Intelligent dehydration device for corrugated paper production

A dehydration device and corrugated paper technology, which is applied in the field of corrugated paper processing, can solve the problems of uncontrollable pressure, scratches on the smooth surface of corrugated paper, and easily damaged corrugated paper, so as to reduce labor intensity, improve processing quality, and reduce heat dissipation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

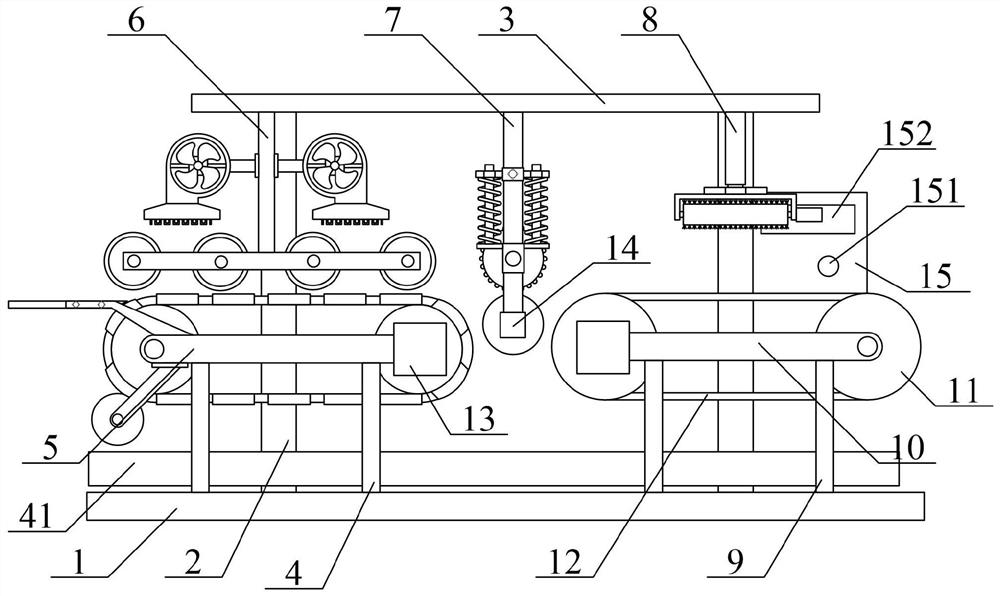

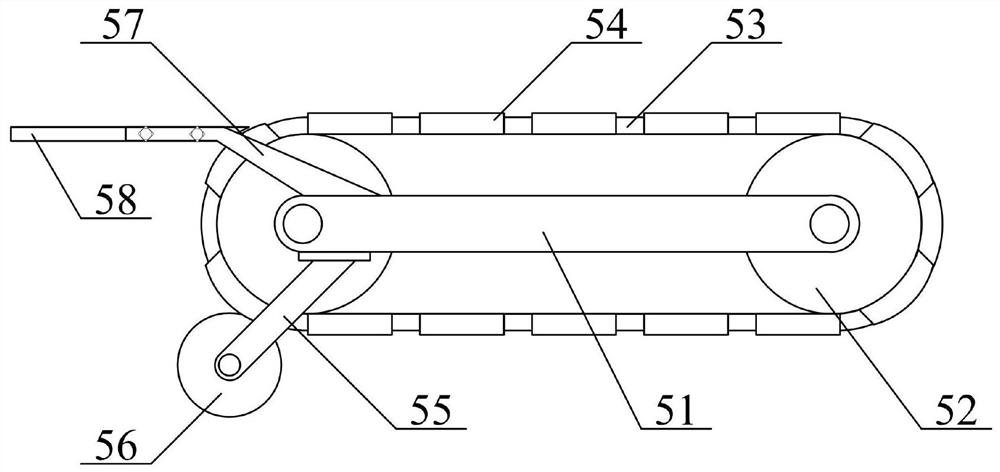

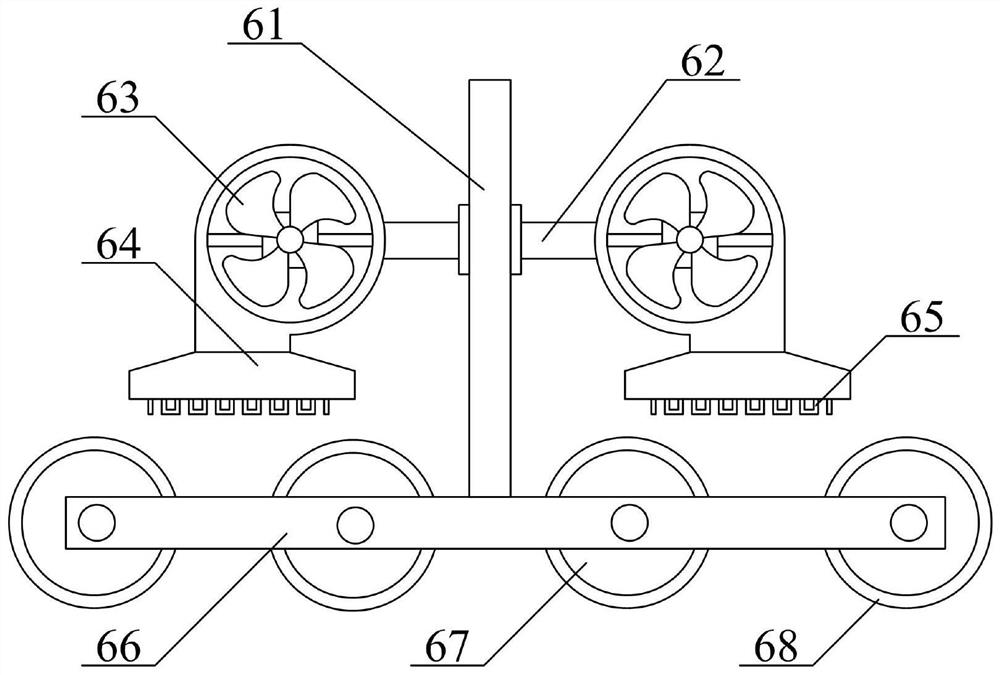

[0040] as attached figure 1 And attached figure 2 As shown, the dehydration device for intelligent corrugated paper production includes a bottom plate 1, a support beam 2, a horizontal plate 3, a support rod 4, a corrugated paper water absorption frame structure 5, an auxiliary extrusion drying frame structure 6, and a corrugated paper extrusion water frame structure 7, Rotary cleaning rack structure 8, bracket 9, beam 10, drive roller 11, conveyor belt 12, driving motor 13, rotating motor 14 and control box 15, and the support beam 2 is welded on the left and right sides of the upper rear end of the bottom plate 1 respectively; The horizontal plate 3 is bolted to the upper front end of the support beam 2; the support rod 4 is bolted to the upper left side of the bottom plate 1; the corrugated paper absorbent frame structure 5 is installed on the inner upper part of the support rod 4; The auxiliary extrusion drying frame structure 6 is installed on the lower left side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com