through the flow guide plate, the waste materials obtained after laser cutting can be cleared in time, and the influence on machining quality of laser cutting of the next time is prevented. By arranging the material pushing air cylinder, the pushing plate and a long groove in the side wall, machined products can be pushed out of the protecting box body conveniently, products to be machined are placed into the long groove, and the machining efficiency is improved. By arranging the first lifting air cylinder and the scraper, the waste materials remaining on the machining platform can be further cleared, and the machining quality is furtherimproved. The protecting box body is provided with a wind input hole and a wind output hole, the temperature in the protecting box body is lowered, and the machining quality is ensured.

Owner:朱慧

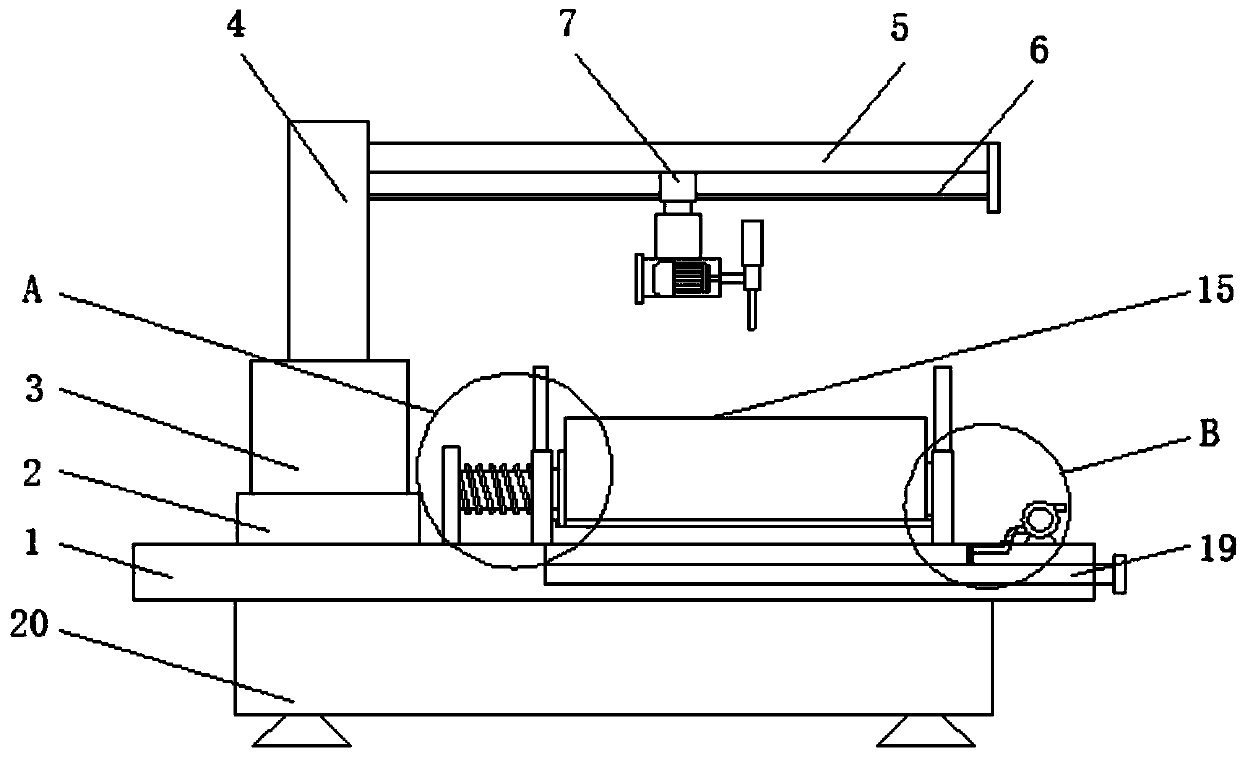

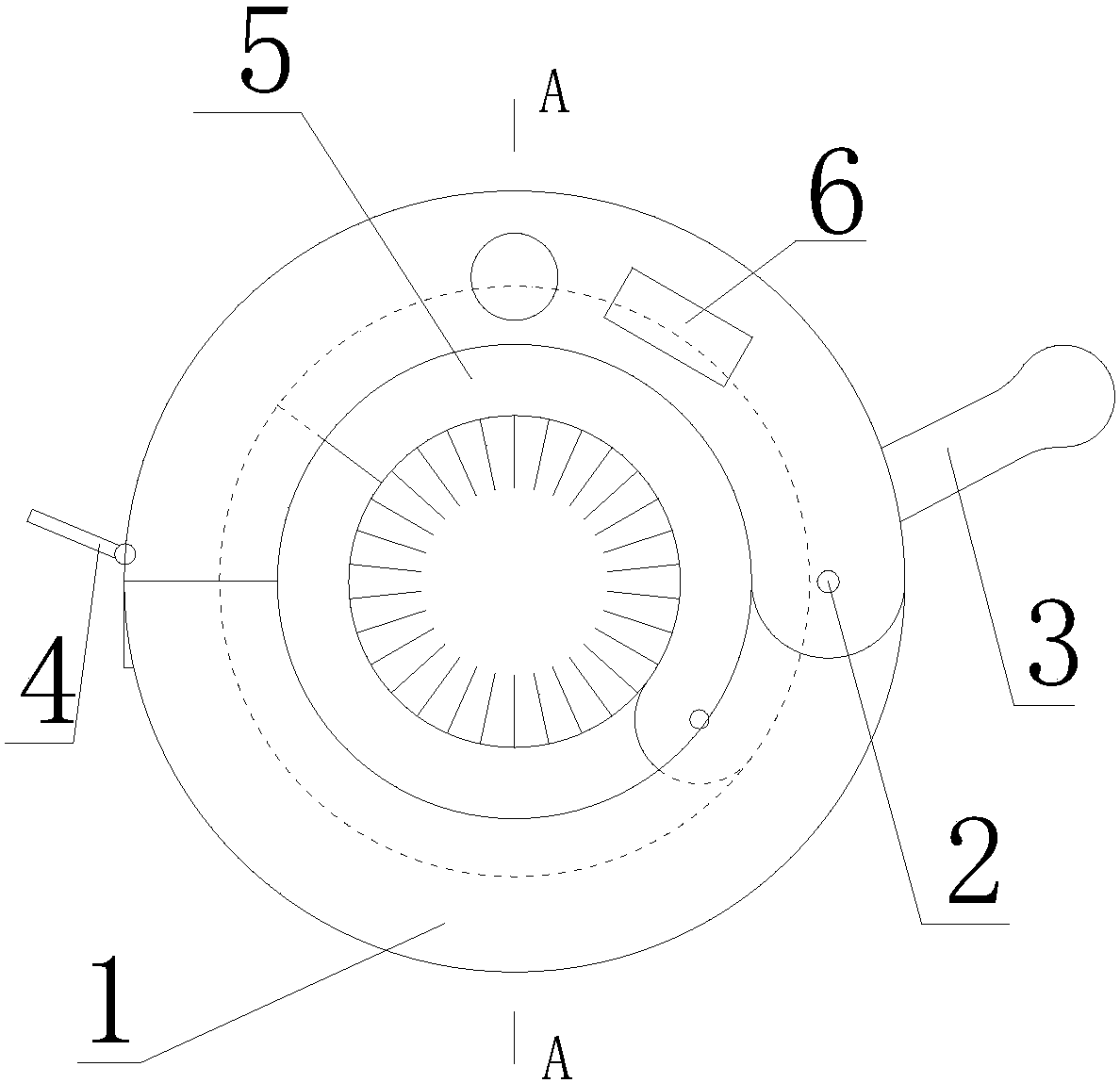

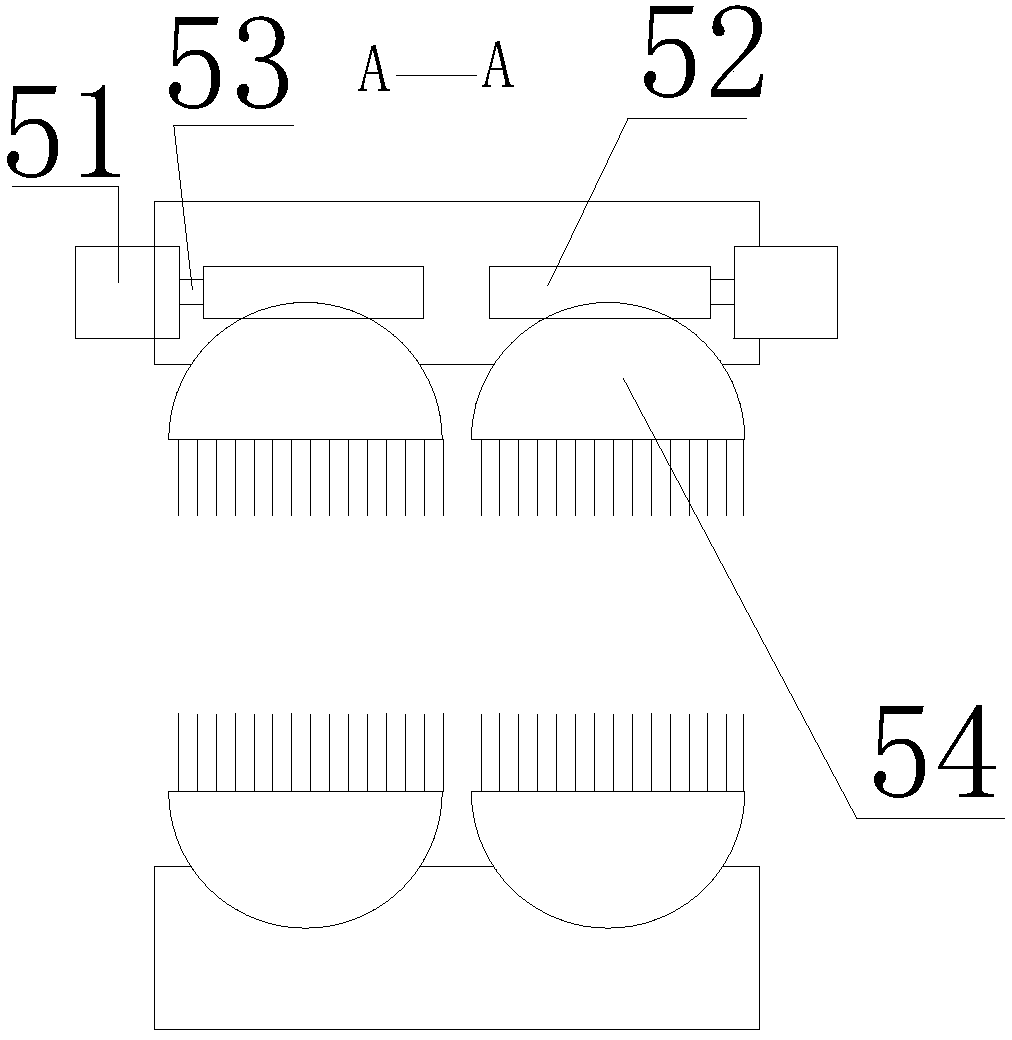

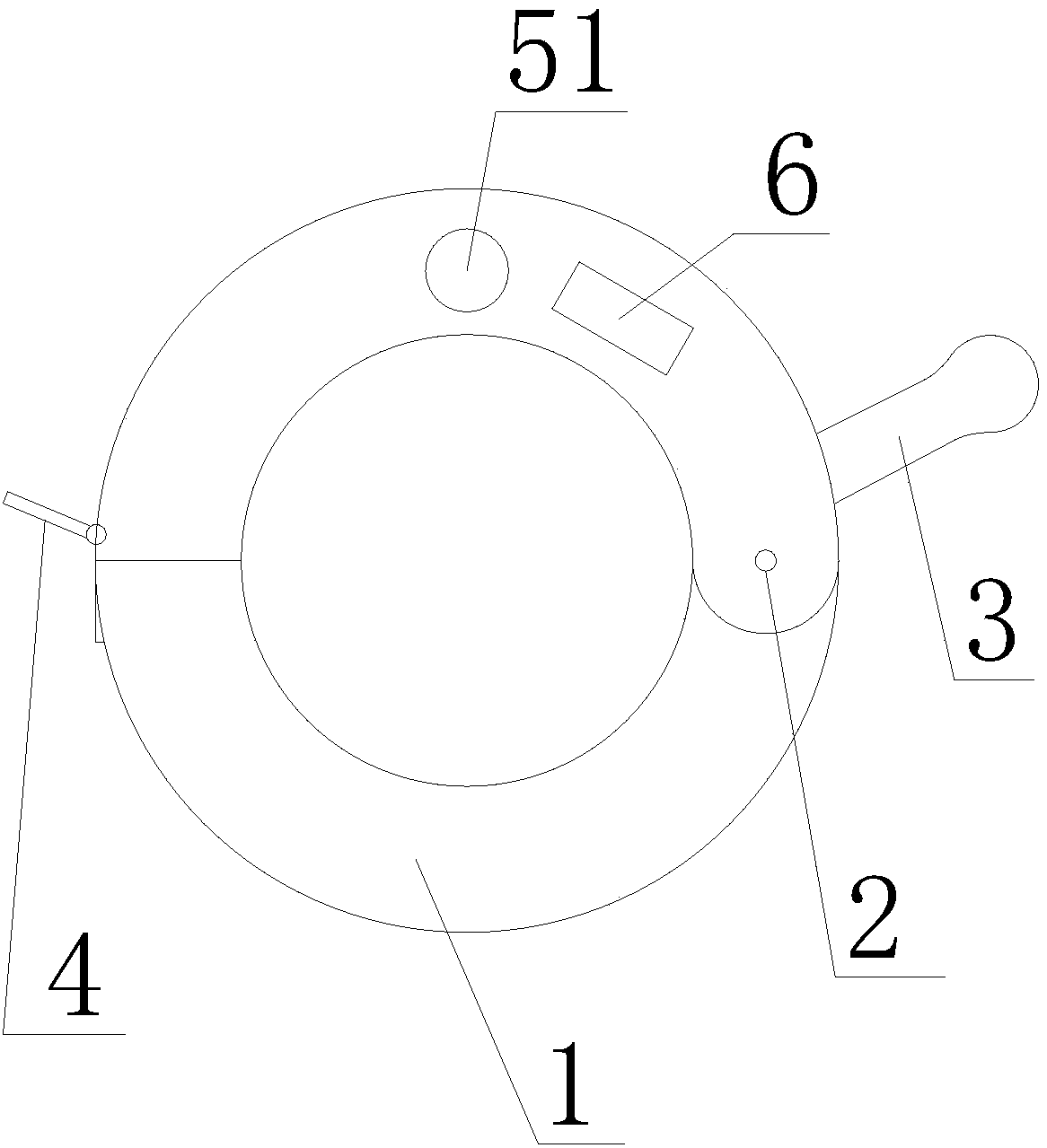

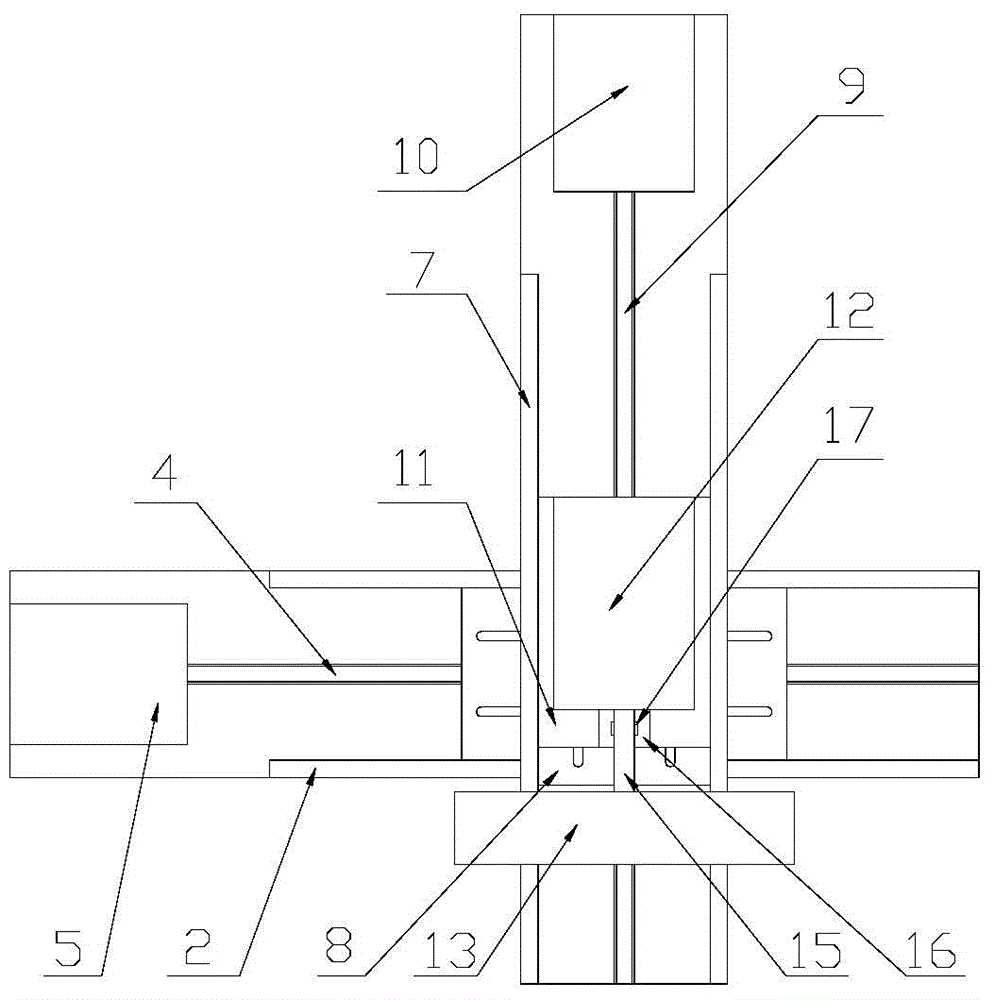

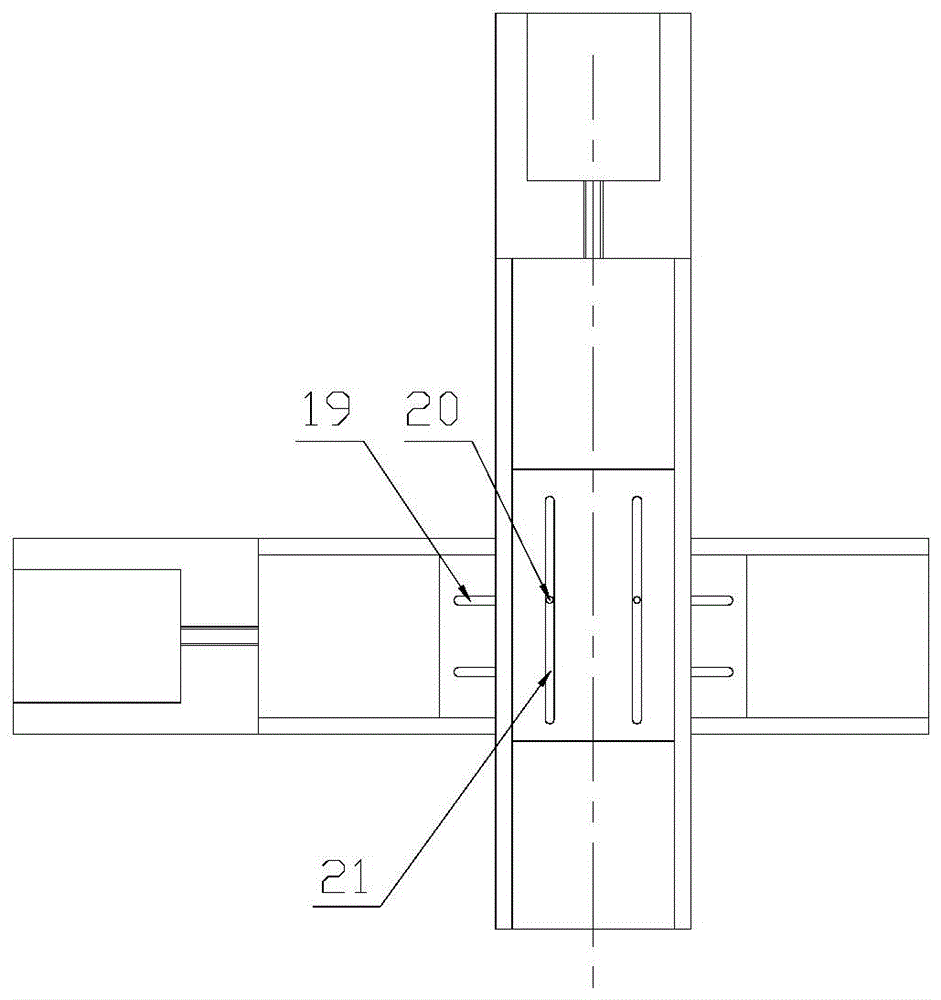

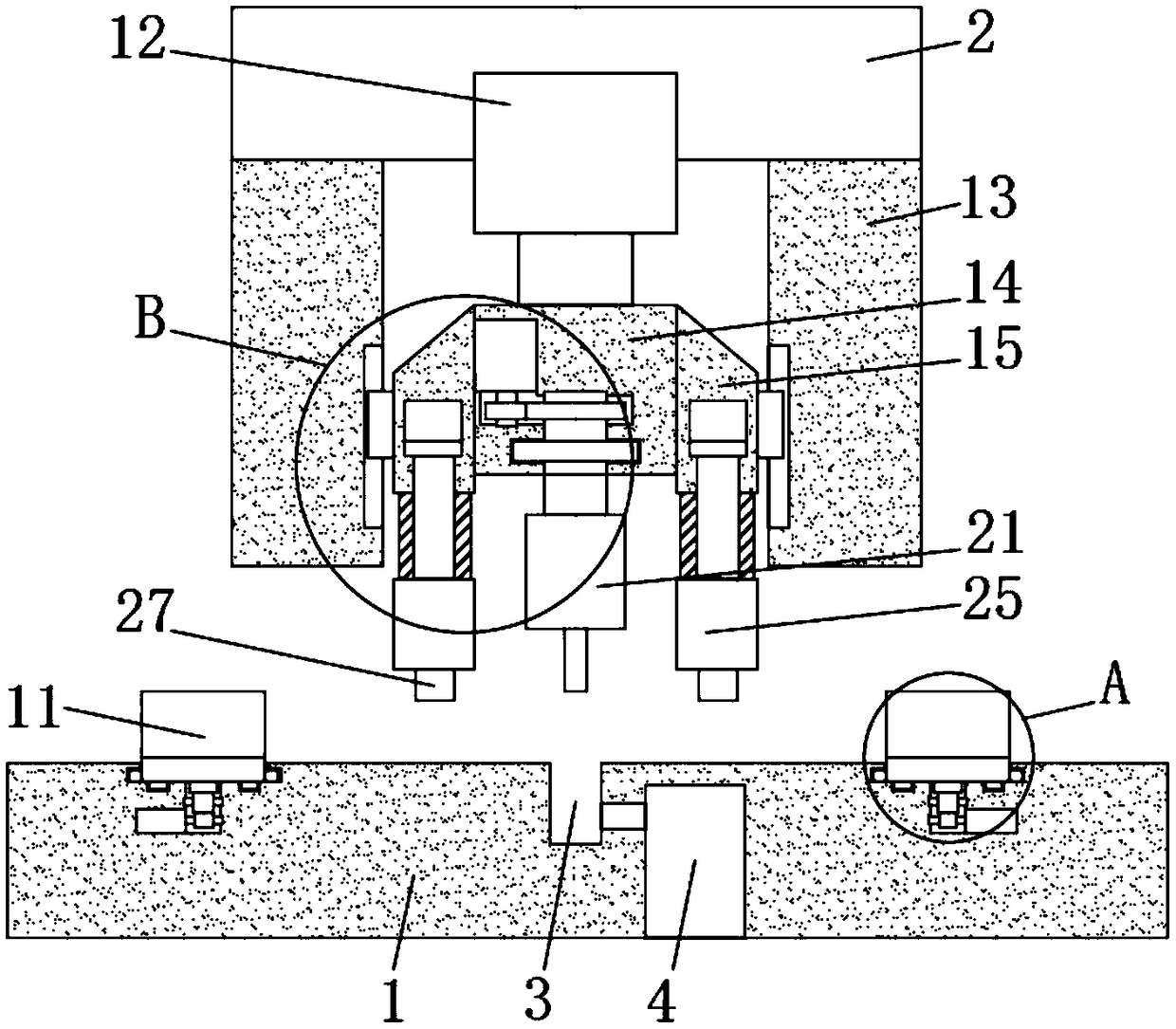

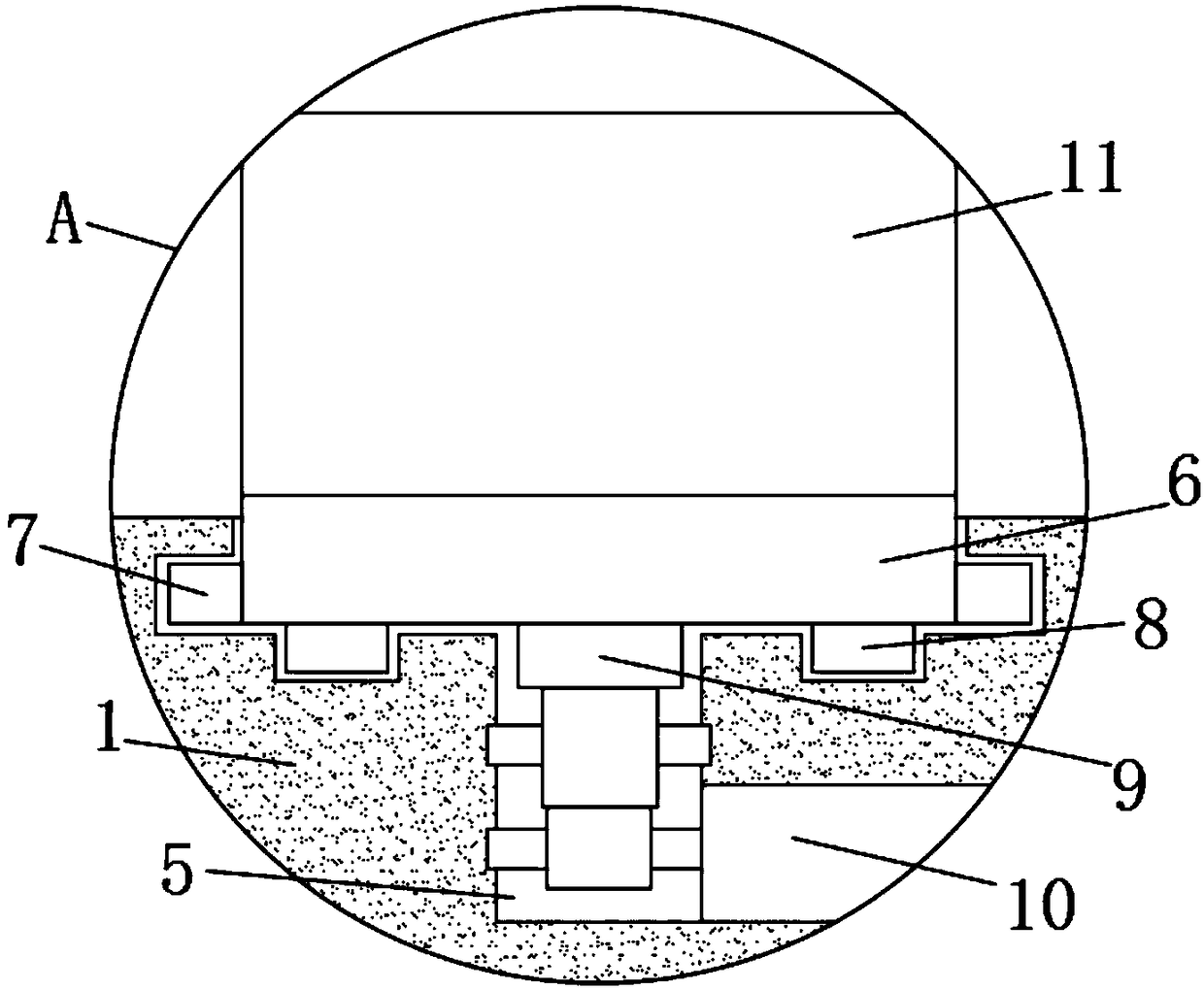

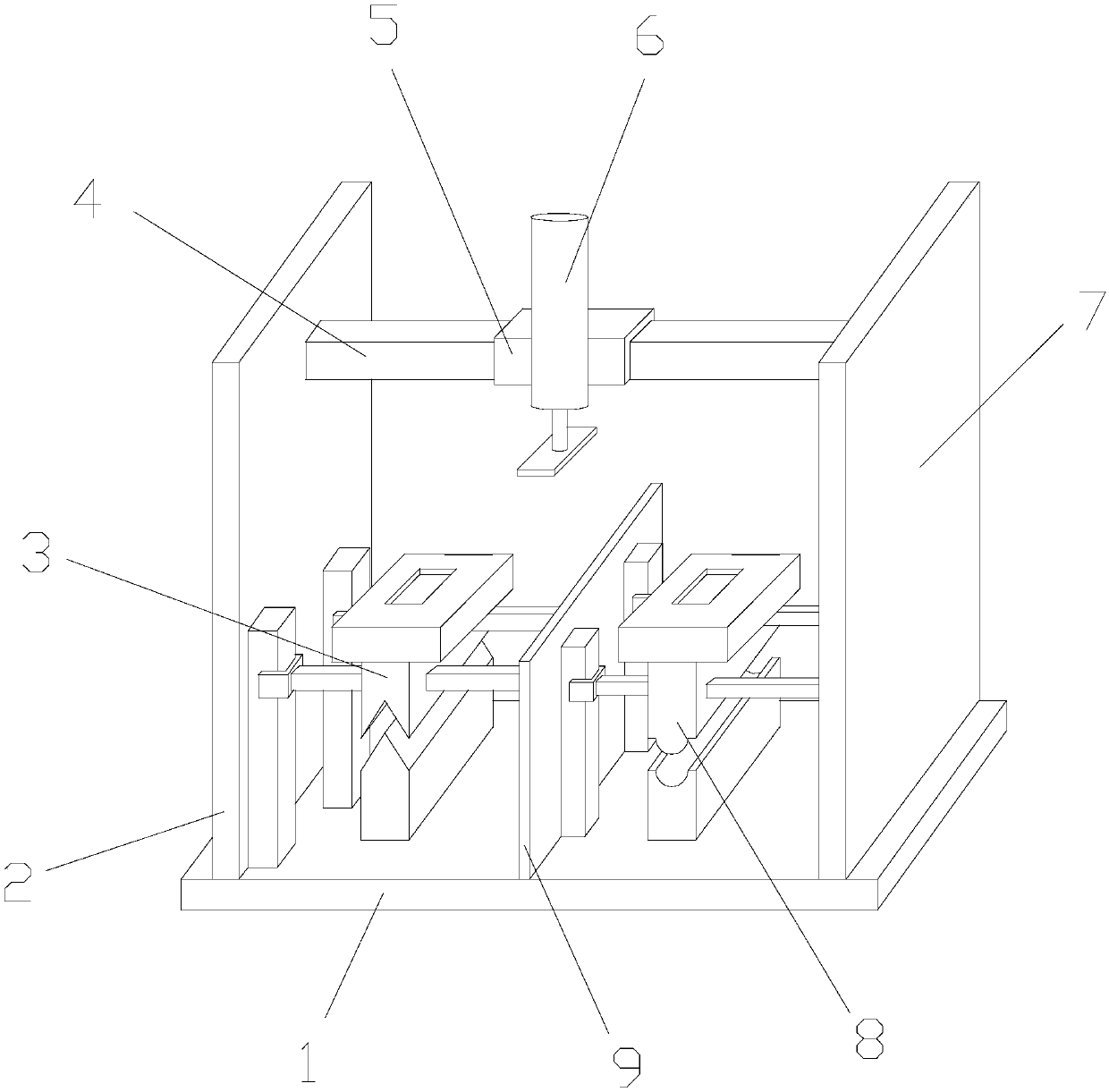

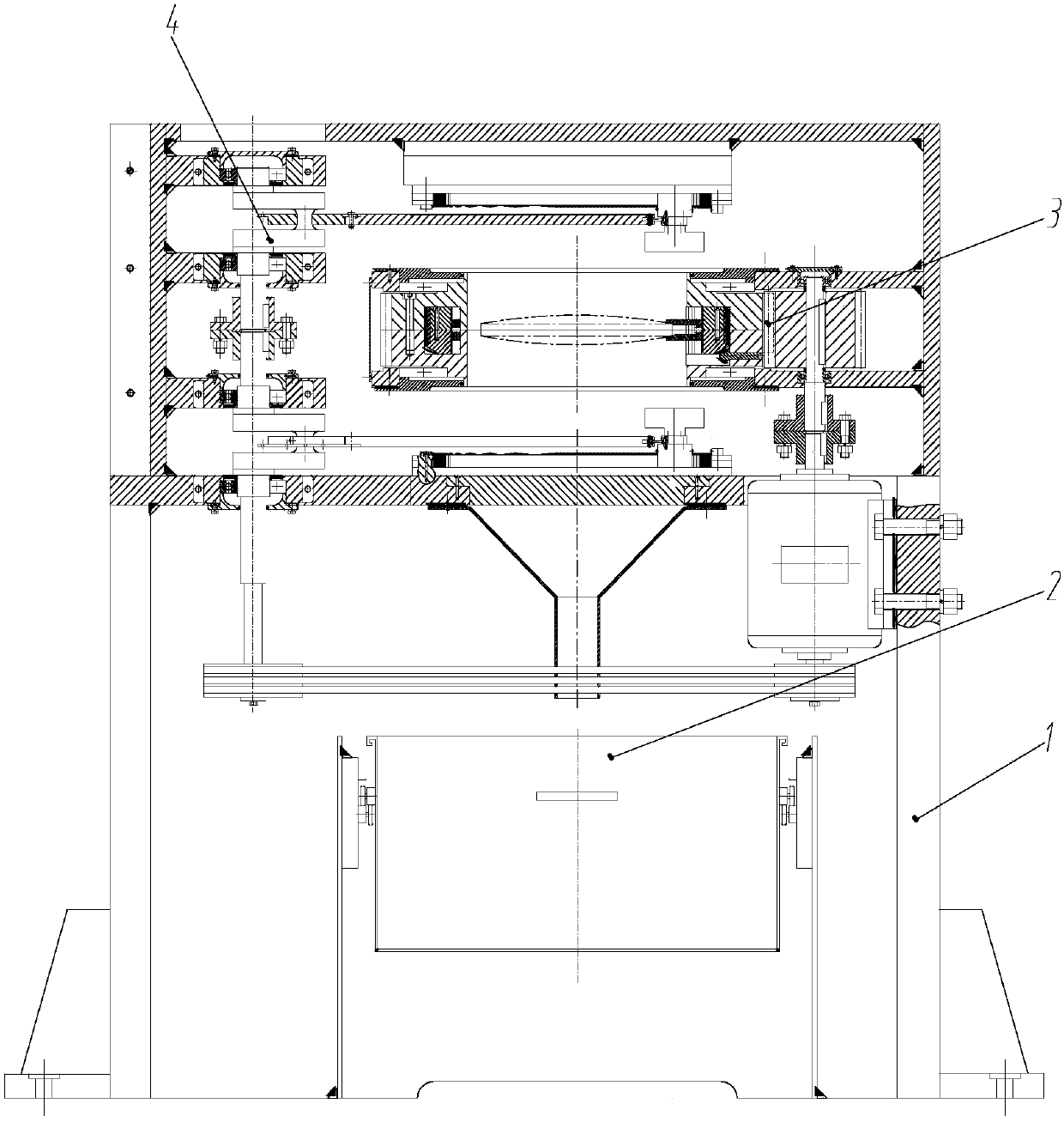

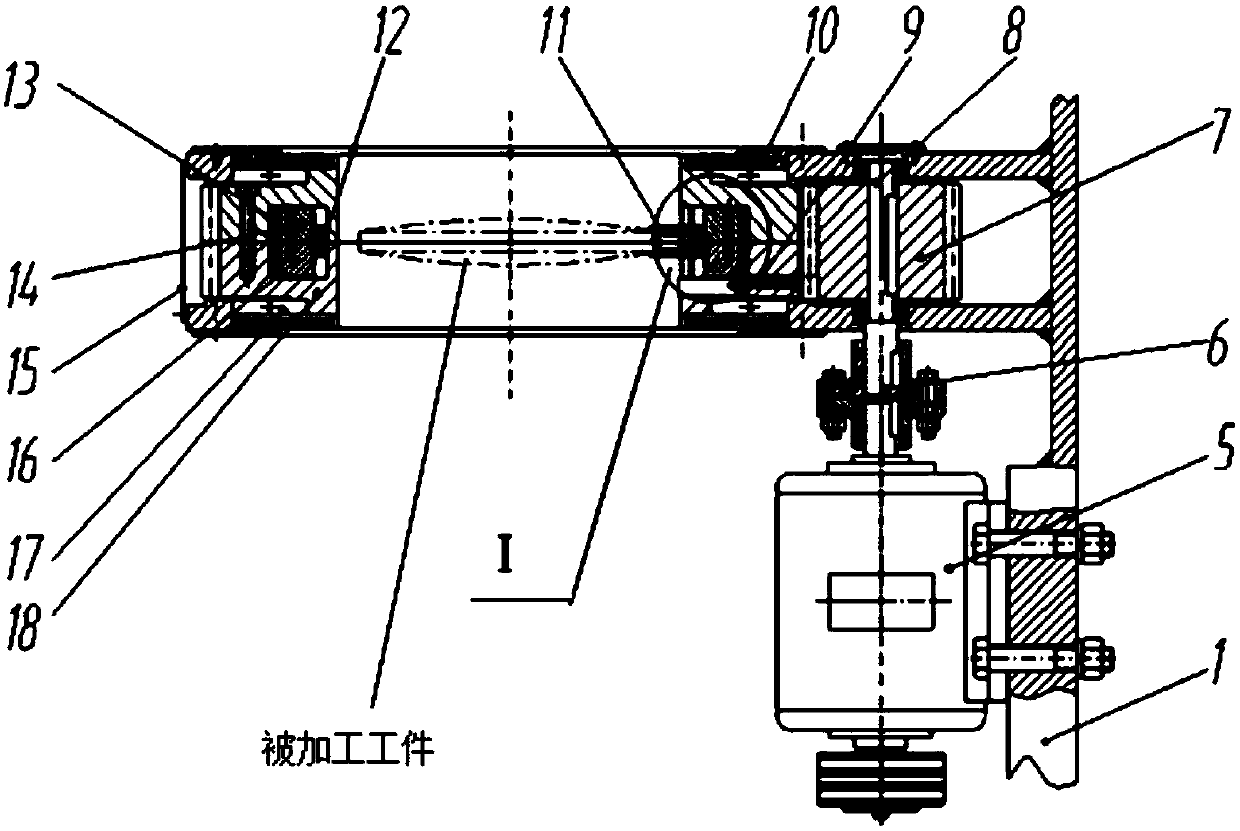

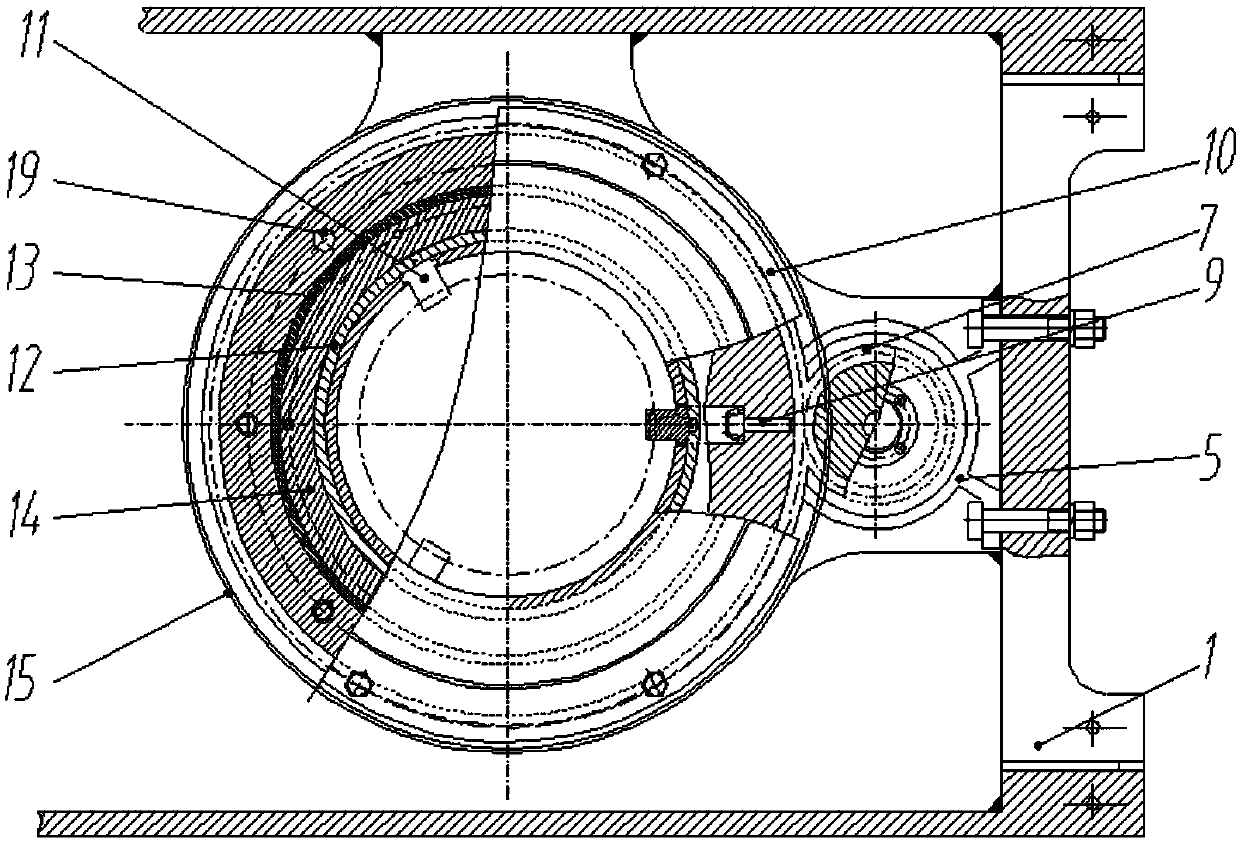

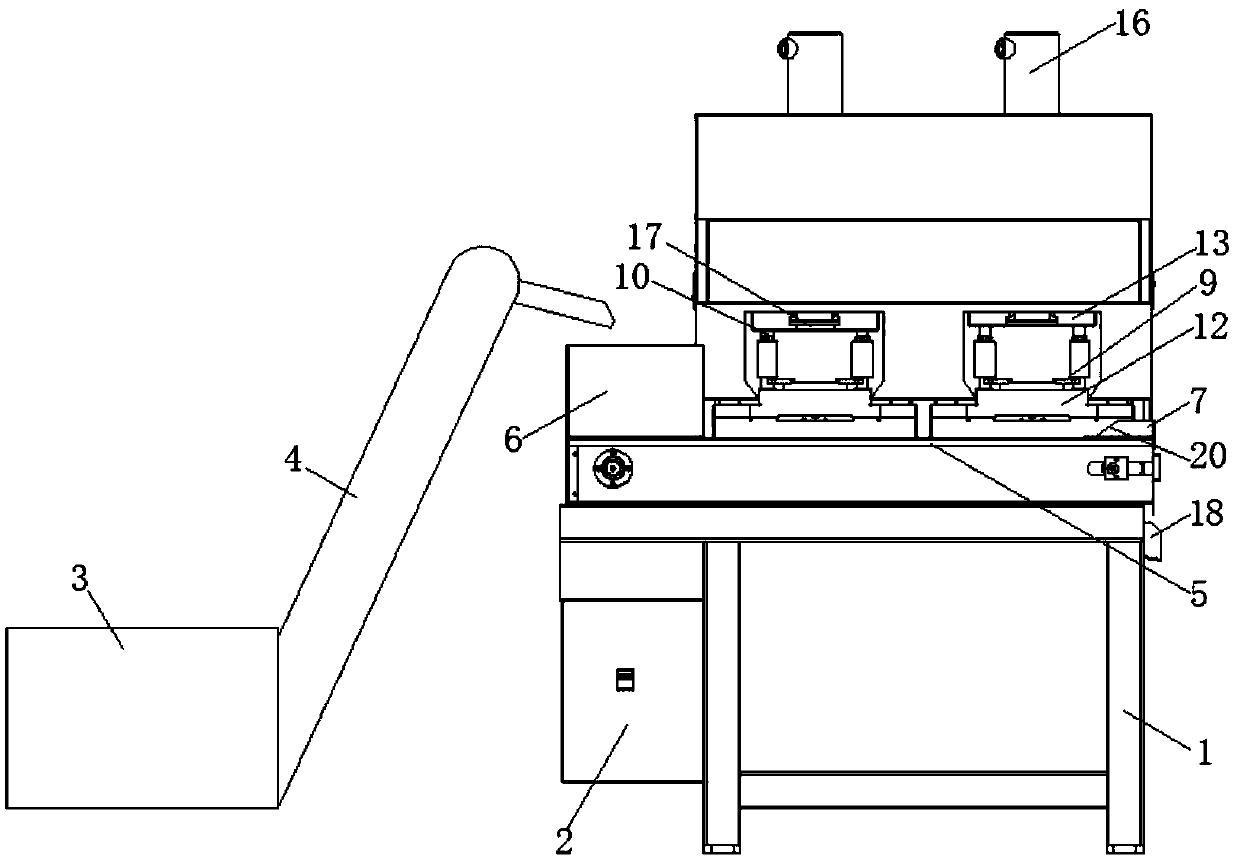

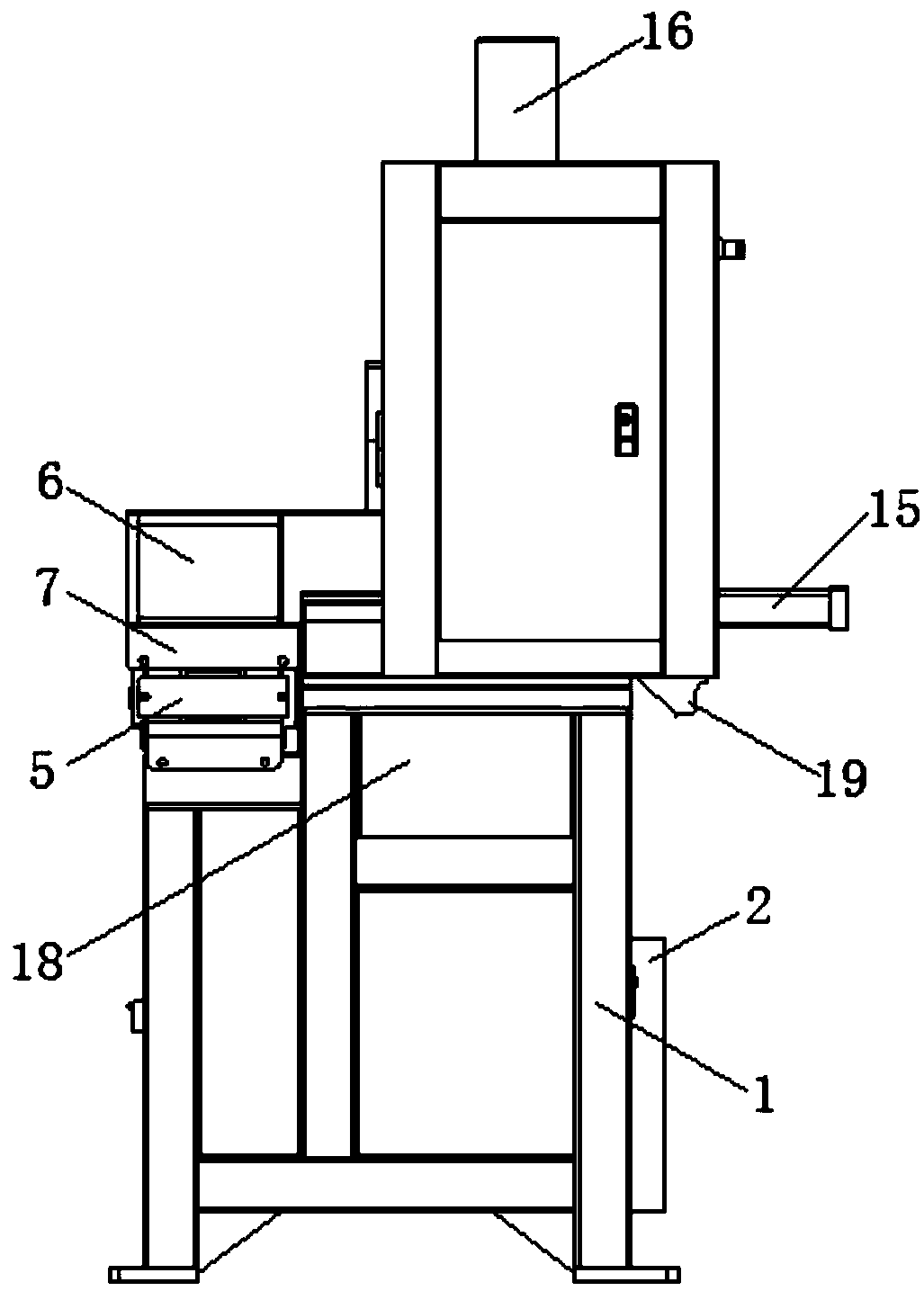

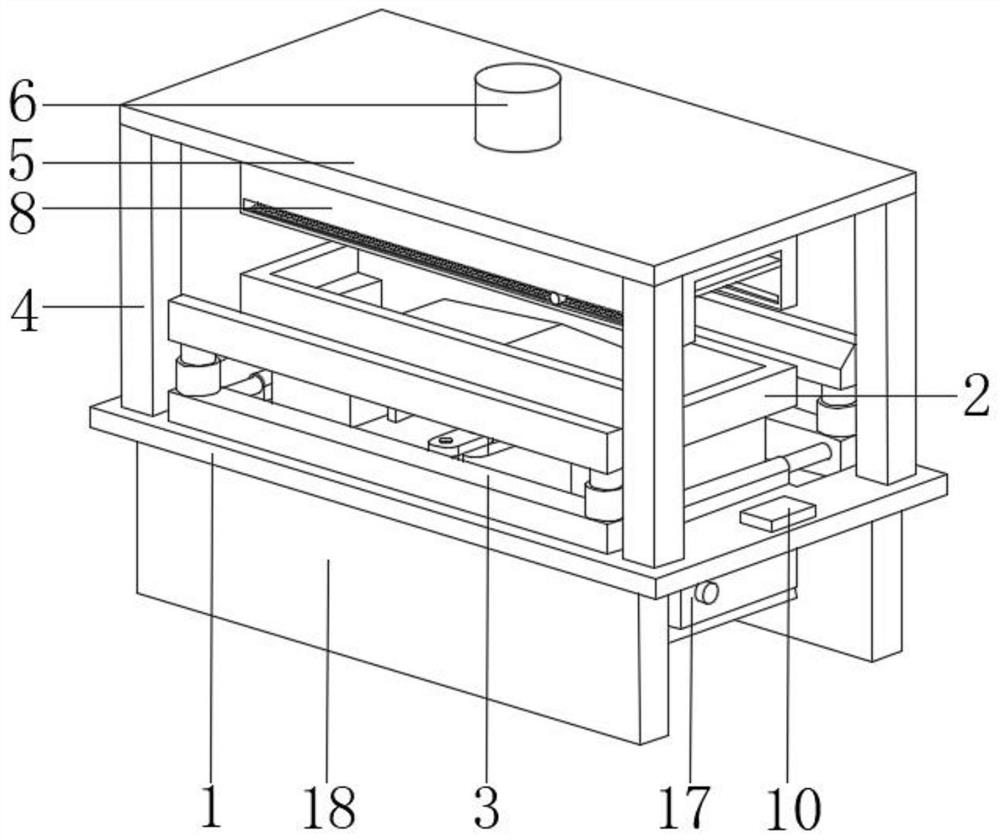

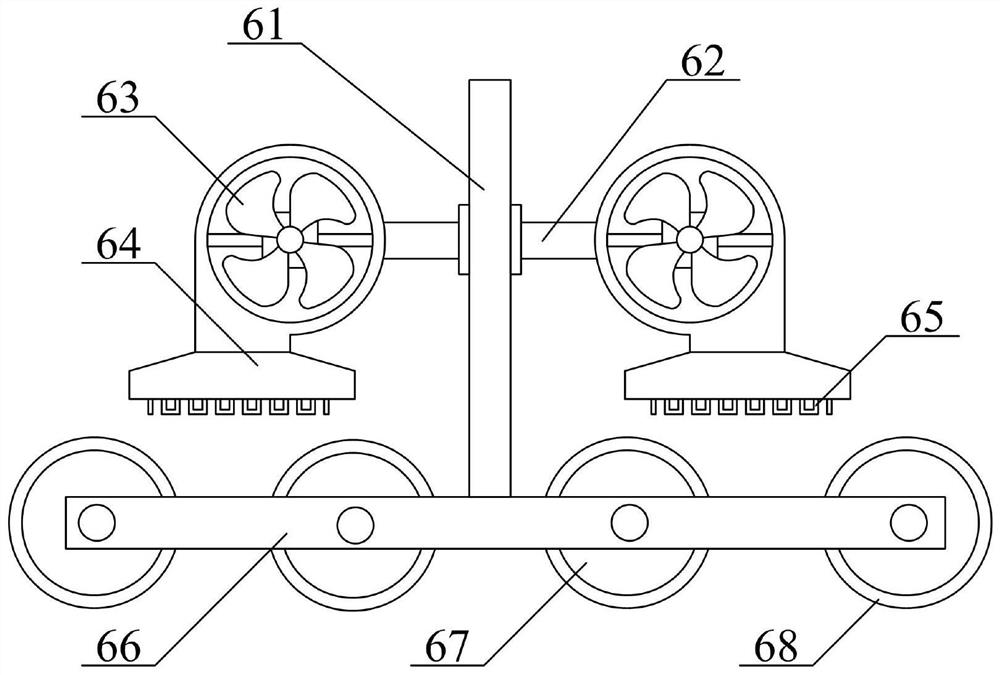

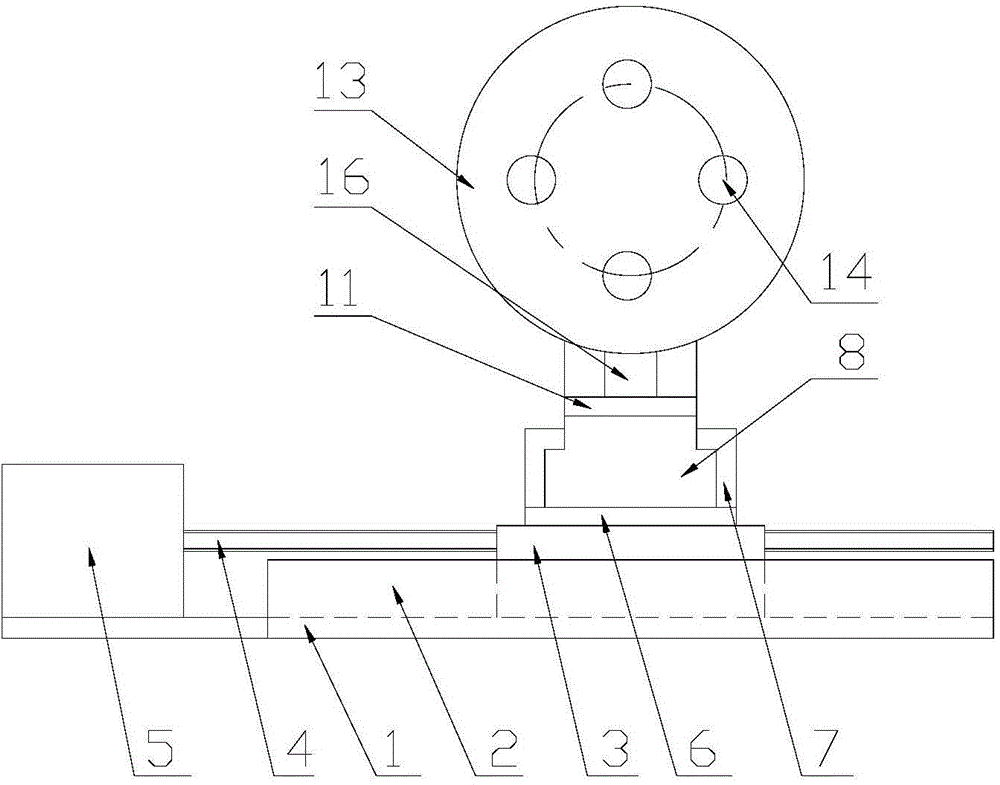

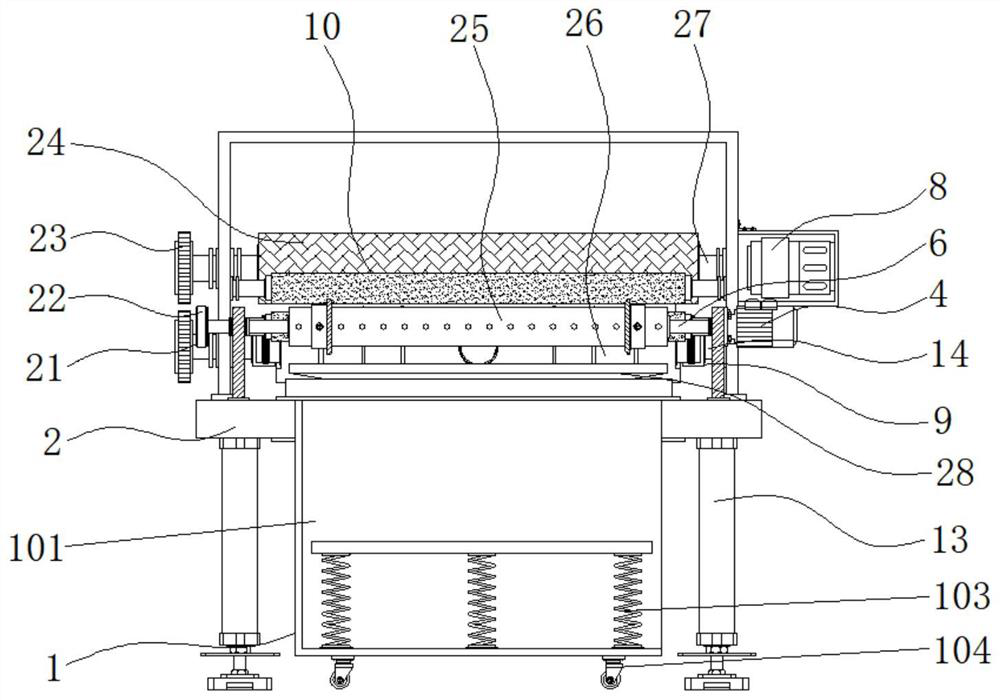

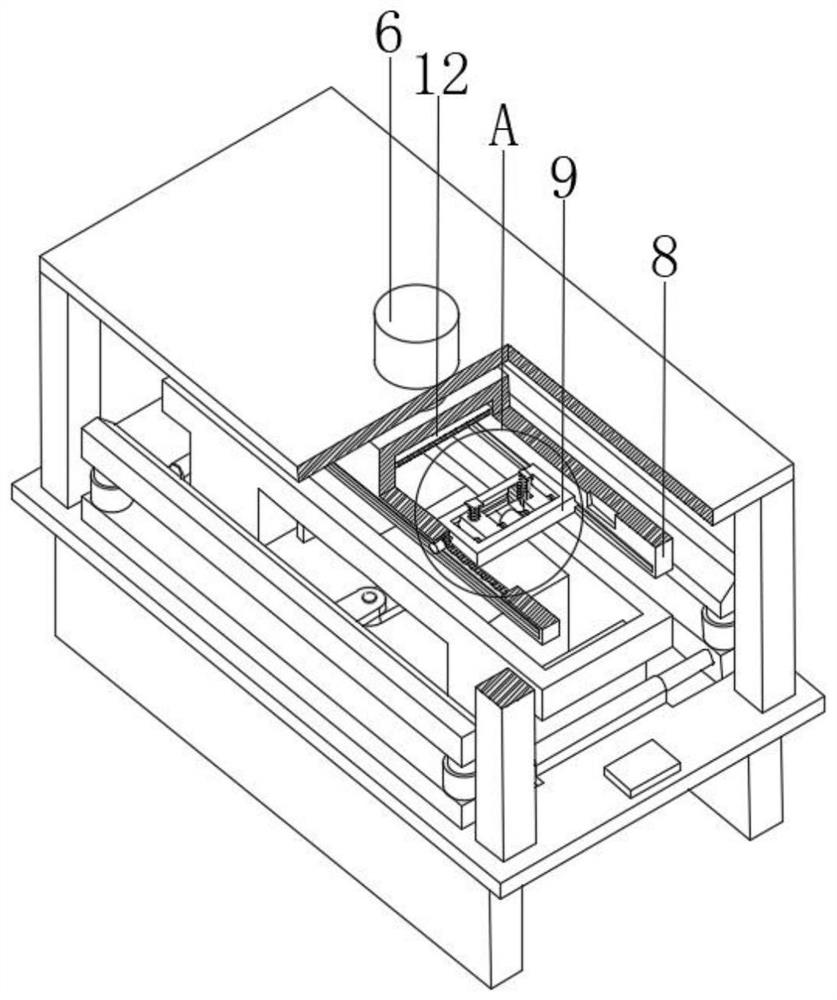

Magnetic grinder for two-sided disc small-curvature-surface component

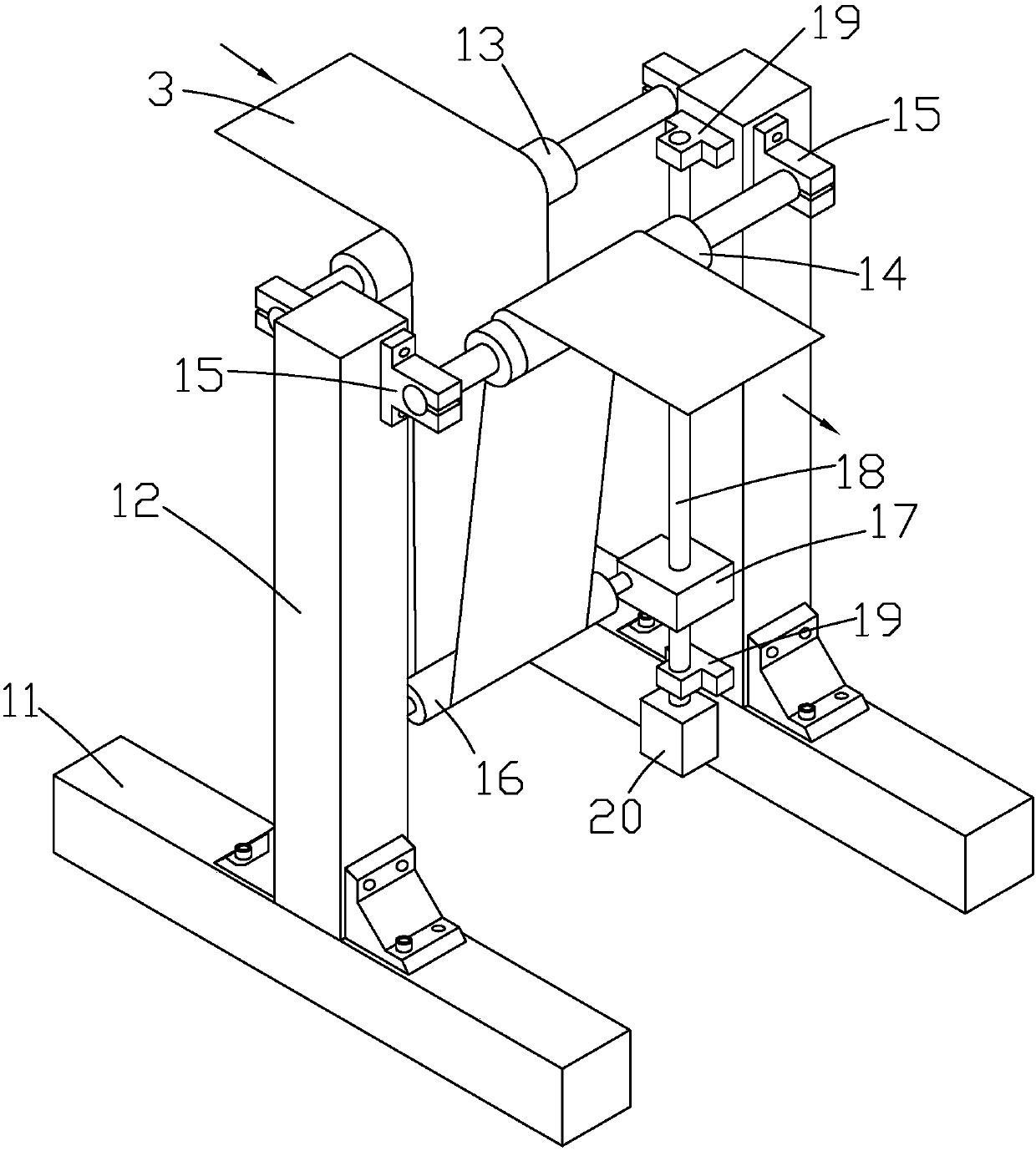

PendingCN107617932AImprove processing qualityImprove processing efficiencyGrinding work supportsLinear motionEngineering

The invention discloses a magnetic grinder for a two-sided disc small-curvature-surface component. The magnetic grinder comprises a workpiece rotating mechanism, a workpiece clamping mechanism, a magnetic grinding head reciprocating linear motion mechanism and a magnetic grinding material collecting device. When the whole magnetic grinder is driven by a double-shaft output motor, a workpiece can rotate through gear transmission, and double-eccentric-crankshaft sliding blocks can be driven through belt transmission to assist a magnetic grinding head in reciprocating linear motion; the transmission ratio of the gear transmission to the belt transmission is 1:1, that is, the magnetic grinding head performs the reciprocating linear motion once when the workpiece rotates in a circle; under theaction of a magnetic brush, machining tracks on the workpiece can be uniformly distributed on the whole machining surface through the matching between the rotating motion and the reciprocating linearmotion; in the above process, the grinding material is collected by the magnetic grinding material collecting device, thereby improving the workpiece machining quality and efficiency; and accordingly,the magnetic grinder can be utilized for the finishing grinding of a high-precision large-diameter lens, and has an extensive application prospect in the field of high-precision machining.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

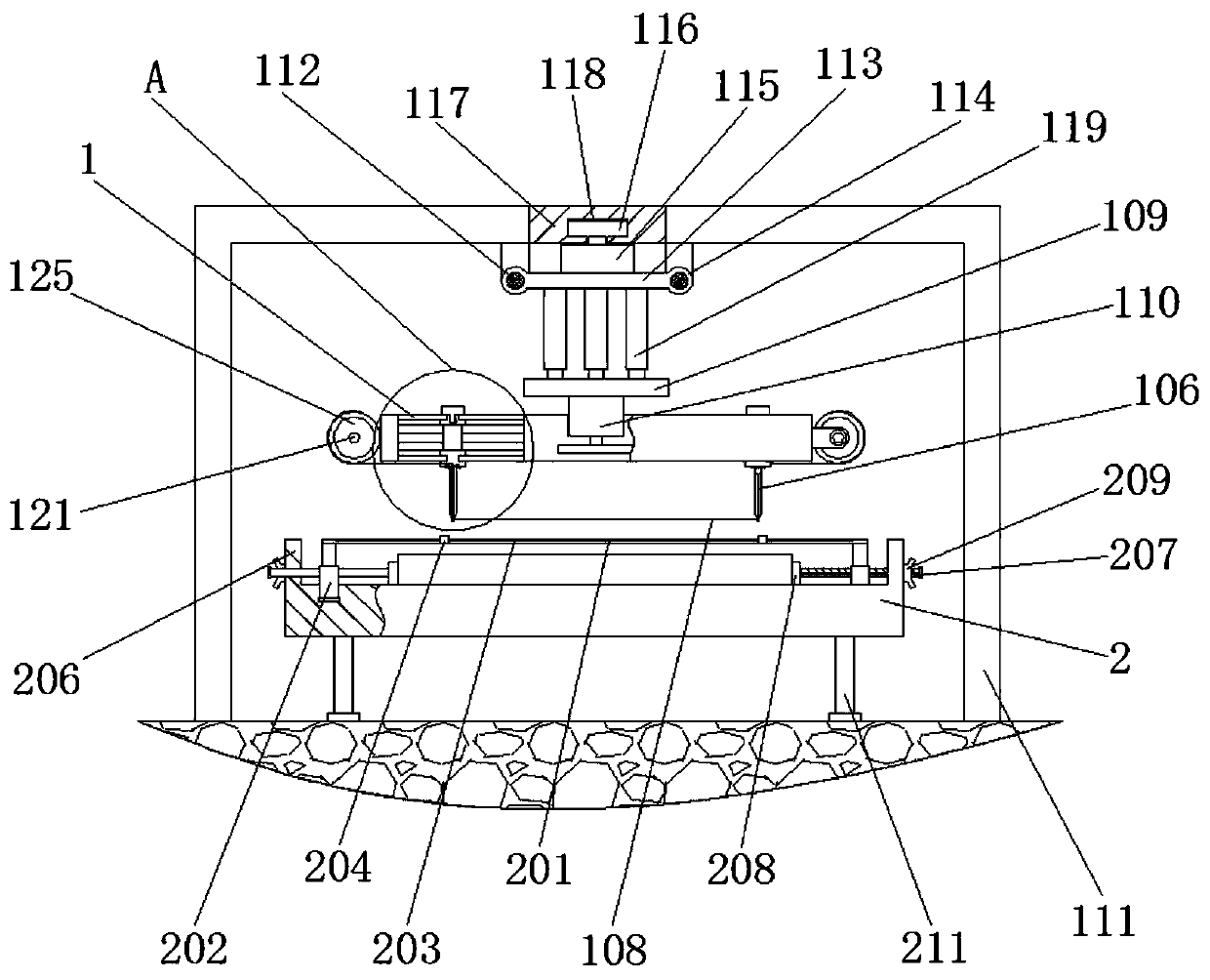

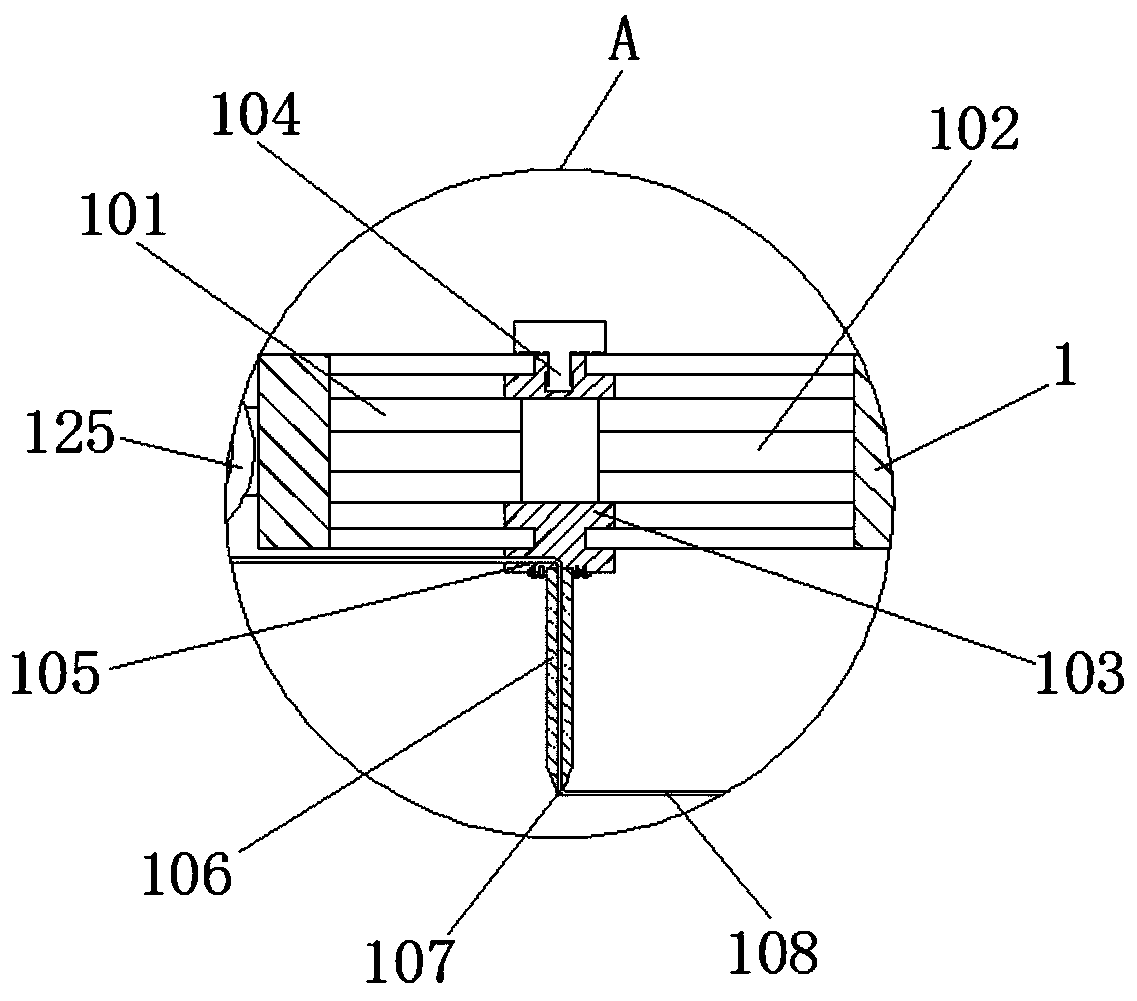

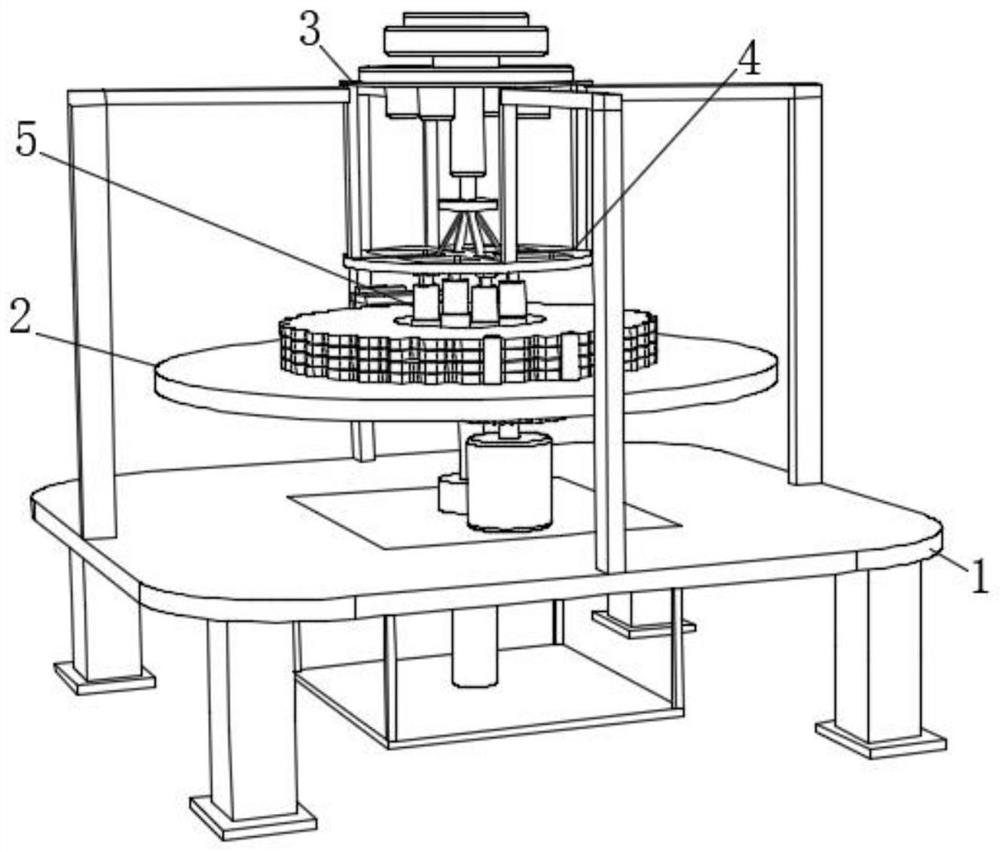

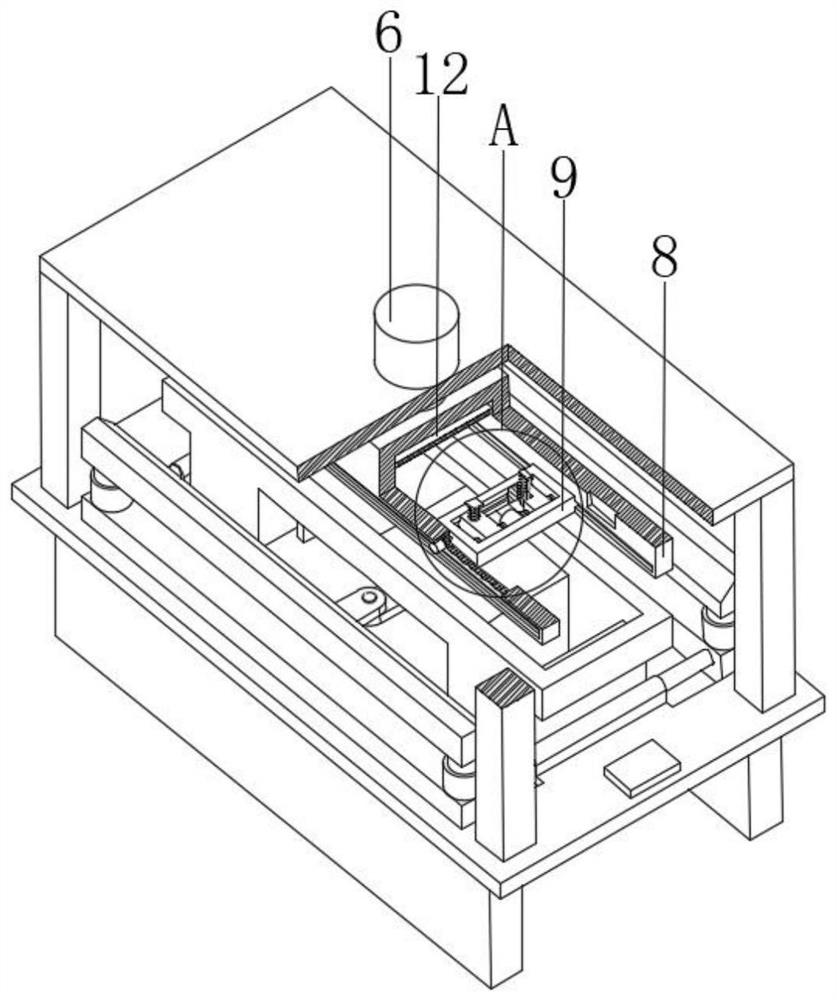

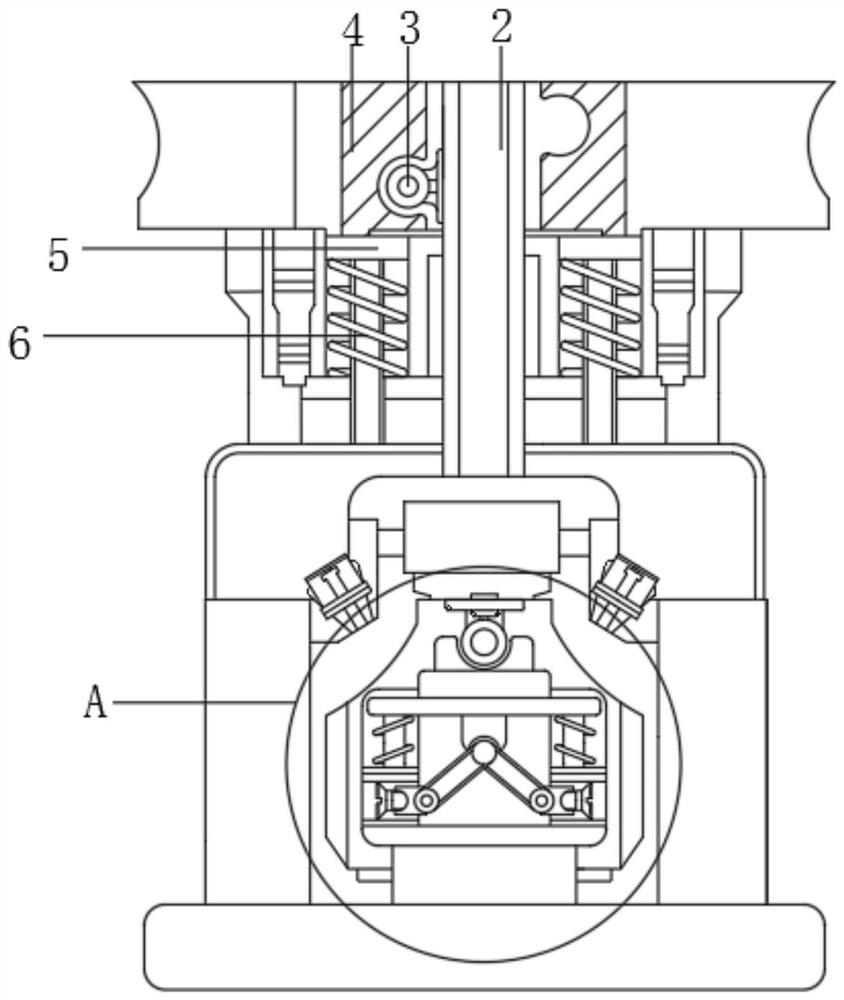

Polishing device used for gear machining and use method of polishing device

InactiveCN112139611AEasy to grindImprove the efficiency of grinding processingGear-cutting machinesGear teethGear grindingGear wheel

The invention discloses a polishing device used for gear machining and a use method of the polishing device, and relates to the technical field of gear machining. The polishing device comprises a machine frame assembly. A positioning assembly is arranged inside the machine frame assembly. A top frame assembly is arranged at the upper end of the machine frame assembly. A limiting assembly is arranged at the position, over the positioning assembly, of the bottom side of the top frame assembly. Four polishing assemblies are symmetrically arranged on the bottom side of the limiting assembly. The machine frame assembly comprises a fixed base. A fixed bottom frame is fixedly installed at the bottom end of the fixed base, a telescopic cylinder is fixedly installed at the upper end of the fixed bottom frame, and a lifting table is fixedly installed at the telescopic end of the telescopic cylinder. By means of the polishing device and the use method, multiple gears can be conveniently subjectedto polishing machining at the same time, the improvement of the polishing machining work efficiency of the gears is facilitated, the situation that the machining quality is influenced by deviation during gear grinding can be effectively prevented, assembly columns are rotated and subjected to face replacement after being detached and taken out, and polishing faces of polishing rollers can be changed by installing the assembly columns on assembly sliding blocks.

Owner:马鞍山金瓦格机械科技有限公司

Novel forging edge cutting machine

PendingCN110653317AEasy to operateImprove efficiencyDirt cleaningForging/hammering/pressing machinesStructural engineeringAssembly line

The invention relates to the technical field of edge cutting machines, and discloses a novel forging edge cutting machine. The novel forging edge cutting machine comprises a machine frame, a main control cabinet is arranged on the side surface of the machine frame, a storing frame is arranged at the side portion of the machine frame, a lifting machine is arranged on the side surface of the storingframe, and a horizontal-moving feeding assembly line is arranged at the front portion of the front surface of the machine frame; and a material steering mechanism located right below the dischargingend of the lifting machine is arranged at the feeding end of the horizontal-moving feeding assembly line, and a material stopping station is arranged at the tail end of the horizontal-moving feeding assembly line. According to the novel forging edge cutting machine, quick and continuous feeding can be achieved through the combination of the lifting machine and the horizontal-moving feeding assembly line, the finished forgings can automatically slide out by using a processing sliding way after processing finishing, the operation is convenient and fast, two stations are placed together, the processing time of each station is between 2-3 seconds, an operator can place the forgings on the two stations correspondingly, cycling of processing is achieved, and the efficiency is higher.

Owner:钟欣航

Adjustable cable bridge punching and bending machining integrated machine

ActiveCN112058964AGuaranteed stabilityPrevent affecting processing qualityPerforating toolsMetal-working feeding devicesCable trayMachining process

The invention discloses an adjustable cable bridge punching and bending machining integrated machine which comprises a workboard table, a bending structure and a punching structure. Openings are symmetrically formed in the left and right sides of the upper surface of the workboard table, a bridge placing table is arranged in the middle of the upper surface of the workboard table, the inner part ofthe bridge placing table is of a hollow structure and the openings in the bottoms of the left and right sides communicate to the corresponding openings in the surface of the workboard table, separately, supporting columns are symmetrically arranged at four corners of the upper surface of the workboard table, the top ends of the supporting columns are fixedly connected to the bottom surface of a top plate, a hydraulic pump and a hydraulic telescopic column are mounted in a mounting port at the center of the upper surface of the top plate, and an oil outlet in the bottom end of the hydraulic pump communicates to an oil inlet in the upper end of the hydraulic telescopic column. The adjustable cable bridge punching and bending machining integrated machine can hold and fix the cable bridge toprevent the cable bridge from deviating in a machining process to affect the machining quality, and further can bend the cable bridge effectively, and can be used for bidirectional interval adjustmentof a punched hole.

Owner:江苏中顺电气有限公司

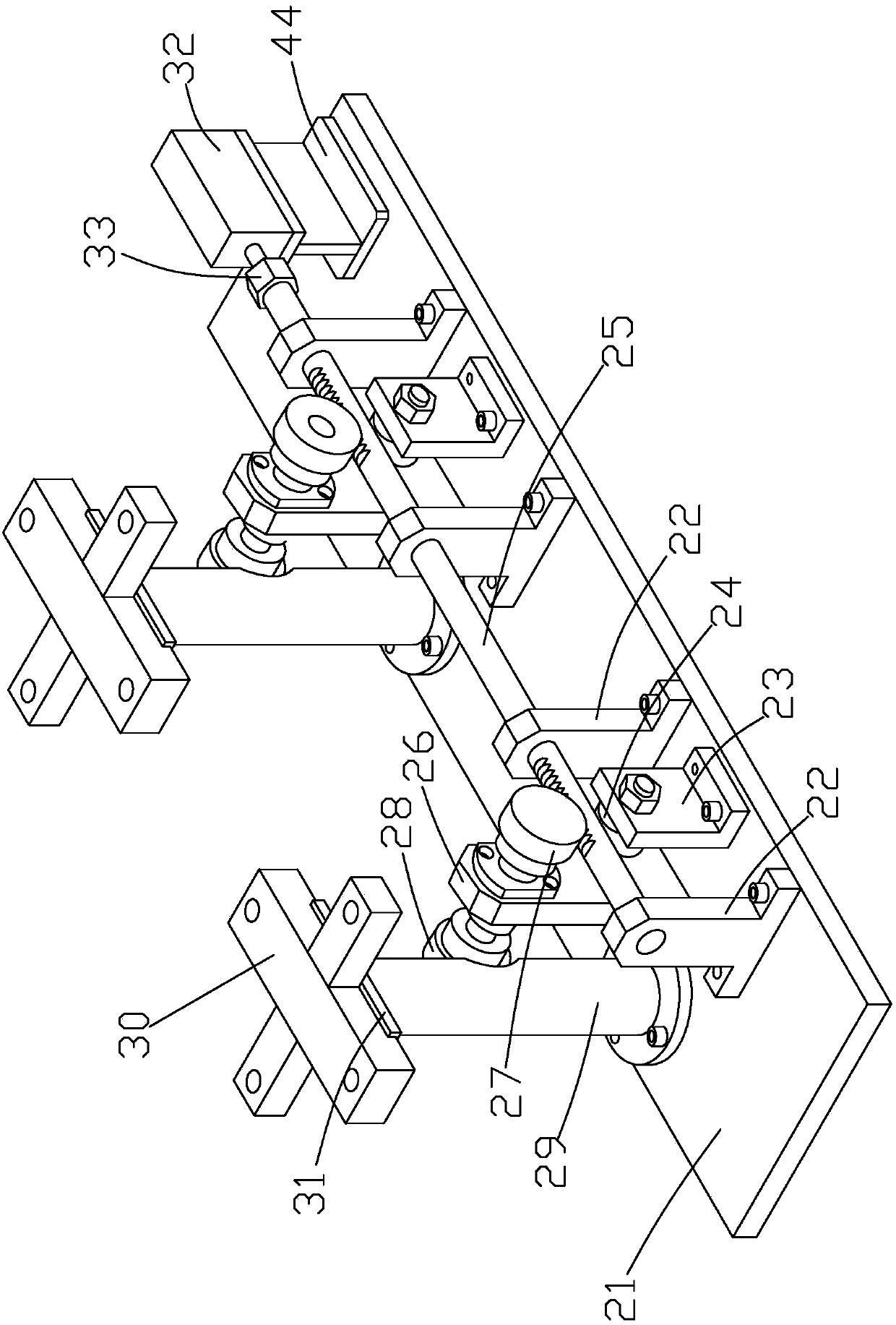

A sheet metal punching positioning and fixing device

InactiveCN107321841BReduce vibrationBuffer impact force of hammerMetal-working feeding devicesShaping safety devicesPunchingRoller screw

The invention discloses a punching positioning and fixing device for sheet metal. The punching positioning and fixing device comprises a U-shaped base plate; a plurality of damping devices are fixedly connected to the bottom of the inner surface of the U-shaped base plate; L-shaped fixing columns are connected to the outer surfaces of roller screws in a threaded mode; an objective table is fixedly connected to the middle position of the top of a supporting block; a buffering device is fixedly connected to the top of a fixing block; a horizontal pushing device is fixedly connected to the position, located at one side of the fixing block, at the bottom of an inner cavity of the objective table; turbine boxes are fixedly connected to one sides of the bottoms of inner cavities at the tops of the L-shaped fixing columns; and fixing plates are connected to the ends, close to the objective table, of threaded rods in a rotating mode. The invention relates to the field of sheet metal machining equipment. The punching positioning and fixing device has the advantages that a workpiece to be machined can be fastened, displacement of the workpiece can be prevented, the machining precision and the machining quality in the machining process of the workpiece can be protected, vibration can be reduced, a machine can be protected, and therefore the impact force of a punch hammer can be buffered in the punching process, the device can be protected, waste materials caused by punching can be pushed out, and the phenomenon that the machining quality is influenced due to the obstruction of the waste materials can be avoided.

Owner:柳州易晟模具有限公司

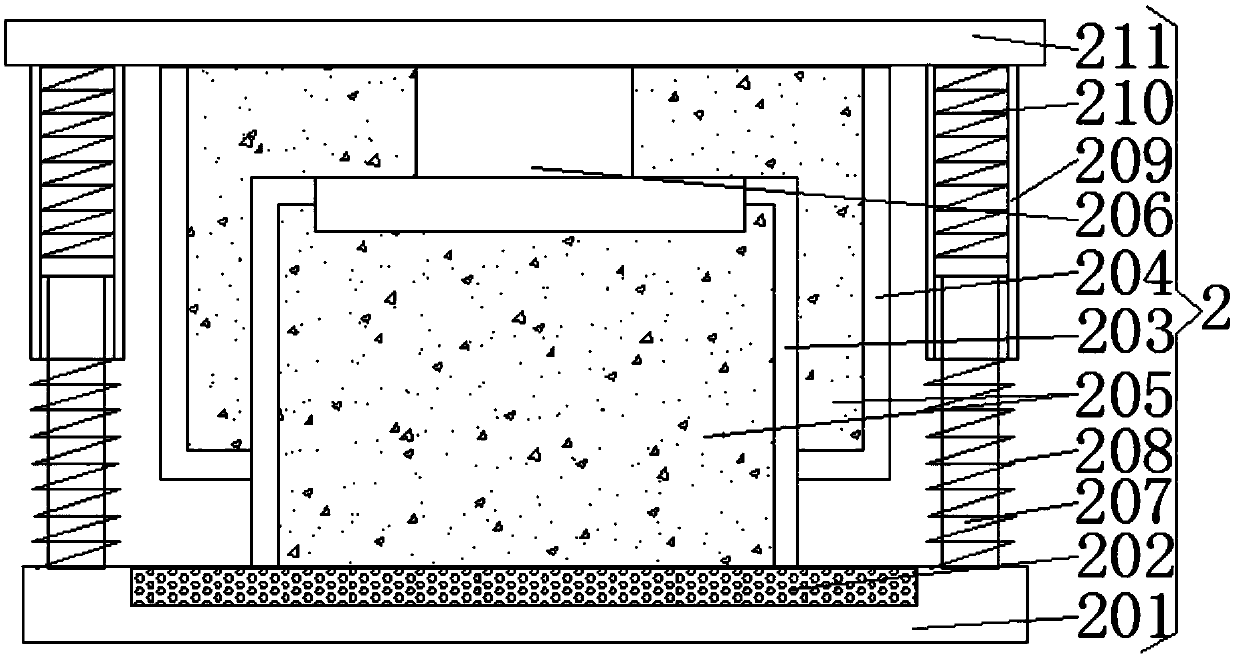

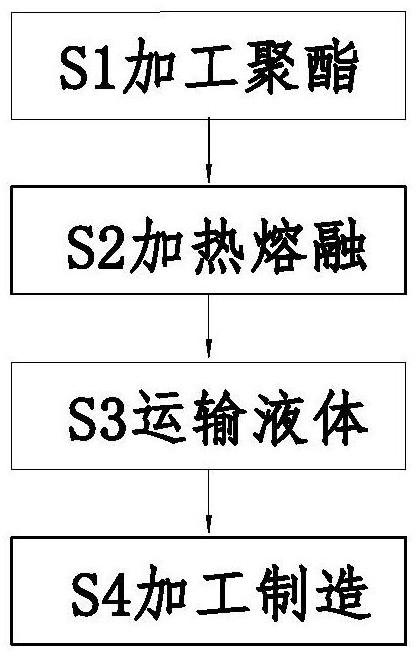

Manufacturing process of spun-bonded non-woven fabric

ActiveCN112458549AImprove efficiencyAffect UtilizationSpinning solution de-aeratingFilament forming substance formingPolyesterProcess engineering

The invention relates to a manufacturing process of spun-bonded non-woven fabric. A device implementing the manufacturing process comprises a workbench, a conveying device and a processing device, wherein the conveying device is fixedly installed at the upper end of the workbench, the processing device is fixedly installed at the upper end of the left side of the conveying device, and the conveying device comprises a heat preservation barrel, a heating plate, a glass plate, a first motor, a screw rod, a filtering plate, a conveying pipe and a heat preservation pipe. Polyester slices are heatedthrough the conveying device and are completely in a molten state, so that processing quality is prevented from being affected, meanwhile, liquid polyester attached to the inner wall of a part is scraped to prevent a utilization rate of the polyester from being affected, and polyester raw materials are sliced through the processing device and screened, so that the polyester slices which do not meet the standard are prevented from entering the conveying device and thus prevented from affecting the processing efficiency, meanwhile, the particle size of the polyester slices can be limited as required, and thus the use efficiency of equipment is improved.

Owner:佛山市顺德区宝富莱无纺布有限公司

Nanometer grinding device for grinding new material and grinding method

InactiveCN113941401AReduce delivery powerReduce processing stepsGrain treatmentsEngineeringMachining process

The invention relates to the technical field of grinding, in particular to a nanometer grinding device for grinding a new material, which comprises a shell, wherein a rotating shaft is movably connected in the shell, a roller is fixedly connected to the outer surface of the rotating shaft, a limiting cover is movably connected to the front end of the roller, a fixing plate is movably connected to the outer surface of the rotating shaft and located at the lower end of the roller, a compression spring is fixedly connected to the lower end of the fixing plate, a connecting block is fixedly connected to the lower end of the rotating shaft, a connecting ball is fixedly connected to the lower end of the connecting block, and a clamping block is movably connected to the lower end of the connecting ball. When the pressure intensity of the lower end of a pressure adjusting block is increased, internal fine standard particles are filtered by a filter plate and output to the outside through a discharging one-way valve so as to be collected, and when particles which are not filtered by the filter plate are transferred by a circulating mechanism under the action of the pressure intensity, the particles enter an outer cover again and are processed again. Therefore, the effect that when the internal material does not reach the standard in a machining process, machining is automatically cycled is achieved.

Owner:嘉兴市贤亿沓科技有限公司

Intelligent dehydration device for corrugated paper production

InactiveCN112197522AGood for second dehydrationImprove dehydration effectMechanical working/deformationDrying solid materials without heatElectric machinePaper production

The invention provides an intelligent dehydration device for corrugated paper production which comprises a bottom plate, supporting beams, a transverse plate, supporting rods, a corrugated paper waterabsorption frame structure, an auxiliary extrusion drying frame structure, a corrugated paper extrusion water outlet frame structure, a rotary cleaning frame structure, a support, a cross beam, a transmission roller, a conveying belt, driving motors, a rotary motor and a control box. The supporting beams are welded to the left side and the right side of the upper part of the rear end of the bottom plate; the transverse plate is connected to the upper parts of the front ends of the supporting beams through bolts; the supporting rods are in bolted connection to the left side of the upper part of the bottom plate; and the corrugated paper water absorption frame structure is arranged on the upper parts of the inner sides of the support rods. The intelligent dehydration device for corrugated paper production provided by the invention has the beneficial effects that through the arrangement of a rolling roller, the conveying belt and sponge mats, the rolling roller drives the conveying beltto rotate to guide corrugated paper to move leftwards, meanwhile, the sponge mats can absorb residual water in the corrugated paper, so that secondary dehydration of the corrugated paper is facilitated, the residual water in the corrugated paper is sucked out, and a dehydration effect of the equipment on the corrugated paper is improved.

Owner:ZHEJIANG RONGSHENG PAPER IND HLDG

Thread rolling machine capable of machining thread ends with different lengths

PendingCN112756523APrevent affecting processing qualityAvoid pollutionScrew-threads articlesScrew threadEngineering

The invention belongs to the field of thread rolling machines, particularly relates to a thread rolling machine capable of machining thread ends with different lengths, and aims at solving the problems that an existing thread rolling machine can only machine bolts with the thread ends with the specific lengths, different devices need to be replaced if the thread ends with the different lengths need to be machined, the production cost is increased, the bolts are not firmly fixed when the bolts are machined, and the machining quality is reduced. According to the scheme, the thread rolling machine comprises a base, the top of the base is fixedly connected with a machine frame, and the inner wall of one side of the machine frame is fixedly connected with an electric push rod. The thread rolling machine is reasonable in structure and convenient to operate, the machined bolts are stably clamped, and therefore it can be prevented that when the machined bolts are machined, the machined bolts move, and the machining quality is influenced; and meanwhile, the distance of the machined bolts between a movable thread plate and a static thread plate is adjustable, so that the threaded ends with the different lengths can be machined, additional equipment is not needed, the production cost is reduced, and use is convenient.

Owner:福建新峰科技有限公司

Glass steel winding molding method

InactiveCN108454078AGuaranteed temperaturePrevent affecting processing qualityFiberMaterials science

The invention belongs to the technical field of glass steel molding and particularly relates to a glass steel winding molding method which comprises the following steps: I, preparing raw materials; II, preparing a glue liquid; III, inspecting equipment; IV, cleaning a core mold; V, performing winding molding, pouring the glue liquid into a glue trough, equally dividing a fiber into two parts, feeding one part of the fiber through a glue soaking tank and a glue extrusion roller, dividing multiple glued fibers into a plurality of groups, further feeding through a fiber division device, bundlingthe fibers, winding according to a set wire shape, firstly winding a layer of fibers which are not soaked into the flue, secondly winding a layer of the glued fibers, winding in sequence alternatively, adjusting a gluing device at any time to control the glue quantity on the fibers, scraping off excessive glue at any time when the fibers are wound, observing fiber ordering situations, measuring thicknesses, and powering off a machine when design requirements are met; VI, performing curing; VII, performing demolding.

Owner:关清英

One-hand opening knife processing device based on laser cutting technology

PendingCN110508934APrevent affecting processing qualityImprove work efficiencyLaser beam welding apparatusLaser cuttingMechanical engineering

The invention provides a one-hand opening knife processing device based on laser cutting technology, and belongs to the technical field of laser cutting. The one-hand opening knife processing device comprises a housing and a lathe inserted into the housing, wherein the lathe is provided with a conveyor belt capable of moving circumferentially; a laser cutting head is arranged in the housing; the laser cutting head is positioned above the conveyor belt and capable of linearly moving back and forth along an X axis and a Y axis; and the laser cutting head is also provided with a plurality of mobile fixing assemblies for fixing to-be-cut products. The laser cutting head can quickly cut to-be-processed workpieces into target products so as to increase the work efficiency. Processing surfaces after cutting are flat and smooth so as to eliminate a subsequent manual grinding process and save the cost. The mobile fixing assemblies can automatically fix the workpieces when the laser cutting headperforms cutting, and the mobile fixing assemblies can move along with the laser cutting head so as to prevent the workpieces from loosening resulting in the influence on the processing quality, savethe time required by workpiece clamping, workpiece unfastening and other processes, and improve the work efficiency.

Owner:ZHEJIANG JUXING TOOL

Clamping device of numerical control machine tool

InactiveCN105773212APrevent affecting processing qualityImprove clamping effectPrecision positioning equipmentExpansion mandrelsMachine toolRotating disc

The invention discloses a clamping device of a numerical control machine tool. The clamping device of the numerical control machine tool is larger in moving range, capable of clamping multiple workpieces at a time and performing machining in turn, and higher in working efficiency. The clamping device comprises a first base, a first moving plate is arranged on the first base in a sliding fit manner, a first lead screw is arranged in the first moving plate in a thread fit manner, and the first lead screw is connected with a first driving motor on the first base; a second base is fixed to the first moving plate, a second moving plate is arranged on the second base in a sliding fit manner, and a second lead screw is arranged in the second moving plate in a thread fit manner; the second lead screw is connected with a second driving motor on the second base, a mounting seat is arranged on the second moving plate, and the mounting seat is longitudinally parallel to a second guide rail; a third driving motor is arranged on the mounting seat, and a rotating disc is fixed to a rotating shaft of the third driving motor; four clamps are arranged on the rotating disc, and a square is formed by the four clamps; and the crossing point of the diagonal lines of the square is located on the axis line of the first driving motor.

Owner:重庆丰德数控机床有限公司

High-efficiency and energy-saving mixing device

InactiveCN106914180ASimple structureImprove stirring efficiencyRotating receptacle mixersTransportation and packagingEngineeringMotor shaft

The invention belongs to the technical fields of environmental-protection and energy-saving mechanical devices, and especially relates to a high-efficiency and energy-saving mixing device. The high-efficiency and energy-saving mixing device comprises a stirring tank, a supporting rack, a motor storage box, sound insulating sponge, a motor pedestal, a switch, a motor, an emergency stop button, a sealing bearing, a motor shaft, a sun gear, a planetary gear, a tooth profile, stirring vanes, spoilers, a sealing cover and a sealing ring, the motor storage box is arranged at the bottom of the device, the motor is arranged in the motor storage box, the motor is fixed on the motor pedestal, and the switch and the emergency stop button are arranged at the right side of the motor storage box in parallel. The device has the advantages of reasonable structure, high pertinence, realization of bidirectional rotation of the stirring vanes and the spoilers under the driving of the same motor by using the gears transmission, increase of the stirring efficiency, saving of resources, wide application prospect, and suitableness for promotion and application.

Owner:嘉钰培鑫(天津)科技有限公司

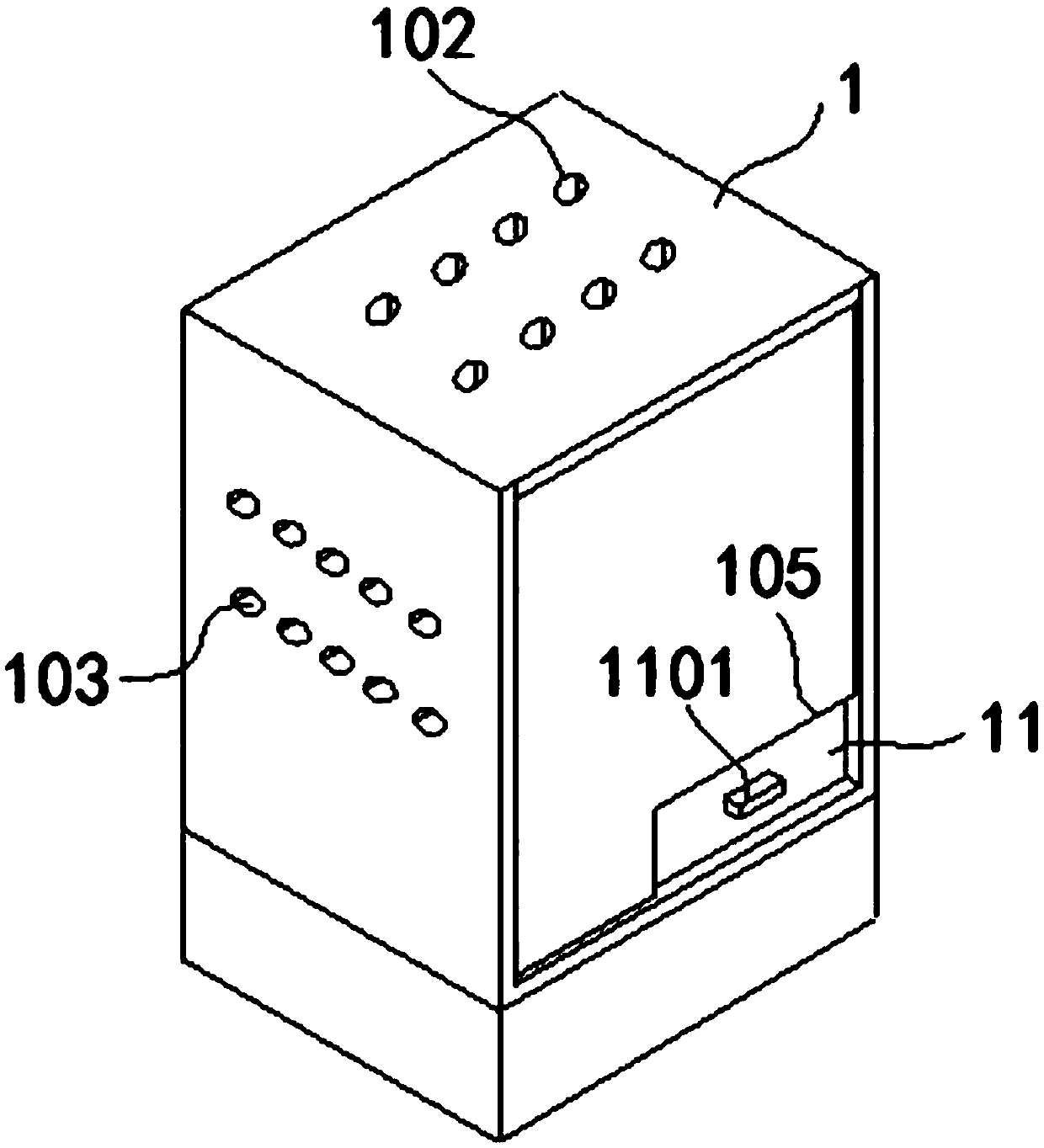

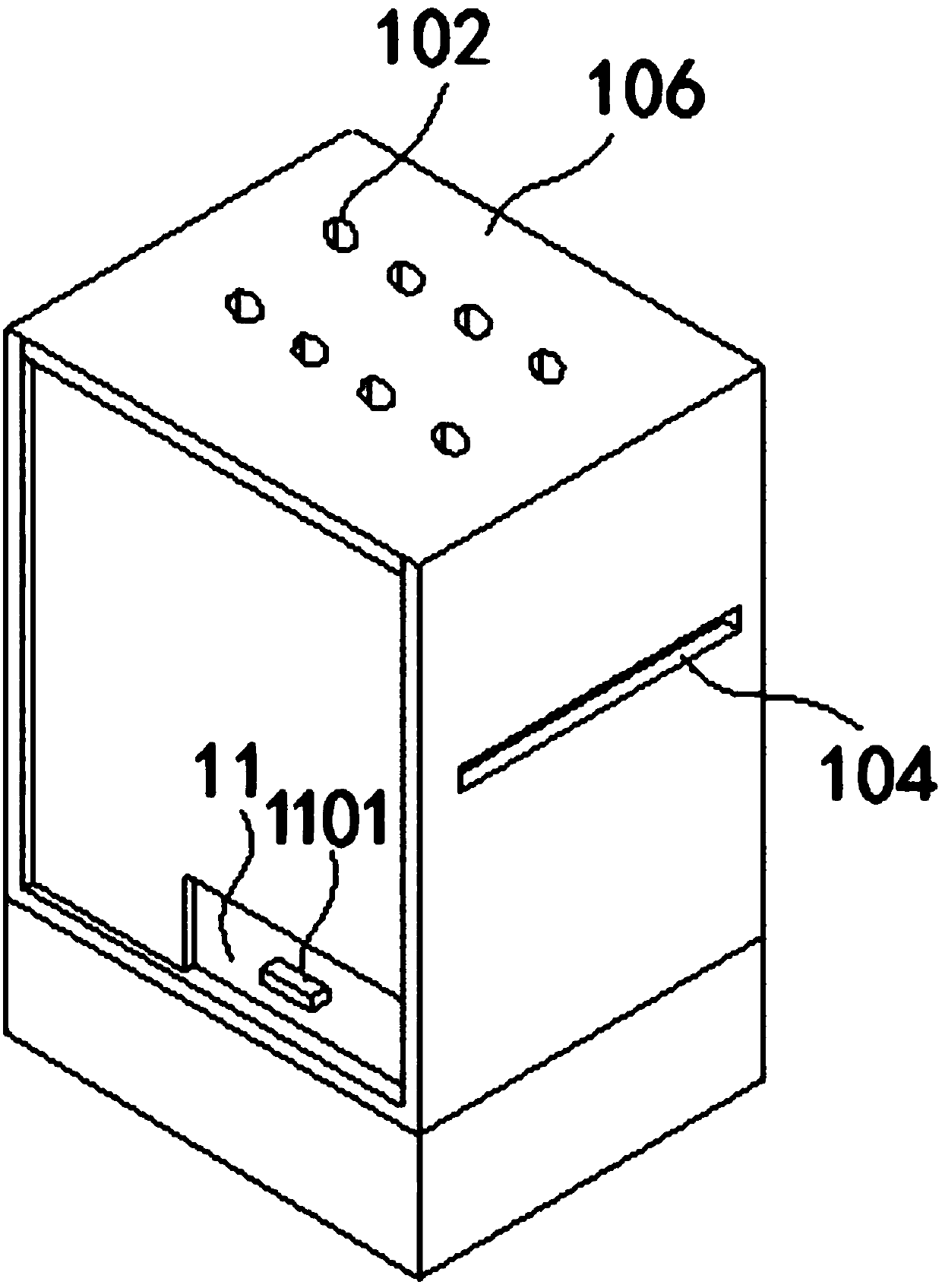

Waste removing device

InactiveCN108031983AAchieve dumpingClean up in timeWelding/cutting auxillary devicesAuxillary welding devicesLaserPush out

The invention discloses a waste removing device. The waste removing device comprises a protecting box, a processing platform, a discharging air cylinder, a first lifting air cylinder, a scraper, a guide plate, a supporting rod, a second lifting air cylinder, a pushing air cylinder, a push plate and a waste box. By arranging the discharging air cylinder on the lower side of the processing platform,waste dumping can be achieved, waste is guided into the waste box through the guide plate, and thus the waste generated after laser cutting can be removed in time and prevented from affecting the processing quality of the next time of laser cutting; by arranging the pushing air cylinder, the push plate and a long groove in the side wall, a processed product can be conveniently pushed out of the protecting box, a to-be-processed product can be placed in through the long groove, and thus the processing efficiency is improved; by arranging the first lifting air cylinder and the scraper, residualwaste on the processing platform can be further removed, and thus the processing quality is further improved; by forming air inlet holes and air outlet holes in the protecting box, the temperature inthe protecting box is reduced, and the processing quality is guranateed.

Owner:朱慧

Carton manufacturing device

InactiveCN113290932AAchieving Orientation StabilityRealize limitBox making operationsPaper-makingCartonPaperboard

The invention discloses a carton manufacturing device, and particularly relates to the technical field of carton machining. The carton manufacturing device comprises a bottom plate, six groups of supporting columns are uniformly and fixedly connected to the two ends of the bottom of the bottom plate, a collecting structure is arranged at one end of the bottom plate, and a frame is fixedly connected to the middle of the top end of the bottom plate. A cleaning mechanism is arranged on the other side of the bottom of the bottom plate, during use, machined paperboard waste is collected through a collection hopper, the waste is conveyed into a box body through a discharging pipe, discharging is assisted through a negative-pressure fan, the waste is prevented from being accumulated in the collection hopper, the paperboard waste is collected through a collection bag arranged in the box body, after the collection bag is full, the collection bag can be conveniently and rapidly detached and cleaned through a clamping structure formed between a clamping block and a clamping groove, the operability is high, the working environment is optimized, and the situation that the paperboard waste is accumulated in the machining position to affect machining operation of cartons is prevented.

Owner:邵顺喜

Micro-adjusting injection molding device for processing earphone connectors

ActiveCN111976082AStay parallelAvoid compromising production qualityCoatingsMobile bearingEngineering

The invention discloses a micro-adjusting injection molding device for processing earphone connectors, and relates to the technical field of earphone connector injection molding. The micro-adjusting injection molding device for processing the earphone connectors comprises a bottom fixing plate, wherein an injection mold is fixedly installed at the upper end of the bottom fixing plate. According tothe device, when a cylindrical adjusting screw rotates, a moving bearing can move front and back on the outer circle of the cylindrical adjusting screw through the arrangement that the moving bearingis connected with the cylindrical adjusting screw in a threaded mode, the moving bearing moves to drive an annular moving sleeve to move, and the annular moving sleeve drives a ring-shaped limit sleeve to move front and back through a rectangular connecting rod to adjust the position of the ring-shaped limit sleeve, so that earphones corresponding to different lengths of metal plugs can adjust the supporting point position of the ring-shaped limit sleeve during injection molding, so as to ensure that the metal plugs are always kept in parallel states, the situation of tilting, affecting the production quality, when the metal plugs are connected to injection positions.

Owner:湖北省迈尔森科技有限公司

An adjustable punching and folding processing machine for cable tray

ActiveCN112058964BGuaranteed stabilityPrevent affecting processing qualityPerforating toolsMetal-working feeding devicesCable trayClassical mechanics

The invention discloses an adjustable punching and folding processing integrated machine for cable bridge, which comprises a working platform, a bending structure and a punching structure; There is a bridge placement platform in the middle. The interior of the bridge placement platform is a hollow structure and the openings at the bottom of the left and right sides are respectively connected with the corresponding openings on the left and right sides of the upper surface of the work platform. The four corners of the upper surface of the work platform are symmetrically provided with pillars. The top of the top is fixedly connected with the bottom surface of the top plate, and a hydraulic pump and a hydraulic telescopic column are installed in the installation port at the center of the top plate, and the oil outlet at the bottom of the hydraulic pump communicates with the oil inlet at the upper end of the hydraulic telescopic column; the adjustable cable tray The punching and folding processing integrated machine can press and fix the cable tray to prevent the deviation of the cable tray during the processing process from affecting the processing quality. It can also effectively bend the cable tray and adjust the two-way spacing of the punching holes.

Owner:江苏中顺电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com